Flexible resistance type pressure sensor with machine-weaved structure and use thereof

A technology of resistive pressure and sensors, which is applied in the directions of sensors, applications, instruments, etc., can solve the problems of undisclosed flexible resistive pressure sensors and applications of undisclosed flexible resistive pressure sensors, so as to prevent sudden infant death syndrome and reduce the occurrence of sudden infant death syndrome. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

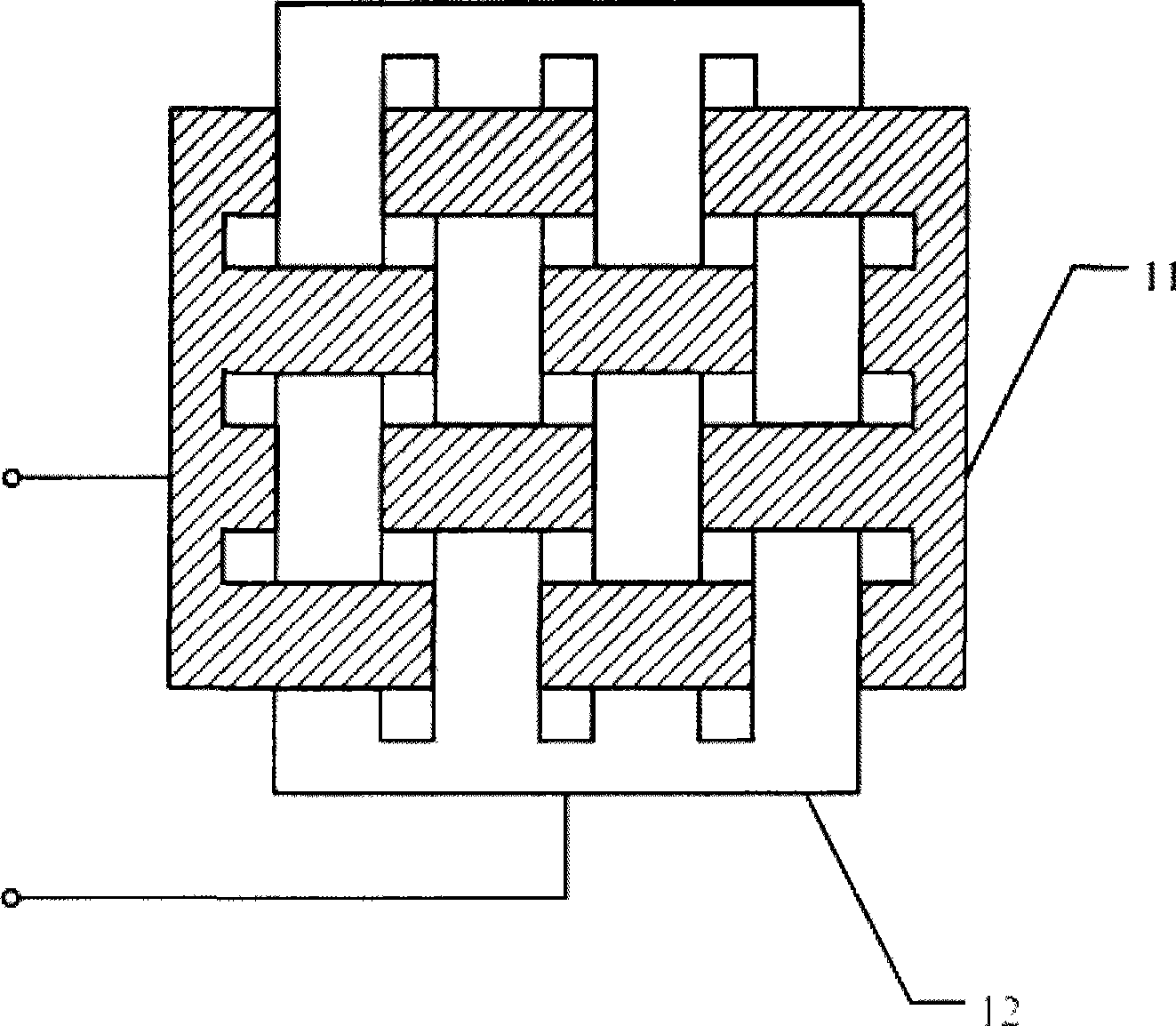

[0022] Such as figure 1 Described is the structural diagram of the parallel flexible resistive pressure sensor of the present invention, which is composed of conductive fibers, and the conductive fibers are interwoven to form a woven fabric with a plain weave structure, and all warp yarns 12 of the woven fabric are connected in parallel with each other, so All weft yarns 11 of the woven fabric are connected in parallel with each other, so that the overall resistance between all warp yarns 12 and all weft yarns 11 is a function of the contact resistance between all single warp yarns 12 and weft yarns 11, and the contact resistance varies with the pressure on the fabric. Variety.

[0023] Warp yarn 12 and weft yarn 11 all select hardness as 10 7 Pa, diameter is the conductive fiber of 0.5mm, and the root number of warp yarn 12 and weft yarn 11 is all 100 ( figure 1 and image 3 Take 4 as an example), the resistivity of the warp yarn 12 is 0.1Ω·m, and the resistivity of the we...

Embodiment 2

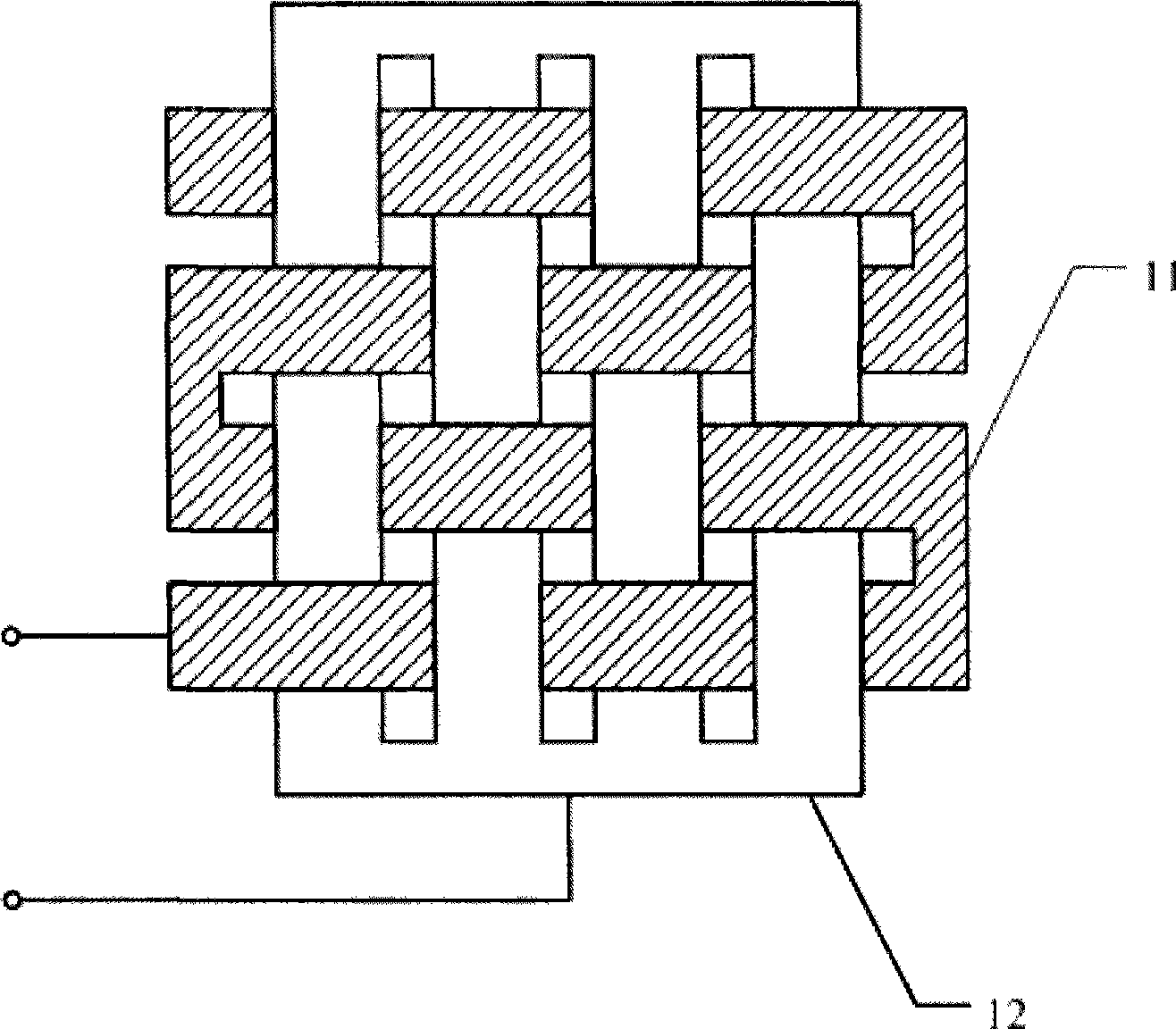

[0032] figure 2It is a structural diagram of the series flexible resistive pressure sensor of the present invention. As shown in the figure, the difference between this embodiment and Embodiment 1 is that all the warp yarns 12 of the woven fabric are connected in parallel, and all the weft yarns 11 of the woven fabric are connected in series.

[0033] Warp yarn 12 and weft yarn 11 all select hardness as 10 7 Pa, diameter is the conductive fiber of 1mm, and the root number of warp yarn 12 and weft yarn 11 is all 50 ( figure 2 and Figure 4 Take 4 as an example), the resistivity of the warp yarn 12 is 0.01Ω·m, and the resistivity of the weft yarn 11 is 10Ω·m.

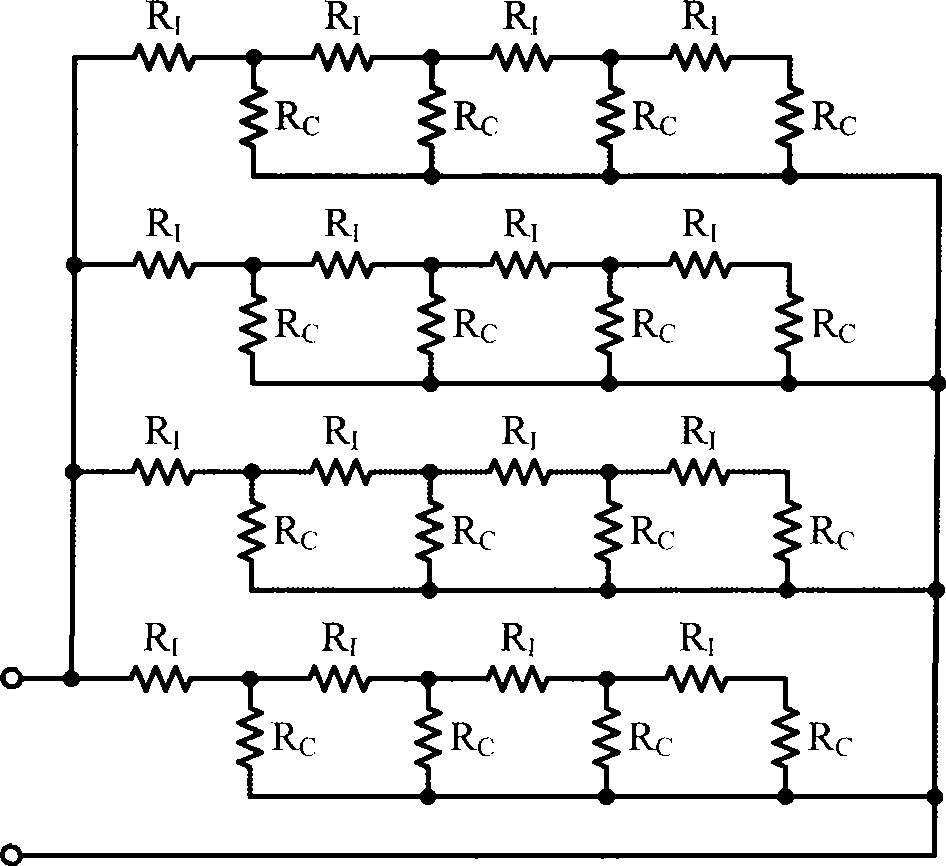

[0034] Figure 4 It is the equivalent circuit diagram of the series flexible resistive pressure sensor of the present invention, wherein the resistance RI and the resistance RC refer to the resistance of the weft yarn itself and the contact resistance at the interweaving point of the weft yarn and the warp yarn resp...

Embodiment 3

[0037] Figure 7 It is a structural schematic diagram of the sleeping posture detection strap of the present invention. As shown in the figure, the difference between this embodiment and Embodiment 1 is that the clothing base 9 is a strap, and the others are the same as Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com