Brittle material breaking apparatus and brittle material breaking method

A technology of brittle materials and disconnecting devices, which is applied in glass cutting devices, fine working devices, stone processing tools, etc., can solve problems such as rising costs, difficulty in shortening the time required for the disconnecting process, and complicated mechanisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Hereinafter, the present invention will be described in detail based on the drawings showing the embodiments of the present invention. In the following description, the brittle material to be broken is a glass plate, and scribe lines are formed in advance using a known scribe line forming device or the like.

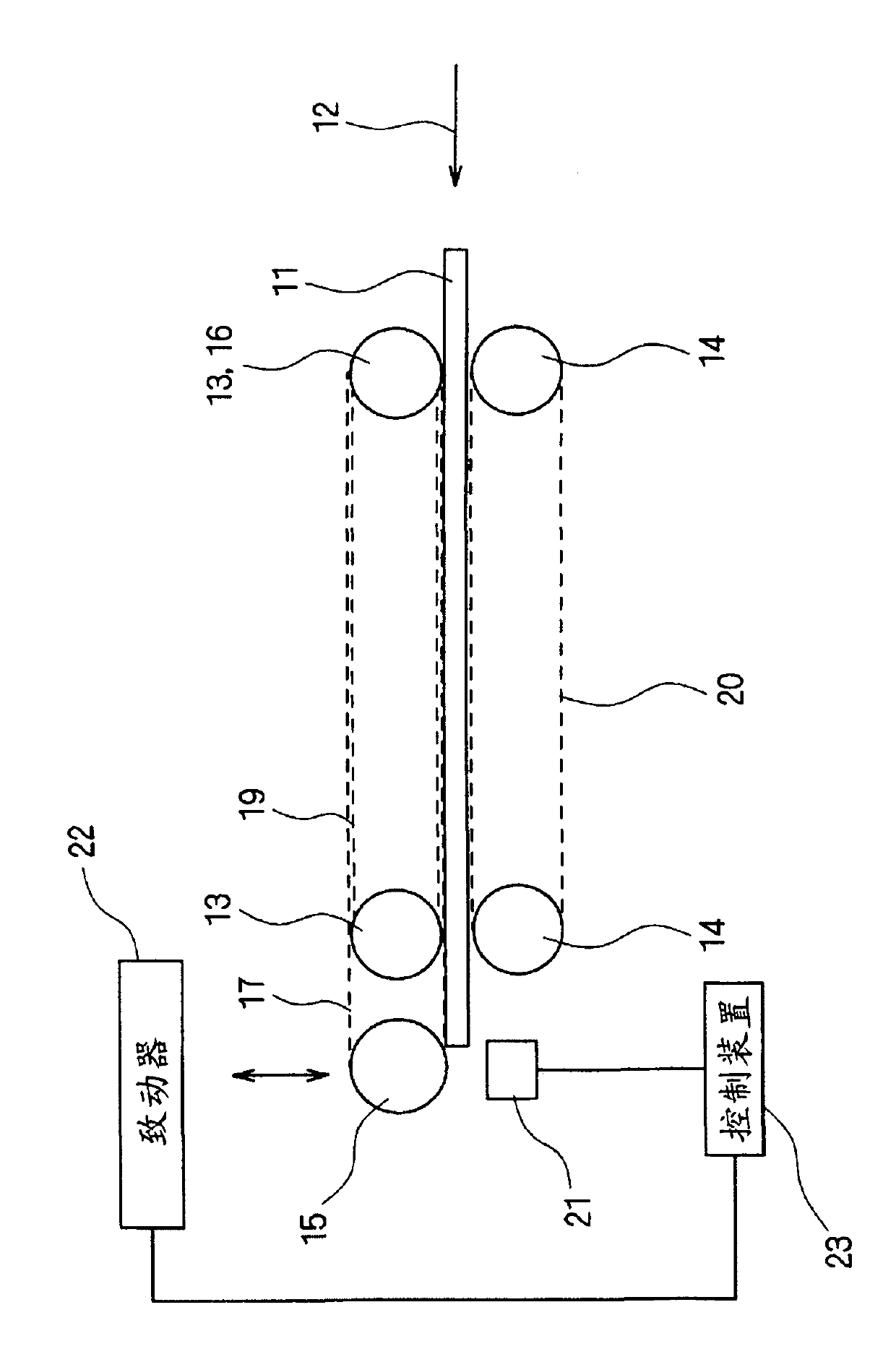

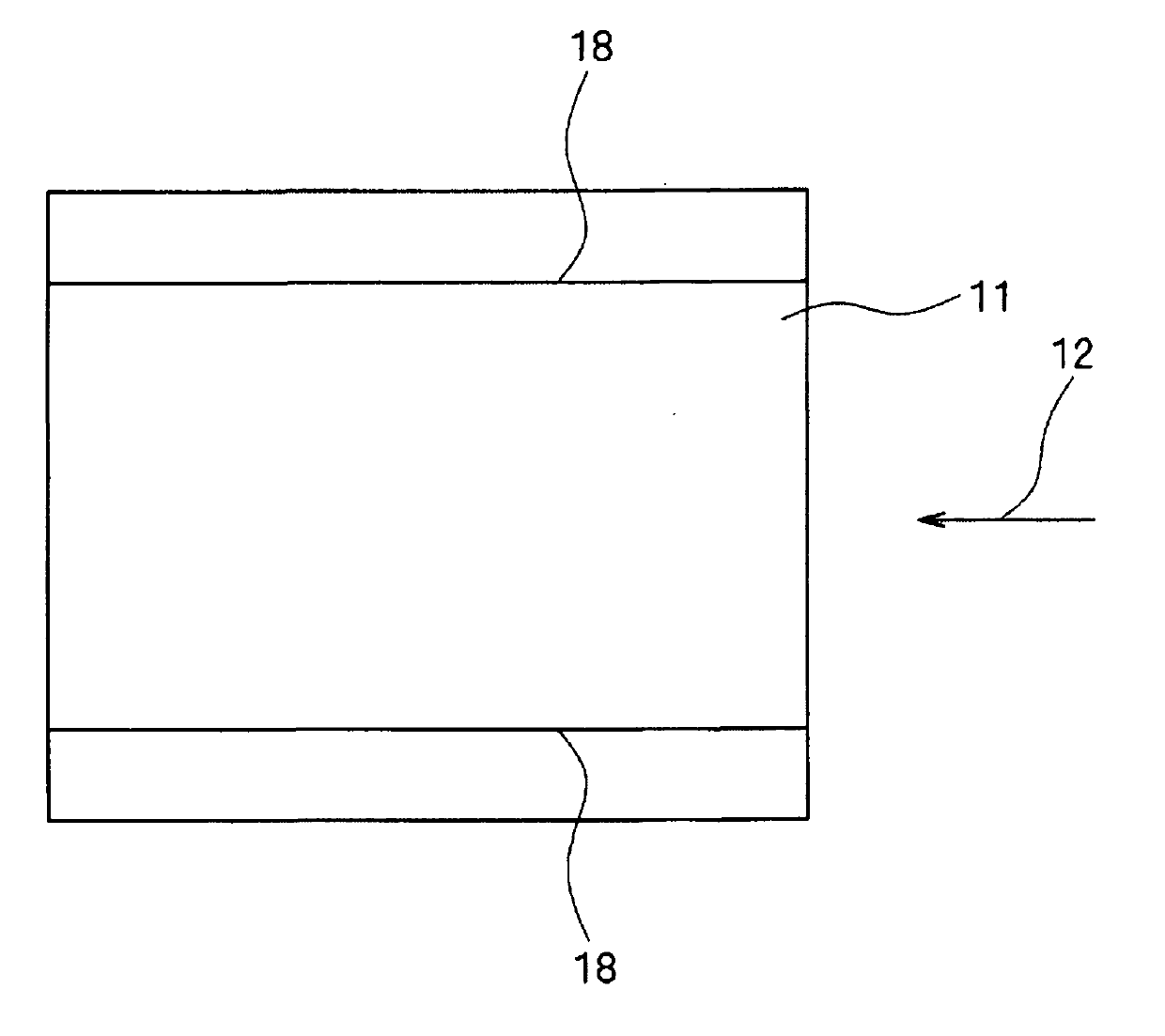

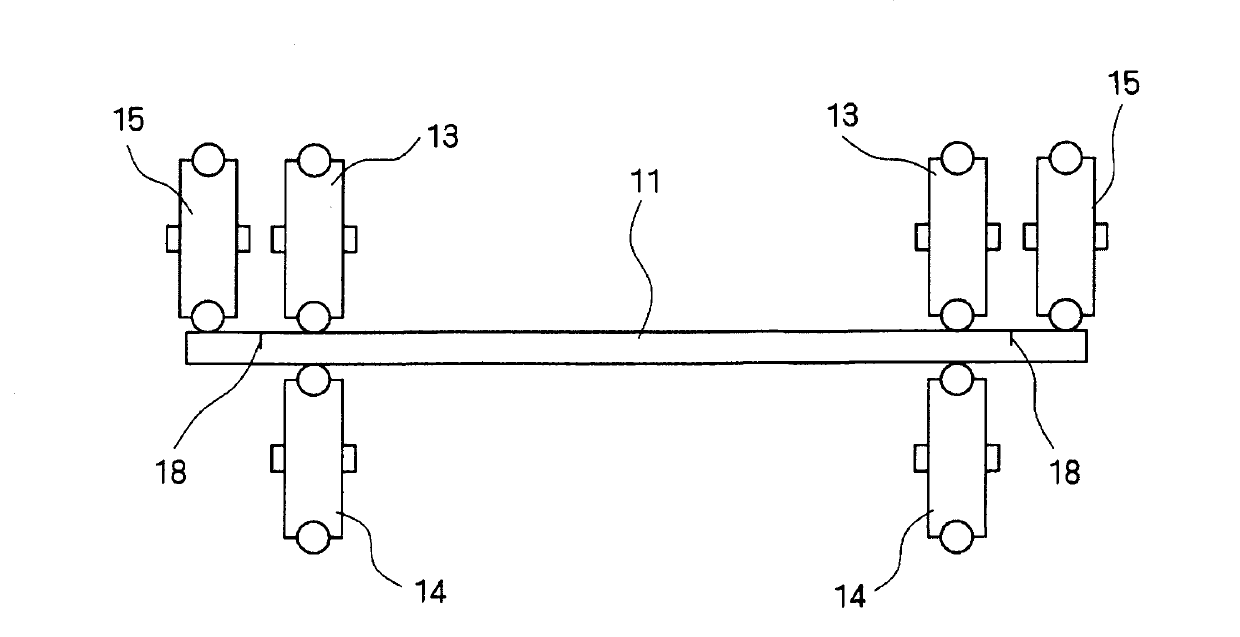

[0024] figure 1 It is a side view which schematically shows the structure of the brittle-material breaking device which concerns on embodiment of this invention seen from the rotation axis direction of a moving roll. like figure 1 As shown, the brittle material breaking device according to this embodiment continuously moves a plate-shaped brittle material such as a glass plate 11 in the arrow 12 direction. The glass plate 11 is clamped from both sides by a pair of upper moving rollers 13 and lower moving rollers 14 at multiple locations, and passes through a plurality of upper moving rollers 13, 13, ... and lower moving rollers 14, 14, ... rotation and movement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com