Novel pass-type screening crusher

A crusher and screening technology, applied in the direction of filter screen, solid separation, grille, etc., to achieve the effect of easy operation, easy replacement and maintenance, easy installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing, the present invention will be further explained and illustrated:

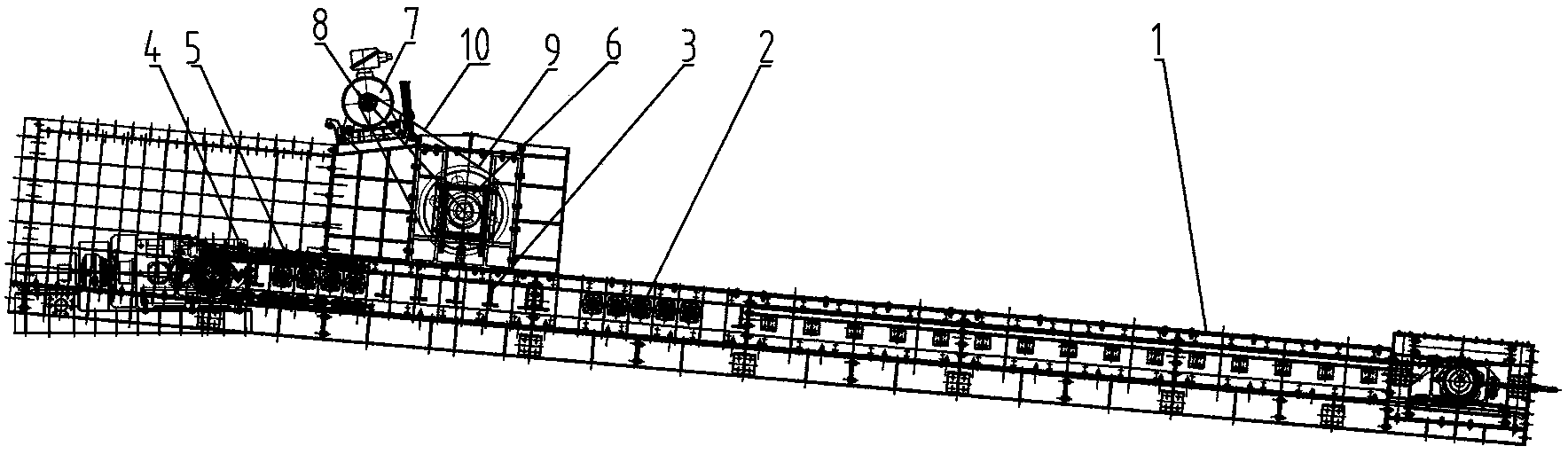

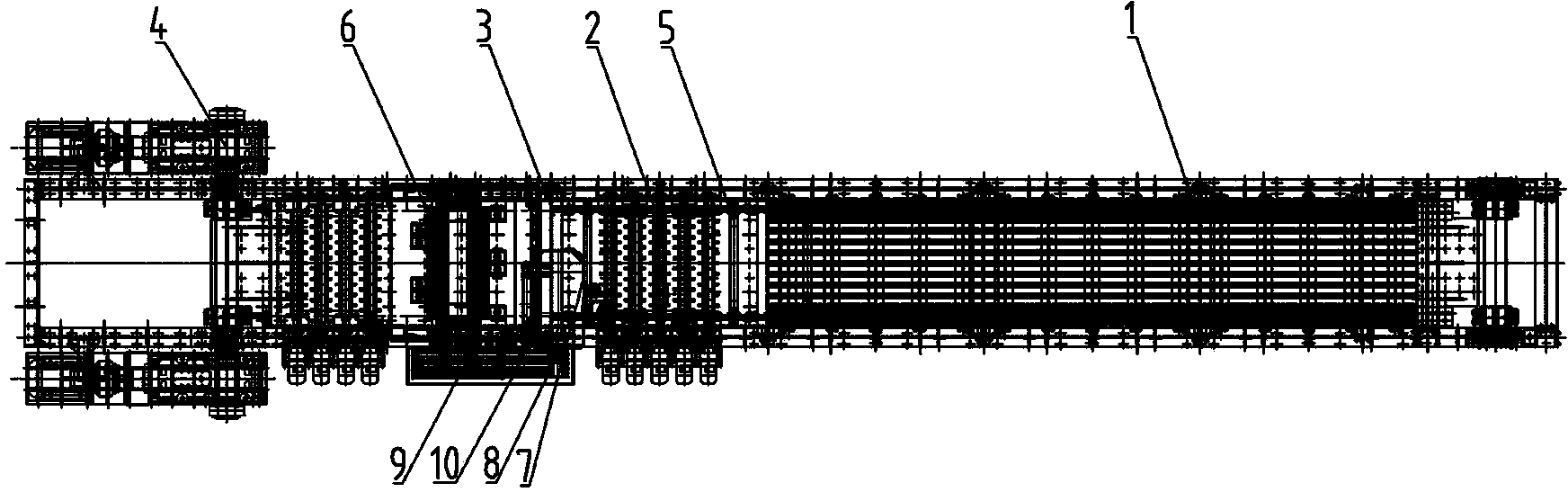

[0026] see Figure 1 to Figure 10 , a new type of through-type screening crusher, including a scraper conveyor slit screening box 1, a scraper conveyor roller type screening box 2, a scraper conveyor crushing box 3, and a scraper conveyor Drive 4, scraper chain 5 and single roller crushing unit, scraper conveyor slit screening box 1 is connected with scraper conveyor roller type screening box 2 and then scraper conveyor crushing box 3 Connect them to form the main body of the whole through-type screening crusher, and then lay the scraper chain 5 on the bottom, and drive the scraper chain 5 to rotate through the scraper conveyor drive 4, wherein:

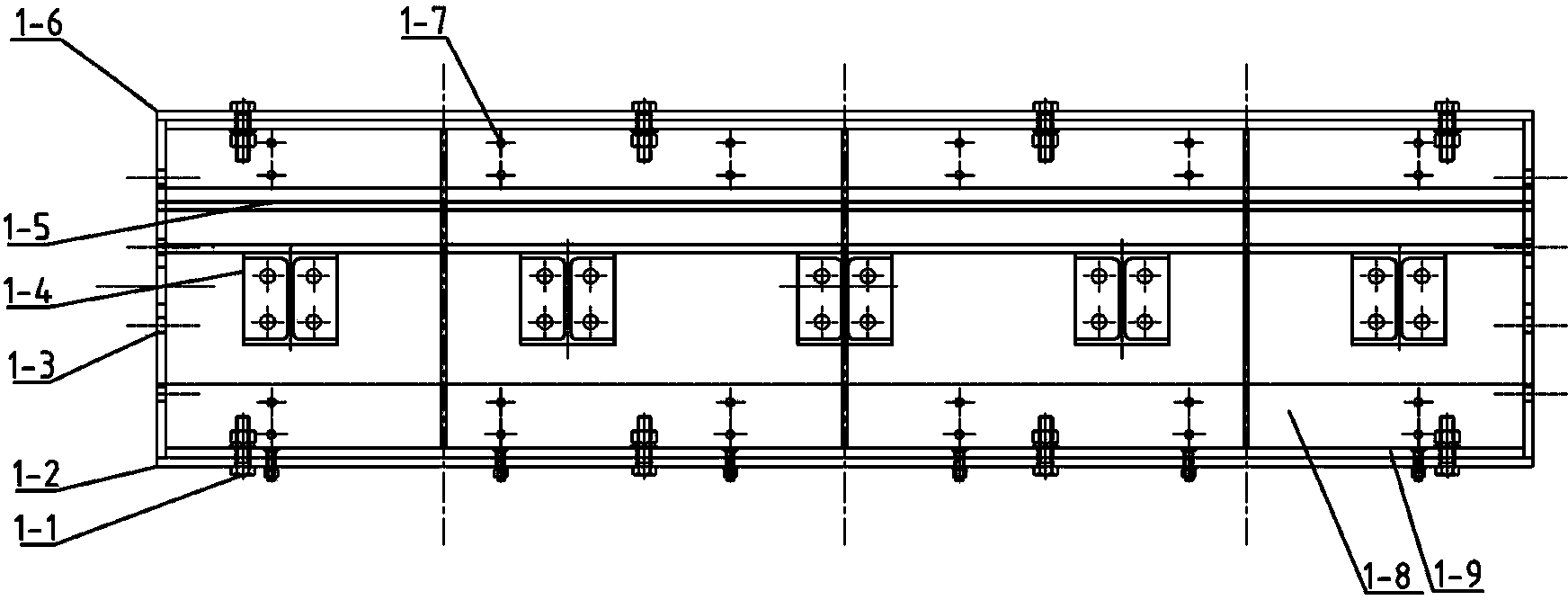

[0027] Slot screening box 1 of scraper conveyor includes glideway plate 1-2, box side plate 1-3, box connecting beam 1-4, guide rail 1-5, upper cover plate 1-6, countersunk head bolts 1-7. The side liner 1-8 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com