Double-color-line anti-counterfeiting paper and production method thereof

A production method and technology for anti-counterfeiting paper, which are applied in the directions of papermaking, textile and papermaking, fiber raw material processing, etc., to achieve the effects of simple manufacturing method, simple anti-counterfeiting means and low material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

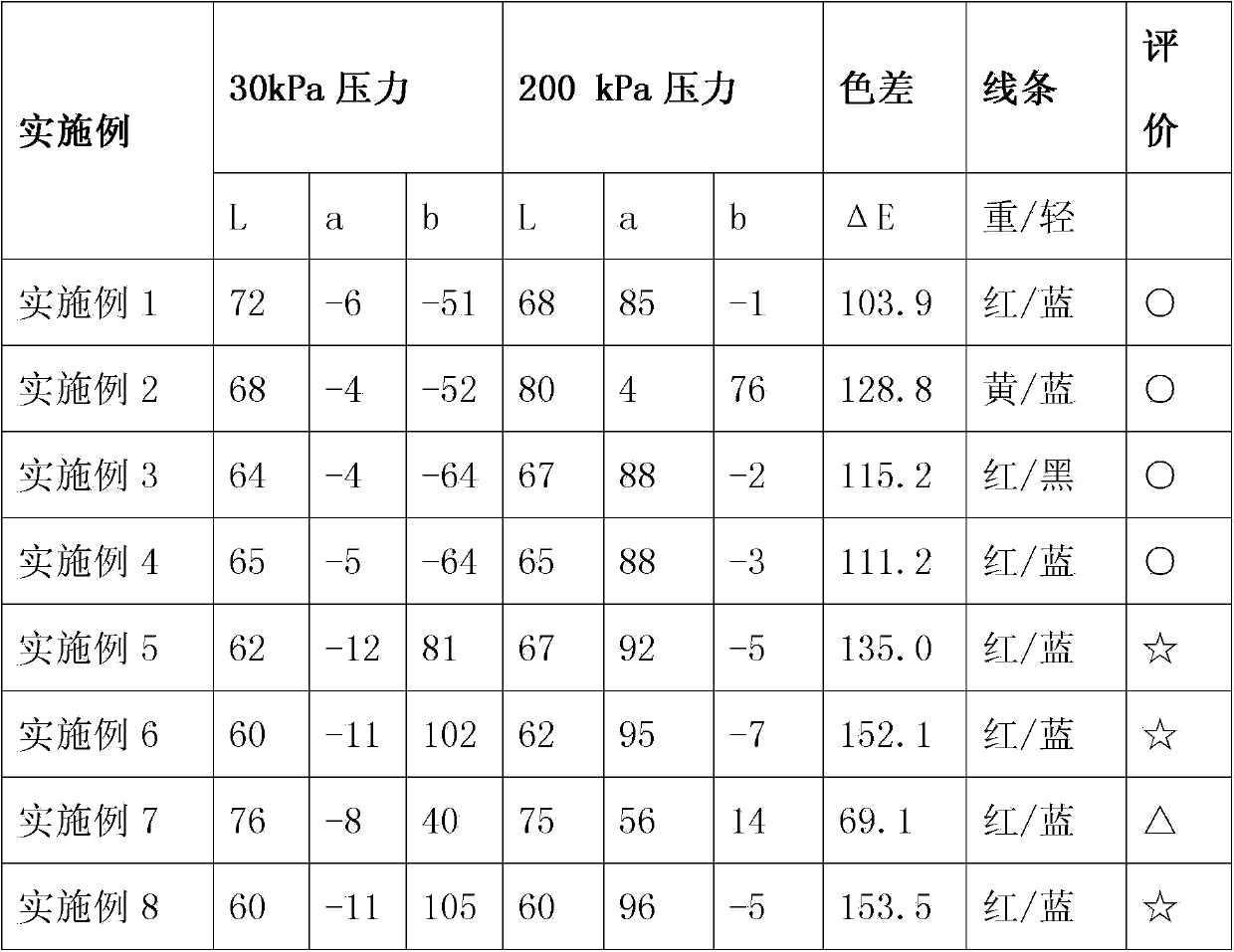

Examples

Embodiment 1

[0029] Preparation of chromogenic material liquid A: Dissolve 1 part of 3,3-bis(1-octyl-2-indol-3-yl)phthalide in 9 parts of mineral spirits. Then add 0.5 parts of styrene maleic anhydride and 2 parts of melamine formaldehyde resin, add water to adjust the solid content to 40%, carry out emulsification and wrapping, the target average particle size is 5±1um, and prepare a red microencapsulated material.

[0030] Preparation of Chromogenic Material B Liquid: Add 1 part of PVA-205 to water, then add 9 parts of 3,3-bis(4-dimethylaminophenyl)-6-dimethylaminophthalide to prepare 40% solid content , after high-speed dispersion and homogenization, grind to an average particle size of 0.2-1.0um, more preferably 0.2-0.4um. Prepared into a red microencapsulated material.

[0031] Preparation of chromogenic material grinding liquid: Add 1.5 parts of PVA-205 to water, then add 9 parts of 2,2-bis(4-hydroxyphenyl)propane with a melting point of 158°C to prepare a solid content of 40%, afte...

Embodiment 2

[0035] On the basis of Example 1, replace the red 3,3-bis(1-octyl-2-indol-3-yl)phthalide in the chromogenic material A liquid with the yellow 3-diethyl amino-6,8-dimethylfluoran).

Embodiment 3

[0037] On the basis of Example 1, the blue 3,3-bis(4-dimethylaminophenyl)-6-dimethylaminophthalide in the chromogenic material B liquid is replaced with the black 2-phenylamino- 3-Methyl-6-dibutylaminofluoran.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com