Mixing pumping system and device thereof

A pumping device and mixing technology, applied in mixers, transportation and packaging, mixer accessories, etc., can solve the problems of high operation intensity, waste of manpower and material resources, single separation of liquid dispensing and pumping links, etc., to avoid air suction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

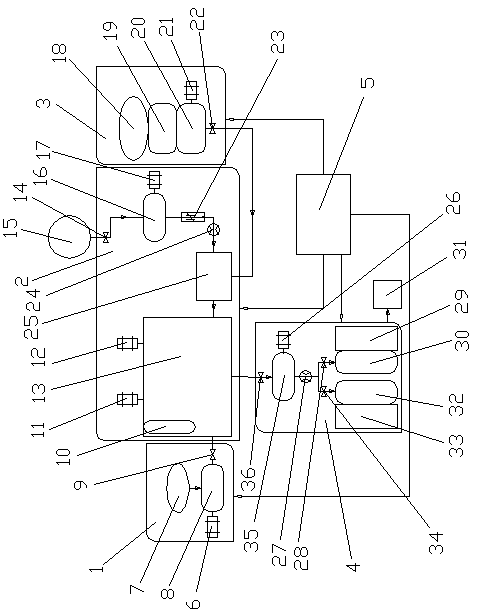

[0027] The technical solutions of the present invention will be further clearly and completely described below in conjunction with the accompanying drawings and embodiments.

[0028] See attached figure 1 , the mixed pumping system works according to the following steps:

[0029] 1. Operation preparation stage: Three parameters are input into the control system 5, the discharge volume of the plug drilling fluid, the dry addition ratio of the dry material and the liquid addition ratio of the liquid material, and remove the regulating valve 23 in the mixing pumping device. The liquid addition valve 9, delivery valve 22, right filling valve 28, left filling valve 34 and pumping valve 36 other than the liquid inlet valve 14 are all closed, the regulating valve 23 is set to a fully open state, the liquid addition pump motor 6, the filling The pump motor 26, the left plunger pump motor 33, the plunger pump motor 29, the conveyor motor 21, the No. 1 agitator 11, and the No. 2 agitat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com