Coal electromagnetic radiation desulfurization upgrading system

A technology of electromagnetic radiation and quality improvement, applied in the field of coal electromagnetic radiation desulfurization and quality improvement system, coal processing device, can solve the problems of high moisture, low taste, low calorific value, etc., to achieve high removal rate, improve quality, improve effect of coal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

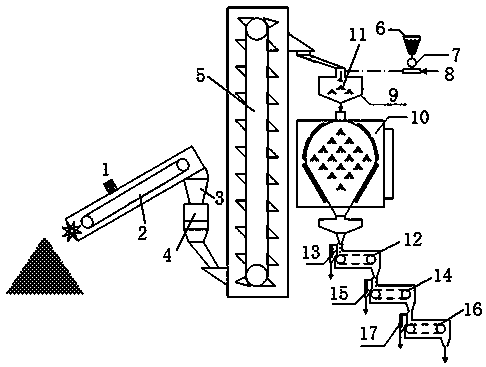

[0043] Such as figure 1 As shown, the coal electromagnetic radiation desulfurization and upgrading system of the present invention includes a feeding and conveying unit, a desulfurization medium feeding unit, a mixing unit, an electromagnetic radiation unit and a magnetic separation unit. The feeding valve of the material unit enters the mixing chamber of the mixing unit together with the desulfurization medium of the desulfurization medium feeding unit in the feeding valve, and enters the electromagnetic radiation unit after being fully mixed in the mixing chamber, and enters the magnetic separation after radiation treatment separate unit.

[0044] 1. Feeding and conveying unit:

[0045] Including coal loading machine, iron remover 1, conveyor belt 2, lower coal hopper 3, crusher 4 and hoist 5. The raw coal is introduced into the coal conveyor belt through the coal loading machine, and the conveyor belt is equipped with an iron remover. After the iron removal, the raw coal ...

Embodiment 2

[0061] The further design of this example is that the umbrella-shaped mixing disc 11 of the mixing unit is provided with only one layer, a total of 2. The rotating shaft of the mixing disc is connected with the driving motor, and each mixing disc is equipped with a driving motor.

Embodiment 3

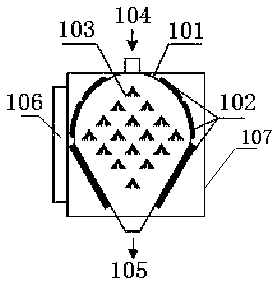

[0063] The further design of this example is that the turntable of the mixing disc 103 of the electromagnetic radiation unit adopts an integral conical surface structure or a multi-blade conical surface structure, the angle β between the conical surface and the rotating shaft is 95-160°, and the surface of the turntable adopts an arc shape face or curved facet. Electromagnetic radiation reactor frequency 900-980MHz, power 25-100KW.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com