Belt type storing and conveying machine and method for storing and conveying gangue for underground heading face

A technology of excavation working face and storage and transportation machine, which is applied in the direction of conveyor, transportation and packaging, etc., which can solve the problems of inability to store gangue, scattered and falling gangue, reduce the burden of washing and selection, improve excavation efficiency, and reduce electricity expenses Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

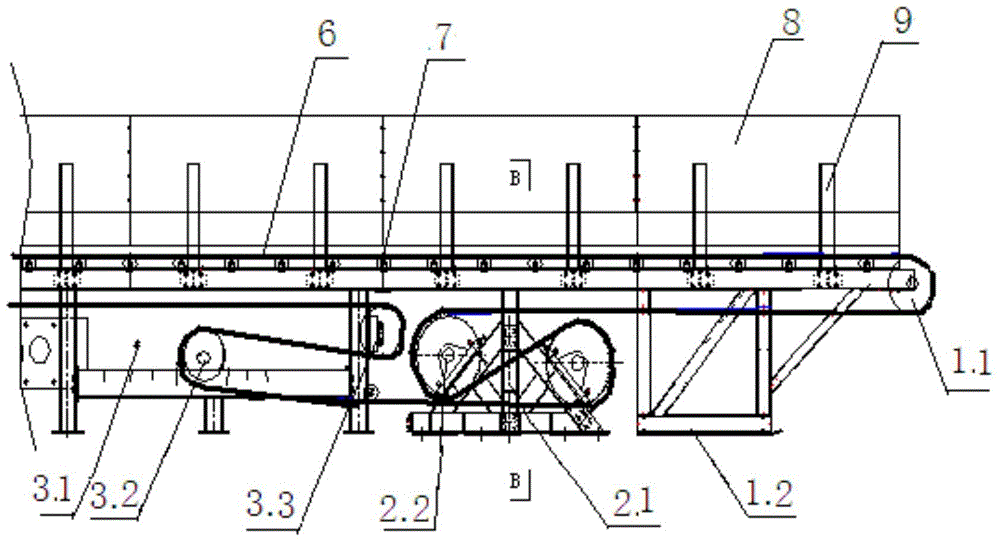

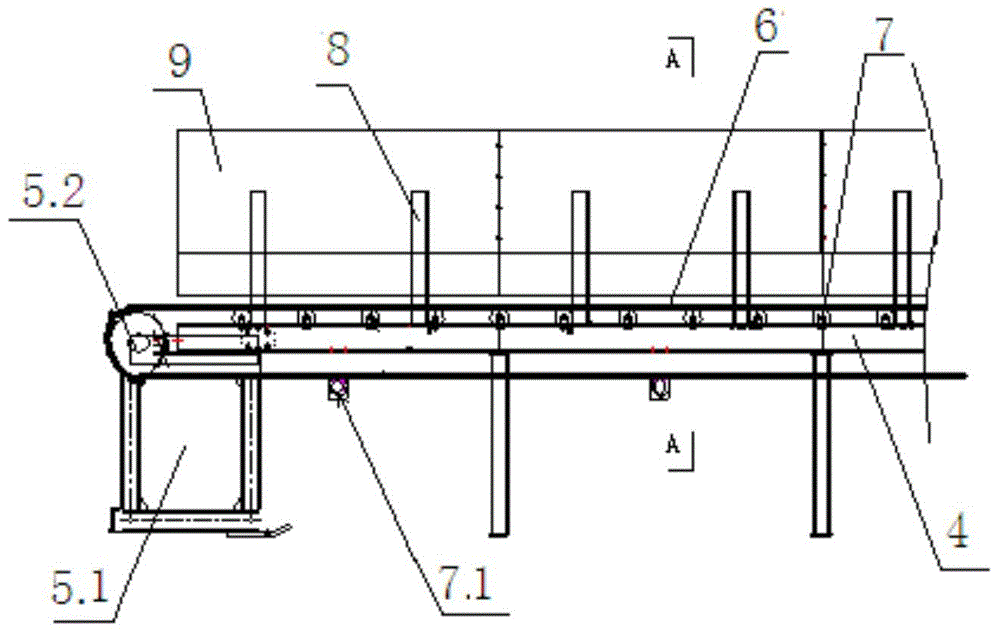

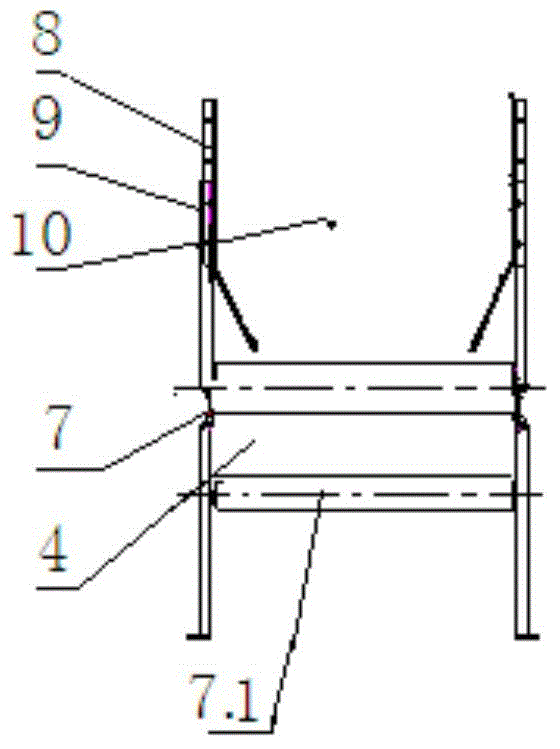

[0020] Such as figure 1 As shown, a belt type storage and transportation machine on the excavation working face, it is arranged with an upper idler 7 and a lower idler 7.1 at a certain distance on the frame 4, and a conveyor belt 6 is arranged on the idler, and the structure of the frame 4 There are rotary drums at both ends, wherein one end of frame 4 is gangue unloading rack 1.2, and the rotary drum installed on gangue unloading rack 1.2 is unloading drum 1.1, and the other end of frame 4 is tail rack 5.1, and the tail rack 5.1 is The installed rotary drum is the tail drum 5.2; a tensioning frame 3.1 is provided under the frame 4, and two tensioning drums are installed on the tensioning frame 3.1, which are respectively the movable first tensioning drum 3.2 and the guide rail for guiding. The second tensioning cylinder 3.3; the bottom of the frame 4 is provided with a driving frame 2.1, and the driving drum 2.2 is installed on the driving frame 2.1; 8 Install the baffle pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com