Material band breaking device

A technology of breaking device and material belt, applied in the direction of contact parts manufacturing, etc., can solve the problems of equipment blockage, low production efficiency, unable to realize intelligent production, etc., and achieve the effect of preventing blockage and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with various embodiments shown in the drawings. However, these embodiments do not limit the present invention, and any structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

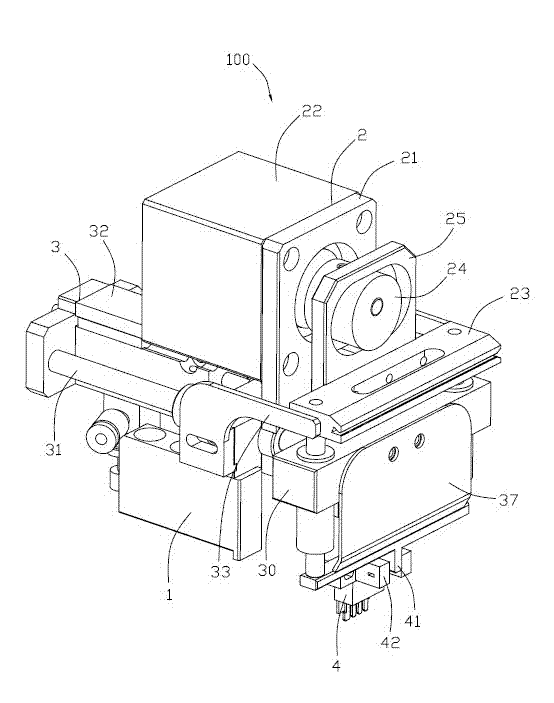

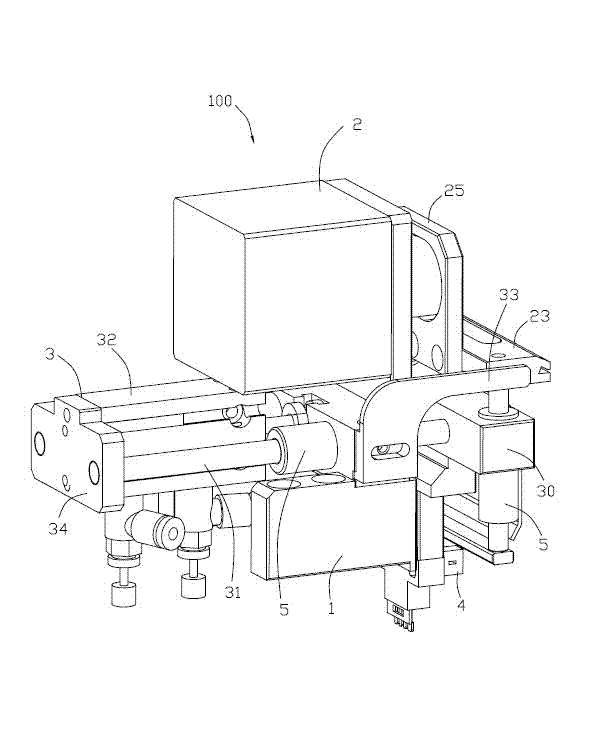

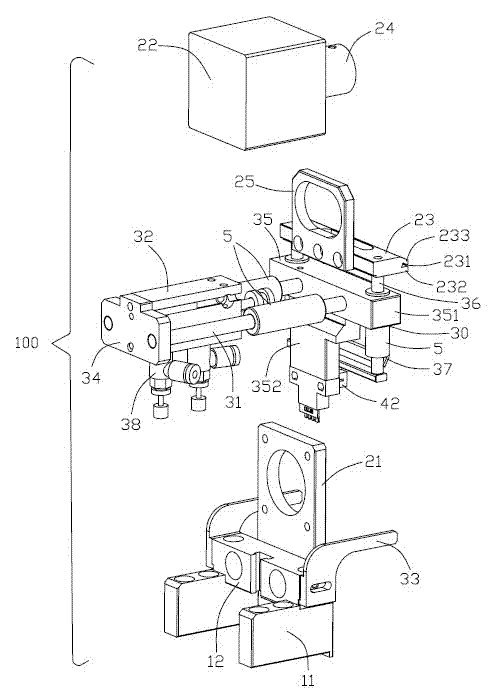

[0018] Please refer to Figure 1 to Figure 3 Shown is a preferred embodiment of the strip breaking device 100 of the present invention. The strip breaking device 100 is mainly used to break off the connecting strip (not shown) on the rear side of the formed conductive terminal (not shown), and includes a support 1 fixed on the support 1 to break the material. The breaking mechanism 2 of the belt, the ejection mechanism 3 fixed on the support 1 to push out the broken strip, and the detection mechanism 4 for detecting the working state of the breaking mechanism 2 to facilitate the control of the ejection mechanism 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com