Method of soldering and solder compositions

A technology of solder and solder layer, applied in the direction of welding/cutting medium/material, welding equipment, welding medium, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

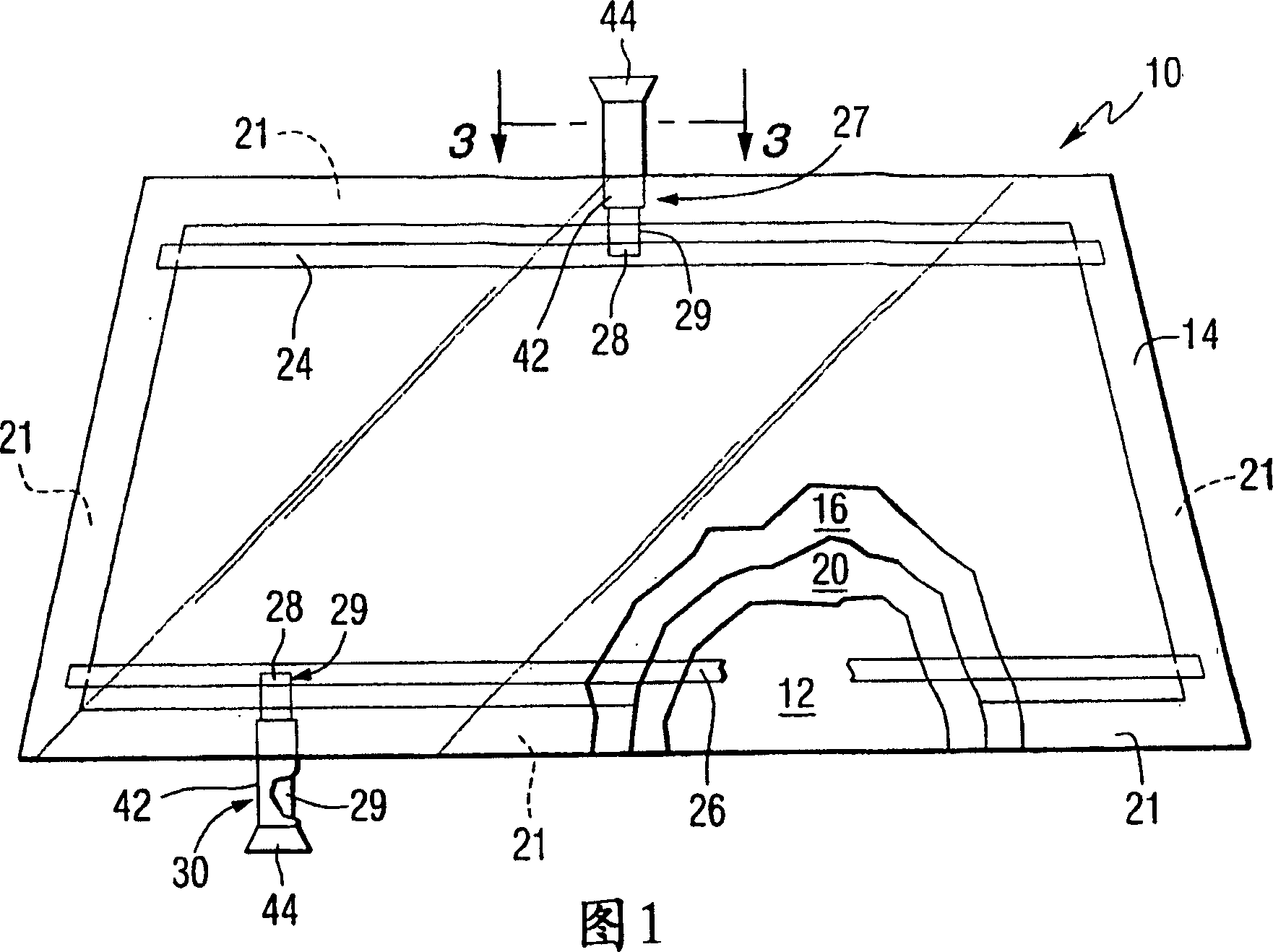

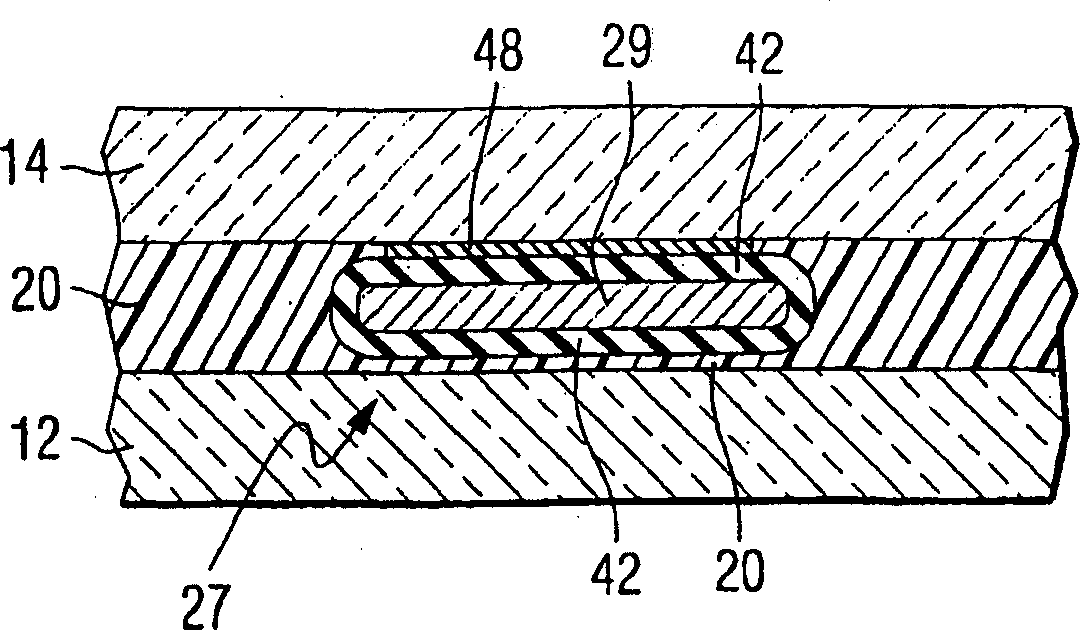

[0046] The invention will now be described with respect to the assembly of components for assembling a non-limiting embodiment of a windshield incorporating features of the invention. Flat pieces of glass shaped to provide glass blanks 12 and 14 are cut from the glass sheet and the edges of the cut pieces are stitched. A conductive ceramic paste is screen printed onto the inner surface of the flat glass piece of blank 14 to provide top busbars 24 and bottom busbars 26 . A black ceramic paste was screen printed onto the edge (not shown) of the inner surface of the glazing of the blank 12 (the intended No. The underlying adhesive provides UV protection. The flat glass piece with busbars and the flat glass piece with black ceramic strips were heated to a temperature of about 700° C. (371° C.) to secure the busbars and blank ceramic strips to their respective glass pieces. After the plate with the ceramic busbars has cooled, a continuous heatable coating of the type described ab...

Embodiment 2

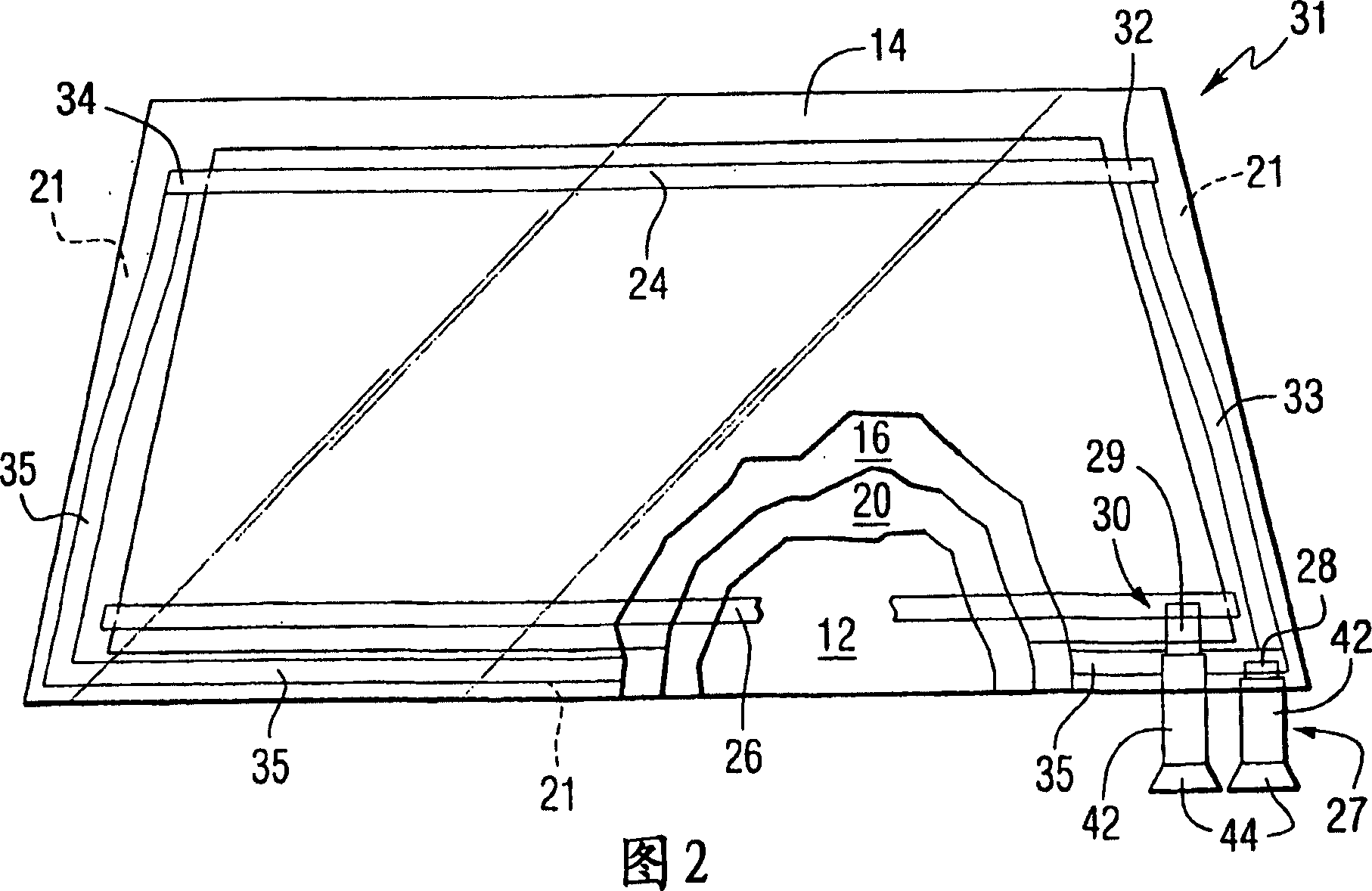

[0050] A glass blank 12 is provided as described above in Example 1. The flat glass piece for the blank 14 is arranged as described above, except that the ceramic bus bars are not bonded to the glass piece. refer to Figure 6 , a circuit 64 such as an antenna circuit is applied on the No. 4 surface of the intended laminate, and a silver ceramic pad 66 is screen printed on the surface in electrical contact with the circuit 64 . The flat glass used for the blank 14 is heated to bond the gasket 66 to the glass. The conductive coating was applied to the inner surface of the glass for blank 14 (No. 3 surface of the desired laminate) as described above. The flat glass pieces for the blanks 12 and 14 are stacked on top of each other on a bent iron 70 of the type known in the art with the coated and black ceramic strips facing each other.

[0051] A bent iron on which the plates are supported moves through a tunnel furnace to heat the plates to their softening temperature. These s...

Embodiment 3

[0058] Glass blanks 12 and 14 were prepared as described in Example 2, except that a circuit 64 was provided on the surface of blank 14 and a ceramic liner 66 was not provided.

[0059] The composite board of Example 2 is placed on the profiled board 14 with the busbars in electrical contact with the coating 16 and the lead assemblies in contact with these busbars. Formed panels 12 were placed on composite 20 as described in Example 2, and the panels were laminated together as described below in the section entitled Laminating Cycle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com