Large fluidized bed system and device for drying and upgrading lignite

A fluidized bed and lignite technology, applied in the direction of drying gas arrangement, drying solid materials, heating to dry solid materials, etc., can solve the problem of not describing the specific particle size and processing speed of different particles, so as to prevent fire and explosion accidents, reduce Small pollution, increased safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

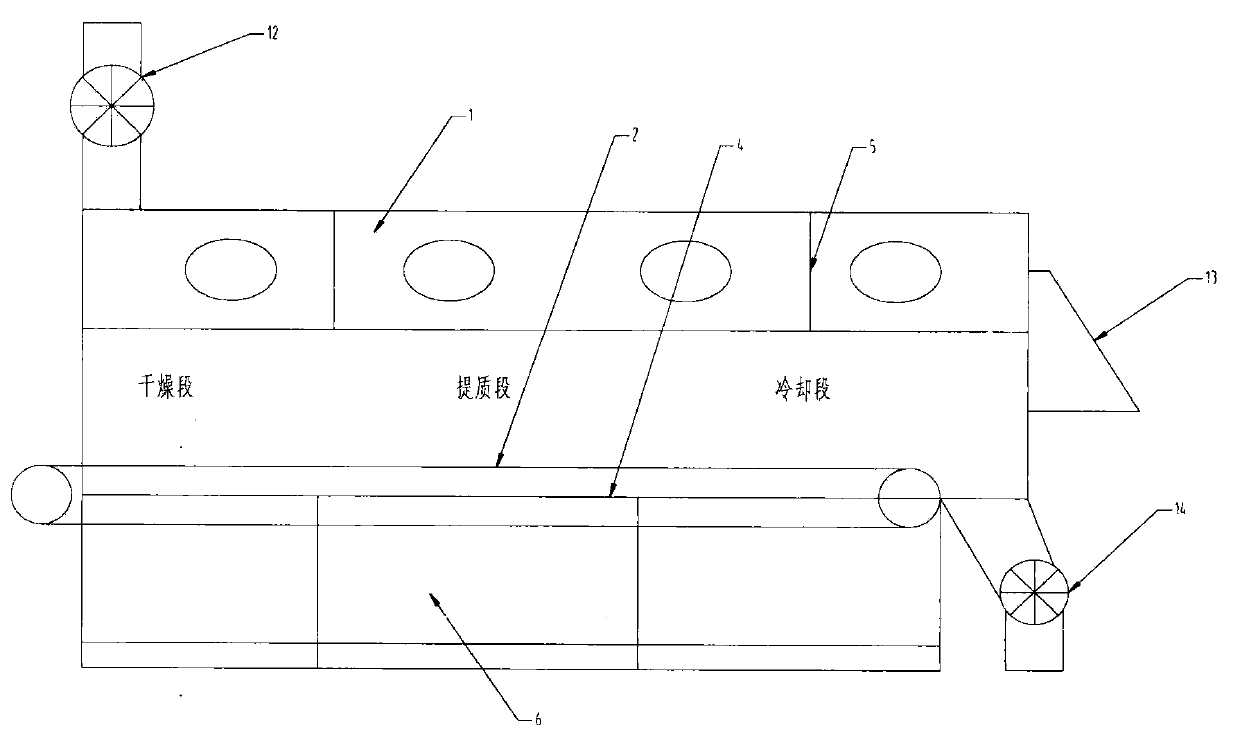

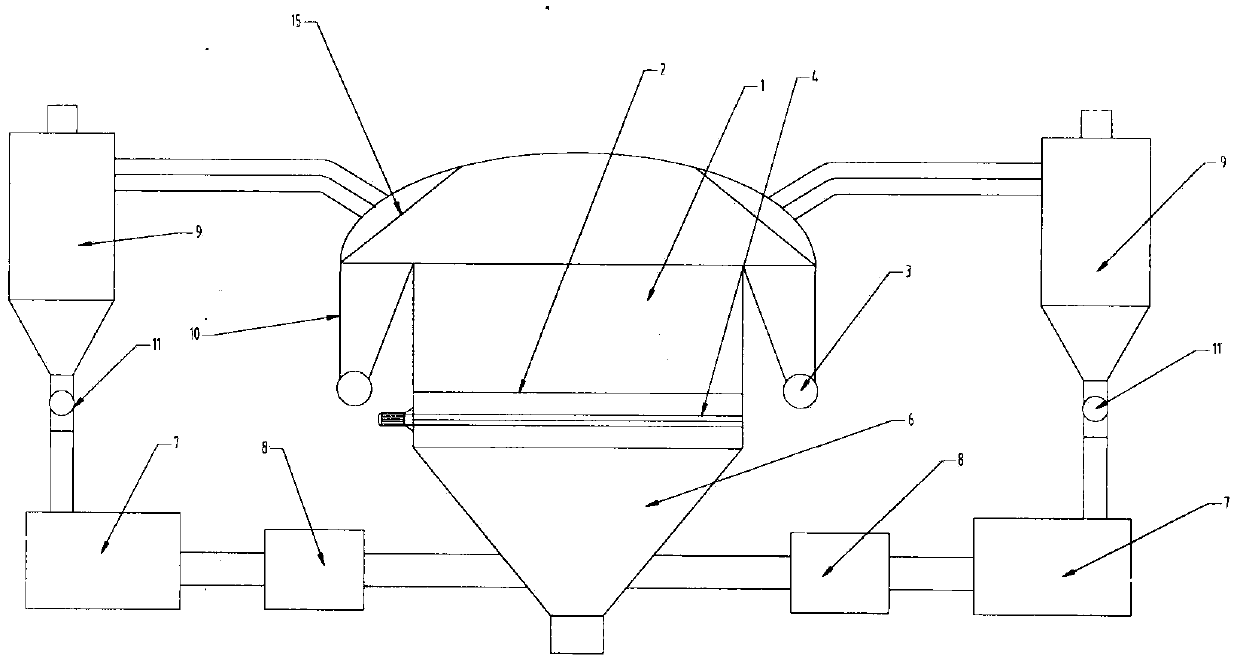

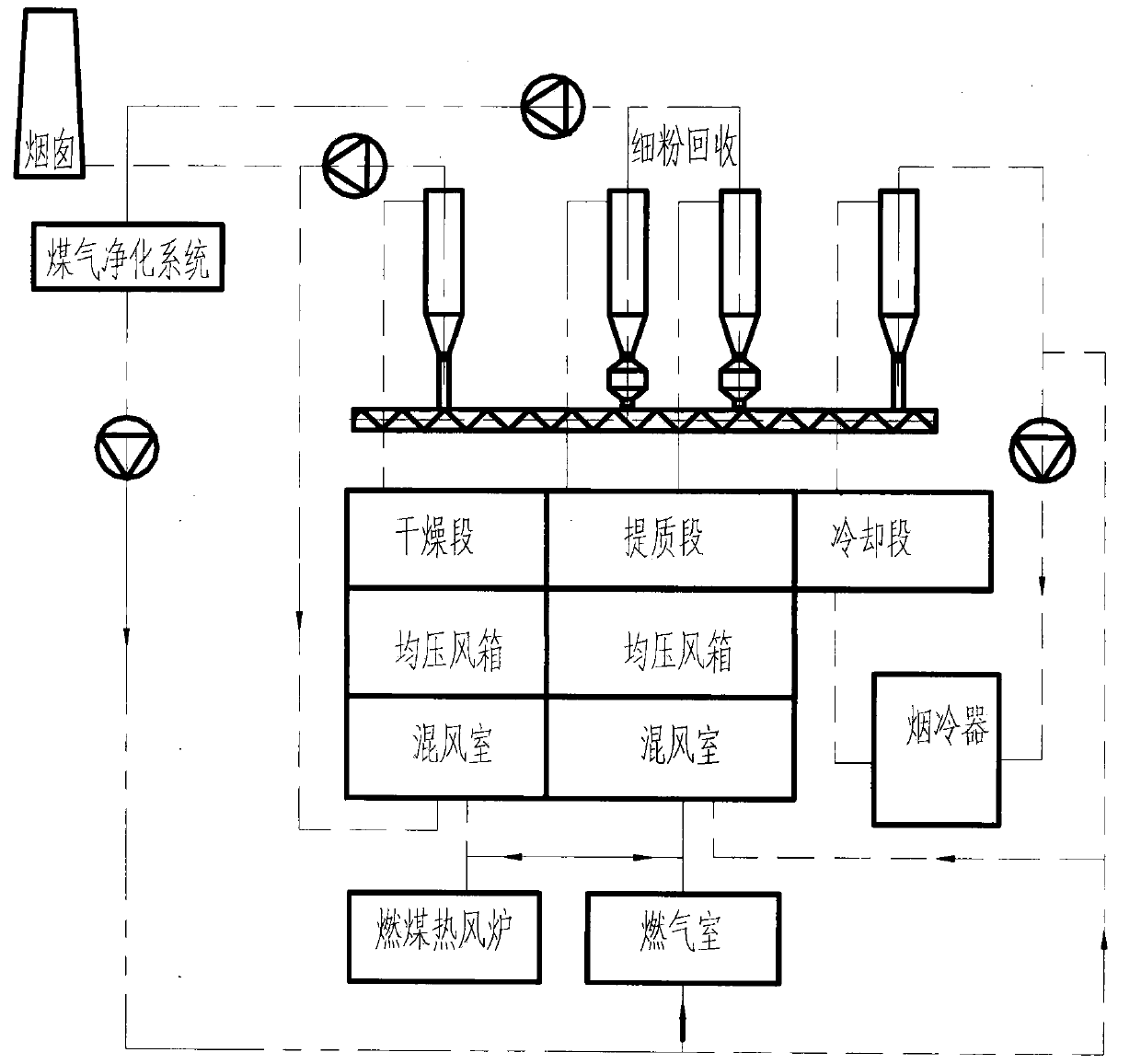

[0048] Such as figure 1 , figure 2 1. A large particle conveyor 2 and a medium particle conveyor 3 are arranged in the fluidized bed 1, and the bottom of the conveyor is an air distribution plate 4. Lignite enters the drying section of the fluidized bed through the feed lock valve 12, and slowly moves forward under the drive of the large particle conveyor 2. In the drying section, the air distribution plate 4 under the large particle conveyor 2 is set to The inclination is at an angle of 70° to the horizontal direction. Driven by the wind force, the medium particles are blown up and are blocked by the dust filter 15 and fall into the medium particle conveyor 3. The 4 holes of the air distribution plate under the medium particle conveyor 3 are for the discharge. The angle between the end tilt and the horizontal plane is 70°, and the medium particles are fluidized and dried under the wind force and the medium particle conveyor 3 drive. The separated large particles are partia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com