Intelligent sorting and in-situ filling device and disassembly and assembly method

A filling device and sorting technology, which is applied in the direction of filling materials, safety devices, chemical instruments and methods, etc., can solve the problems of increasing the transportation cost of gangue out of the well, the impact on the ecological environment of ground buildings, and the irreparable environment, so as to solve the problems of environmental pollution and Destruction, easy disassembly and assembly, and the effect of reducing lifting costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

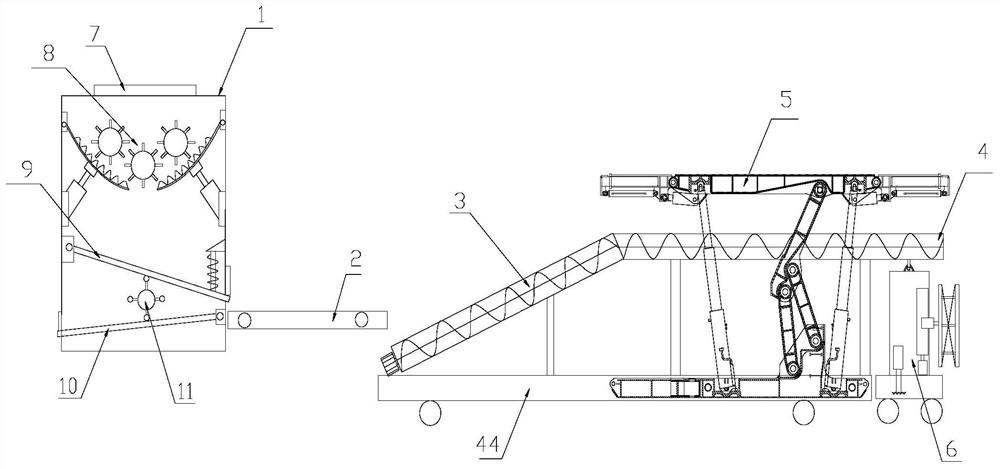

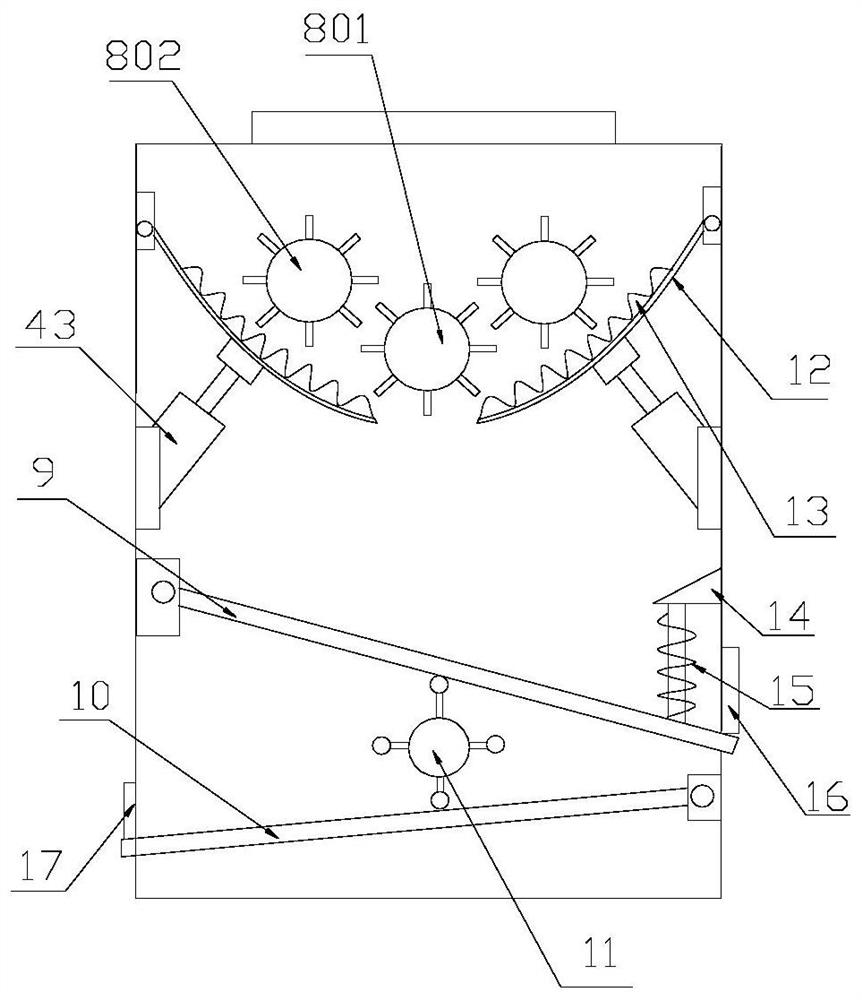

[0051] like Figure 1-Figure 7As shown, an intelligent sorting and on-site filling device includes a sorting bin 1, a gangue conveying component and a compacting component 6, wherein a feeding port 7 is provided on the top of the sorting bin 1, and a crushing component is arranged inside it and the screening assembly, the coal gangue is put into the sorting bin 1 through the feed port 17, the crushing assembly is used to crush the coal gangue, and the crushed coal gangue is divided into coal powder and gangue by the screening assembly, and the coal gangue conveying assembly is located at One side of the sorting bin 1 is used to transport the gangue output from the sorting bin 1 to the goaf for backfilling, and the compacting component 6 is located in the goaf for compacting the backfilled gangue, and the compacting component and The gangue conveying components move synchronously, which is easy to move and disassemble. That is to say, using the sorting bin, coal gangue conveyi...

Embodiment 2

[0056] like Figure 1-Figure 7 As shown, the screening assembly includes a screen 9 and a loading plate 10, and the screen 9 is located above the loading plate 10 for screening coal powder and gangue, and the screen 9 and the loading plate 10 are all inclined set up. The bottom of the sorting bin 1 is provided with a pulverized coal outlet 17 and a gangue outlet 16 . One end of the screen 9 is hinged to the inner wall of the sorting bin 1 , and the other end extends below the gangue outlet 16 . The inclination direction of the loading plate 10 is opposite to that of the screen 9 , and the bottom end of the loading plate 10 extends below the pulverized coal outlet 17 . That is to say, the output directions of pulverized coal and gangue are different, and the separation of pulverized coal and gangue is realized.

[0057] A telescopic assembly is connected between the other end of the screen 9 and the inner wall of the sorting bin 1, and the telescopic assembly includes a fixe...

Embodiment 3

[0061] like Figure 1-Figure 7 As shown, the gangue conveying assembly includes a belt conveyor 2, a first screw conveyor 3 and a second screw conveyor 4, the first screw conveyor 3 is inclined, and the second screw conveyor 4 is located in the hydraulic Below the top plate of the support 5, and the first screw conveyor 3 and the second screw conveyor 4 are located on the mobile platform 44 and move synchronously. The mobile platform 44 is a self-moving structure, the gangue is transported to the temporary storage place through the belt conveyor 2, and the gangue located in the temporary storage place is transported to the first screw conveyor 3 through the auxiliary transportation equipment, and the first screw conveyor 3 and The second screw conveyor 4 is connected, and the gangue falls into the backfilling face of the goaf through the second screw conveyor 4 .

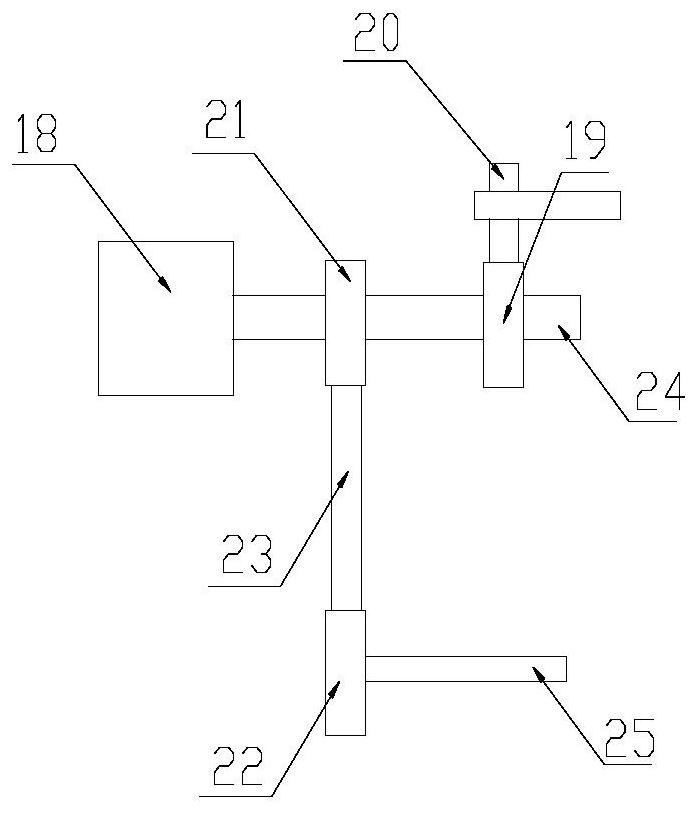

[0062] The compacting assembly 6 includes a positioning oil cylinder group, a compacting oil cylinder 32 and a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com