Fully mechanized working face roadway pre-excavating type fault passing method

A technology of fully mechanized working face and fault crossing, applied in tunnels, ground mining, mining equipment, etc., can solve the problems of increasing raw coal ash, increasing roof pressure, and increasing management difficulty, reducing the loss of electromechanical equipment and speeding up the progress Speed, the effect of reducing roof accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

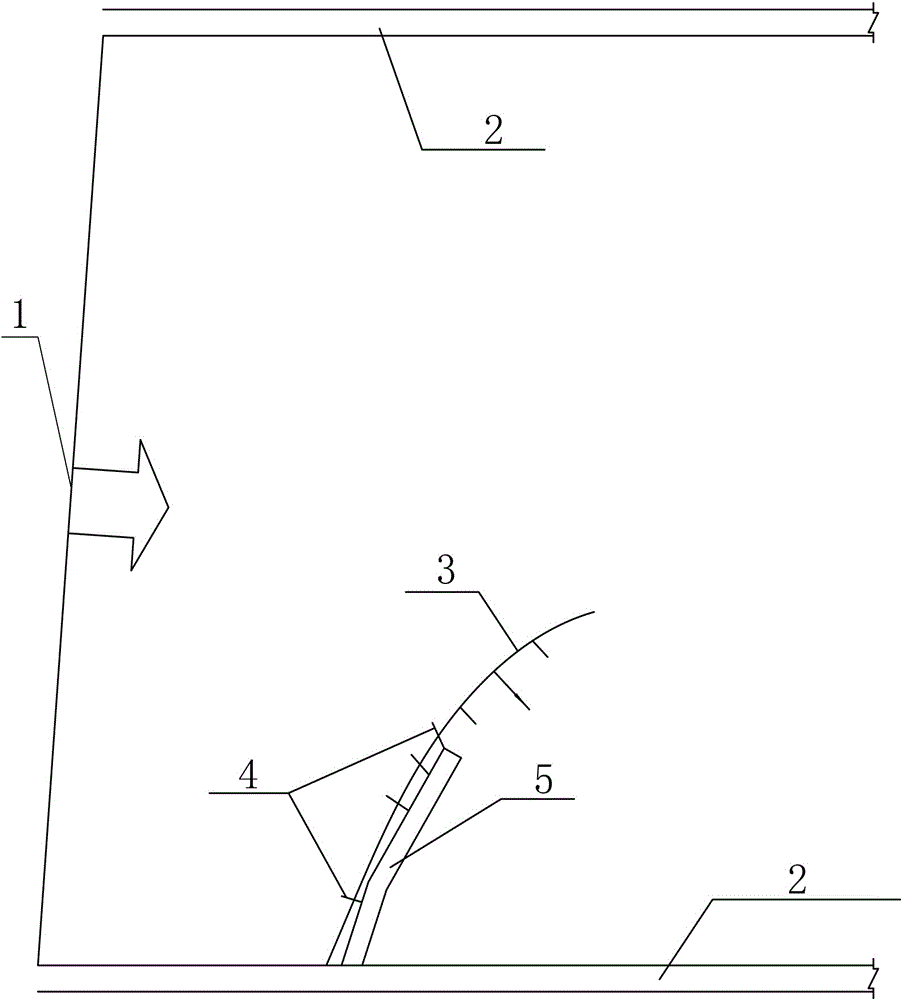

[0027] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0028] refer to figure 1 , a kind of fully-mechanized mining face pre-excavation roadway type crossing fault method described in this specific embodiment comprises the following steps:

[0029] 1) Construction fault roadway;

[0030] 2) Coal exploration by drilling method;

[0031] 3) Reinforcement and support of the shed in the roadway;

[0032] 4) The inclination and pitch angle of the working face should be well controlled during mining.

[0033] Preferably, said step 1) includes the steps of:

[0034] 11) Open the roadway on the side where the exposed rock is located next to the fault plane. Because the lithology of the fault is broken and the mine pressure is obvious, the cross section of the roadway is not easy to be too large.

[0035] 12) Support the roadway. The support form refers to the nature of the surrounding rock. Generally, the ancho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com