An optimization method to improve the accuracy of automatic coal blending in large-volume silos

An optimization method and high-volume technology, applied in loading/unloading, conveyor objects, conveyor control devices, etc., can solve the problems of poor operation stability, large maintenance workload, and high labor intensity, and achieve easy operation and simplified blanking. Devices and processes, highly reliable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] In this embodiment, the actual coal blending amount of Inner Mongolia coal is required to be 9%, and its coal blending optimization method comprises the following steps:

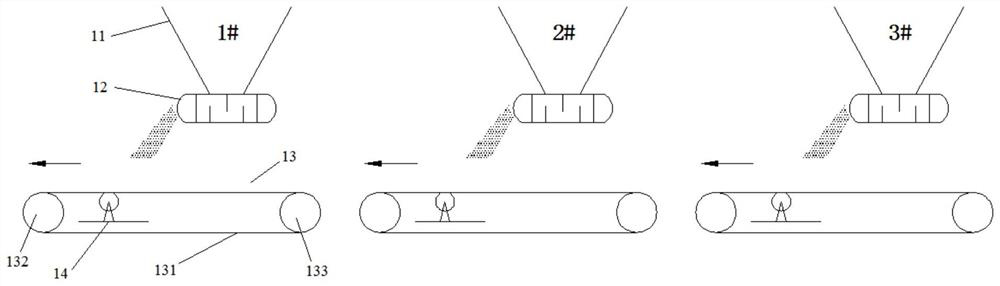

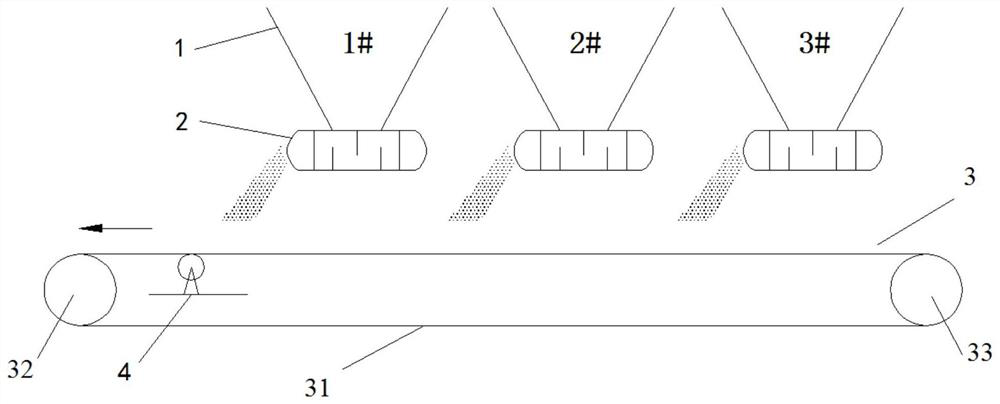

[0045] S1: Count the coal blending amount with the highest probability of use among the actual coal blending amounts of the 3 feeding leaks in each group of feeding leaks in each silo, and use the probability according to the "closest matching principle" The highest coal blending amount is classified as 5%, 10% or 15% coal blending amount, and each feeding nozzle in each group of feeding nozzles uses 5%, 10% or 15% coal blending respectively The given frequency of the corresponding disc feeder when measuring;

[0046] S2: if figure 2 As shown, according to the actual coal blending conditions of 1#, 2# and 3# blanking nozzles in the production situation in the next month, the circles corresponding to the 5% gear, 5% gear and 10% gear are respectively adjusted before coal blending. The given frequenc...

Embodiment 2

[0050] In this embodiment, the actual coal blending amount of Inner Mongolia coal is required to be 16%, and its coal blending optimization method comprises the following steps:

[0051] S1: Count the coal blending amount with the highest probability of use among the actual coal blending amounts of the 3 feeding leaks in each group of feeding leaks in each silo, and use the probability according to the "closest matching principle" The highest coal blending amount is classified as 5%, 10% or 15% coal blending amount, and each feeding nozzle in each group of feeding nozzles uses 5%, 10% or 15% coal blending respectively The given frequency of the corresponding disc feeder when measuring;

[0052] S2: if figure 2 As shown, according to the actual coal blending conditions of 1#, 2# and 3# blanking nozzles in the production situation in the next month, before coal blending, the circles corresponding to the 5% gear, 5% gear and 5% gear are respectively adjusted The given frequenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com