Comprehensive treatment system for underground coal gangue of coal mine

A comprehensive treatment and coal gangue technology, applied in shaft lining, underground chamber, mining equipment, etc., can solve problems affecting coal quality, restricting the transportation capacity of coal transportation system, and difficulty in gangue collection, so as to reduce gangue pollution and improve coal washing Ability and shortening of construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

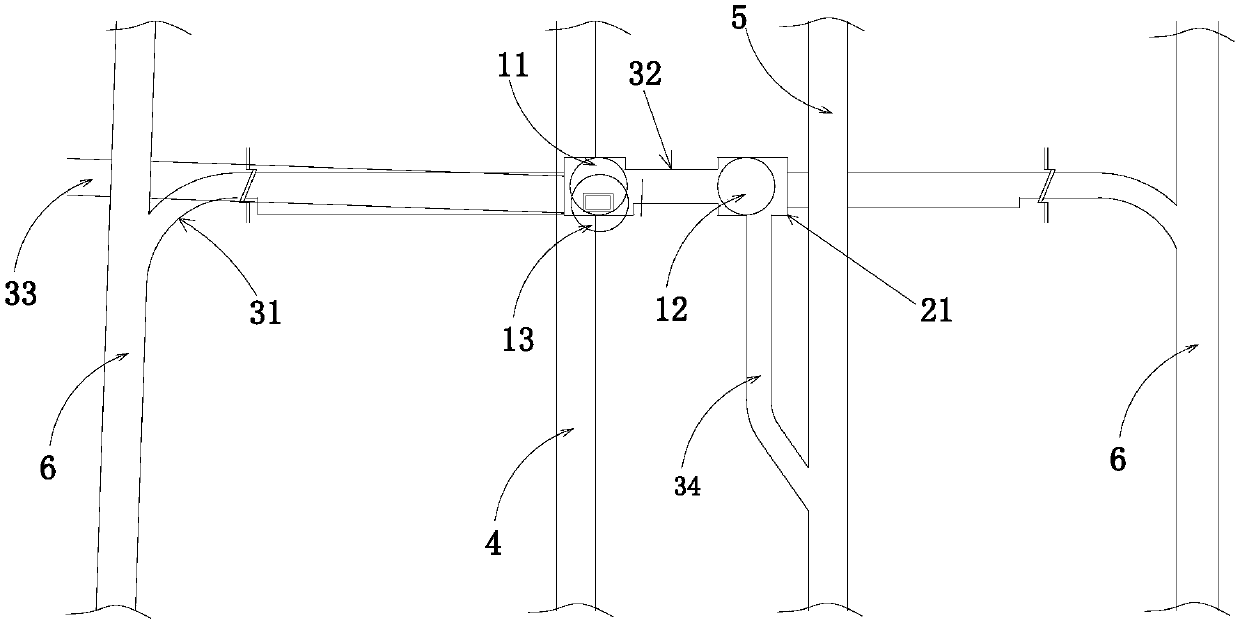

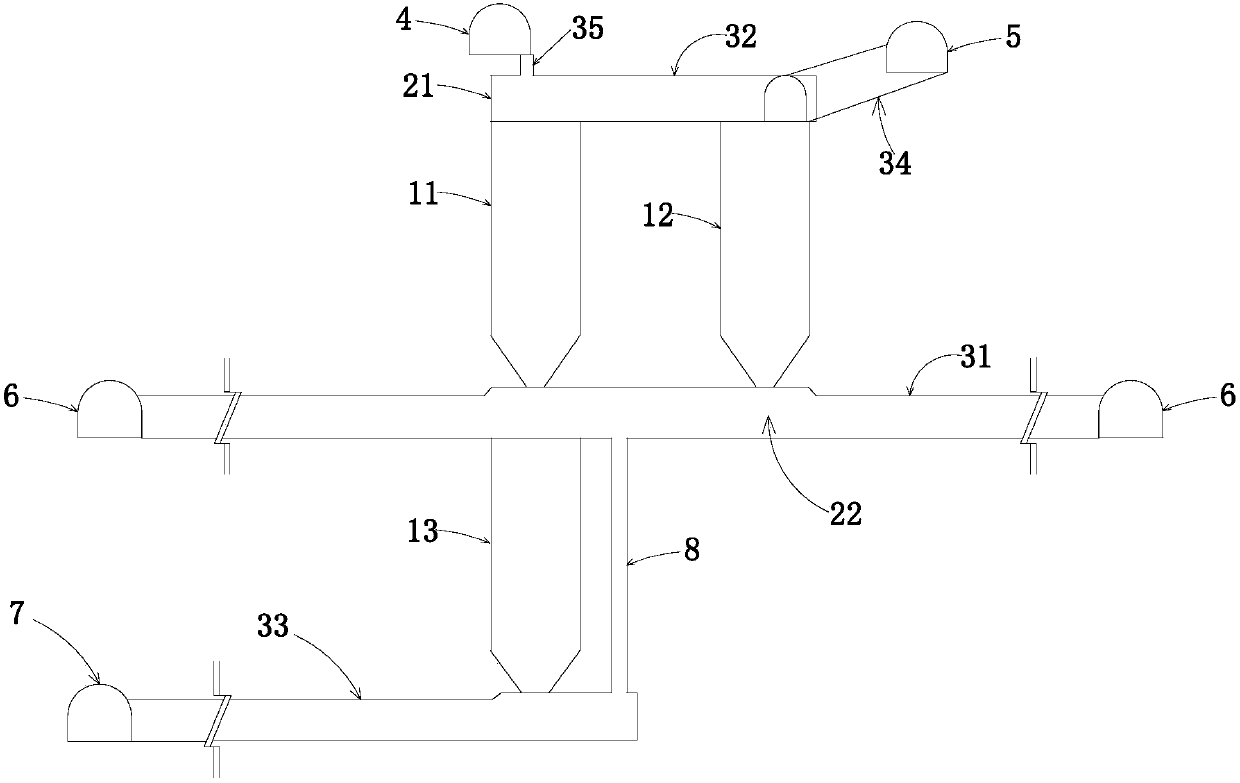

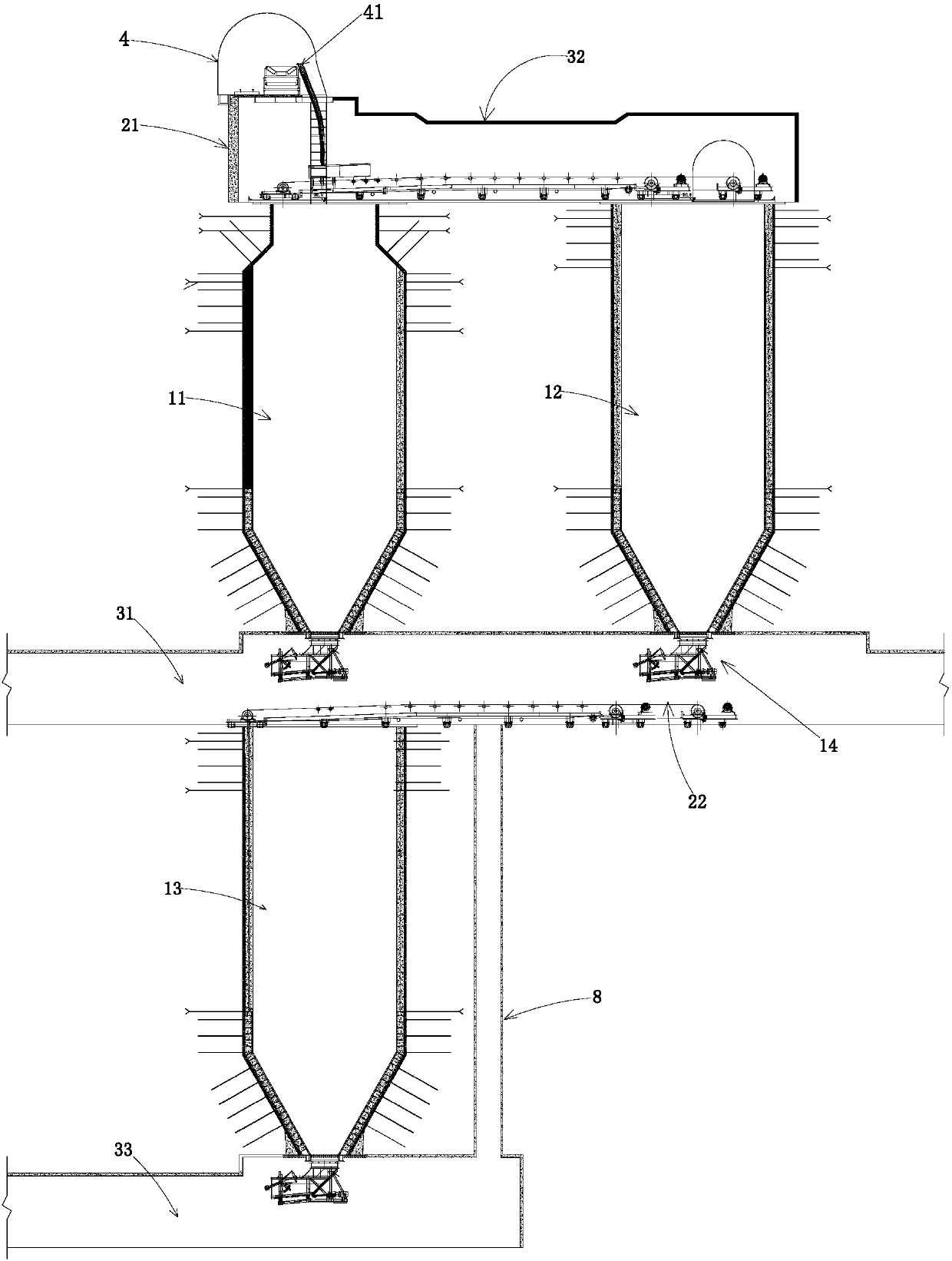

[0031] An underground coal and gangue comprehensive processing system in a coal mine, comprising a comprehensive gangue body bin 1, a gangue bin roof chamber 21, a gangue bin connecting lane 31, a filling connecting lane 33, a warehouse top chamber connecting lane 32, an air inlet 8 and a track Main lane 6, and equipment installed in the laneway or chamber. Construction of 3 gangue bins, specifically coal gangue bin 11, gangue bin 12 and filling gangue bin 13, wherein coal gangue bin 11 and gangue bin 12 are used for transshipment and storage of gangue or coal, and filling gangue bin 13 is used to collect Gangue is used for filling mining. The side wall structure of the comprehensive gangue bin 1 specifically includes a support layer 91 of anchor rods and cables, a shotcrete layer 92 and a masonry and reinforcement layer 93, wherein the entrance of the gangue bin 11 is set on the top of the gangue bin under the belt transportation road 4 The entrance of the gangue bin 21 and ...

Embodiment 2

[0034] combine image 3 The present embodiment shown in the embodiment 1 further explains the specific structural parameters of an underground coal gangue comprehensive processing system in a coal mine. The comprehensive gangue bin 1 includes a gangue bin 11, a gangue bin 12 and a filling gangue bin 13, and its specific parameters are: the diameter of the gangue bin 11 is 7m, the height is 21m, and the horizontal distance between the center line and the belt conveyor in the belt conveyor aisle 4 is less than 1.5m; the gangue bin has a diameter of 7m and a height of 21m; the gangue filling bin 13 has a diameter of 7m and a height of 20m. The structure and support parameters of the side walls of the three gangue bins are as follows: the upper anchor rod of the gangue bin 12 is Φ20×2400mm, the row spacing is 700×700mm, the anchor cable parameters are Φ22×6000mm, and the row spacing is 700×700mm. The thickness of the slurry is 100-150mm, the single-layer reinforcement is tied, th...

Embodiment 3

[0036] This embodiment is a further specific description of the construction method of a coal mine comprehensive treatment system for underground coal and gangue in the above embodiments. The construction method of the underground coal and gangue comprehensive treatment system in the coal mine is as follows:

[0037] A. Construction of chambers and connecting roadways: construction of gangue warehouse connecting lane 31 at the same elevation along track lane 6, construction of 2 gangue warehouse transfer chambers 22 at the exit of gangue bins, construction of connecting lanes or coal sliding along return air road 5 From eye 35 to the roof chamber 21 of the gangue warehouse under the belt transportation alley, the construction warehouse roof chamber connection lane 32 connects the two gangue warehouse roof chambers 21, and the construction of the filling lane 7 in the self-mining area forms a filling connection lane 33. Liaison Lane 33 connects the filling gangue bin 13 and the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com