Circular mould flatwise type biomass extrusion moulding machine

A biomass, flat-laying technology, applied in the direction of material forming presses, presses, raw material extrusion granulation, etc., can solve the problems of large die plate thickness, uneven materials, complex extrusion conditions, etc., to achieve increased The effects of taxiing time, increasing taxiing time, and reducing the chance of being bored

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

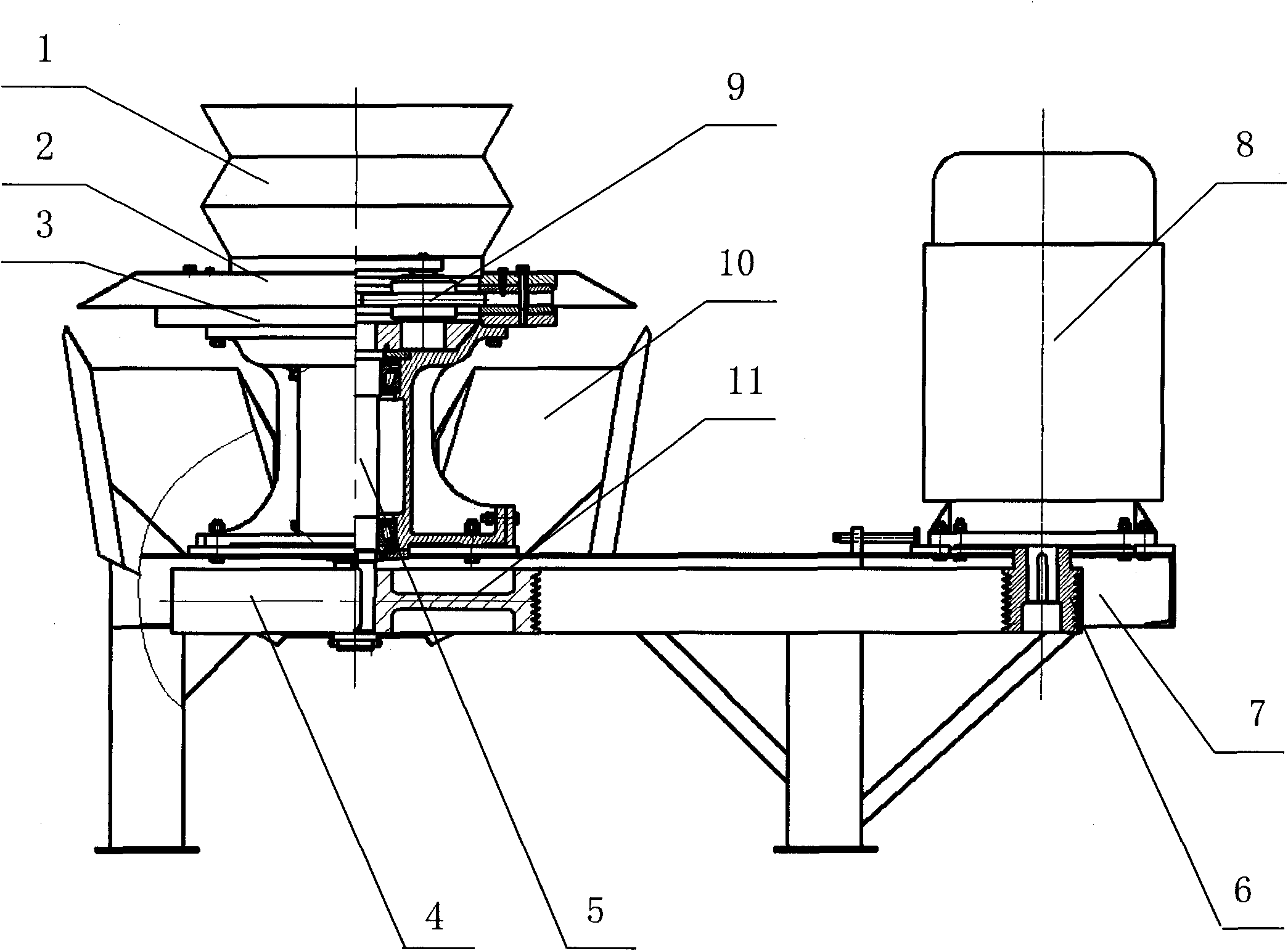

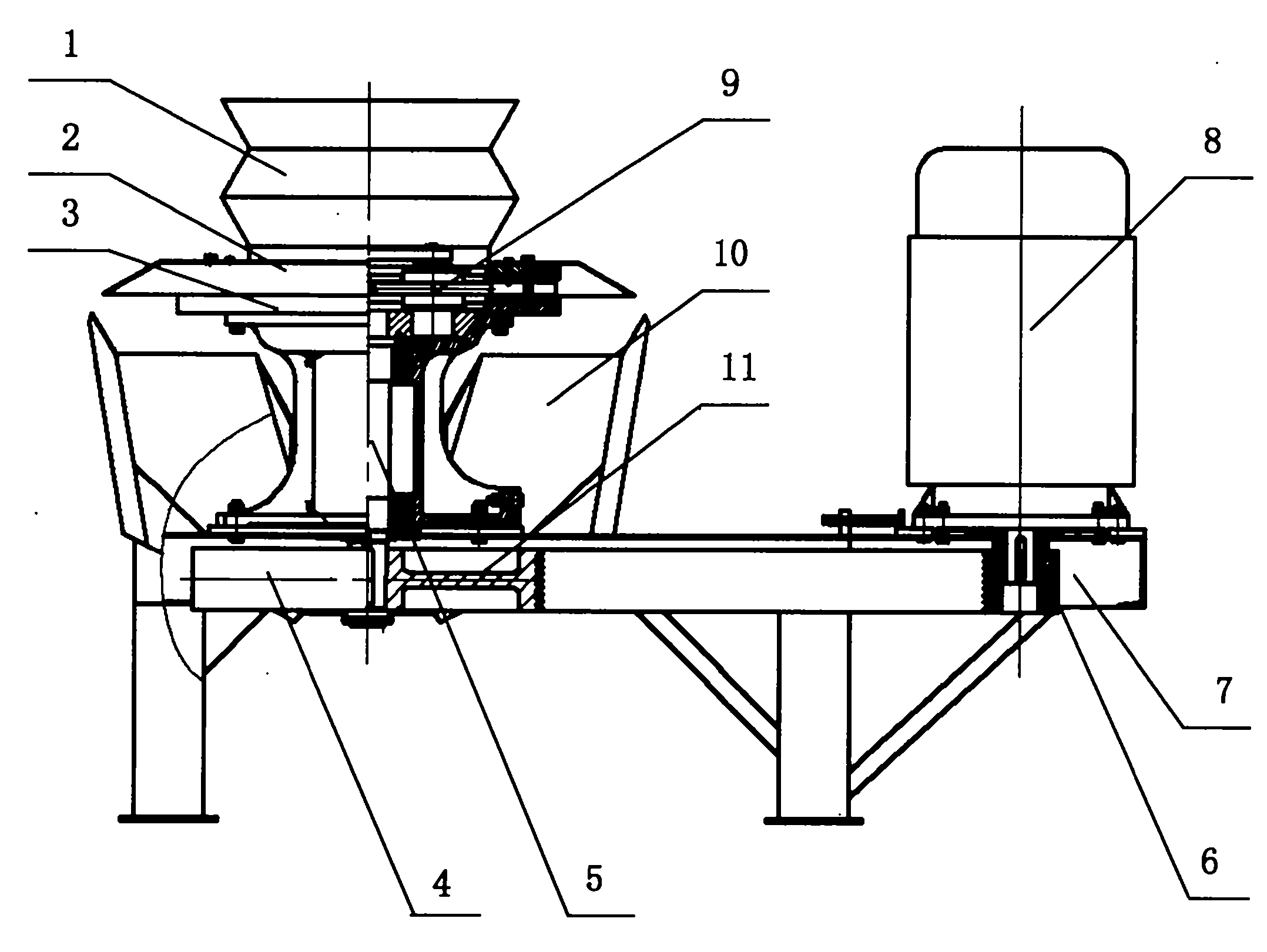

[0019] see figure 1 , the present invention provides a ring die flat biomass extrusion molding machine, which includes a feed receiving hopper 1, a material retaining cover 2, an extrusion device, a transmission device, a discharge receiving hopper 10, a frame 7 and a motor 8. The extruding device is horizontally fixed on the frame 7, and the extruding device is composed of an extruding wheel 9 and a die plate 3, and the die plate 3 is provided with a plurality of radially evenly distributed die plates in the horizontal direction. Each die hole is equal in size, and the central axis of each die hole intersects at one point, which falls on the central axis of the die plate 3. The mold plate 3 is fixed on the frame. The molding machine combines the advantages of the two existing biomass extrusion molding machines, overcomes their respective shortcomings, and has a simple structure.

[0020] The feed receiving hopper 1, the material retaining cover 2 and the mold plate 3 are al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com