Materials crusher

A pulverizer and material technology, used in grain processing, plastic recycling, mechanical material recycling, etc., can solve the problems of equipment parking, broken rollers, high power consumption, etc., to avoid shutdown, uniform force on the body, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation, structure, features and effects provided by the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

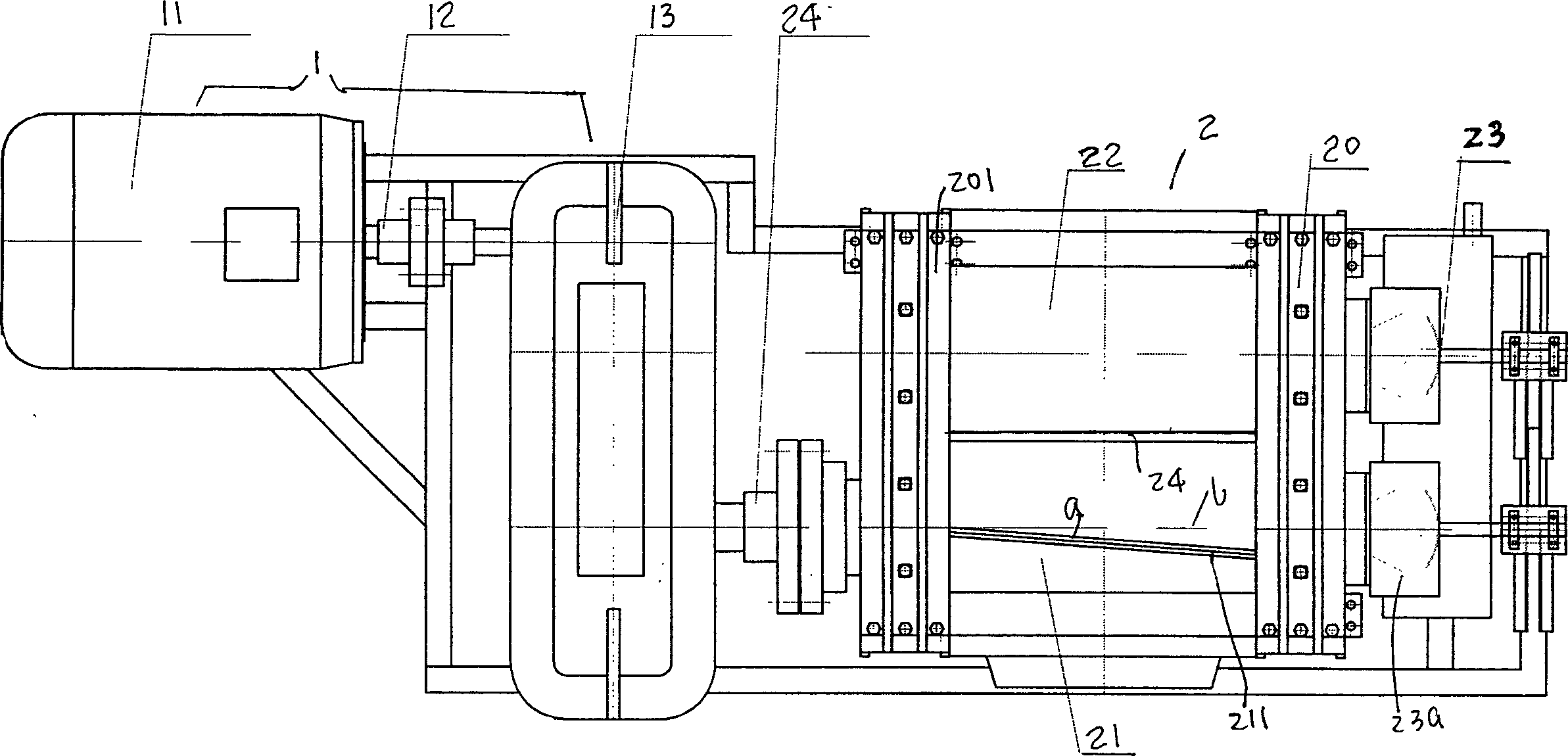

[0025] see Figure 1-3 , a material pulverizer, including a power part 1, the power part is connected by a motor 11 through a first coupling 12 and a reducer 13, wherein,

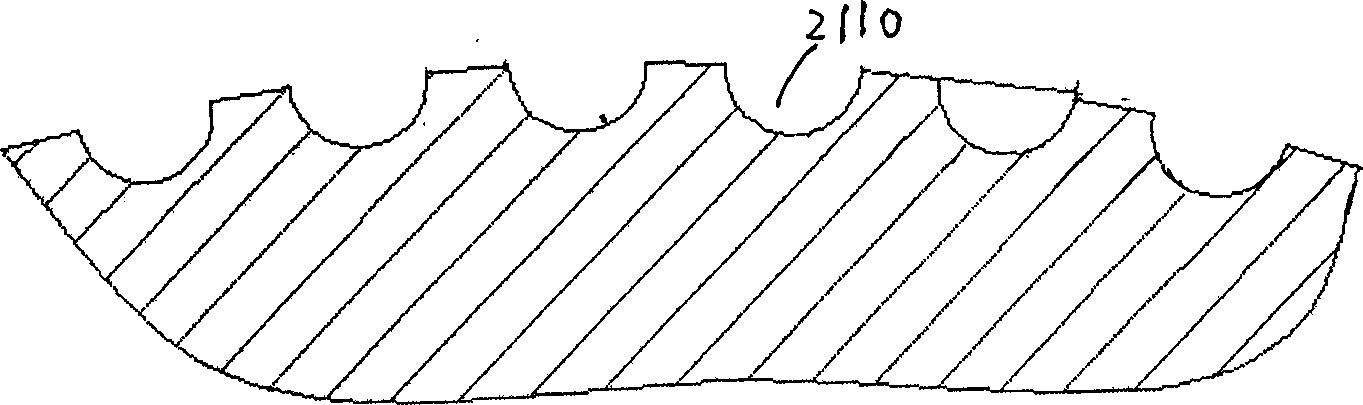

[0026] A material crushing part 2 is composed of a driving roller 21 and a driven roller 22 arranged side by side on the main frame 20. The driving roller is connected with the reducer 13 through the second coupling 14, and the driven roller can rotate freely around the axis.

[0027] The moving roller is installed on the main frame 20 by means of a bearing, which is a self-aligning roller bearing, which can make the main shaft bear even force, drive smoothly, prolong the service life of the bearing, and facilitate installation and maintenance at the same time;

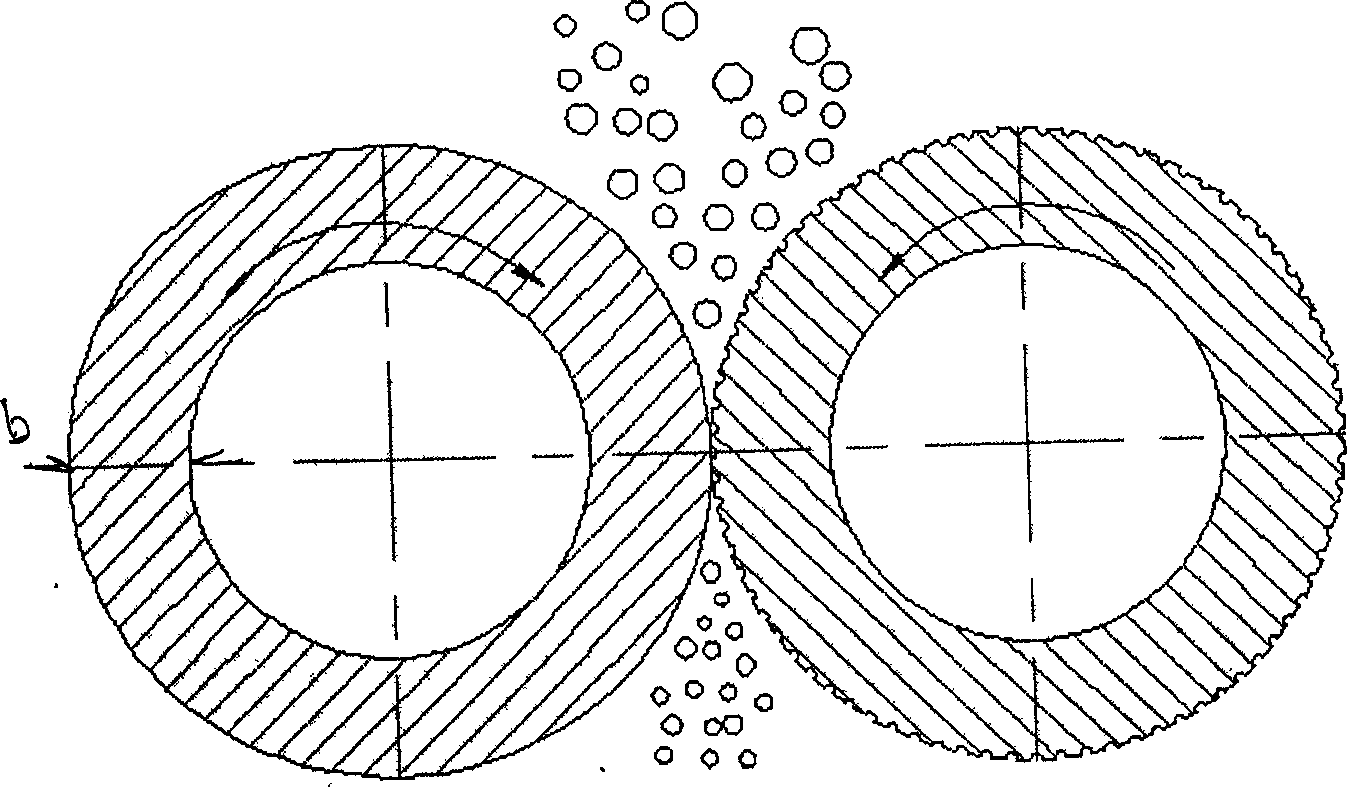

[0028] There is a preset gap 24 betw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com