Tunnel anti-freezing dehumidification system

A technology in tunnels and tunnels, applied in tunnels, tunnel linings, ventilation of mines/tunnels, etc., can solve seasonal freezing damage, rail rot, etc., and achieve the effects of increased life, reasonable design, and a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

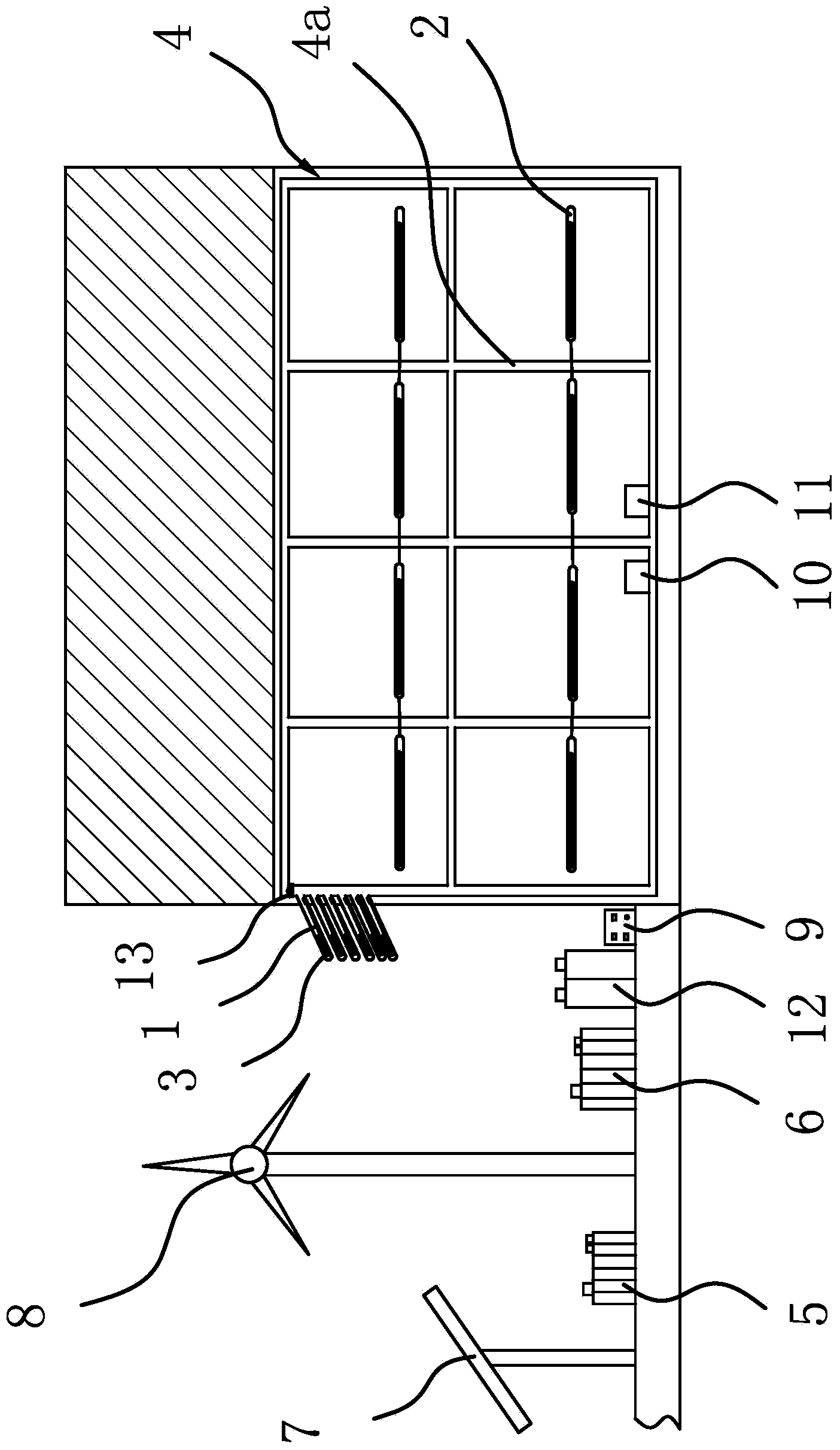

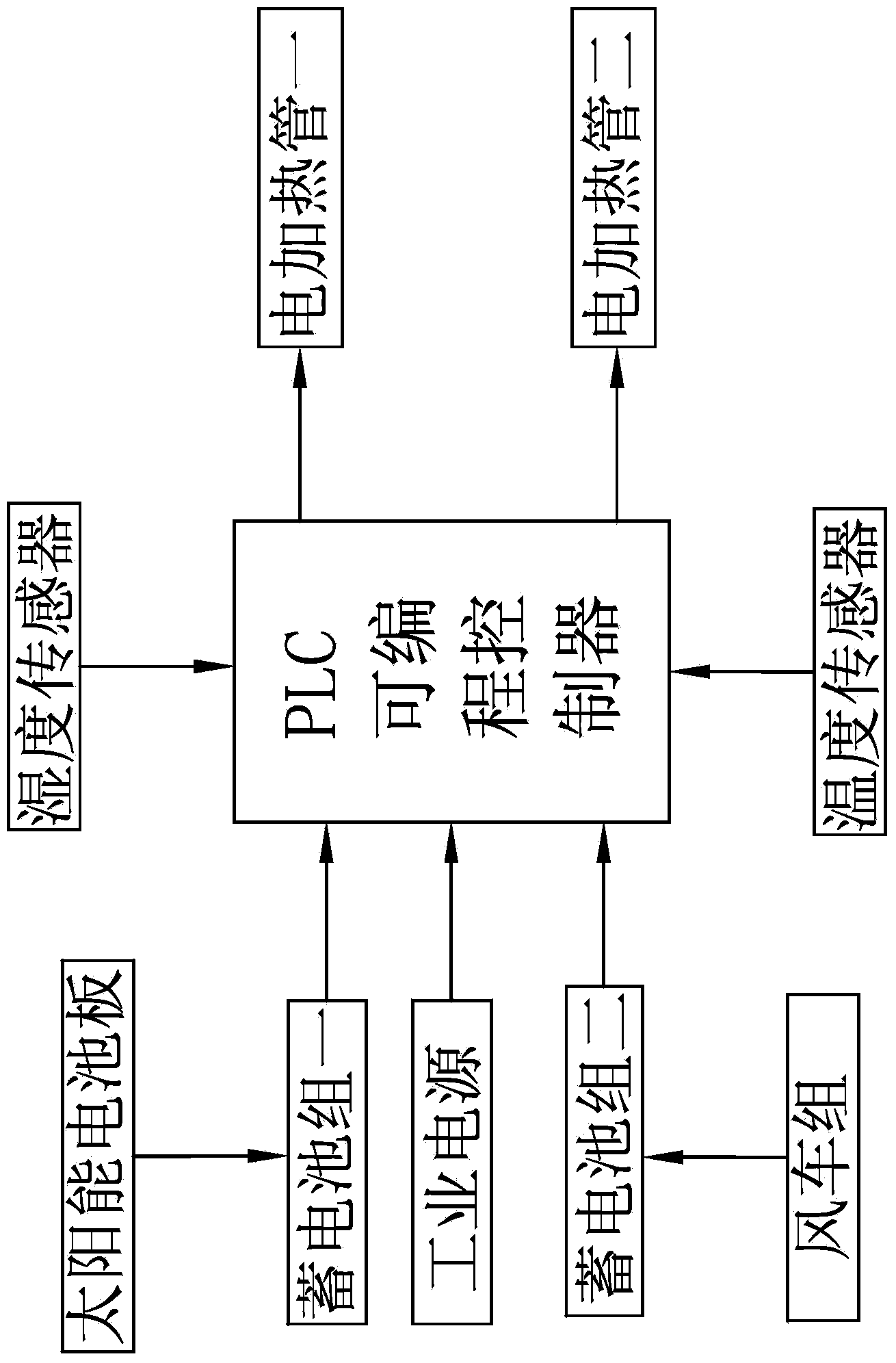

[0024] Such as figure 1 Shown, a kind of tunnel antifreeze dehumidification system, comprises a plurality of solar heat collecting pipes 1 arranged at the tunnel opening and a plurality of electric heating pipes-2 arranged in the tunnel.

[0025] One end of the solar heat collecting pipeline 1 is a closed end, and the other end of the solar heat collecting pipeline 1 is connected with a heating pipeline 4 that can supply heating for the tunnel. The heat dissipation pipes 4a and the heat dissipation pipes 4a are all connected to each other, and one of the heat dissipation pipes 4a is provided with a check valve 13 near the top of the solar heat collection pipe 1 port, and the solar heat collection pipe 1 is also provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com