Slice mining technology and coal winning machine thereof

A layered mining and shearer technology, applied in cutting machinery, ground mining, earthwork drilling and mining, etc., can solve the problems of coal-rock mixed coal quality decline, huge cost of coal preparation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

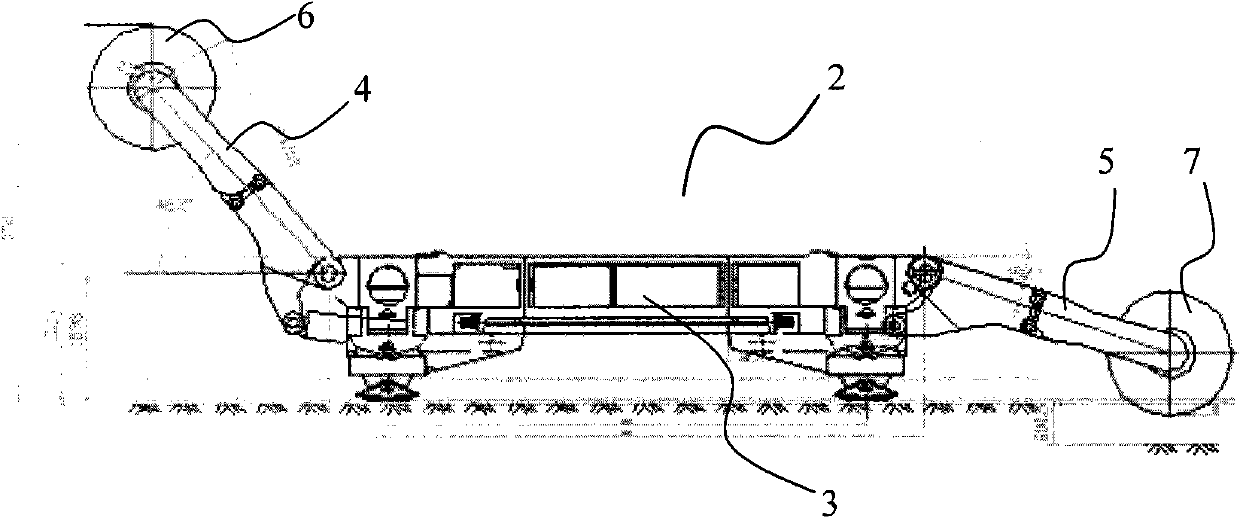

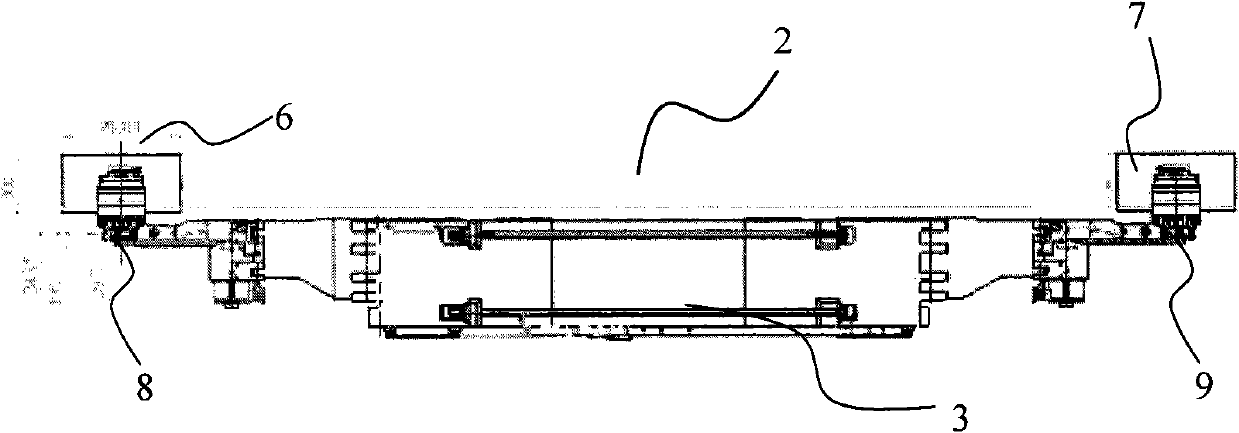

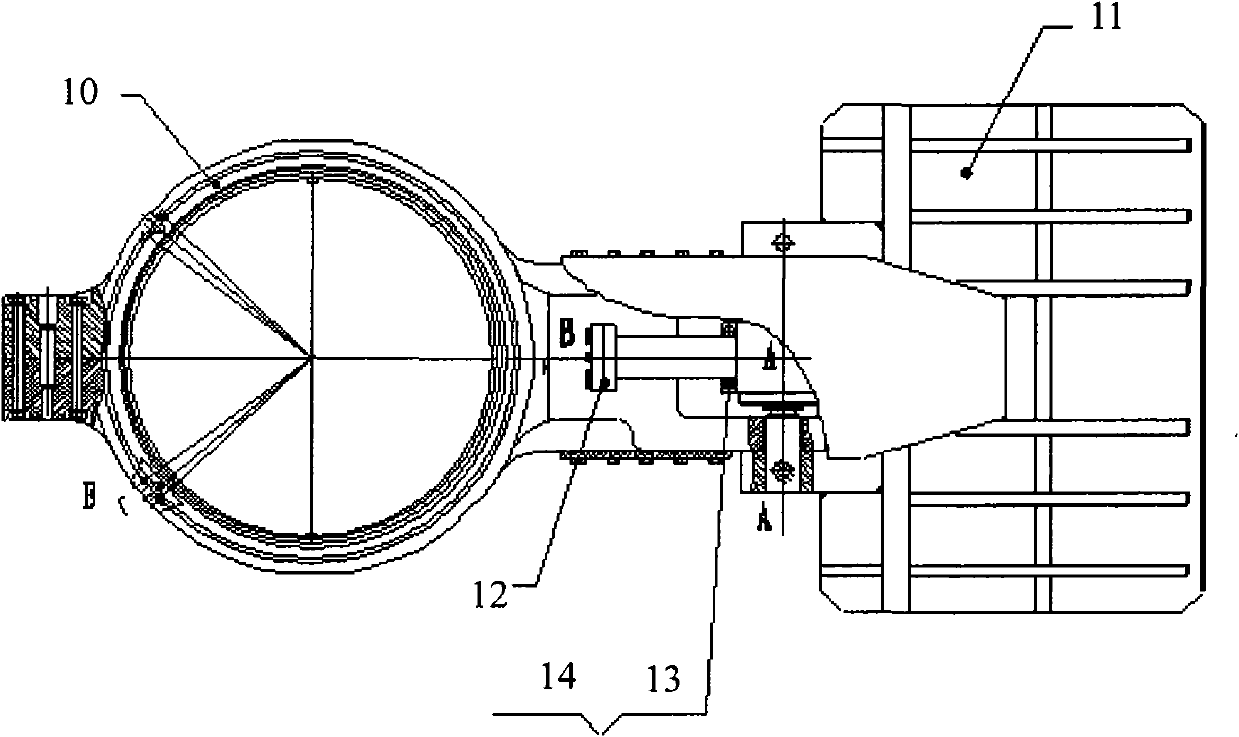

[0018] In the above-mentioned long-arm mining technology in coal seams with complex geological conditions such as interlayers, there is a defect that the upper coal seam and the rock stratum are mined once the coal and rock are mixed, which causes the coal quality to decline, and additional coal preparation procedures are required in the subsequent process to increase the cost. . The invention proposes a layered mining technology. For coal seams with complex geological conditions with interlayers (rock formations or gangue), this technology proposes three-layer mining in one feed, such as figure 1 As shown, the coal seam with interbeds is regarded as three layers, the upper coal seam, the middle rock layer, and the lower coal seam. In one feed, the upper coal seam is mined first, the middle rock stratum is mined, and the lower coal seam is mined secondly. In this way, the coal seam and the rock stratum (that is, the gangue layer) are separated during the mining process, there...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com