Grading production system for open coal breaking and sieving

A production system, crushing and screening technology, applied in the direction of grain processing, etc., can solve the problems of small production capacity of a single production line, large powder content of lump coal, and ineffective use of equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

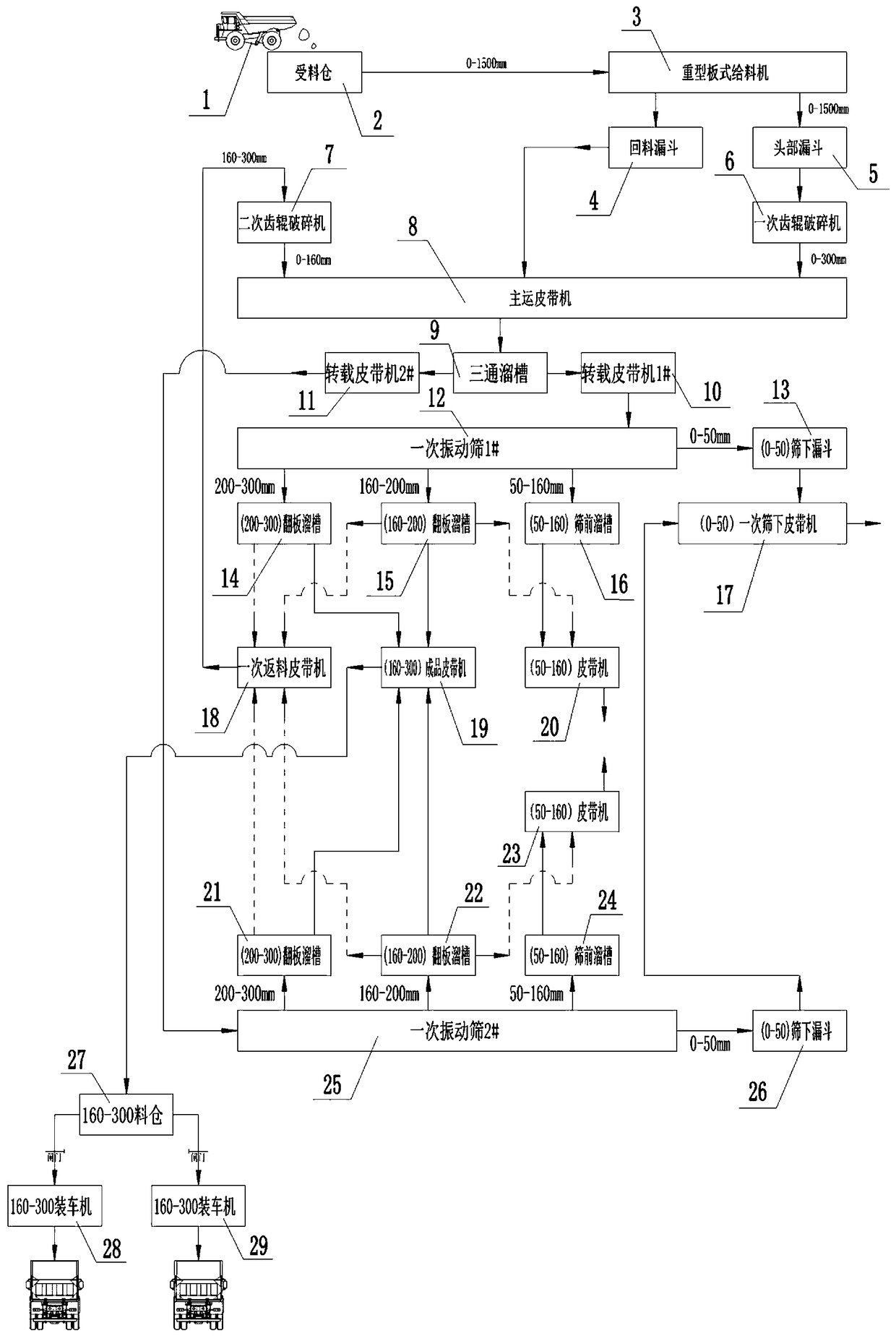

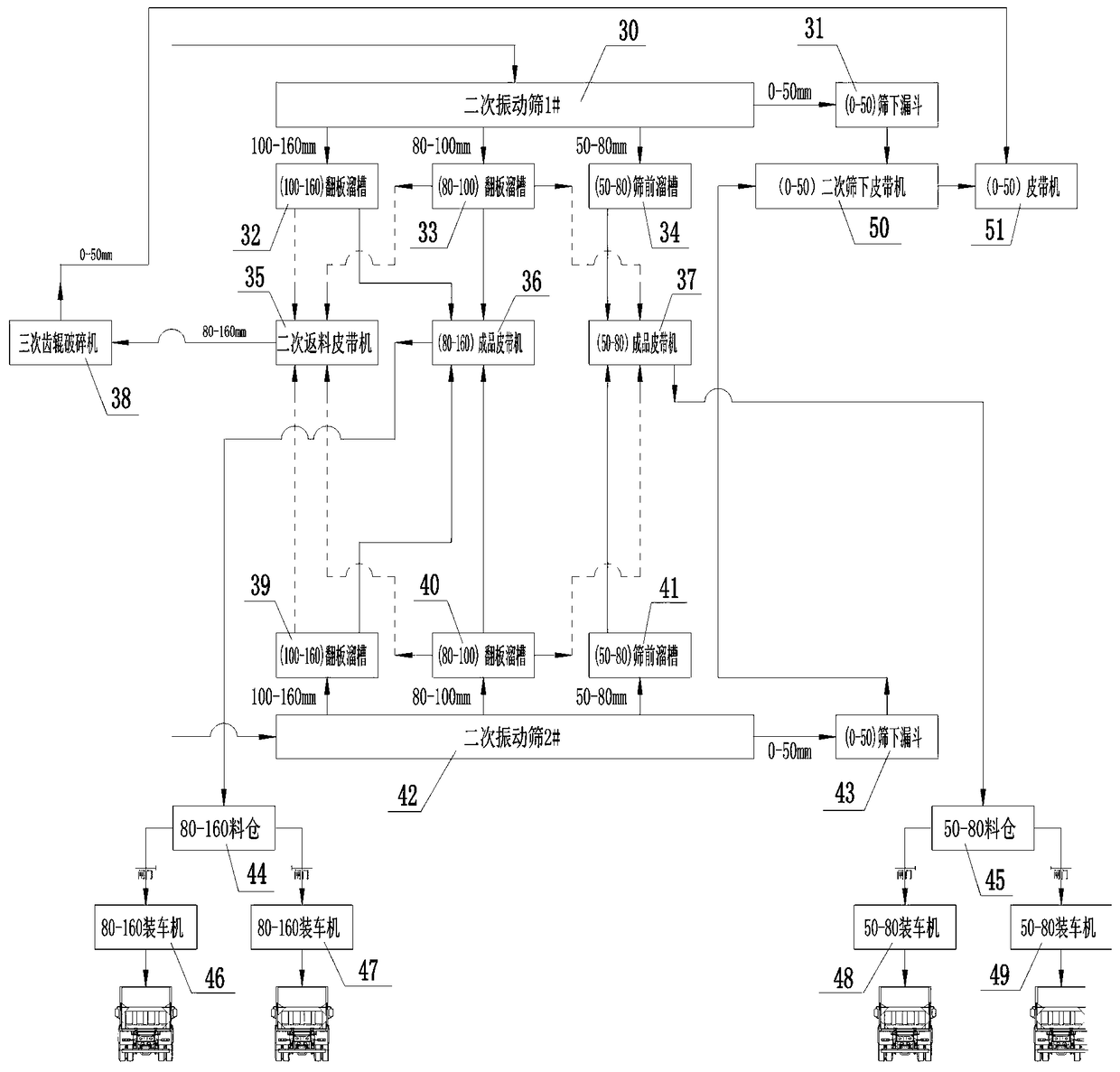

[0023] Below in conjunction with accompanying drawing, the present invention is further explained and illustrated:

[0024] see Figure 1 to Figure 5 , an open-pit coal crushing, screening and grading production system, including mine car 1, receiving bin 2, heavy-duty apron feeder 3, feeder return hopper 4, feeder head hopper 5, primary toothed roller crusher 6. Secondary toothed roller crusher 7. Main conveying belt conveyor 8. Three-way chute 9. First reloading belt conveyor 10. Second reloading belt conveyor 11. Primary vibrating screen A12, 0-50mm first sieve lower funnel 13 , 200-300 mm first flap chute 14, 160-200 mm first flap chute 15, 50-160 mm first sieve chute 16, 0-50 mm primary screen belt conveyor 17, primary return belt conveyor 18. 160-300 mm finished belt conveyor 19. 50-160 mm first belt conveyor 20. 200-300 mm second flap chute 21. 160-200 mm second flap chute 22. 50-160 mm second belt Machine 23, 50-160mm second sieve front chute 24, primary vibrating sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com