Patents

Literature

35results about How to "Reduce material strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

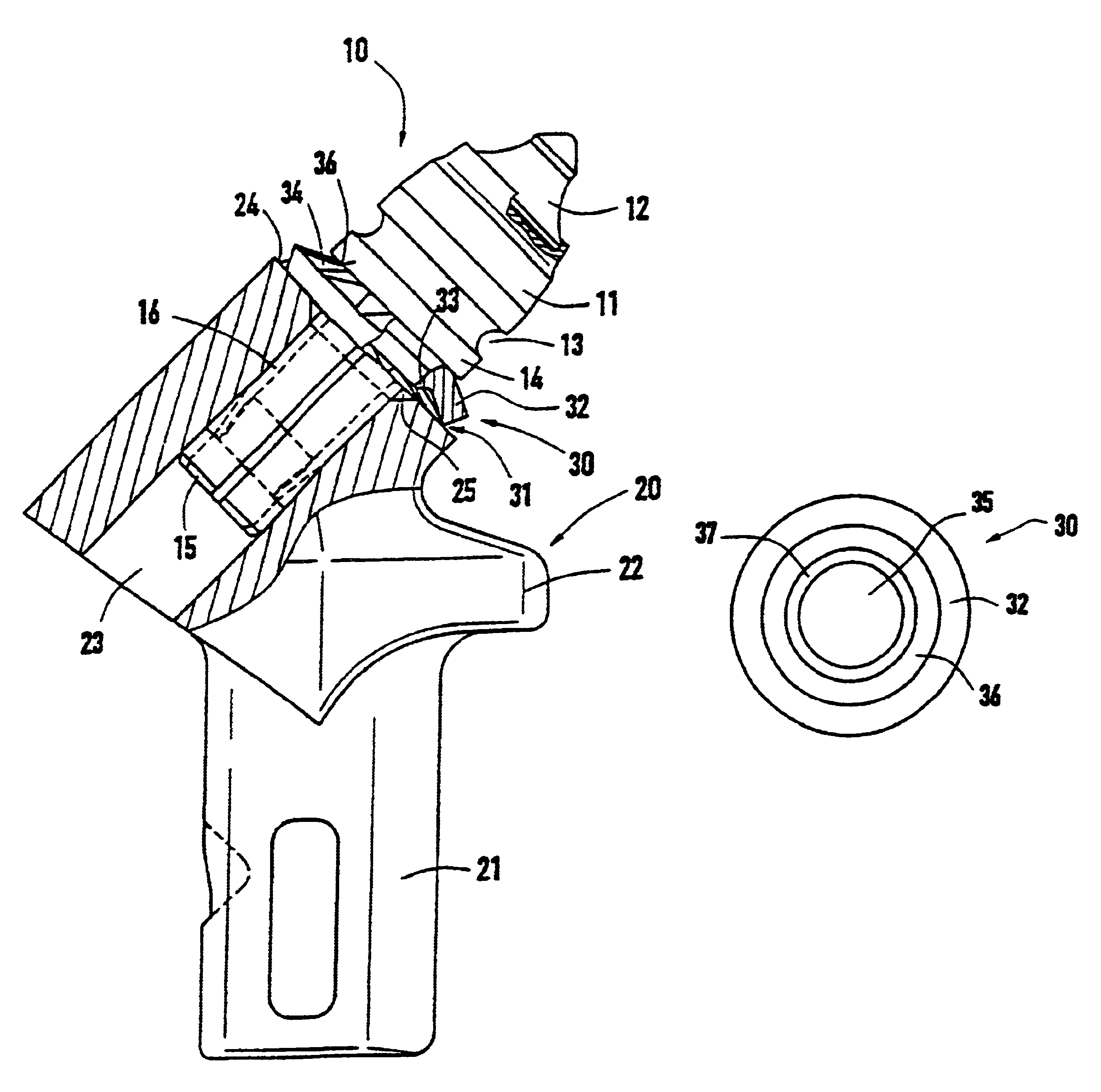

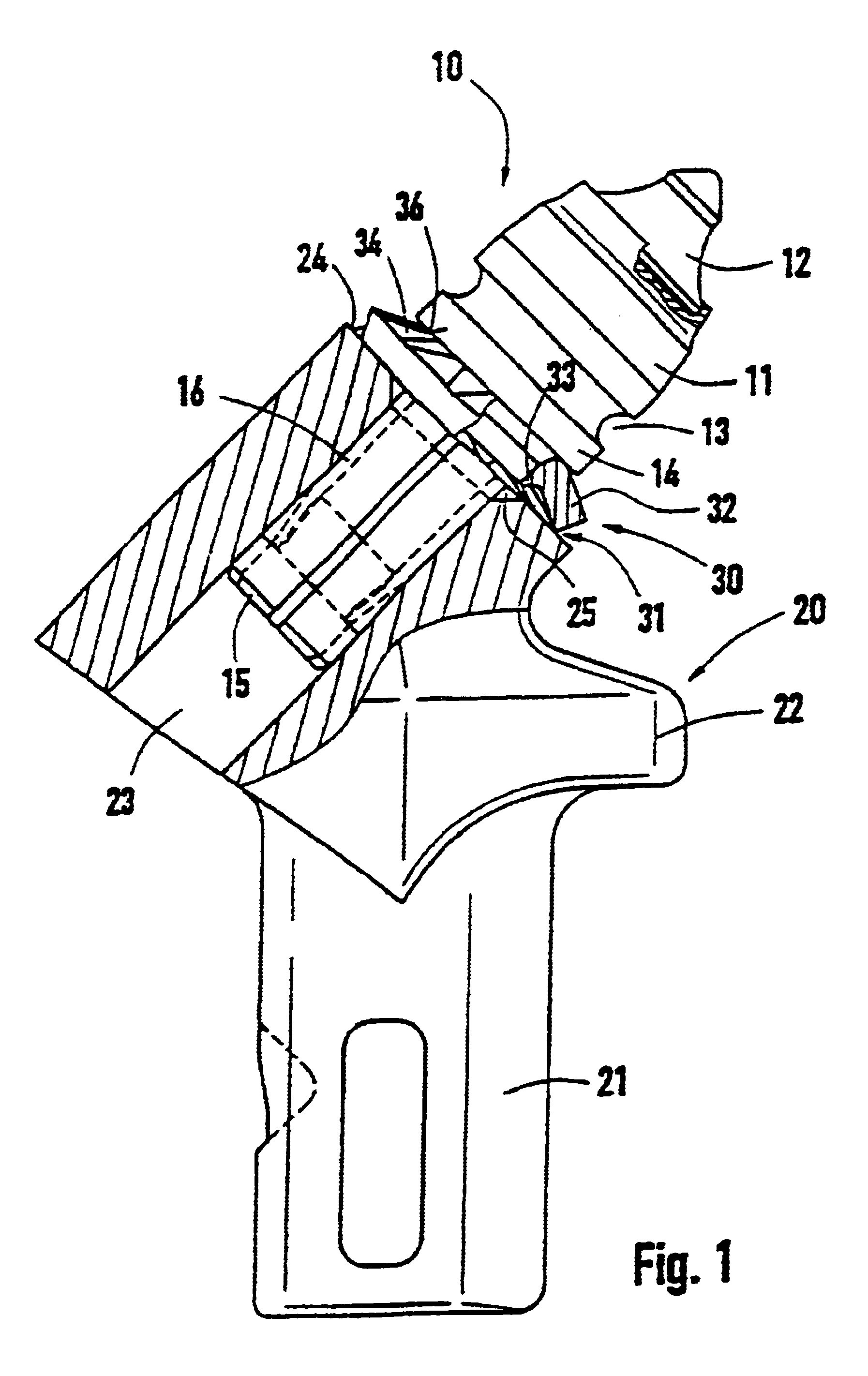

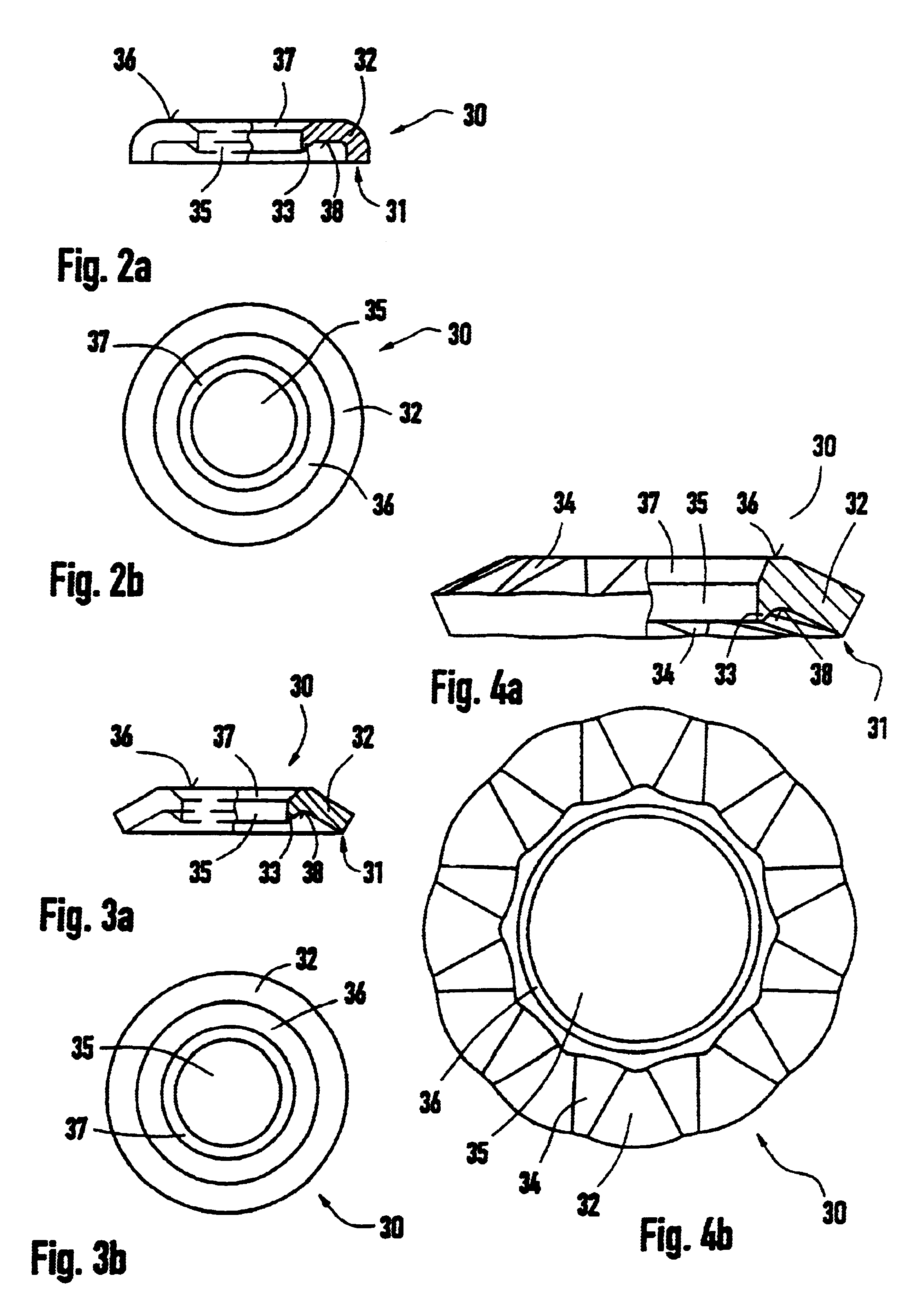

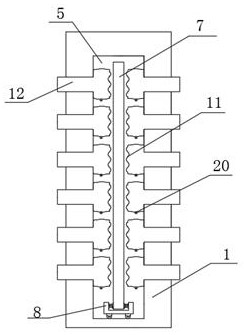

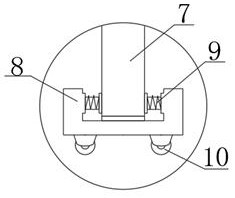

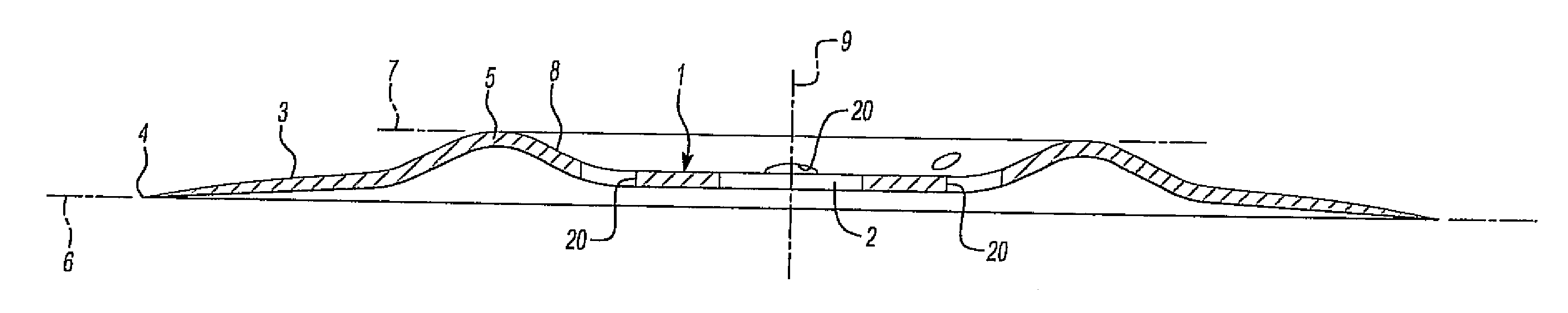

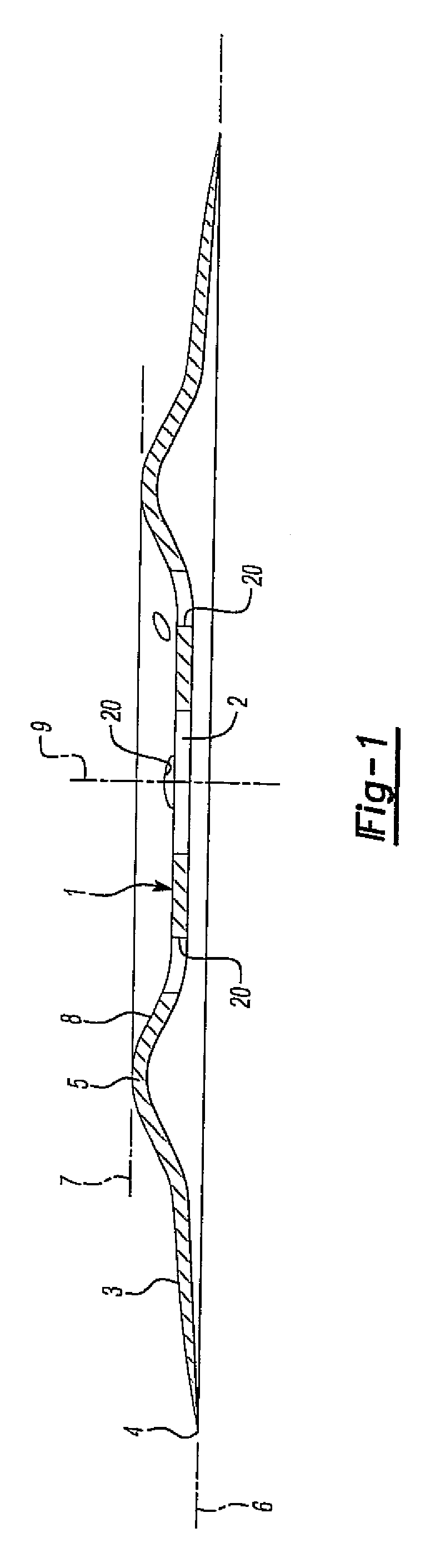

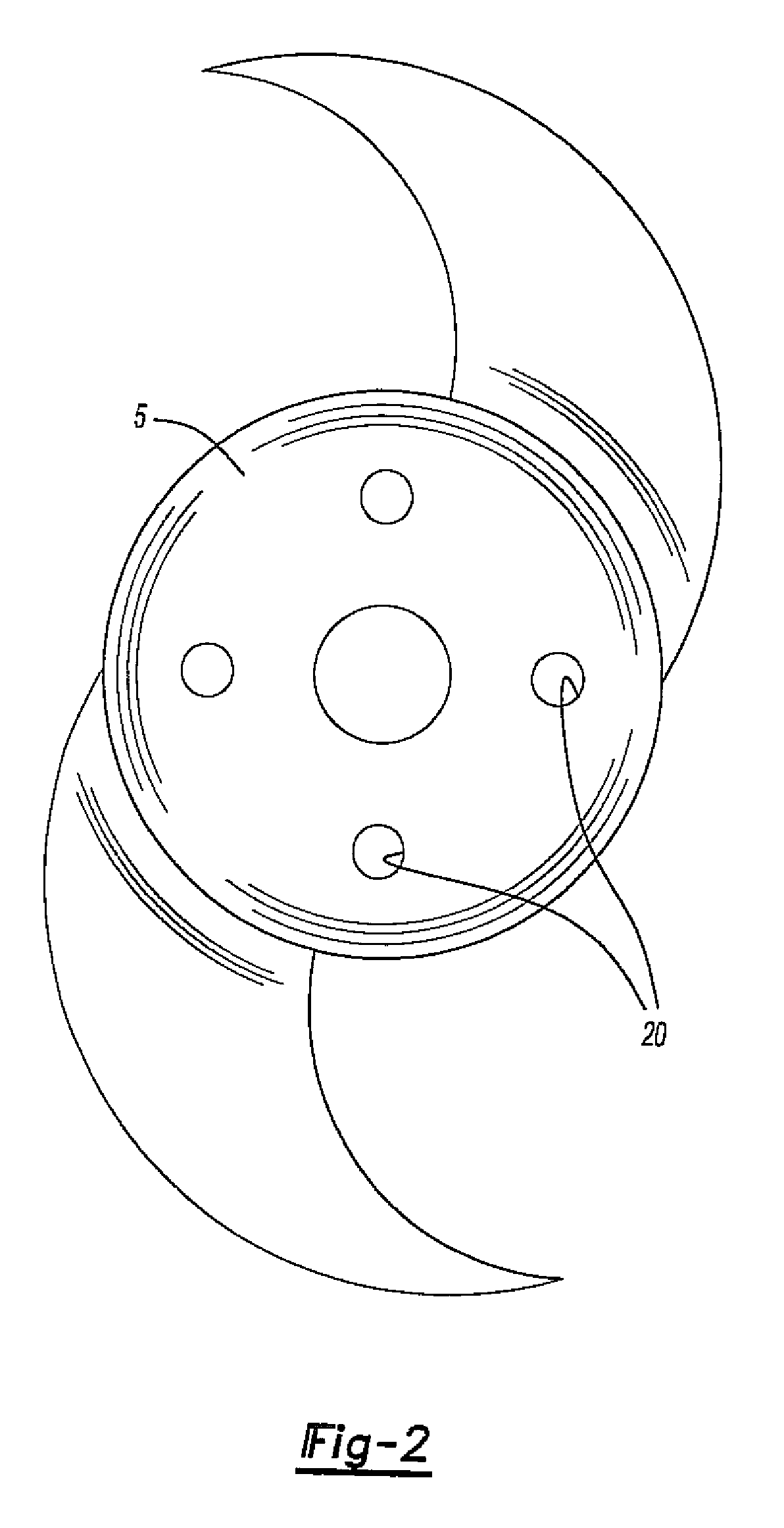

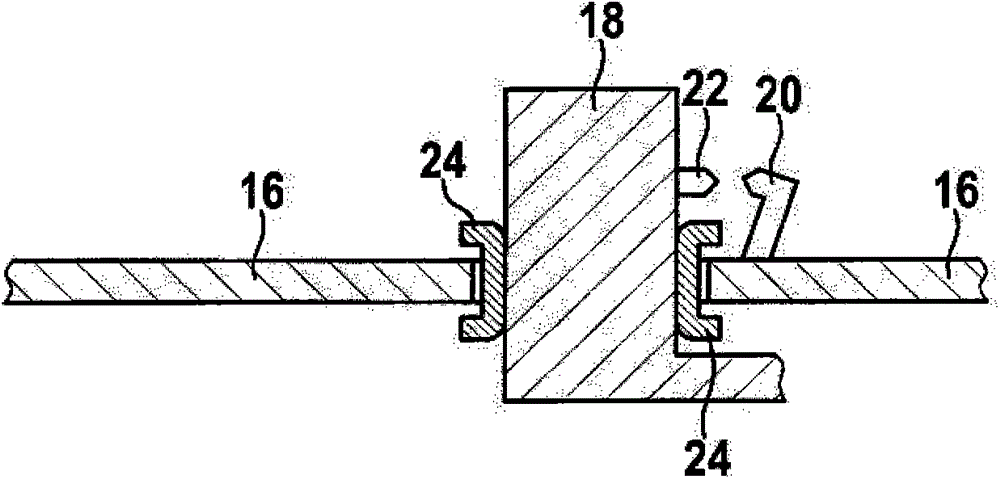

Tool for a street milling, coal-cutting or mining machine

A tool for a street milling, coal-cutting mining machine or the like which includes a chisel with a chisel head and a chisel stem. The chisel stem is rotatably mounted in a receiver of a chisel holder. A perforated wearing protection element is mounted on the chisel head. The chisel head sits closely on the chisel holder while embracing the interposed wearing protection element. This invention achieves improved wearing protection behavior of such a tool. Thus, the inventive wearing protection element has one or more spring elements that elastically support the chisel head by way of the chisel holder.

Owner:BETEK BERGBAU UND HARTMETALLTECHN KARL HEINZ SIMON

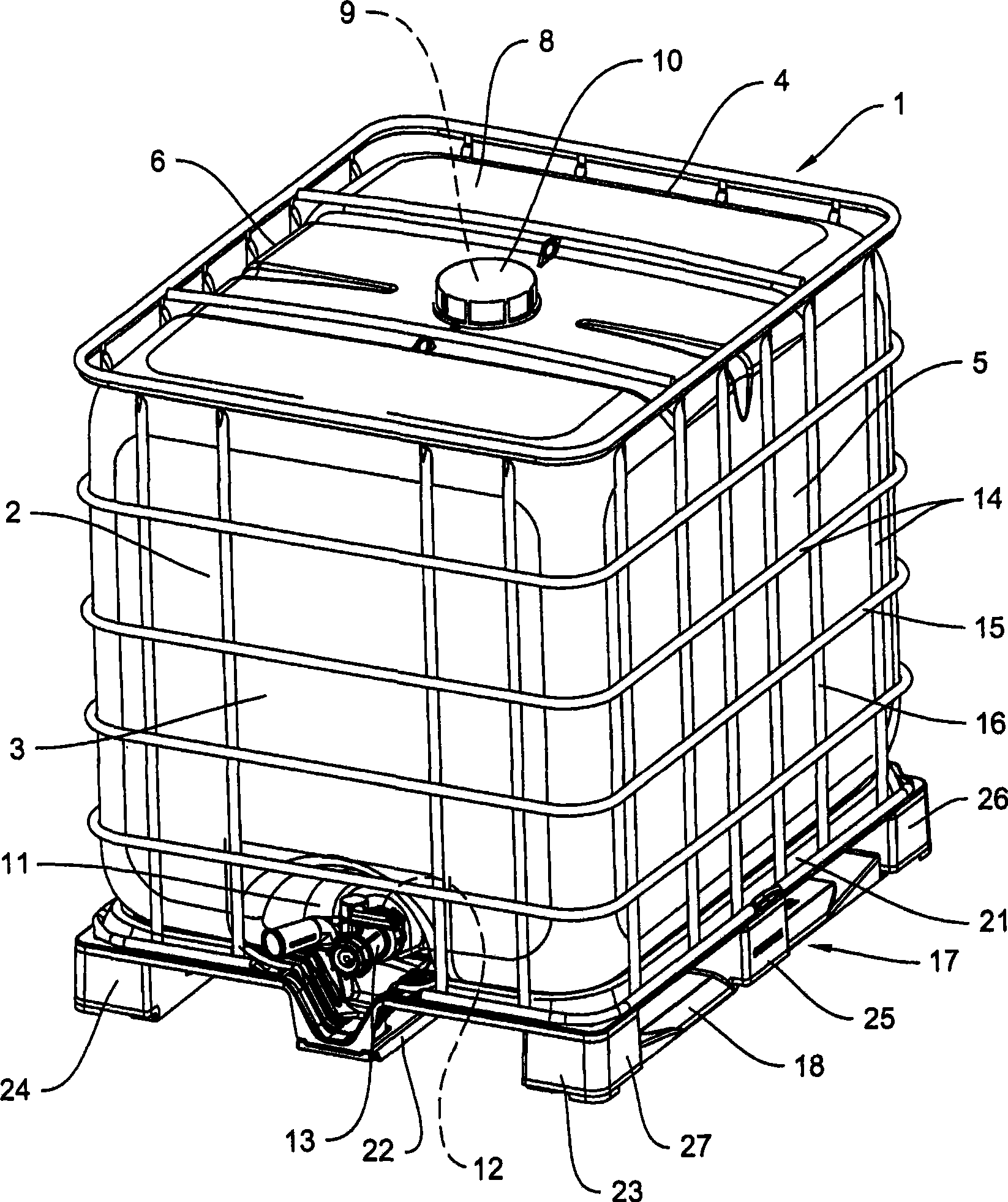

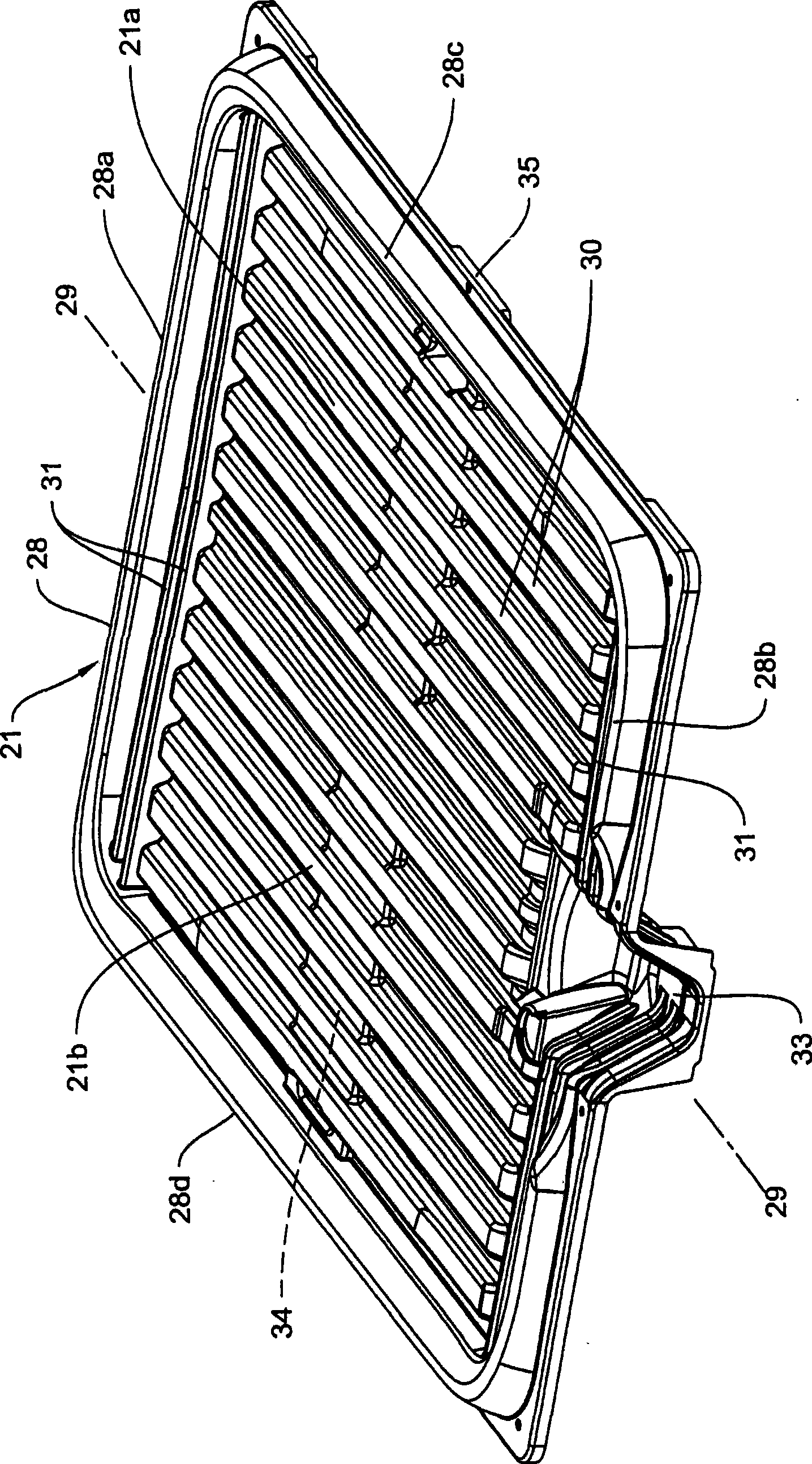

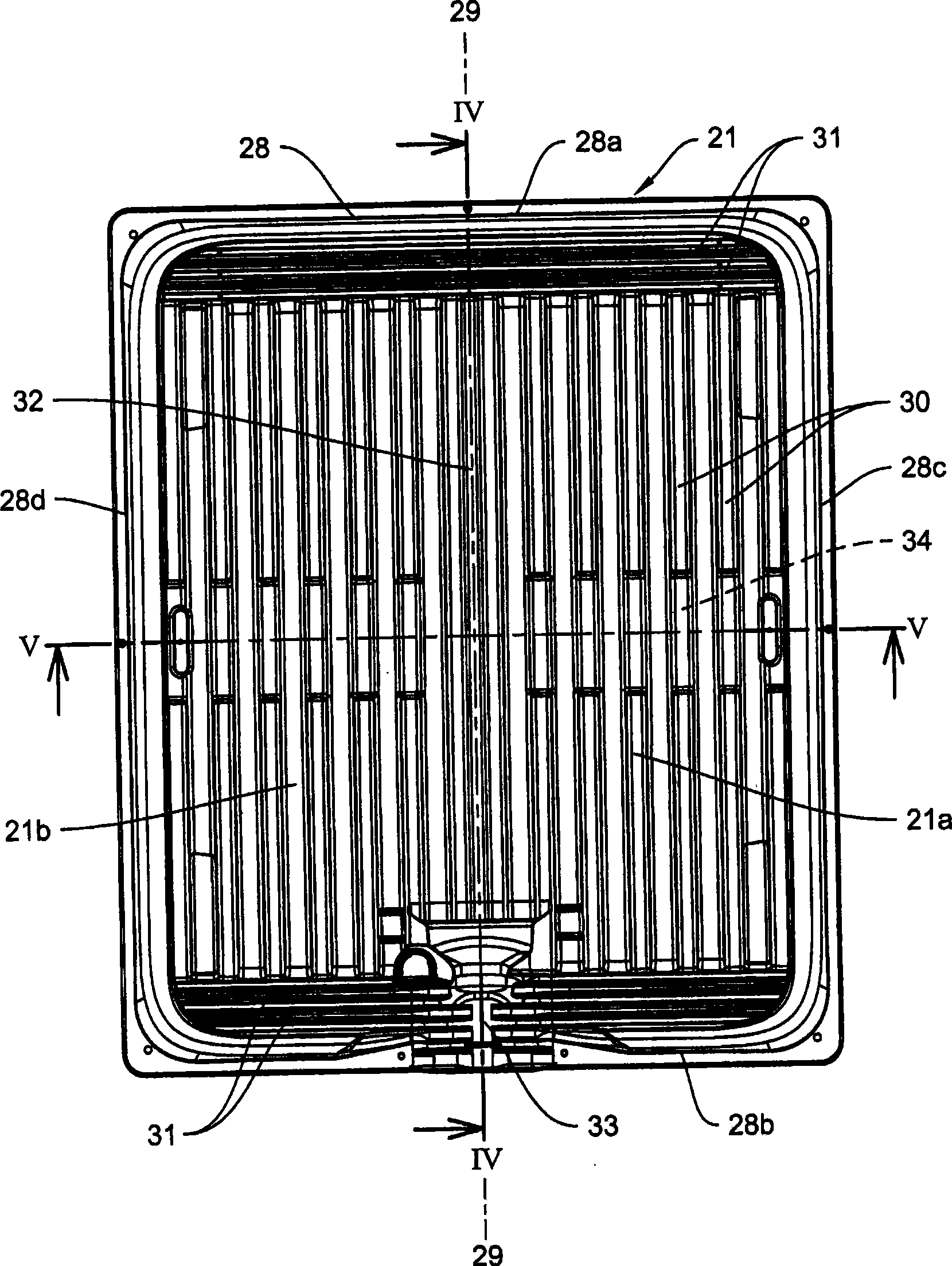

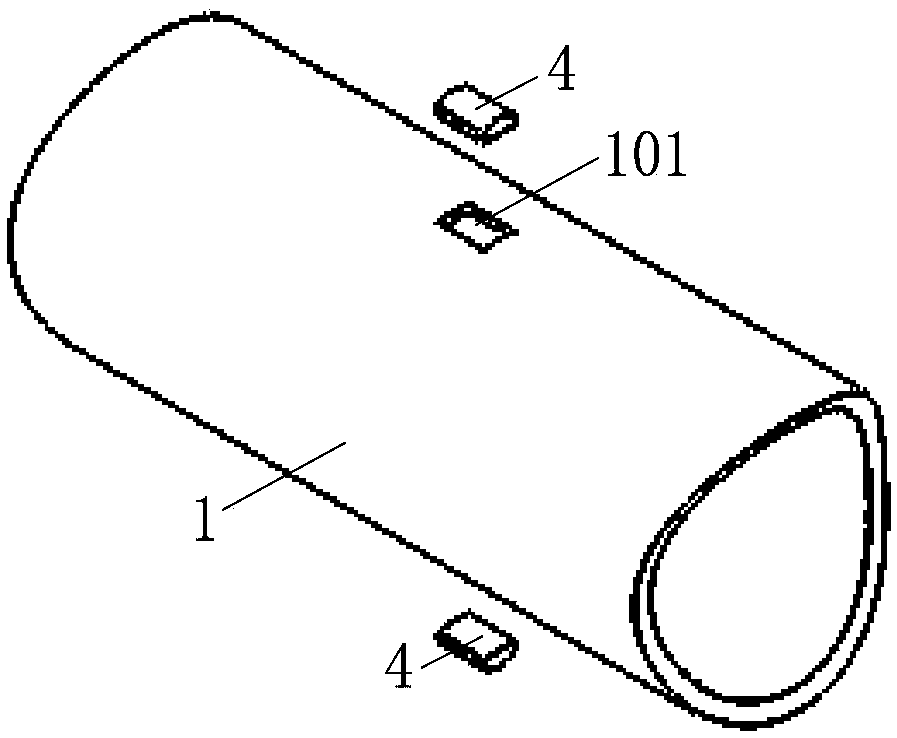

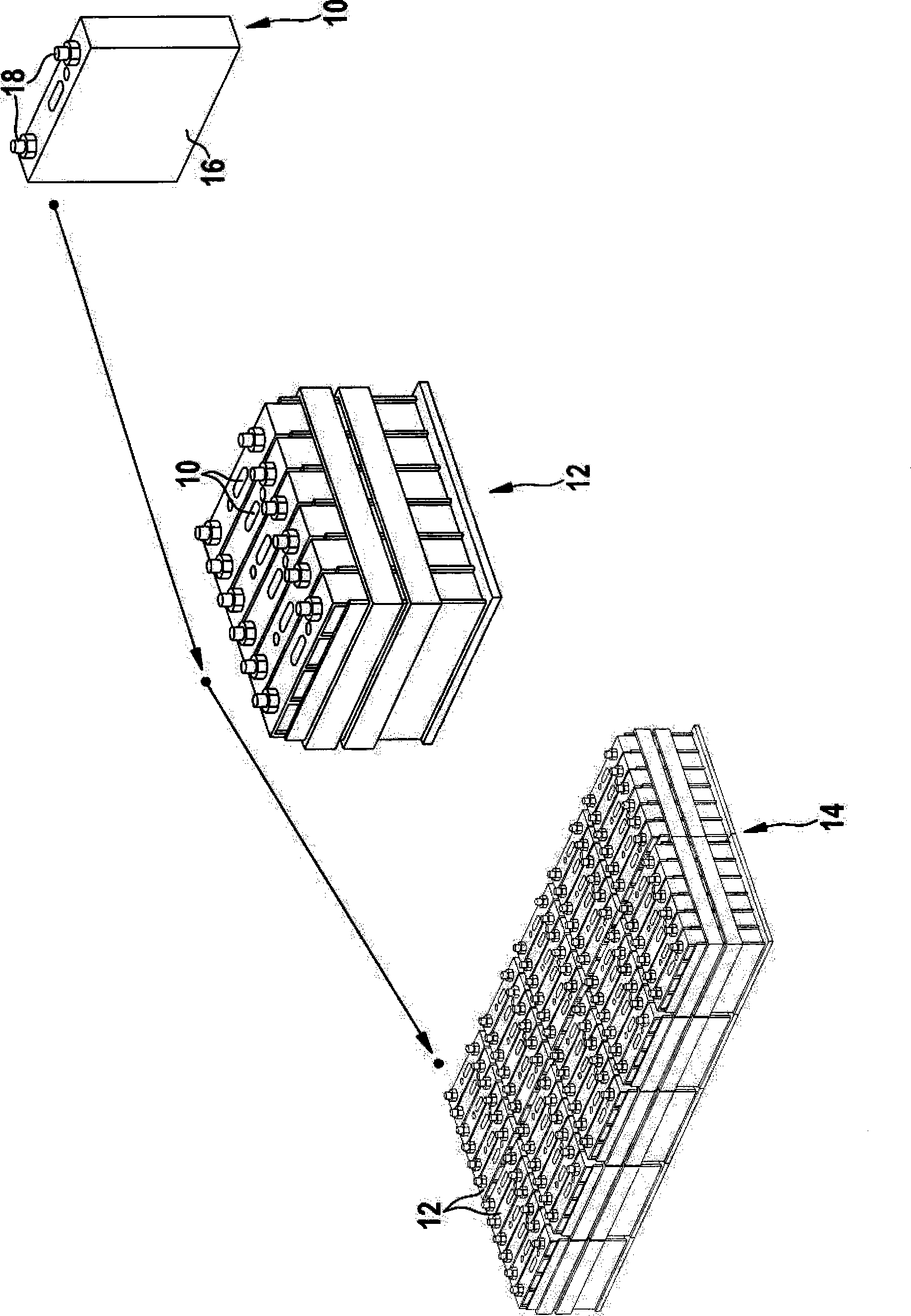

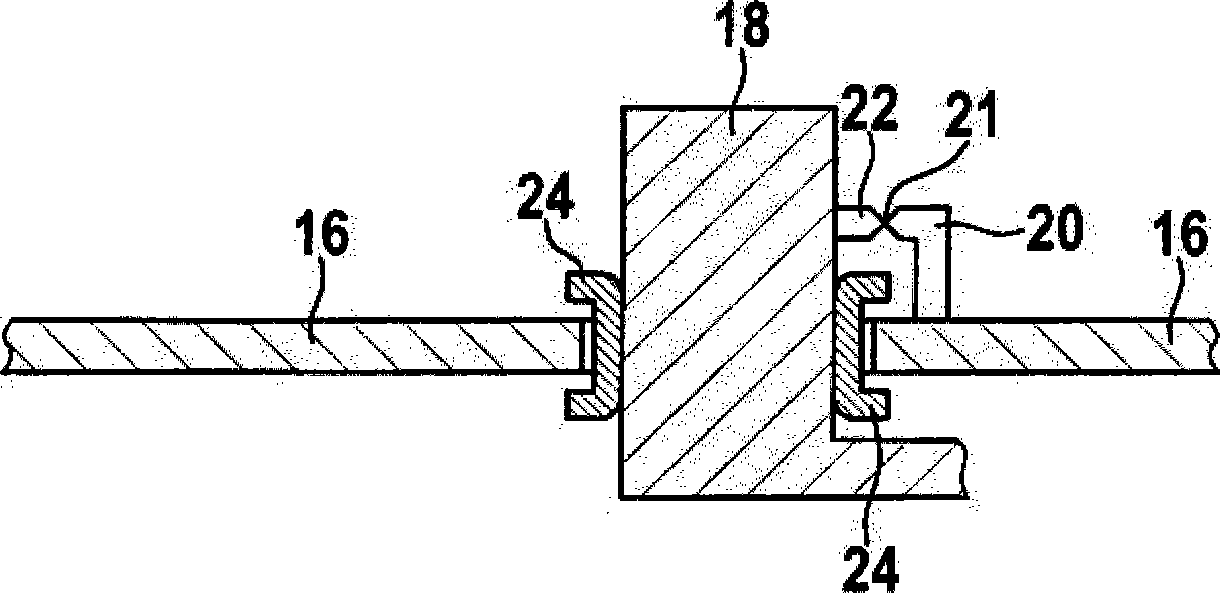

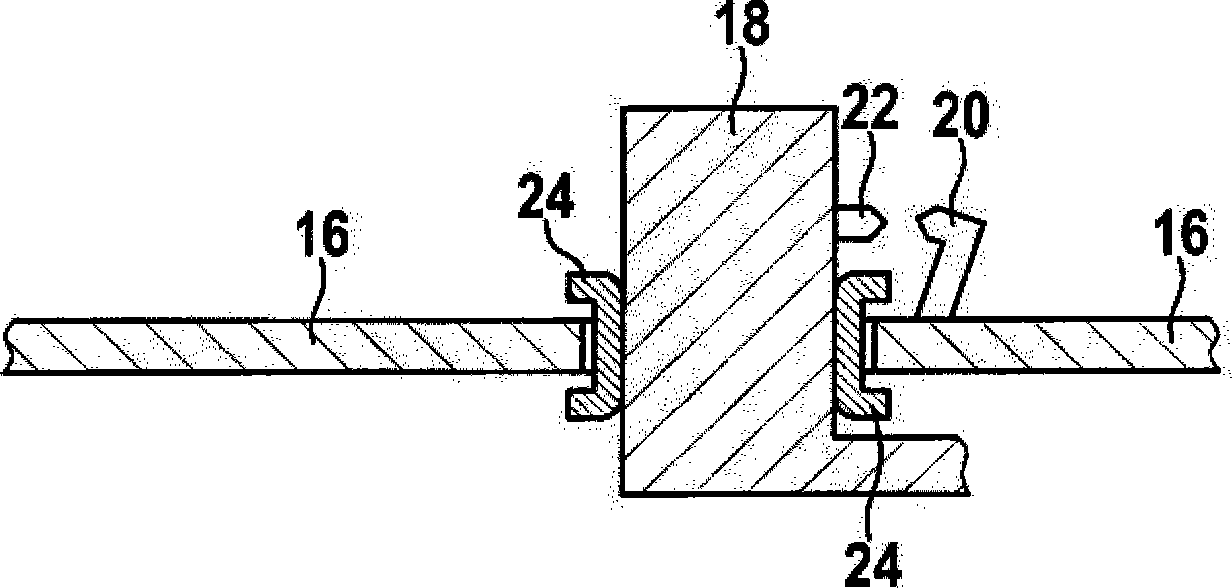

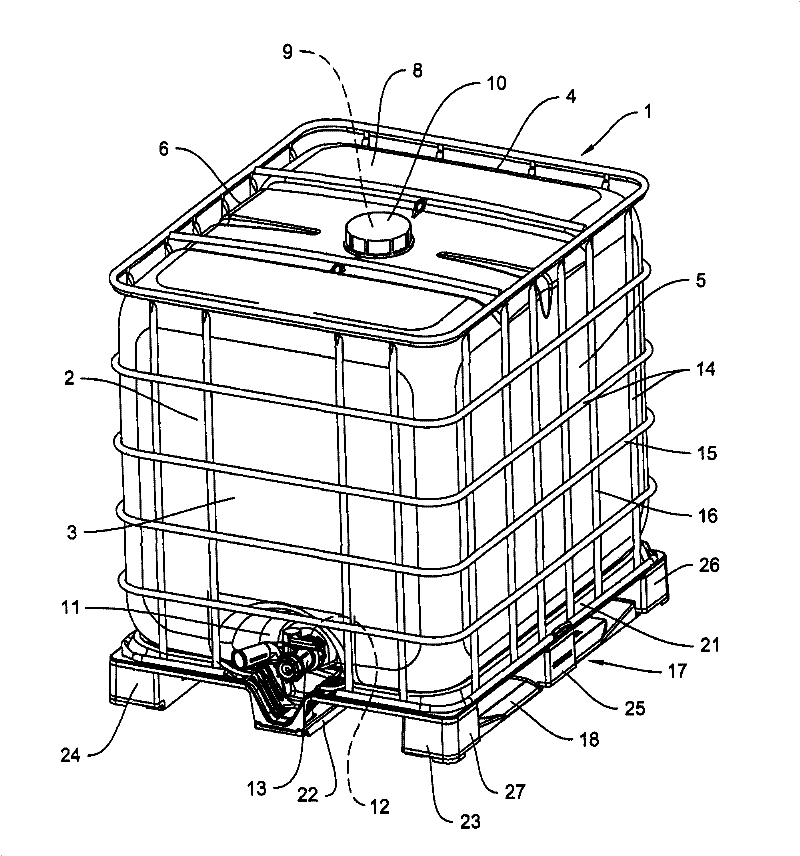

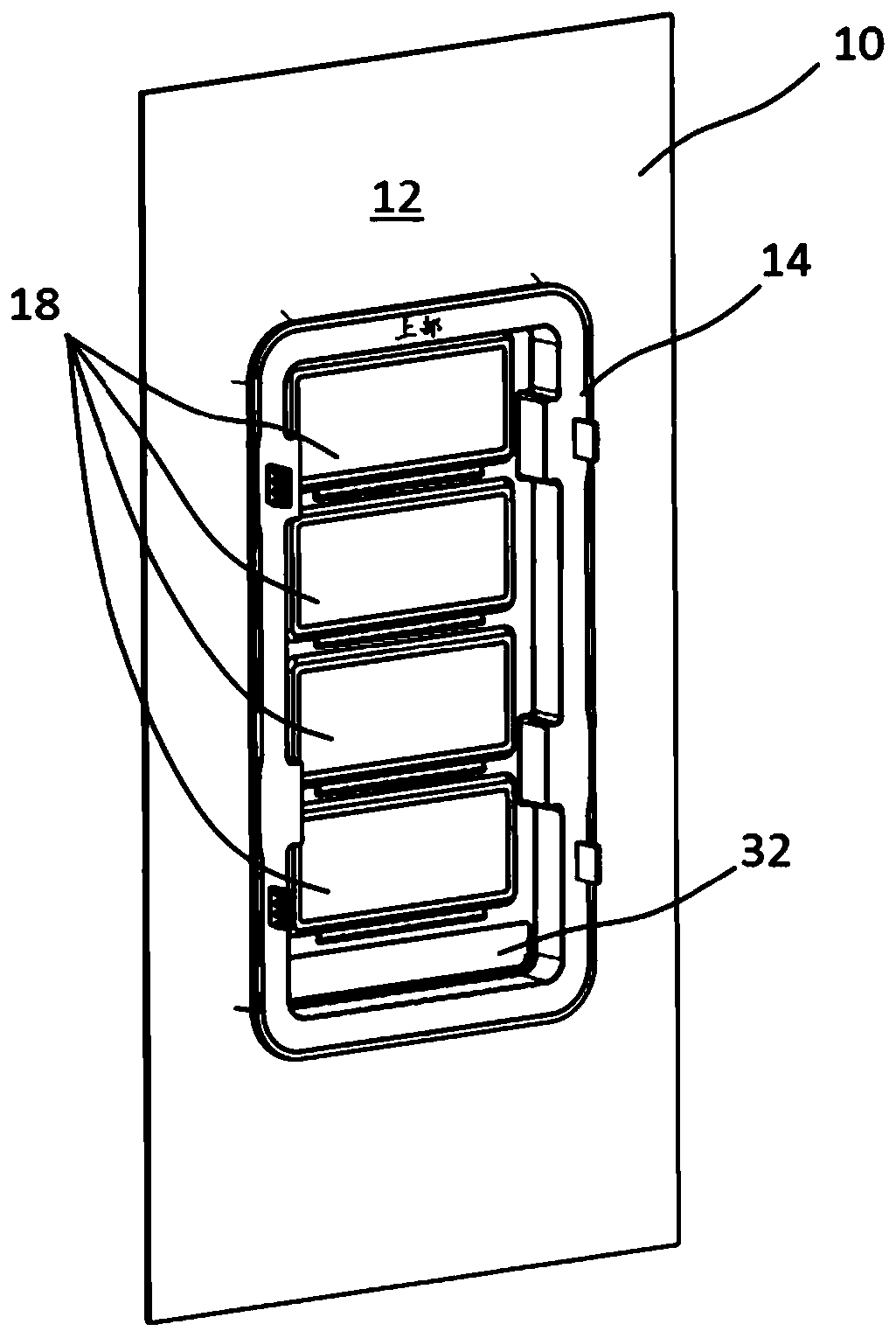

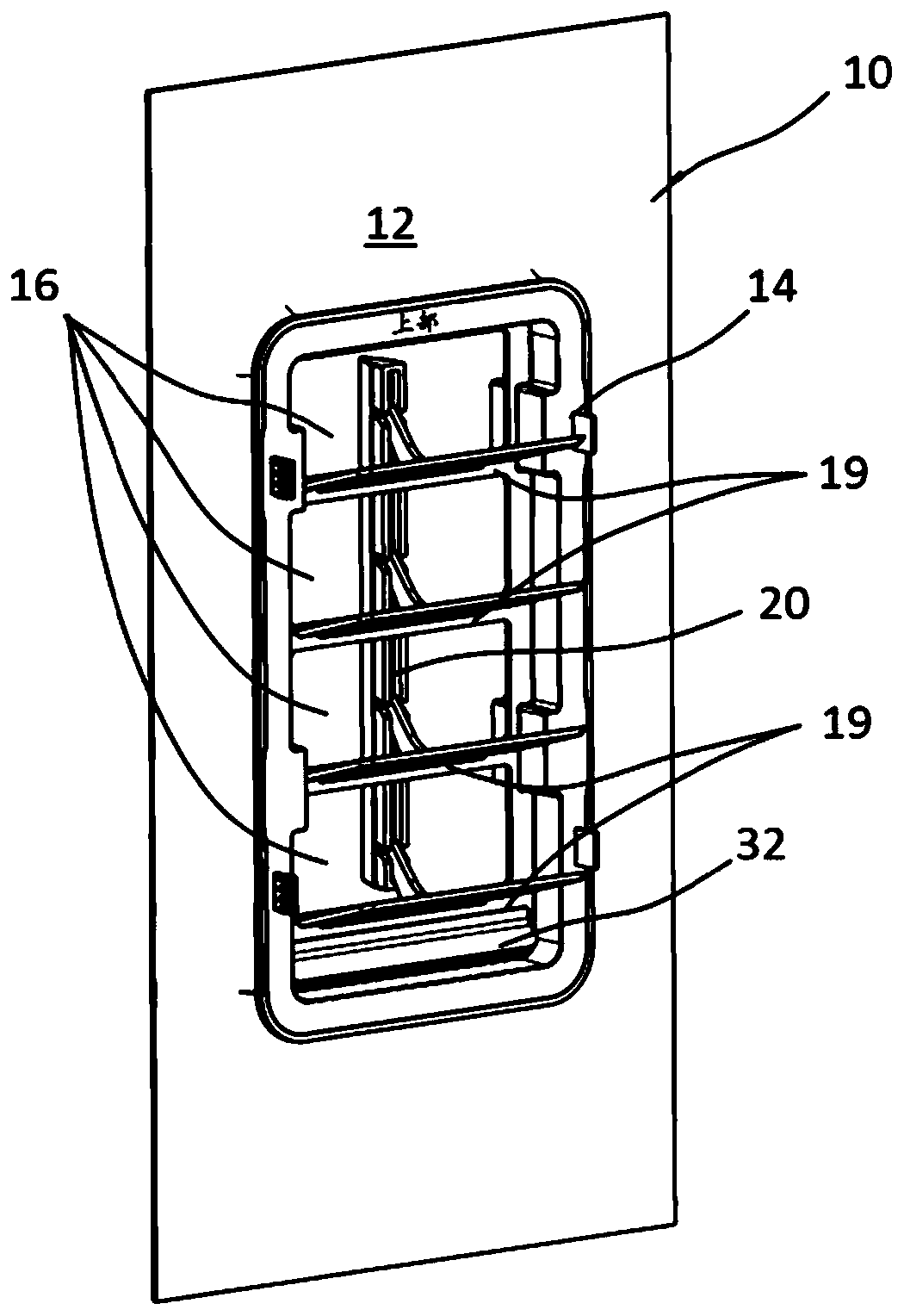

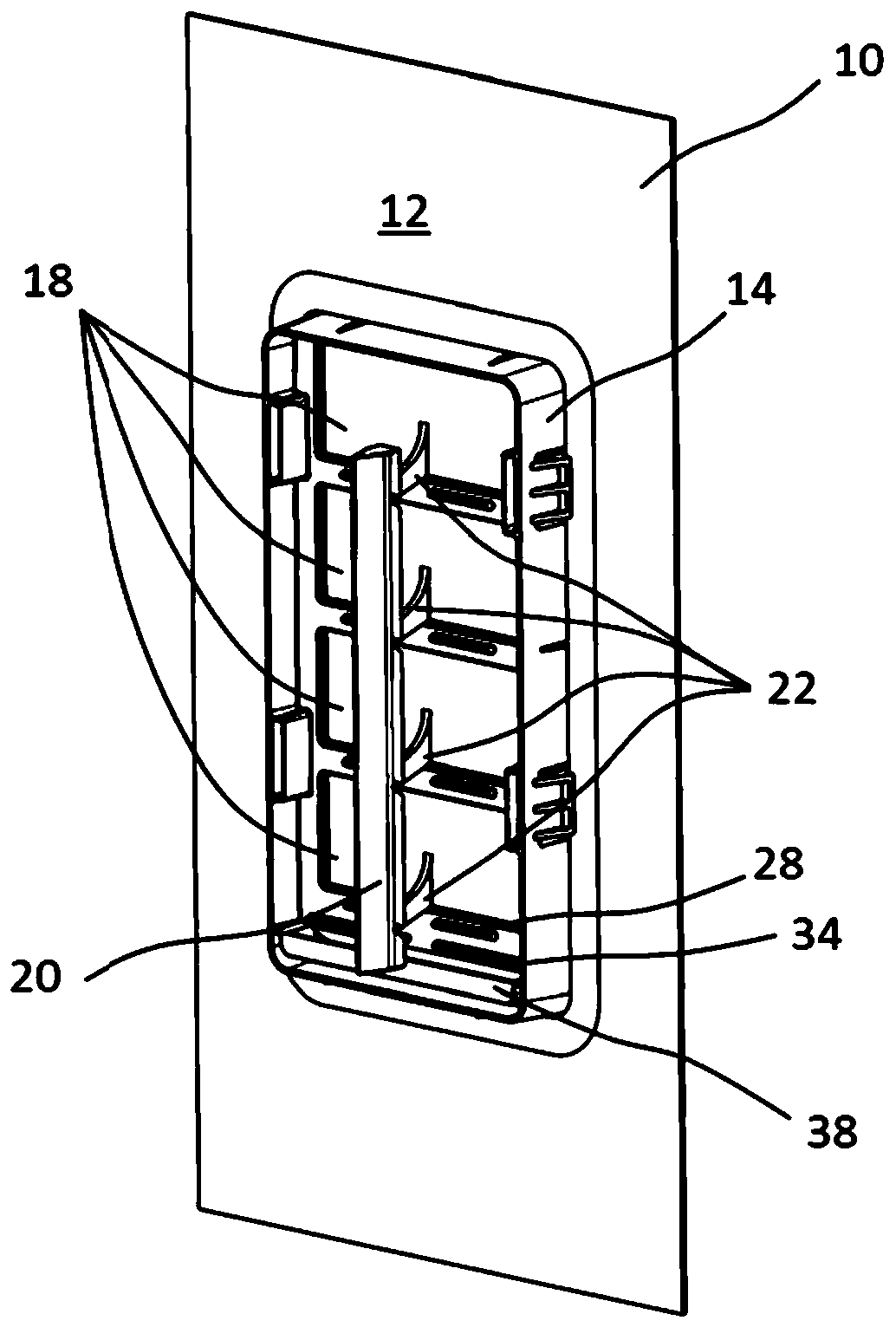

Transport and storage container for liquids

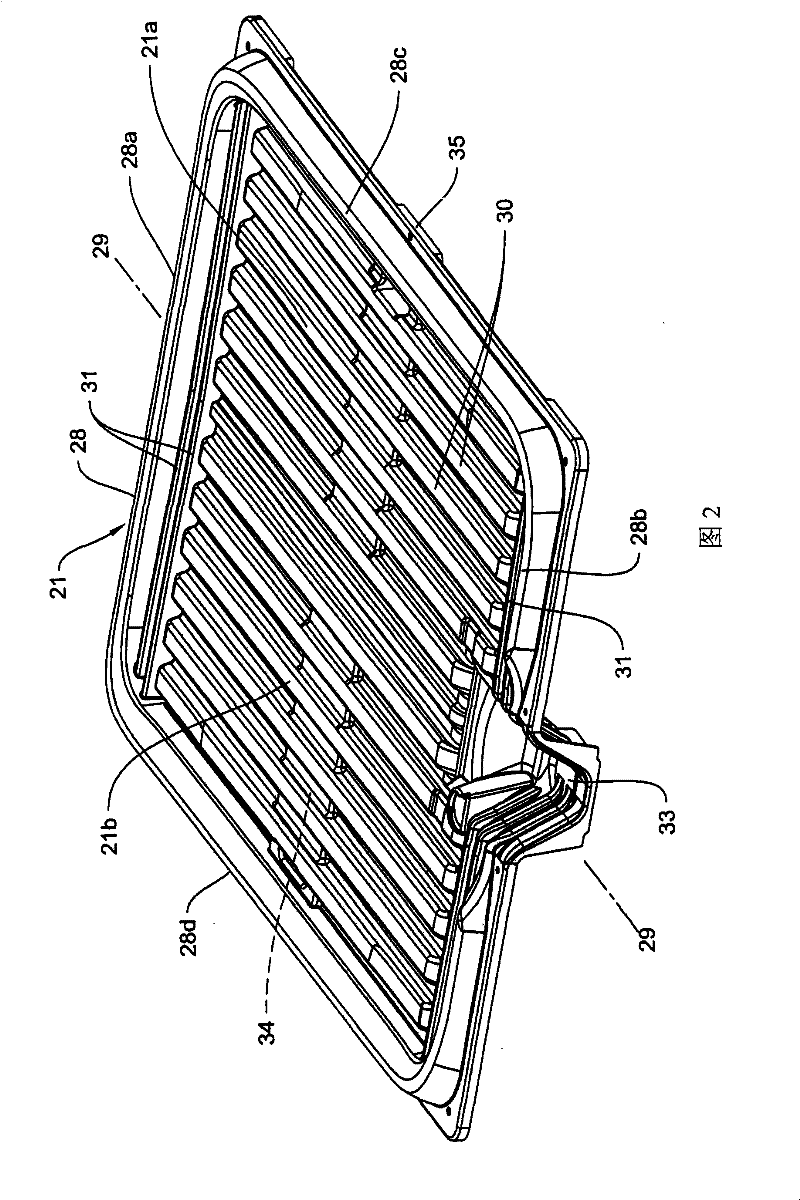

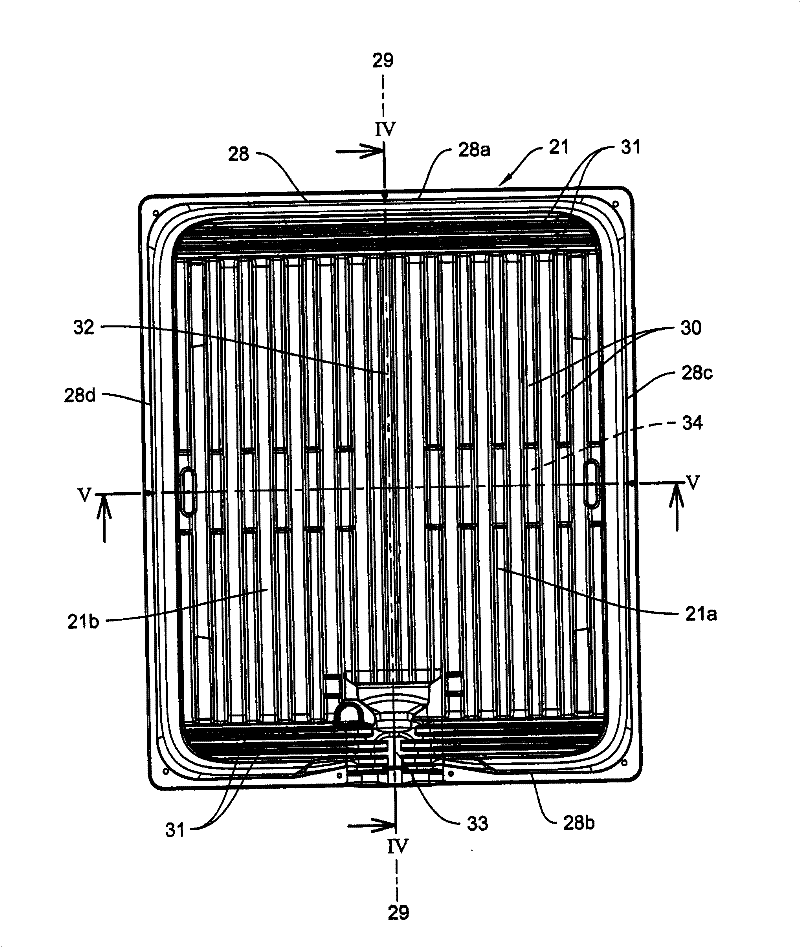

The container (1) has an inner container (2) made of plastic, and an outer casing made of metal grating or sheet metal. A base frame (17) is made of plastic and formed with a runner pallet (18) or a frame pallet. The base(21) is made of plastic and formed as an injection molded part. The base has a longitudinal corrugation and a transverse corrugation that are provided for reinforcing the base(21) and as a support for the inner container(2).

Owner:PROTECHNA SA

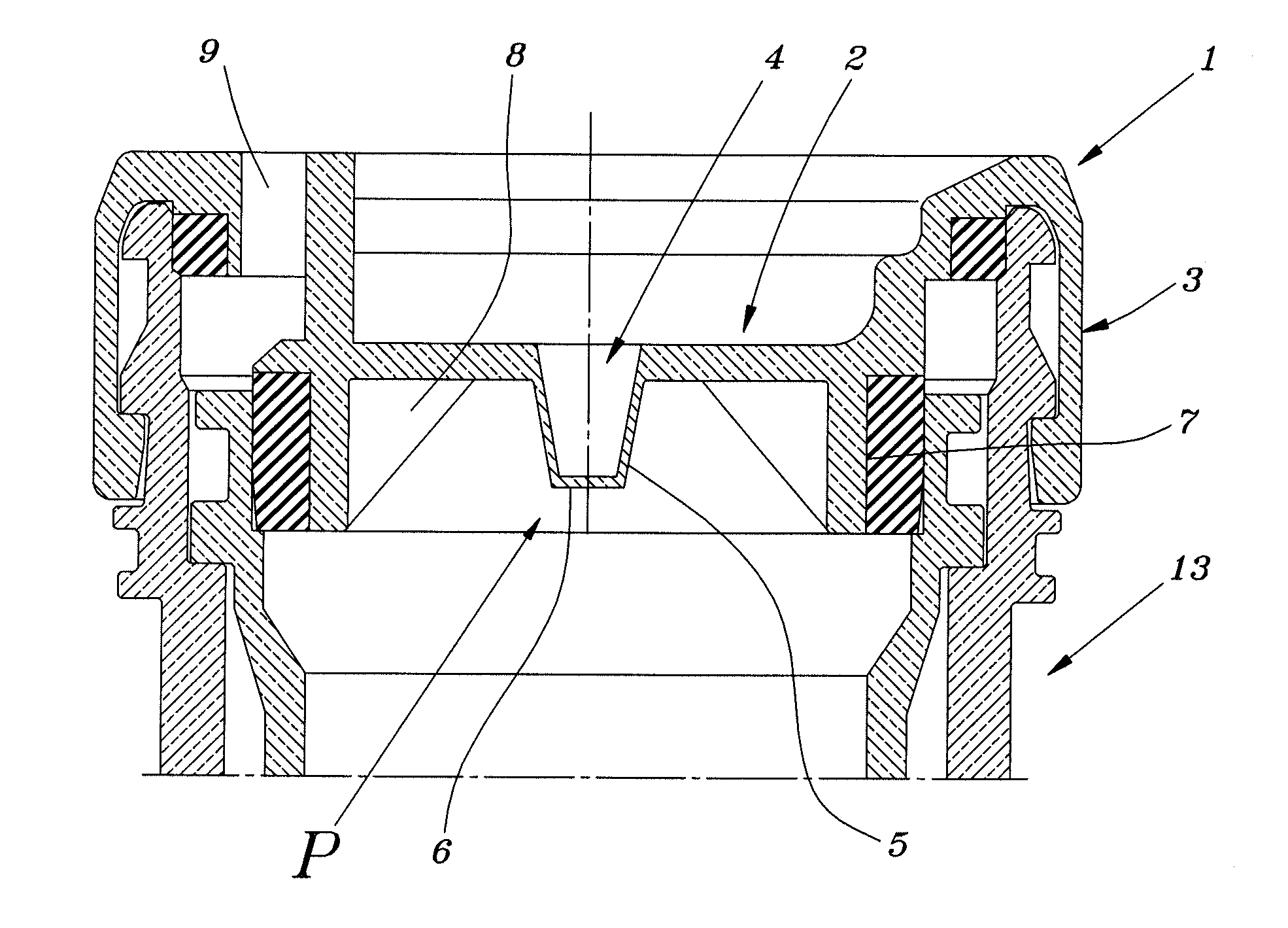

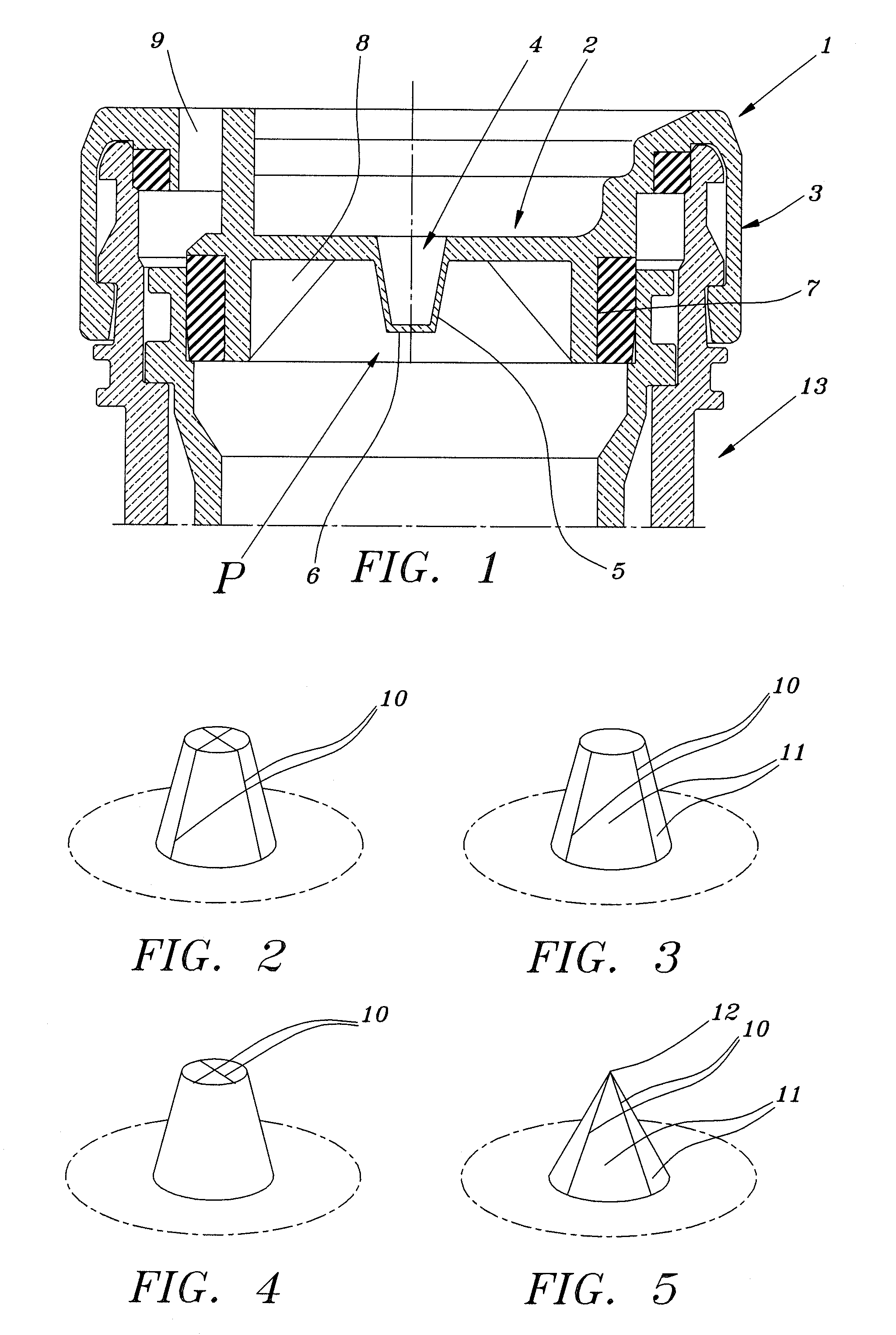

Closure

ActiveUS20110024422A1Prevent contaminationEasy piercingCapsClosure capsEngineeringMechanical engineering

Owner:ANHEUSER BUSCH INBEV SA

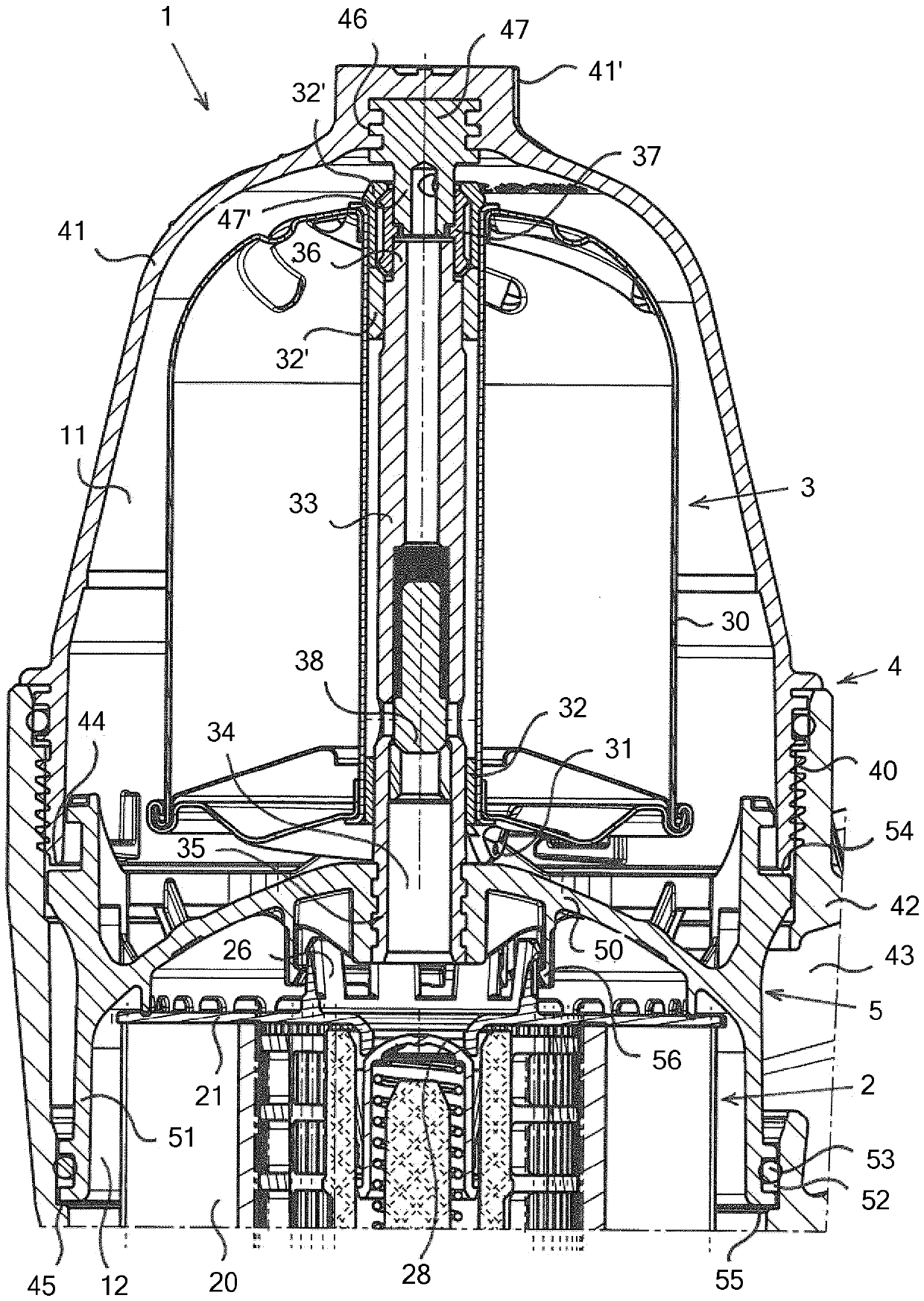

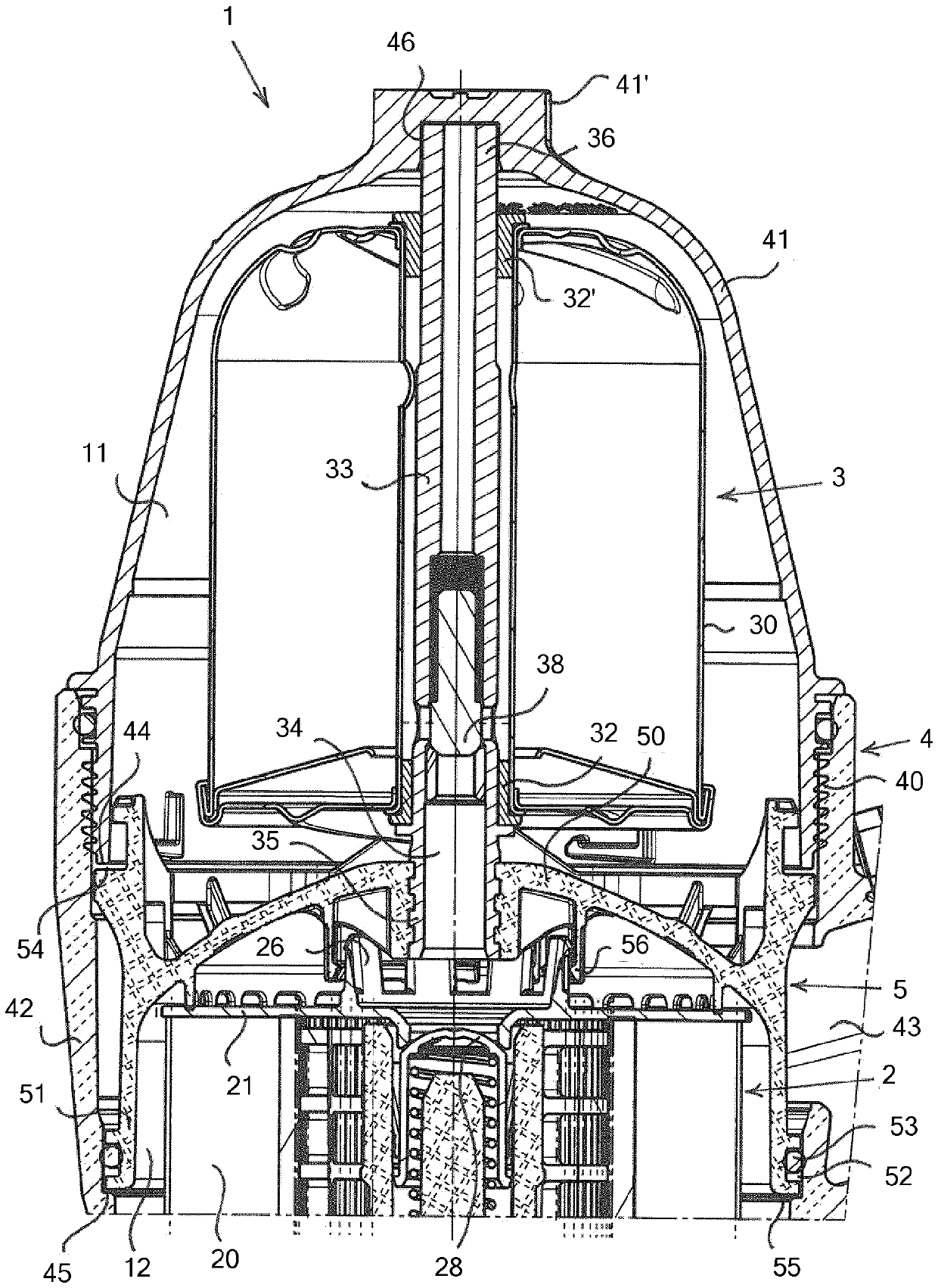

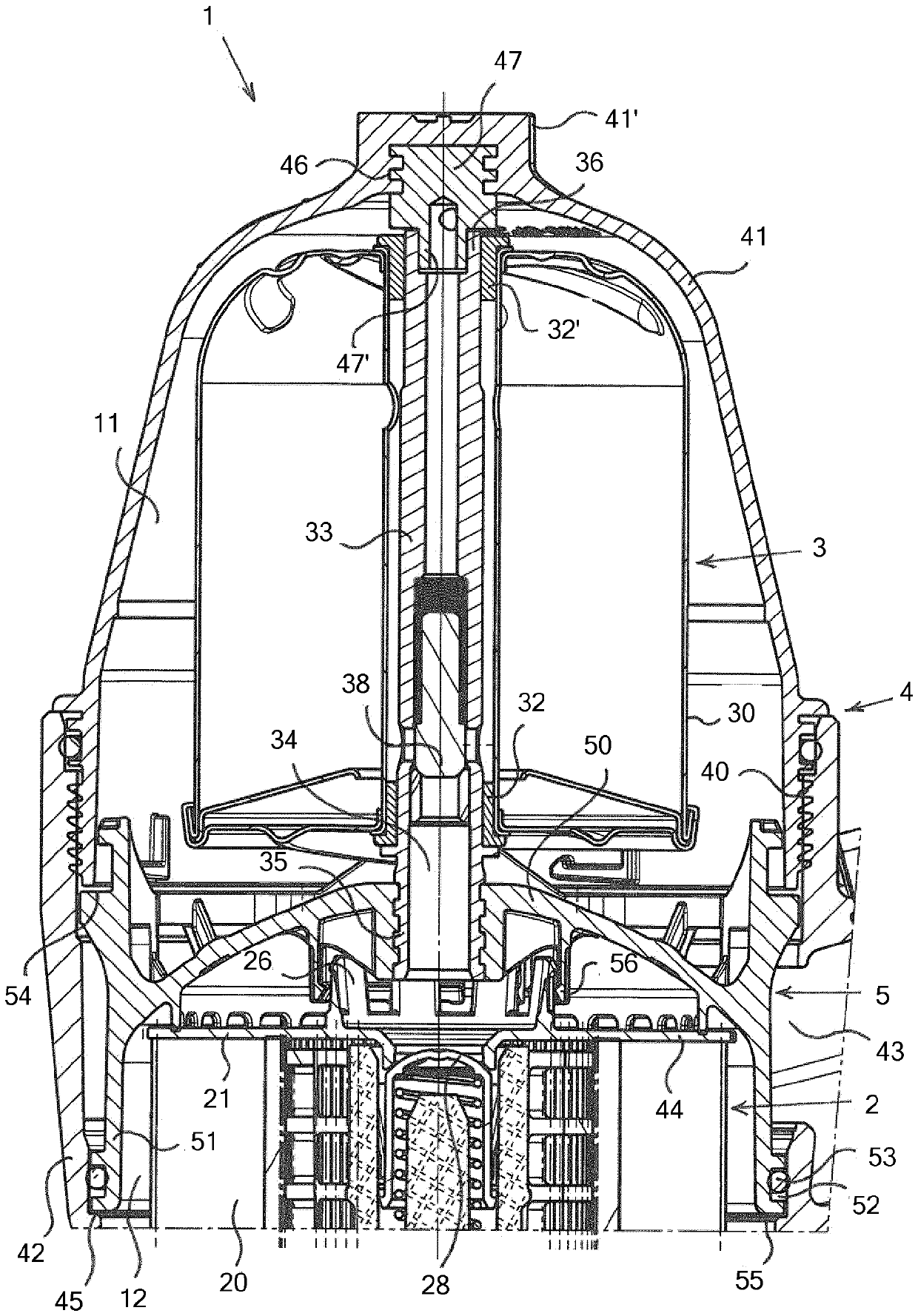

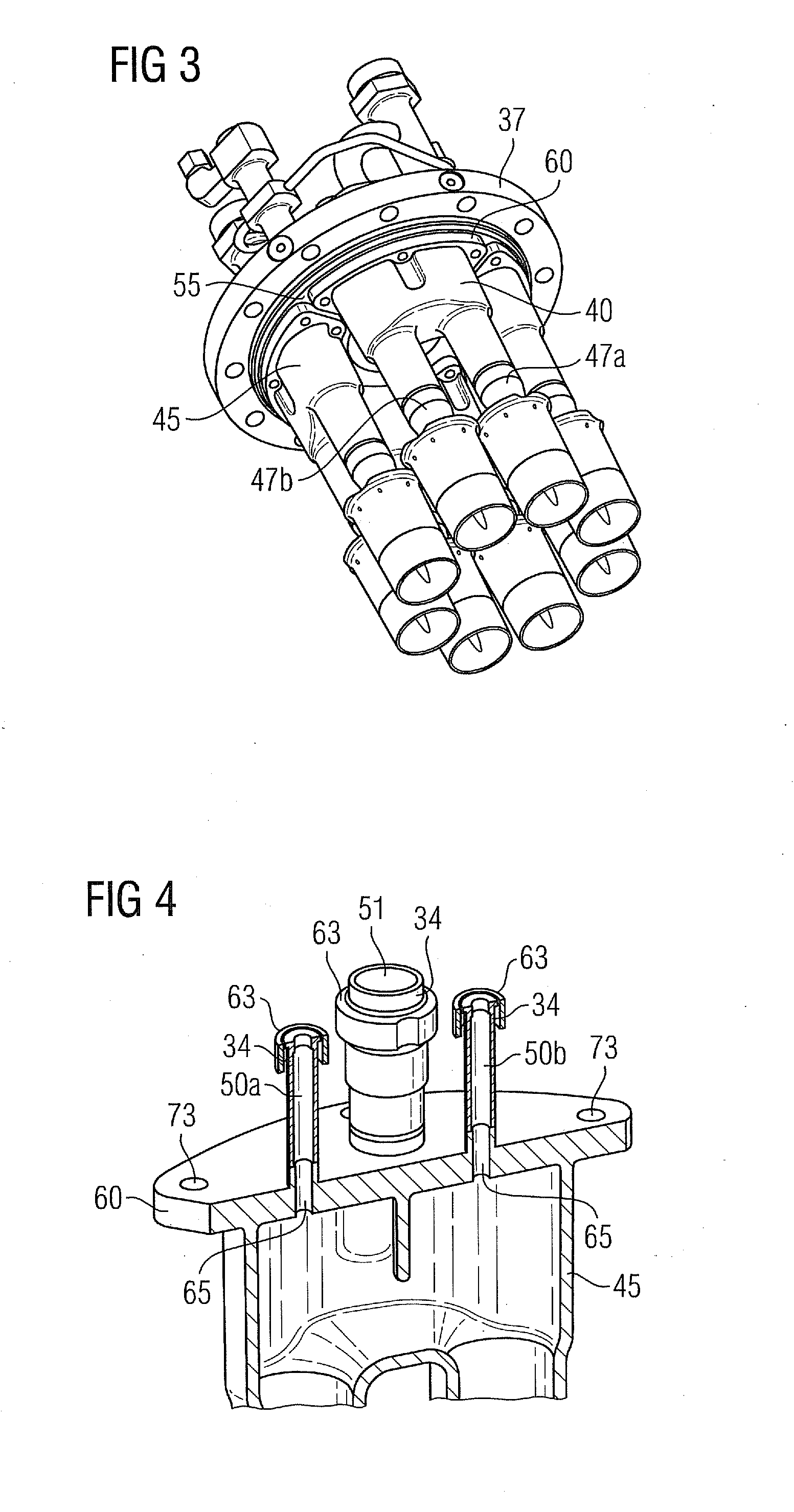

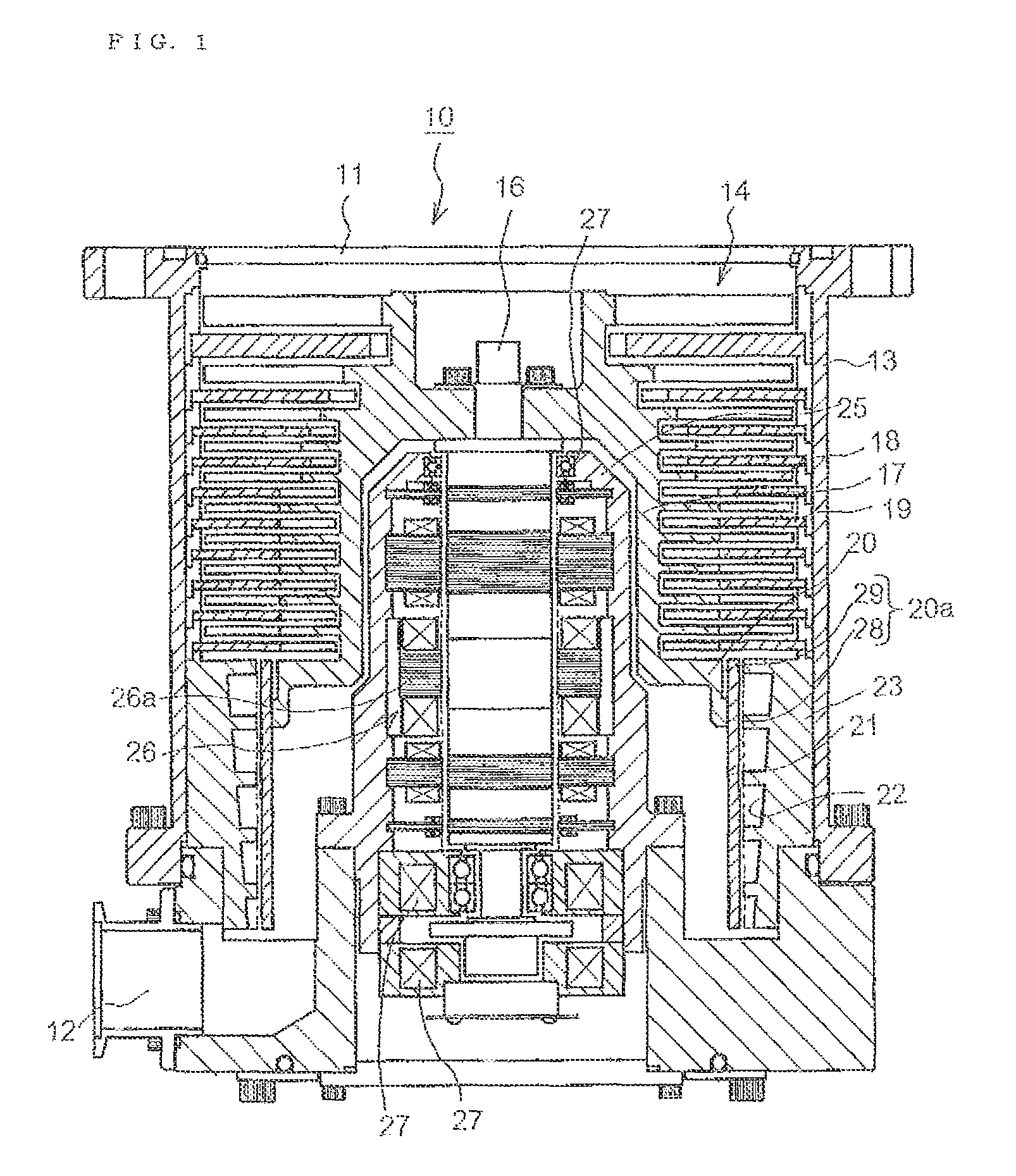

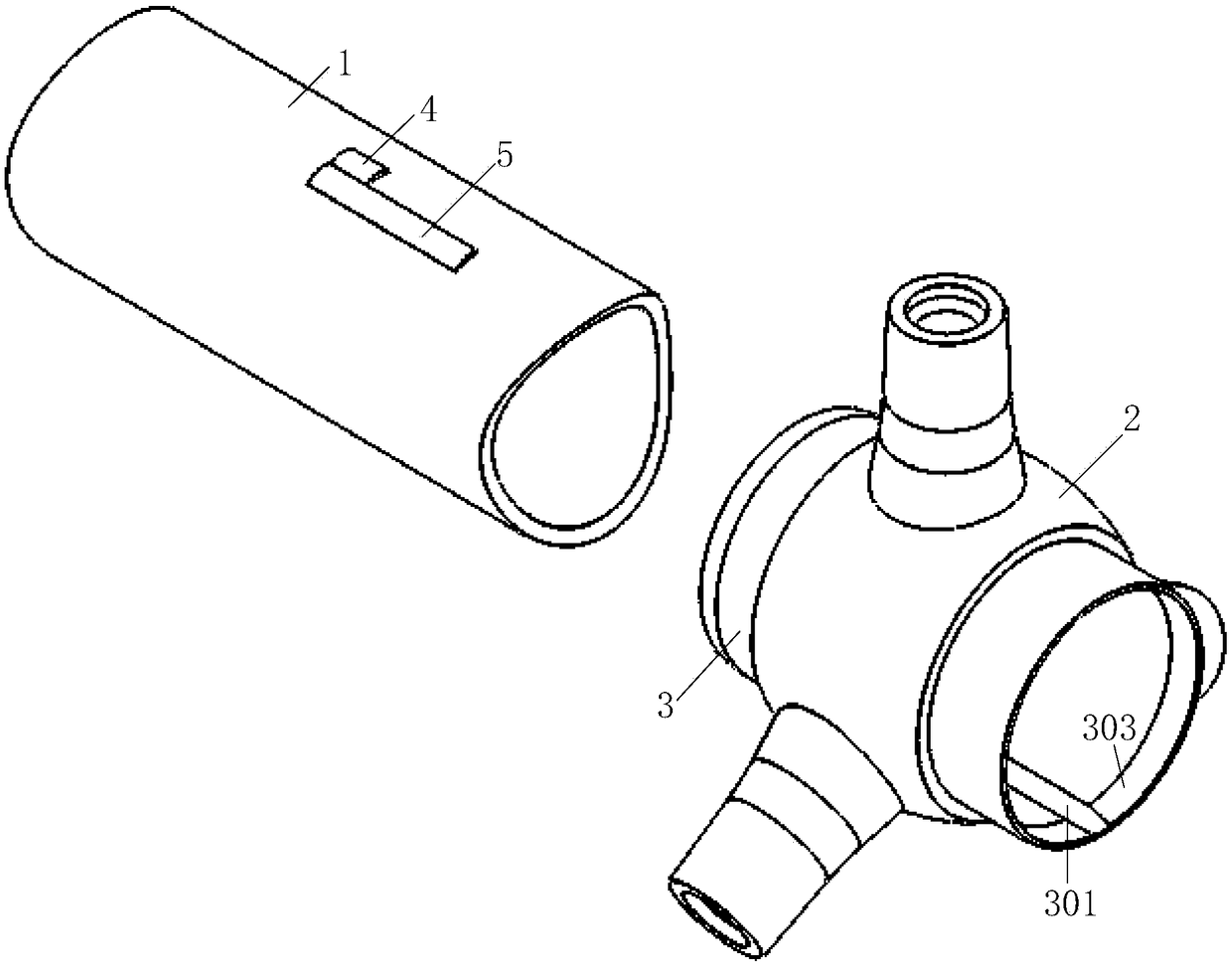

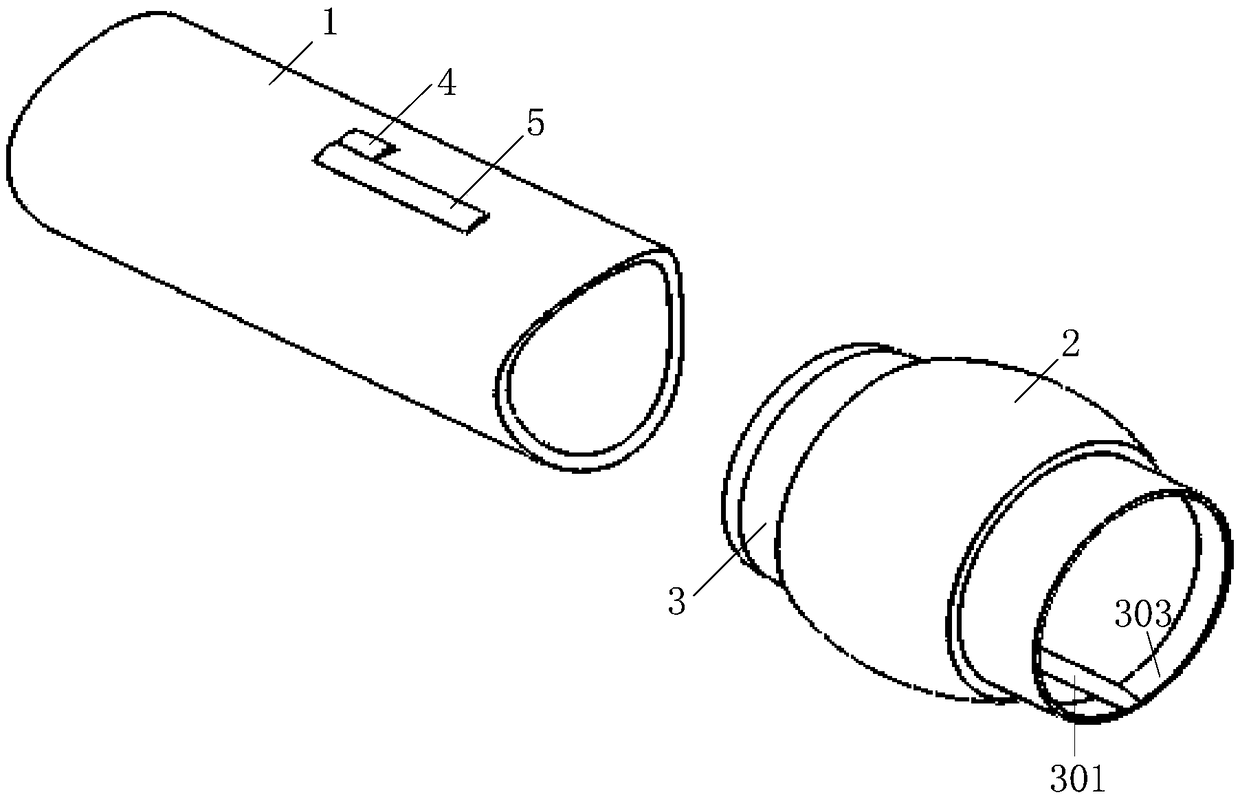

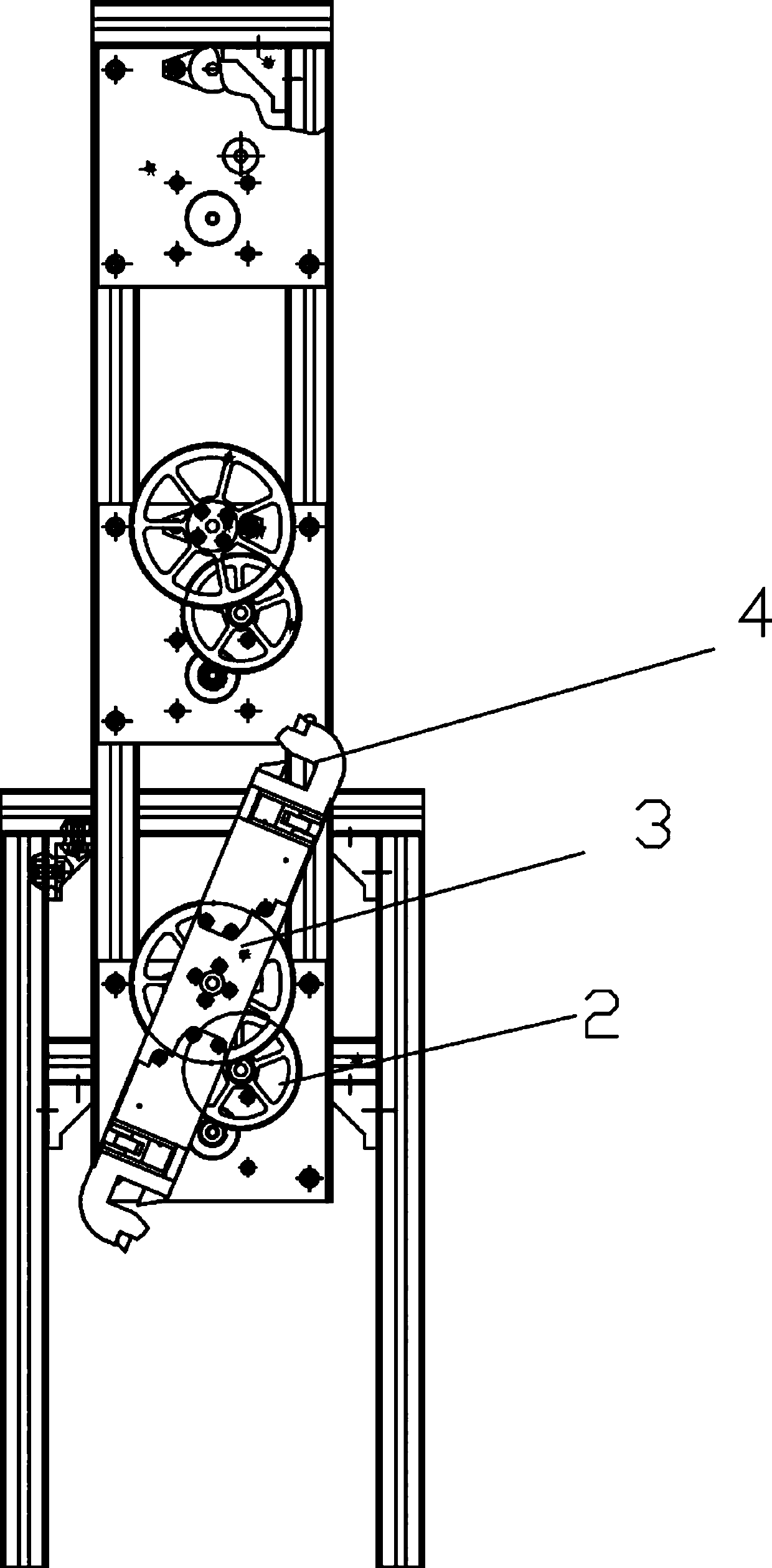

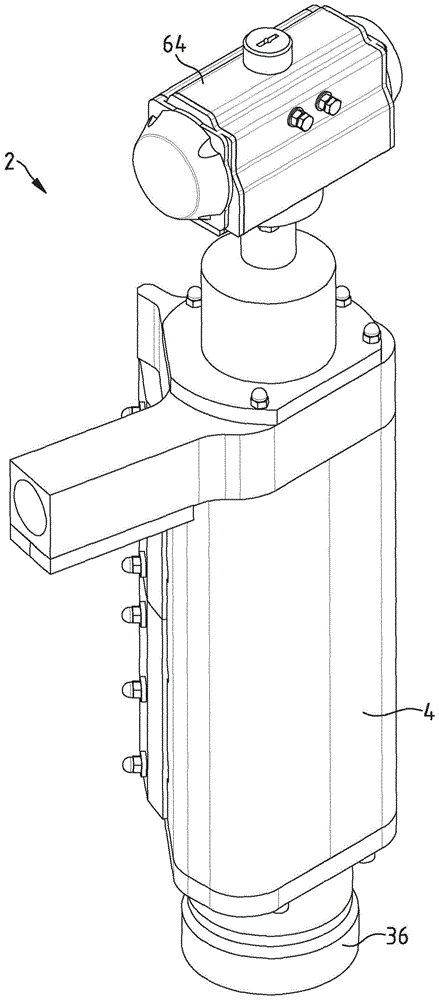

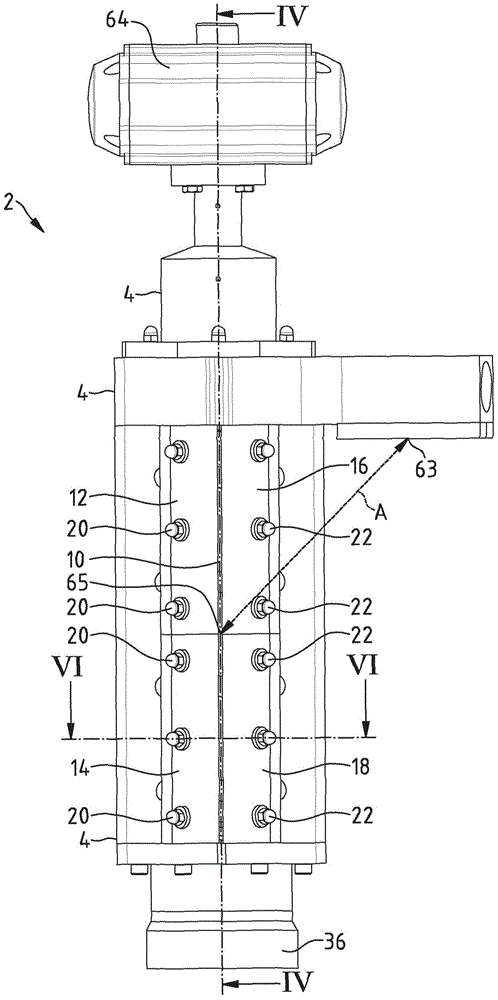

Device for removing impurities from the lubricating oil of an internal combustion engine

ActiveCN106795784AReduce thicknessReduce weightMachines/enginesPressure lubricationEngineeringInternal combustion engine

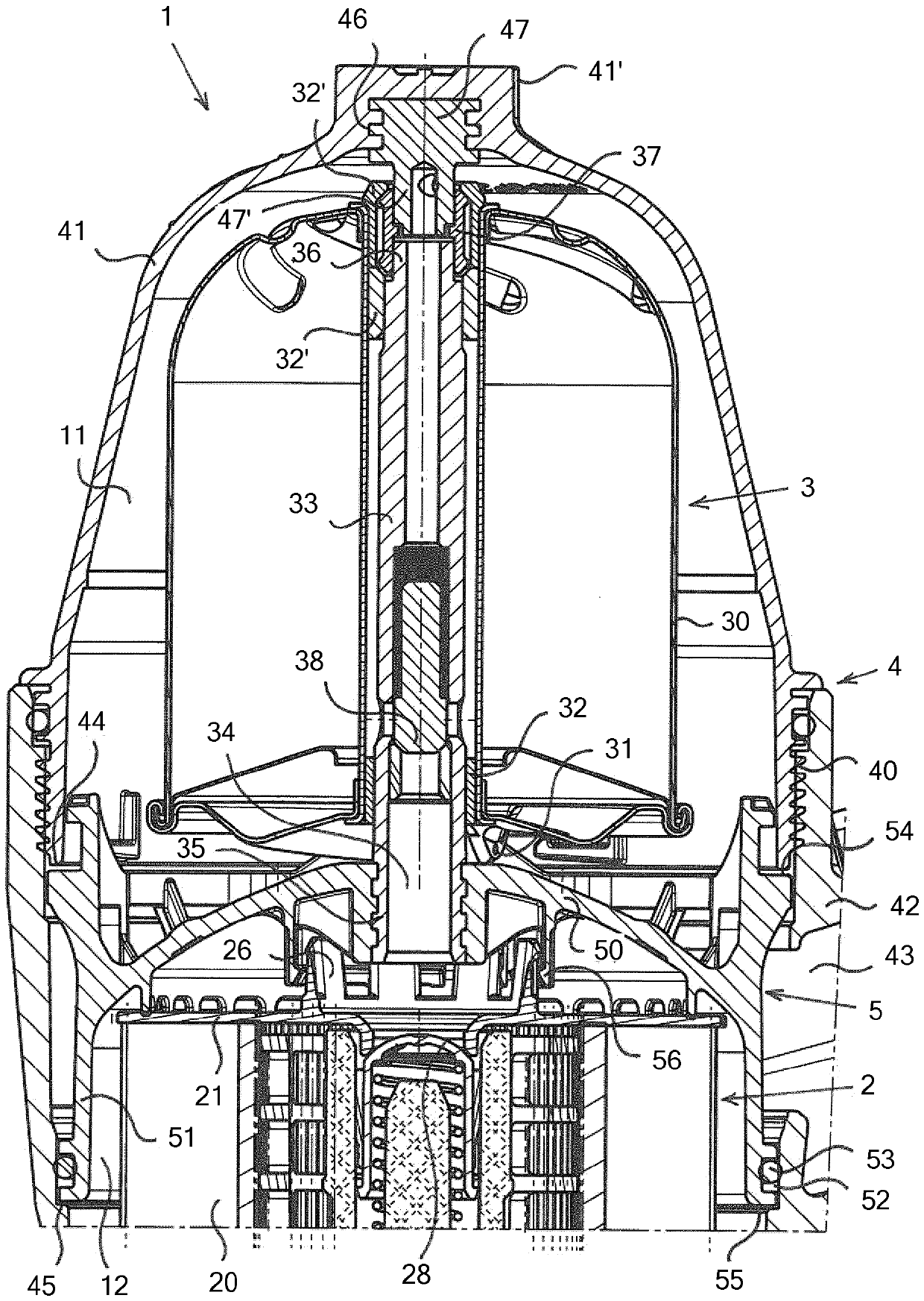

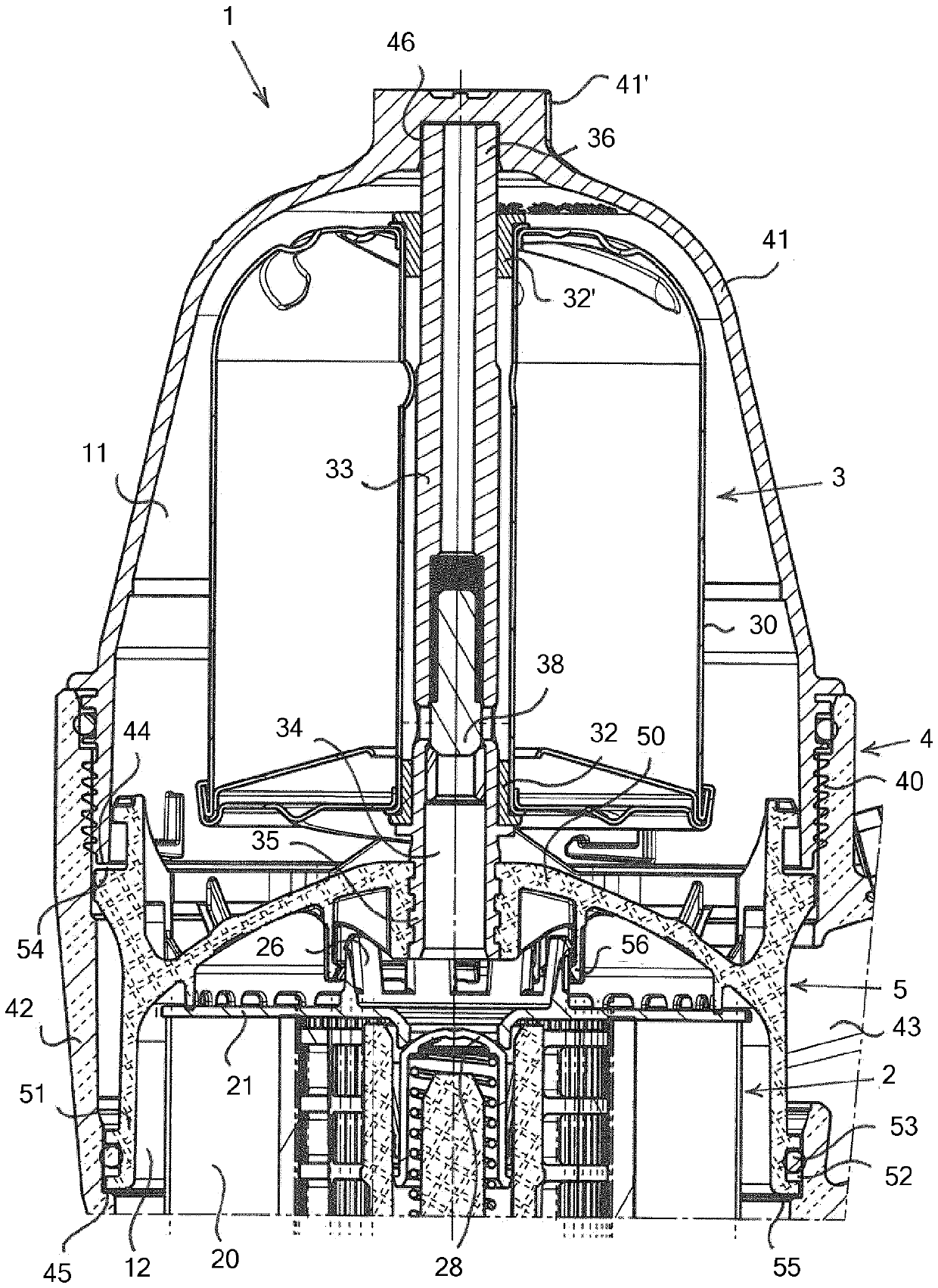

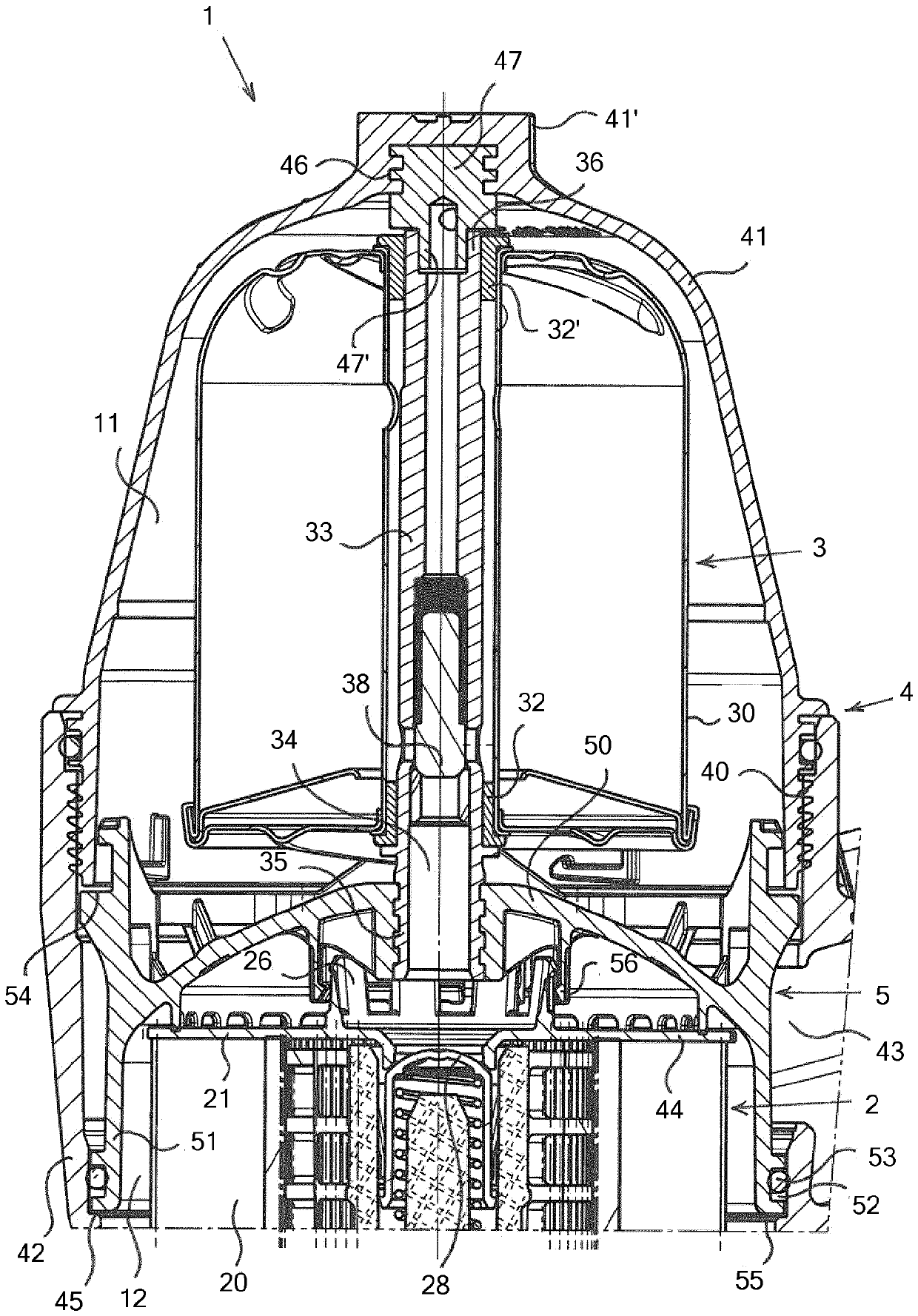

The invention relates to a device (1) for removing impurities from the lubricating oil of an internal combustion engine, wherein the device (1) has a filter insert (2) at the bottom in the operating position of the device and a centrifuge (3) thereabove having a rotationally drivable rotor (30), wherein the filter insert (2) and the centrifuge (3) are arranged one above the other in a common two-part housing (4), which is closed during the operation of the device (1) and which has a removable upper closure cover (41) and a fixed lower housing part (42), wherein a removable intermediate cover (5) is arranged in the housing (4) between the filter insert (2) and the centrifuge (3), which intermediate cover is inserted in a sealing manner and separates a lower filter space (12), which is under the lubricating oil pressure during the operation of the device (1), from an unpressurized upper centrifuge space (11), wherein the intermediate cover (5) is supported radially outside on the closure cover (41) when the closure cover (41) is in the closed state, wherein a rotor shaft (33) rotatably supporting the rotor (30) is attached in or on the intermediate cover (5) by means of a lower end (35) of the rotor shaft and wherein the rotor (30), the intermediate cover (5) together with the rotor axis (33), and the filter insert (2) can be removed from the housing (4) when the closure cover (41) is in the open state. The device (1) according to the invention is characterized in that the closure cover (41) has a supporting surface at the center of the closure cover on the inside and that the rotor shaft (33) is supported axially on the closure cover (41) at the supporting surface by means of an upper end (36) of the rotor shaft when the closure cover (41) is in the closed state.

Owner:HENGST WALTER

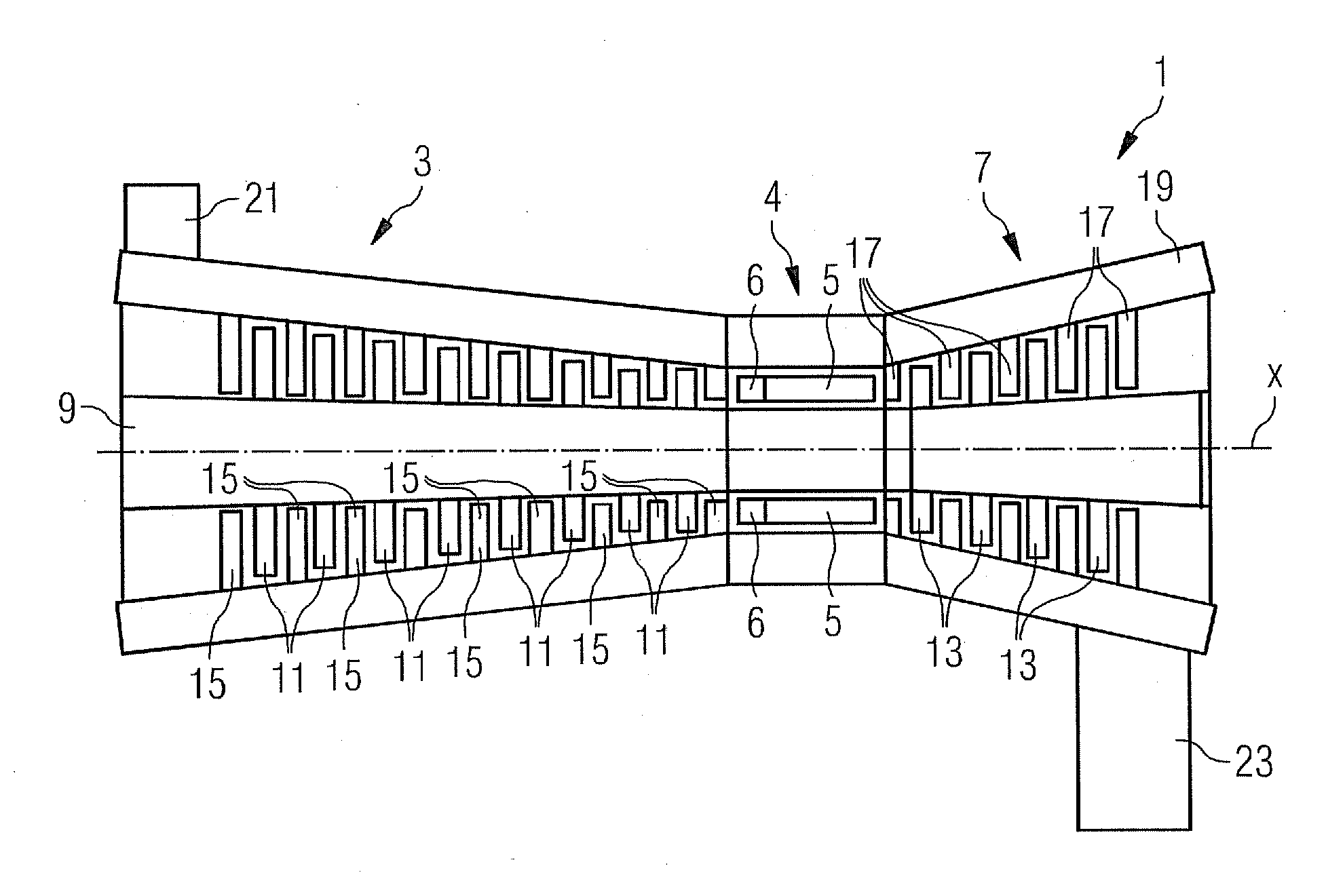

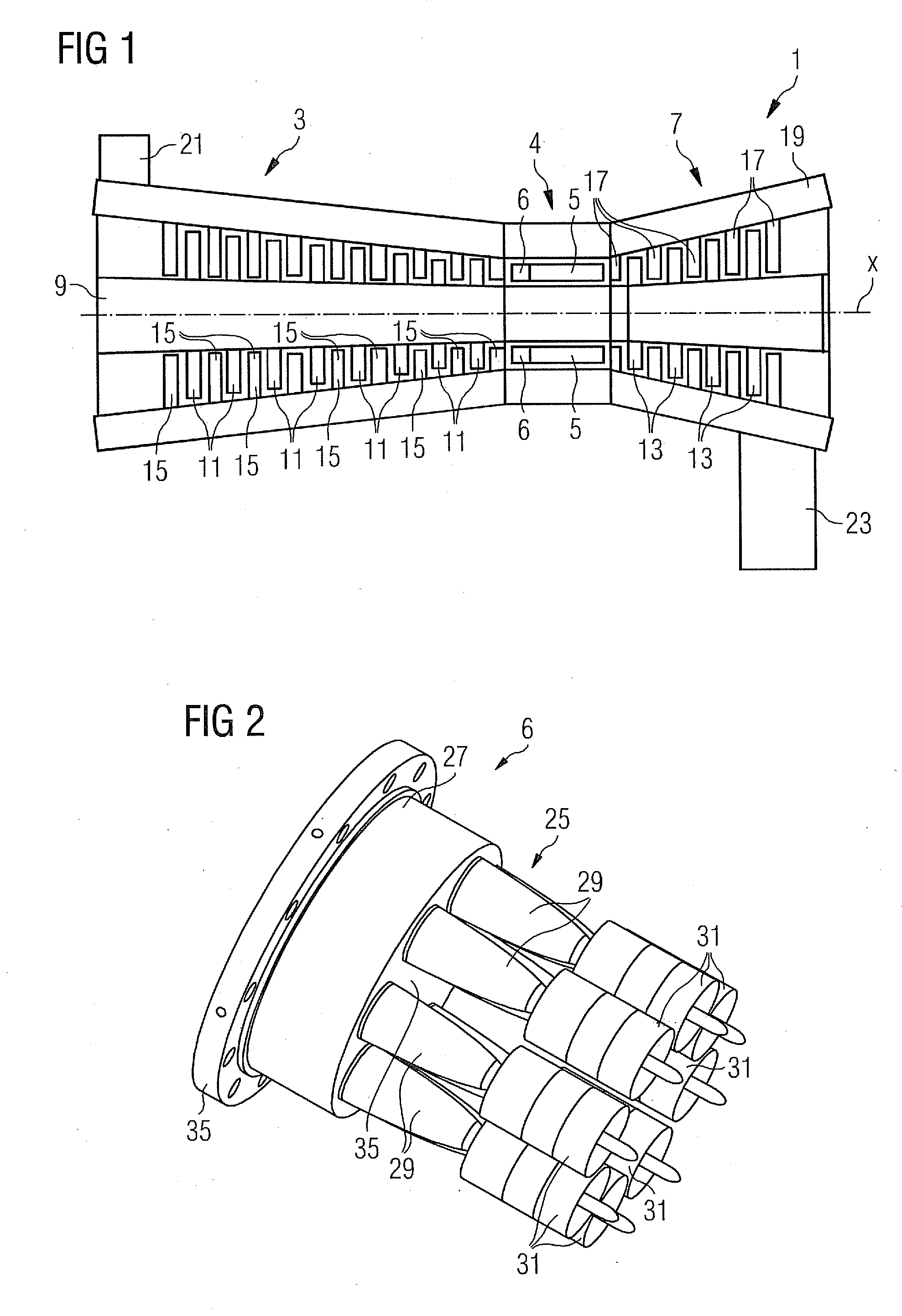

Burner arrangement

ActiveUS20110203285A1Reduced material strengthLow costContinuous combustion chamberGas turbine plantsCombustorEngineering

A burner arrangement is provided. The burner arrangement includes a support and at least two fuel nozzles attached to the support in the direction of flow, with each fuel nozzle including a support-side section which includes a contact surface on the support side with which it rests on a supporting surface of the support, with at least two fuel nozzle tips embodied in one piece extending out from the support-side section in the direction of flow and the support-side contact surface including at least two extension parts projecting in the direction of the support, with the extension parts each embodying a channel through which fuel is fed in each case to the fuel nozzle tips through passages which are arranged in the support-side contact surface of the support-side section.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

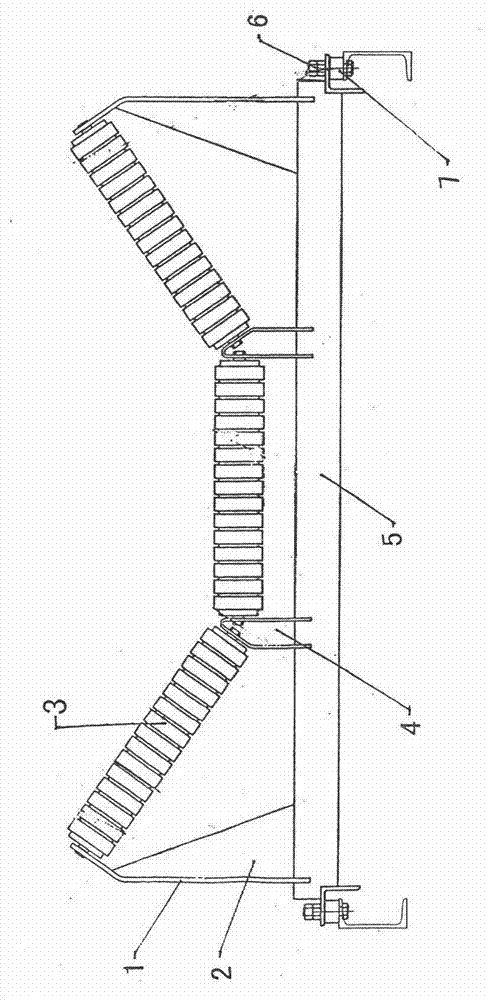

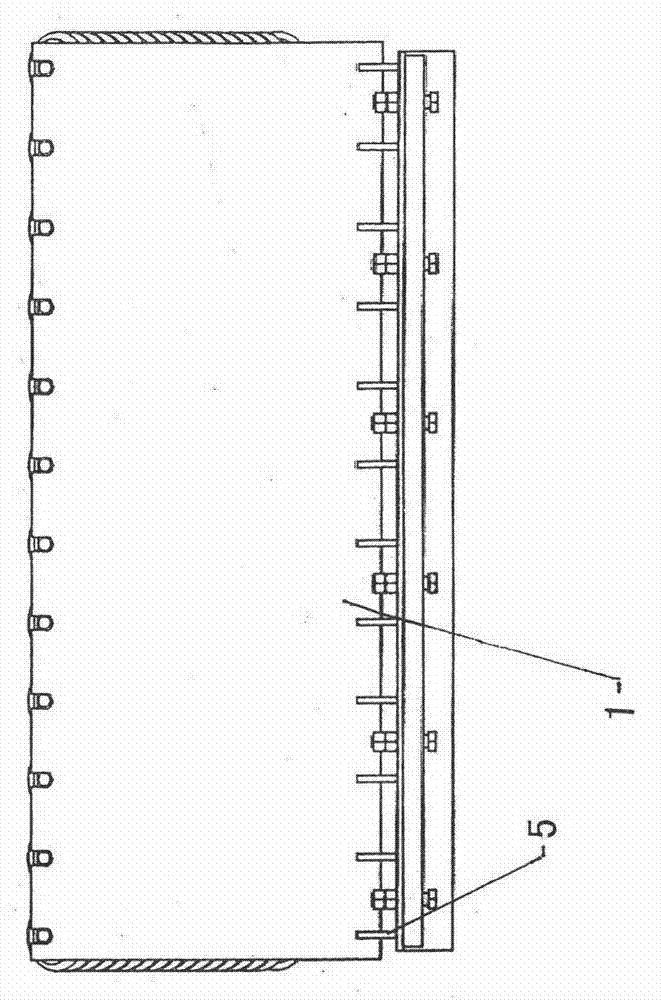

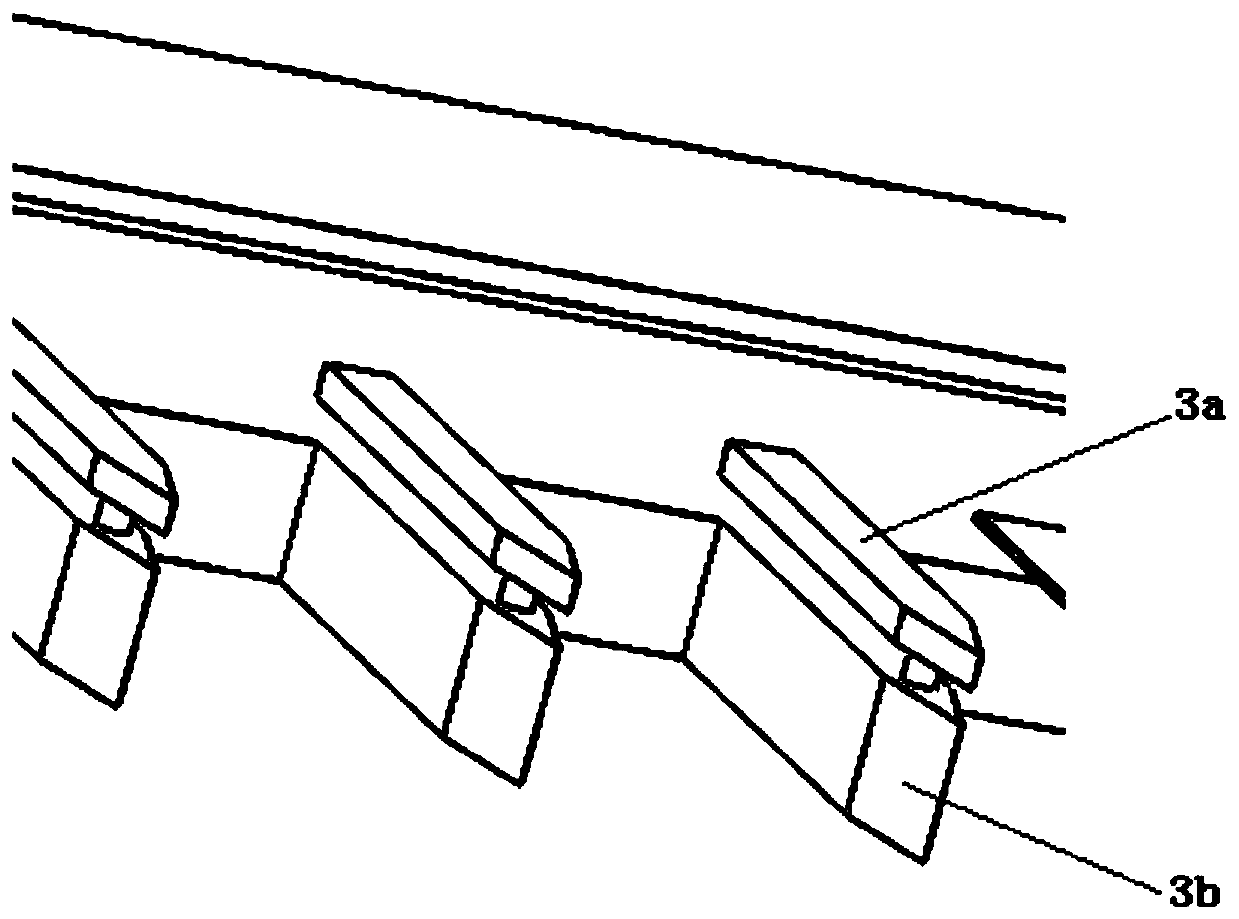

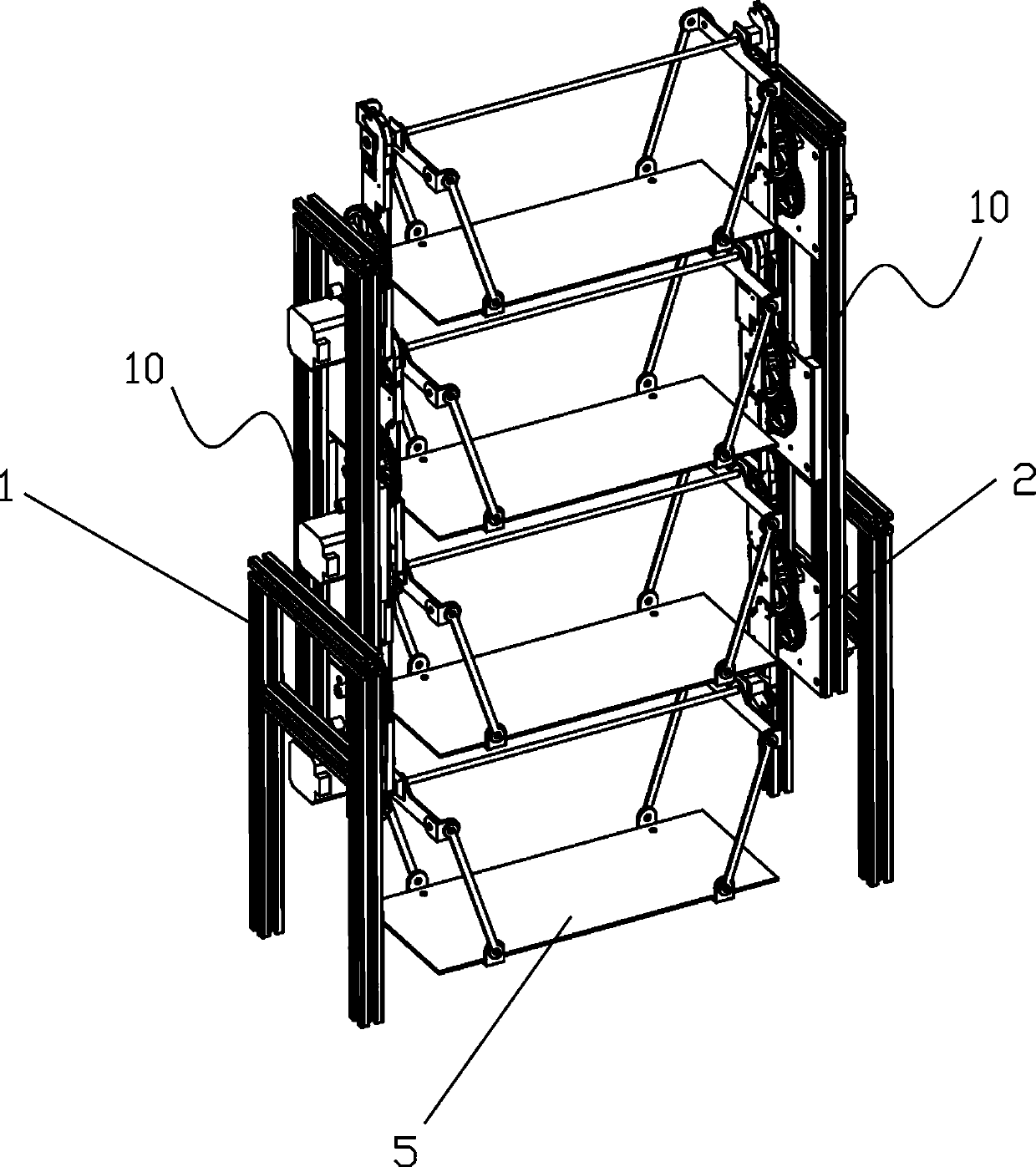

Rolling type buffer bed

InactiveCN102785892AReduce resistanceReduce material strengthConveyorsRollersWorking lifeEngineering

The invention discloses a rolling type buffer bed. A bed body (5) is connected with supporting legs through a bolt set (6) and a buffer pad (7) at the two ends of the bed body (5); side brackets (1) with the same height are symmetrically and fixedly connected at the two ends on the upper surface of the bed body (5); more than one rib plate (2) is close to the inner side of each side bracket (1) and fixedly connected to the four corners on the upper surface of the bed body (5); more than one middle bracket (4) with the same height is symmetrically arranged in the middle close to the bed body (5); and the two ends of each of more than one buffer supporting roller (3) are movably connected to the upper end between each side bracket (1) and each middle bracket (4) and the two ends of each buffer supporting roller are movably connected to the upper end between the symmetrically distributed middle brackets (4). The more than one buffer supporting roller (3) is regularly mounted between each side bracket (1) and each middle bracket (4) and between the two middle brackets, so that a conveyer belt is uniformly in contact with the buffer supporting rollers (3), the buffer effect is enhanced, the working life of the buffer supporting rollers (3) is prolonged, and the dual-buffer effect is achieved due to the effect of the buffer pad (7). Therefore, the rolling type buffer pad is energy-saving, high in strength and stable in operation, and has practical and promotional values.

Owner:HUNAN YINGHONG SCI & TECH

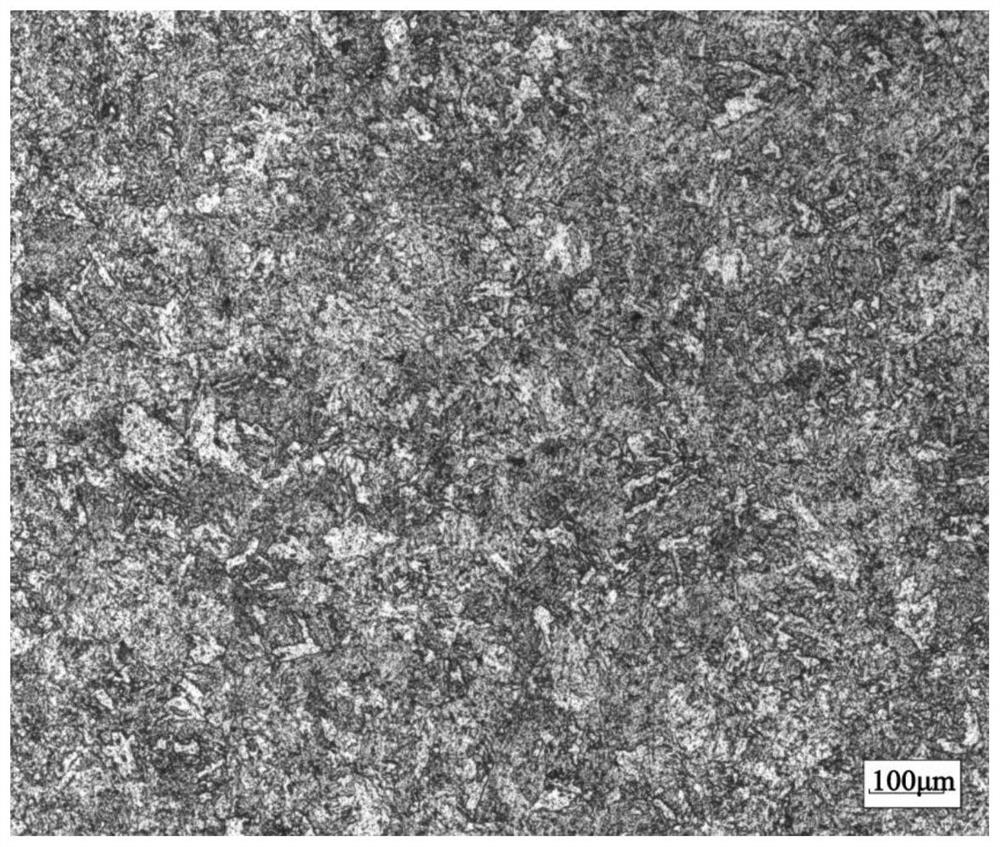

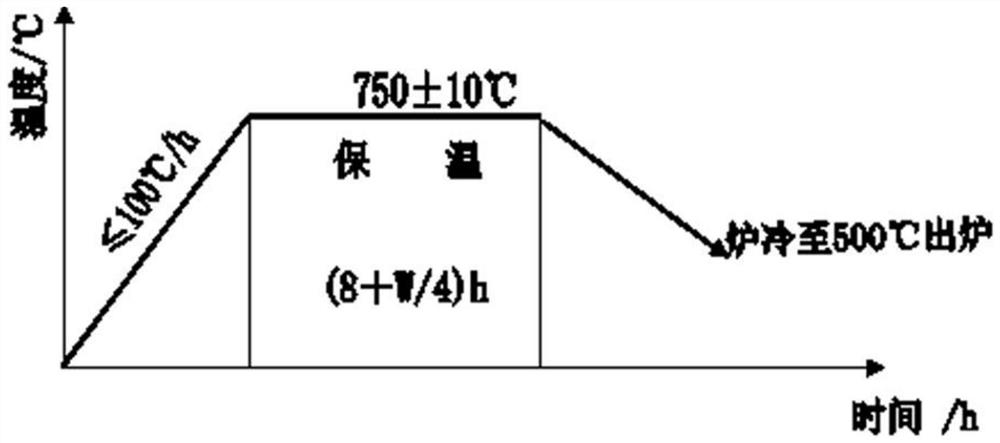

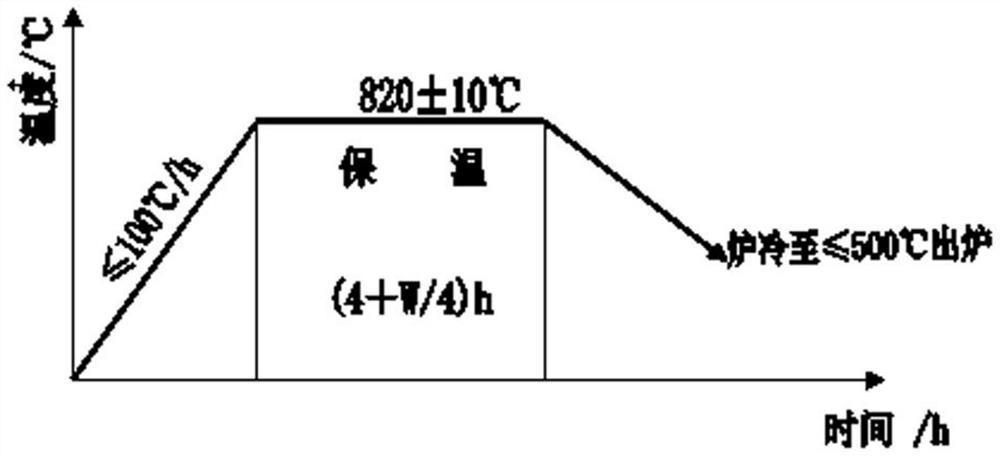

30CrMnSiNi2A high-strength steel for aviation and production method thereof

ActiveCN113502434ADelay and inhibit grain growth tendencyGrain ultrafineProcess efficiency improvementAviationSmelting process

The invention provides 30CrMnSiNi2A high-strength steel for aviation and a production method thereof. The 30CrMnSiNi2A high-strength steel for aviation comprises the following chemical components in percentage by weight: 0.27 to 0.34 percent of C, 0.90 to 1.20 percent of Si, 1.00 to 1.30 percent of Mn, 0.90 to 1.20 percent of Cr, 1.40 to 1.80 percent of Ni, 0.015 to 0.03 percent of Al, 0.02 to 0.03 percent of Mo, 0.02 to 0.03 percent of V, 0.015 to 0.025 percent of Ti, 0.15 to 0.2 percent of W, less than or equal to 0.012 percent of P, less than or equal to 0.01 percent of S and the balance of Fe. According to the 30CrMnSiNi2A high-strength steel for aviation and the production method provided by the invention, a smelting process comprising electric furnace die casting, external refining and electroslag remelting which is always adopted abroad is completely replaced by the method comprising electric furnace continuous casting, external refining and electroslag remelting, so that the effect of improving the material structure property and the fatigue property is obvious. By means of the method, batch, systematic and energy-saving production can be carried out, and energy and cost are obviously saved.

Owner:青海西钢特殊钢科技开发有限公司 +1

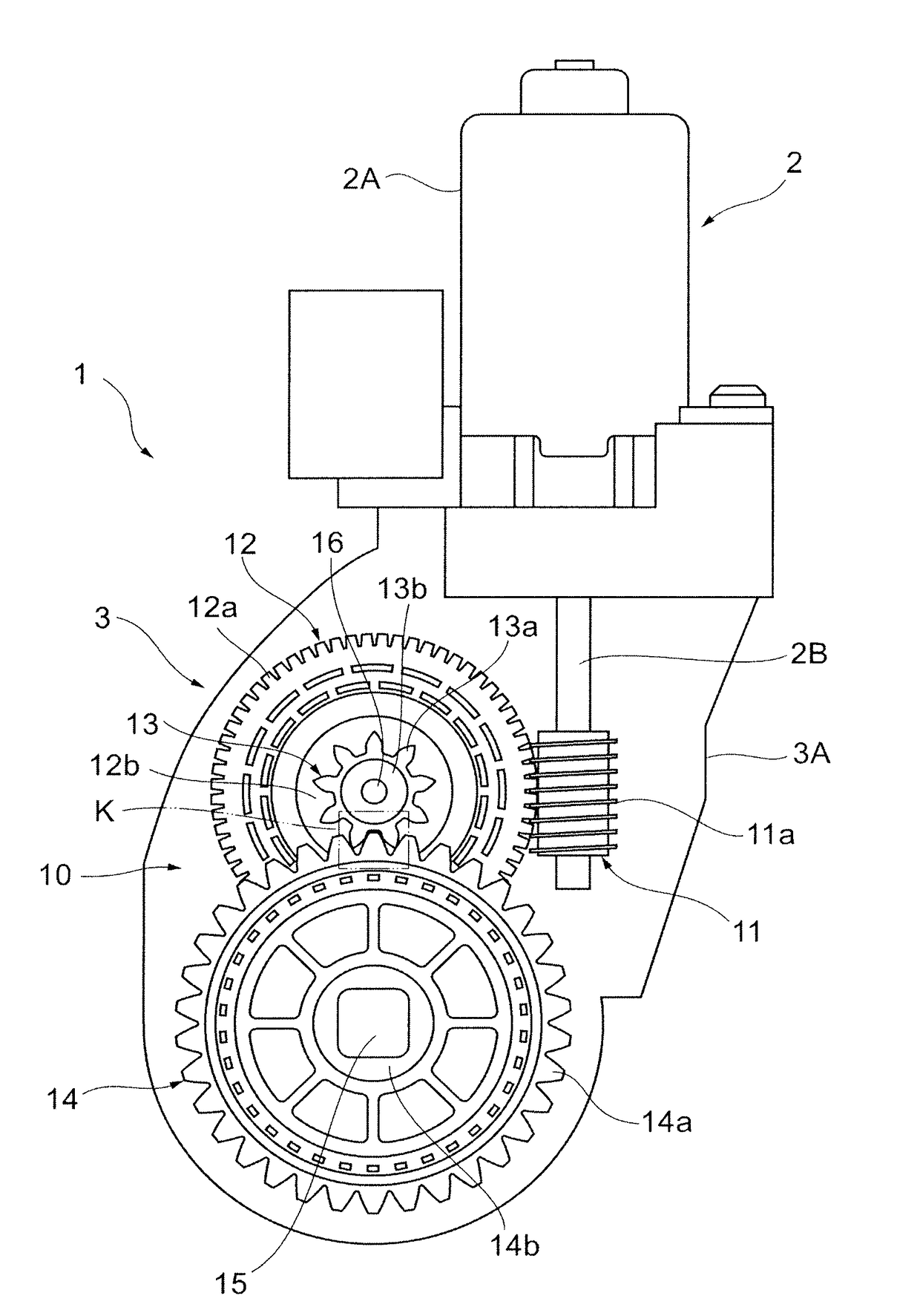

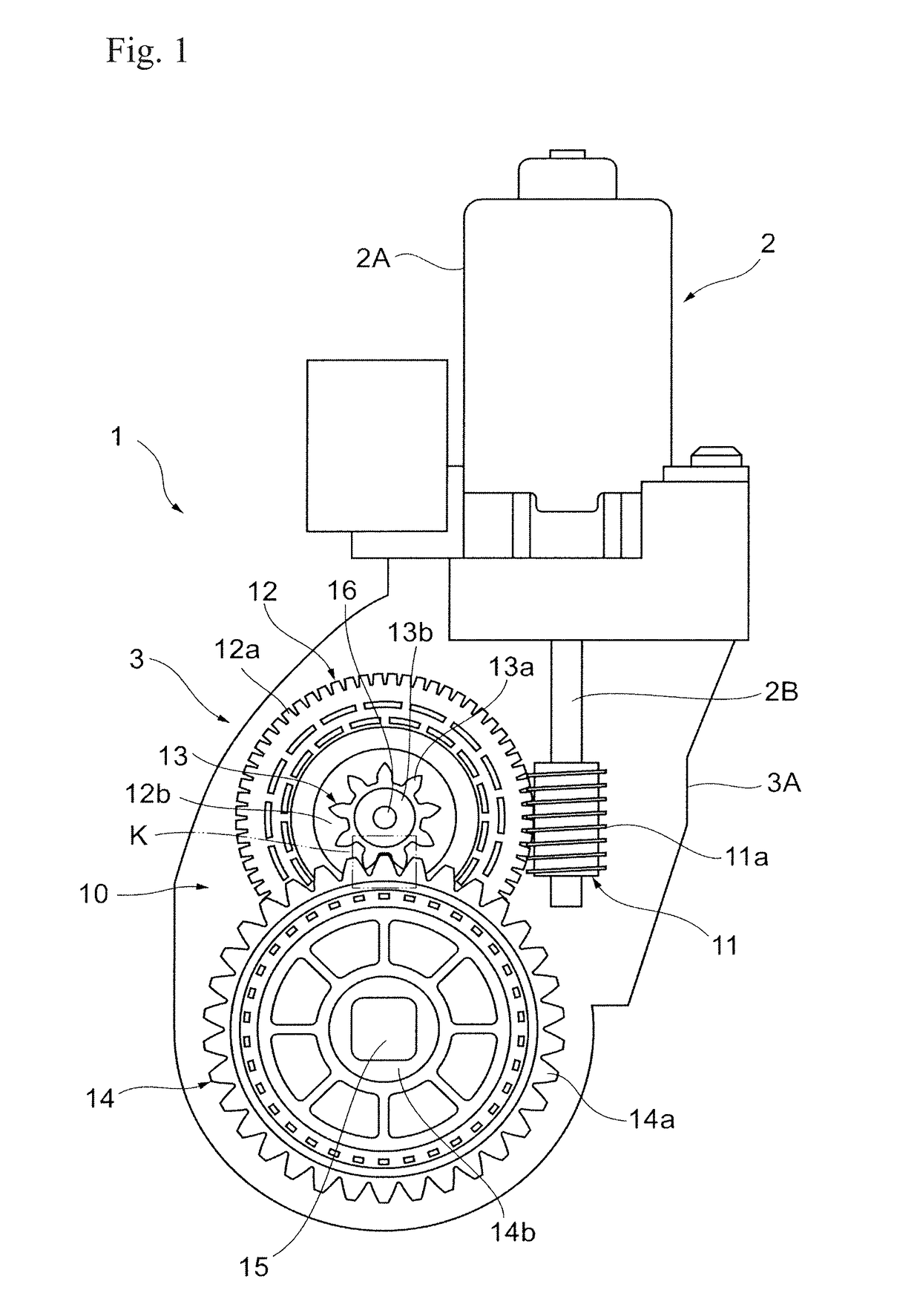

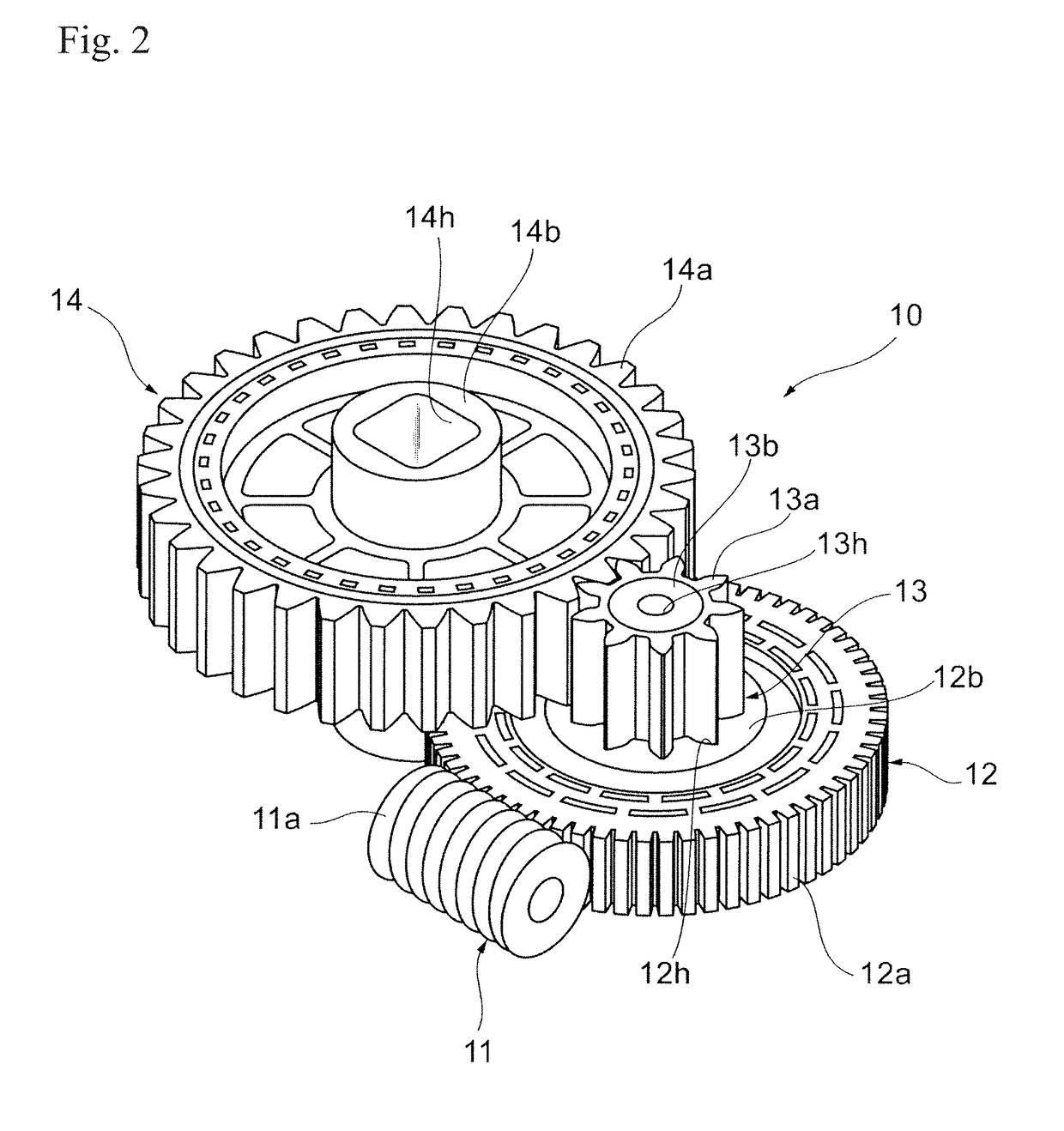

Gear unit, reducer, and reducer-equipped motor

InactiveUS20180142764A1Lower strength of materialHigh material strengthPortable liftingToothed gearingsEngineeringReducer

Owner:MABUCHI MOTOR

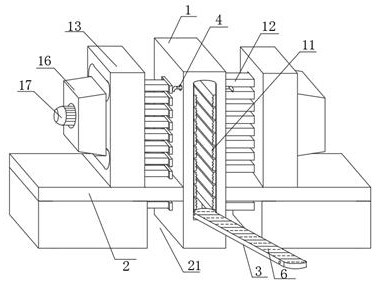

Straightening and repairing device for long cabinet door of ecological and environment-friendly customized furniture

ActiveCN113618869AEasy accessEasy to operateWood working apparatusFurniture partsStructural engineeringMechanical engineering

The invention discloses a straightening and repairing device for a long cabinet door of ecological and environment-friendly customized furniture. The device comprises a straightening and repairing box, the lower half portion of the straightening and repairing box is located in a clamping groove of a horizontal support, a side door is movably arranged on the front end face of the straightening and repairing box, the side door is fixed to an opening of the front end face of the straightening and repairing box through a plug pin, straightening air bag combinations are arranged on the two side walls of the interior of the straightening and repairing box correspondingly, and buffer layers are arranged on the front inner wall and the rear inner wall of the straightening and repairing box and the inner sides of side doors correspondingly. According to the straightening and repairing device, the air bag combinations are used for replacing traditional mechanical strong pressure, the material strength of the air bags is low, damage to wood in the punching process is extremely small, the instantaneous pressure and repeated operation of pulses are utilized, mechanical acting force can be effectively replaced, the straightening effect of the cabinet door is improved, and the working noise is also reduced, the device is suitable for different working conditions, and better use prospects are brought.

Owner:安徽嘉禾整木家居有限公司

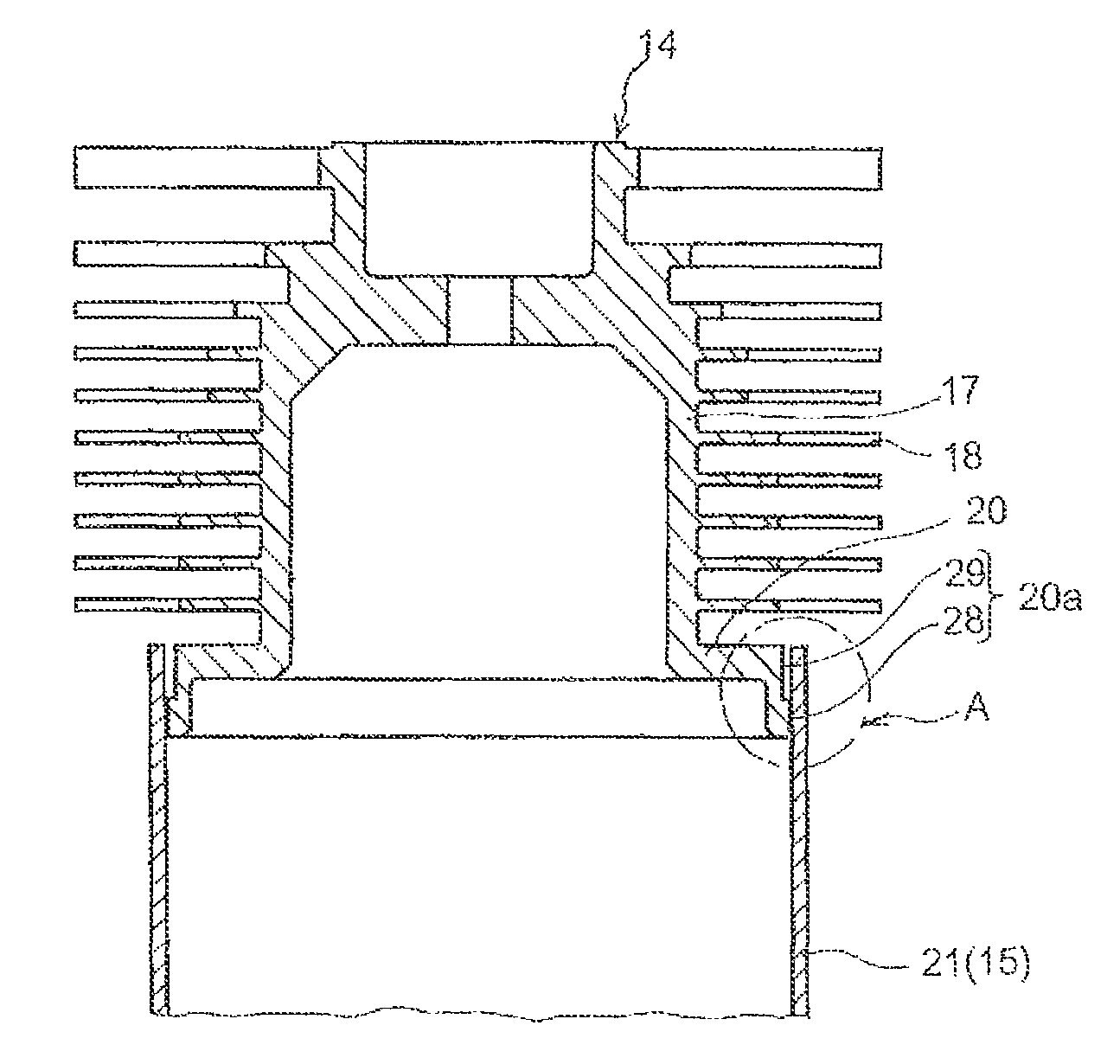

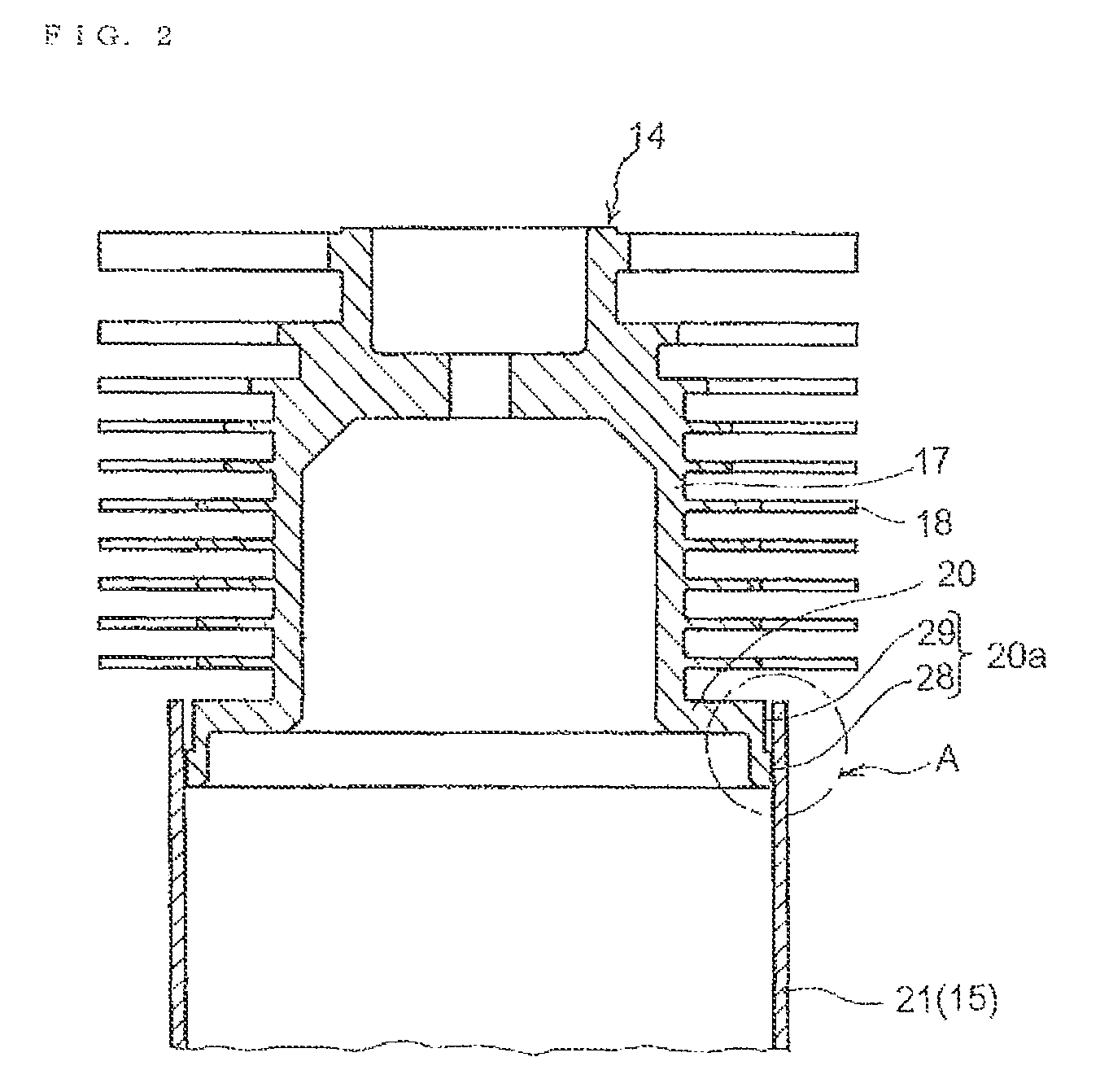

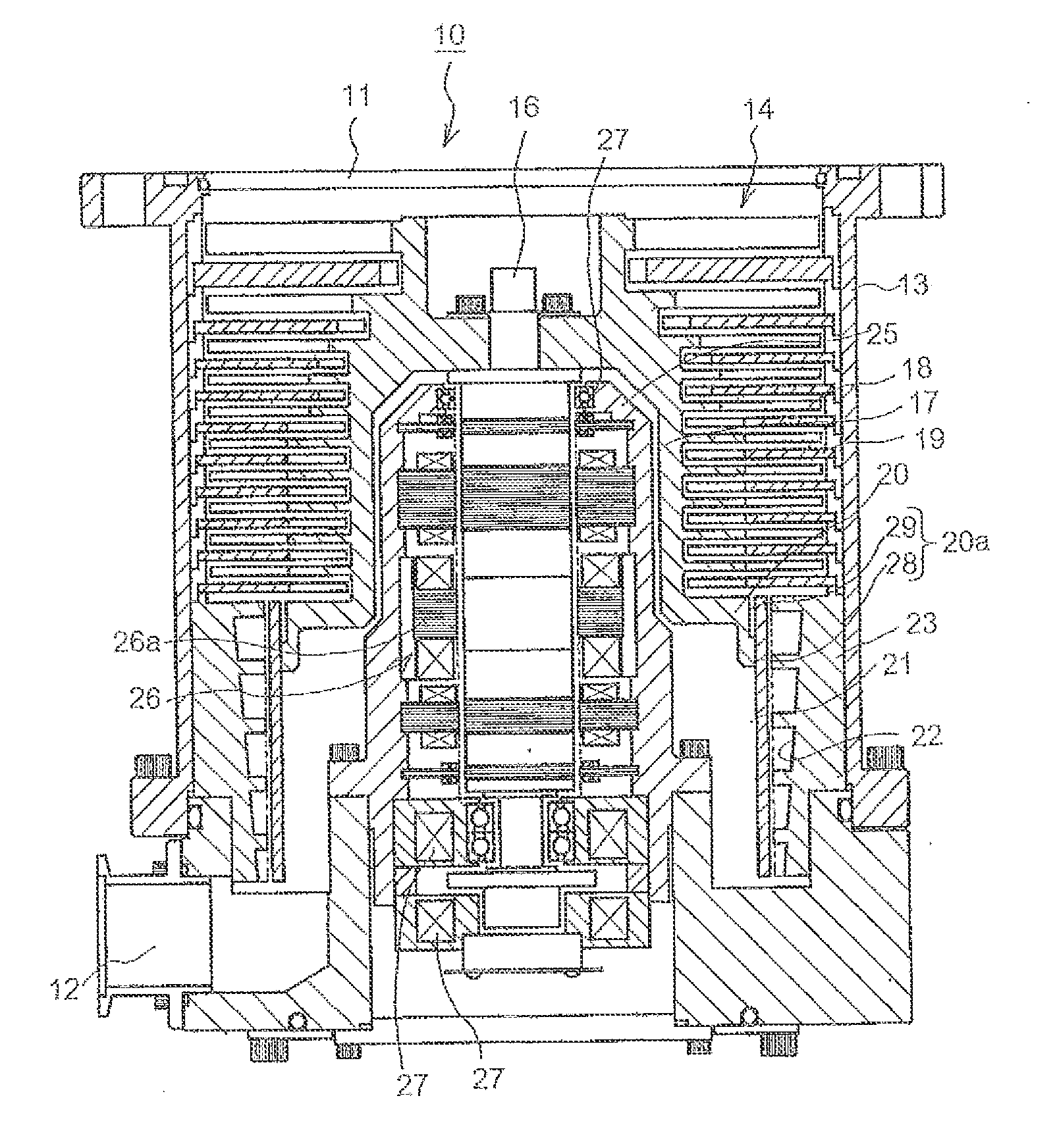

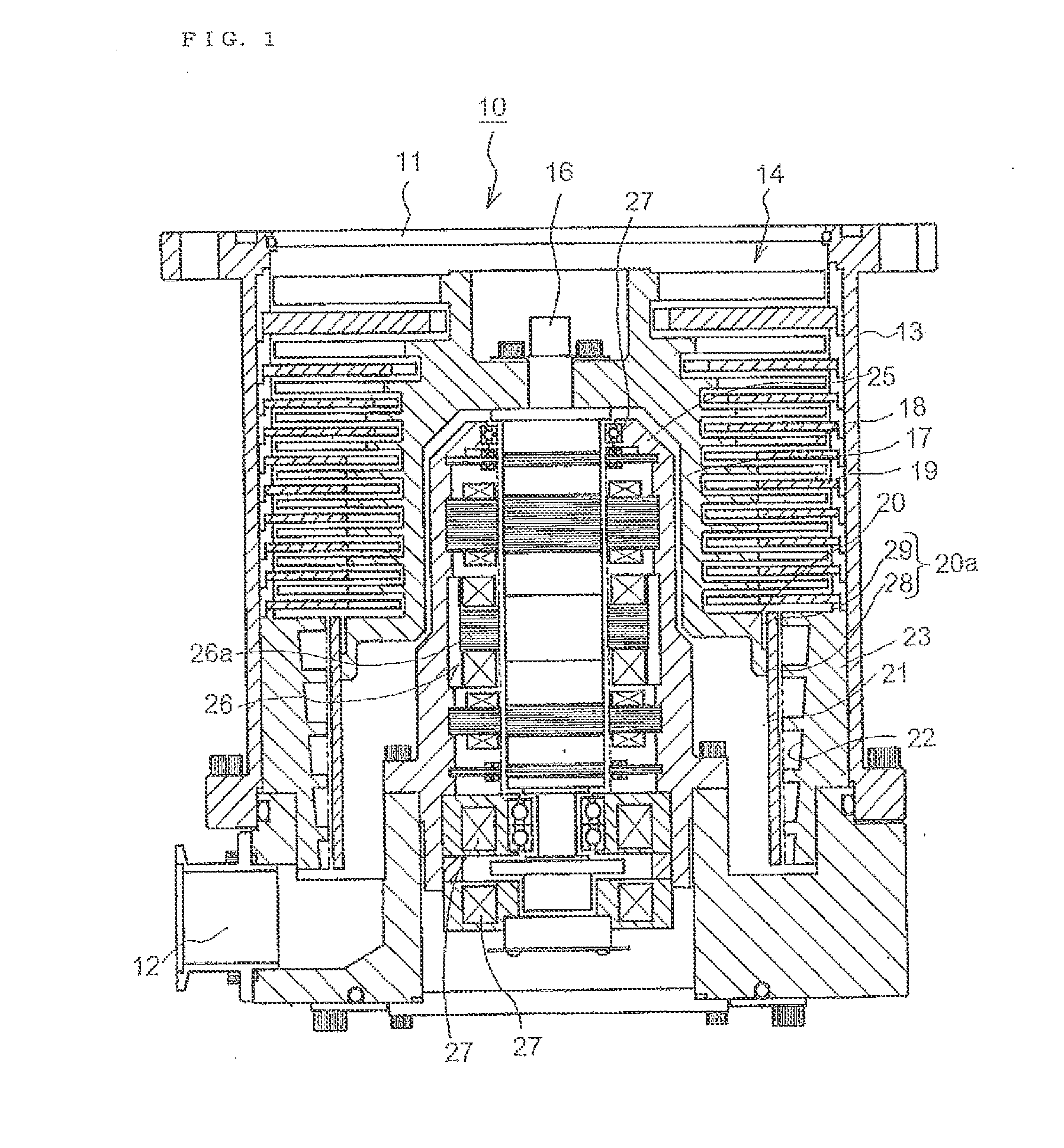

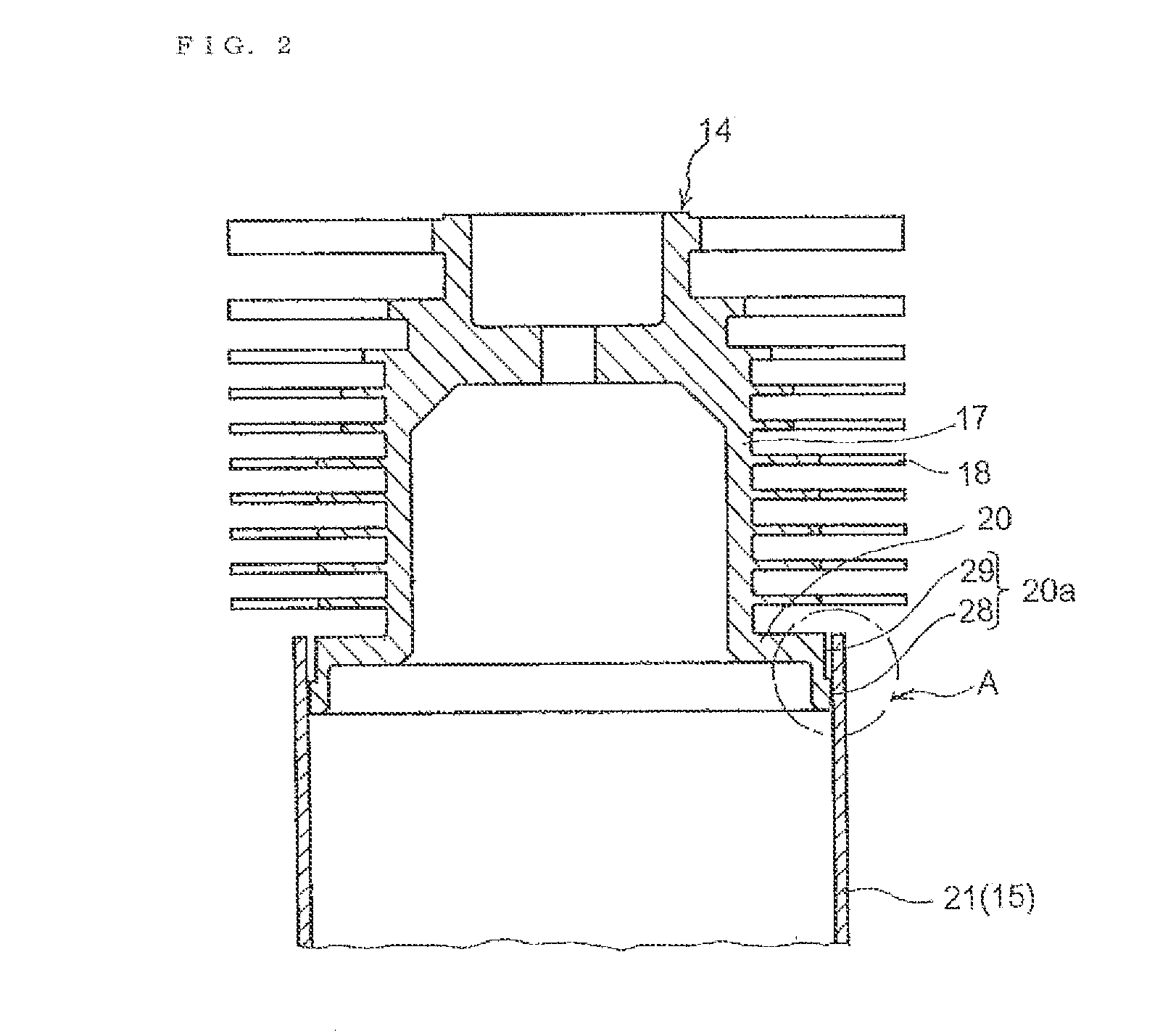

Vacuum pump

Disclosed is a low-cost composite-type vacuum pump having a strength capable of withstanding high loads and using a cylindrical rotor formed from a fiber-reinforced plastic material. Having a turbo-molecular pump section (14) and a thread groove pump section (15), the composite vacuum pump is formed by press-fitting a joint portion (20a) of a rotor (17) of the turbo-molecular pump section (14) into the upper end section of a cylindrical rotor (21) formed from the fiber-reinforced plastic material of the thread groove pump section (15). The joint portion (20a) of the rotor (17) is formed on the lower end side of the rotor (17) integrally with said rotor (17) and in the shape of a cylinder with an L shaped cross section, and is provided with: a contact portion (28) having an outer diameter enable press-fitting into the inner peripheral face of the cylindrical rotor (21); and a small-diameter section (29) positioned above said contact portion (28) and, having an outer diameter smaller than the inner diameter of the aforementioned cylindrical rotor (21), capable of being placed inside the cylindrical rotor (21) away from the inner peripheral face of the cylinder rotor (21).

Owner:EDWARDS JAPAN

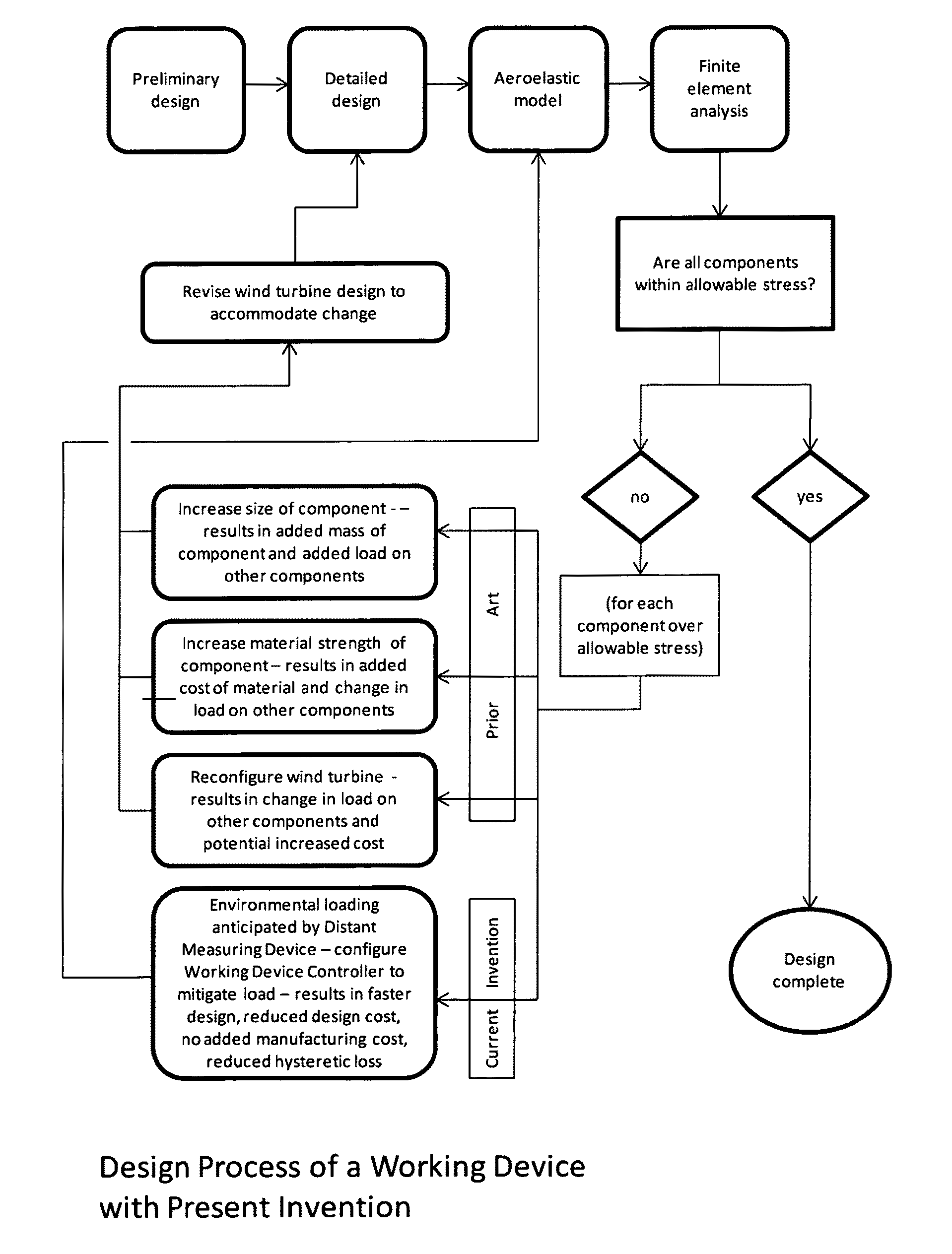

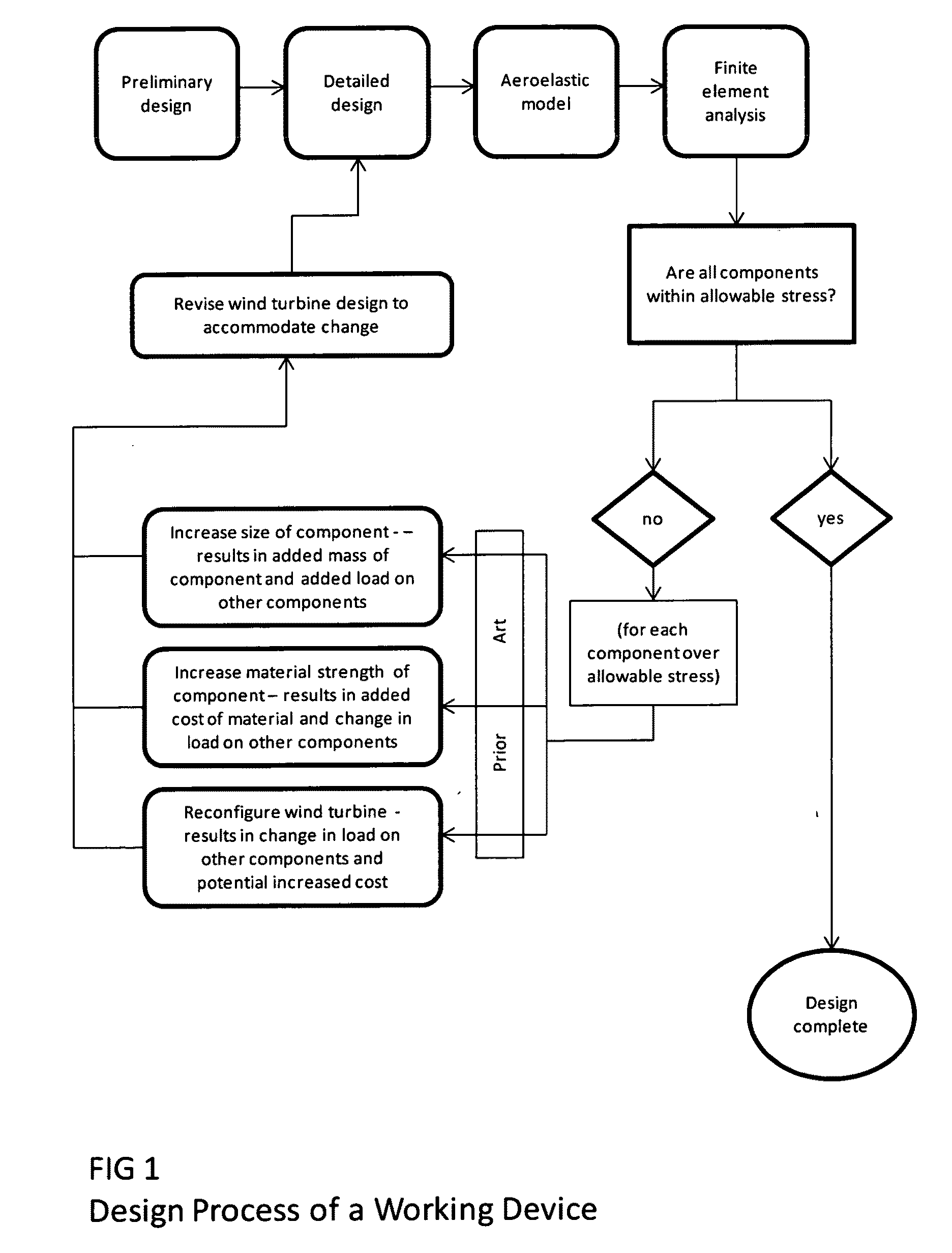

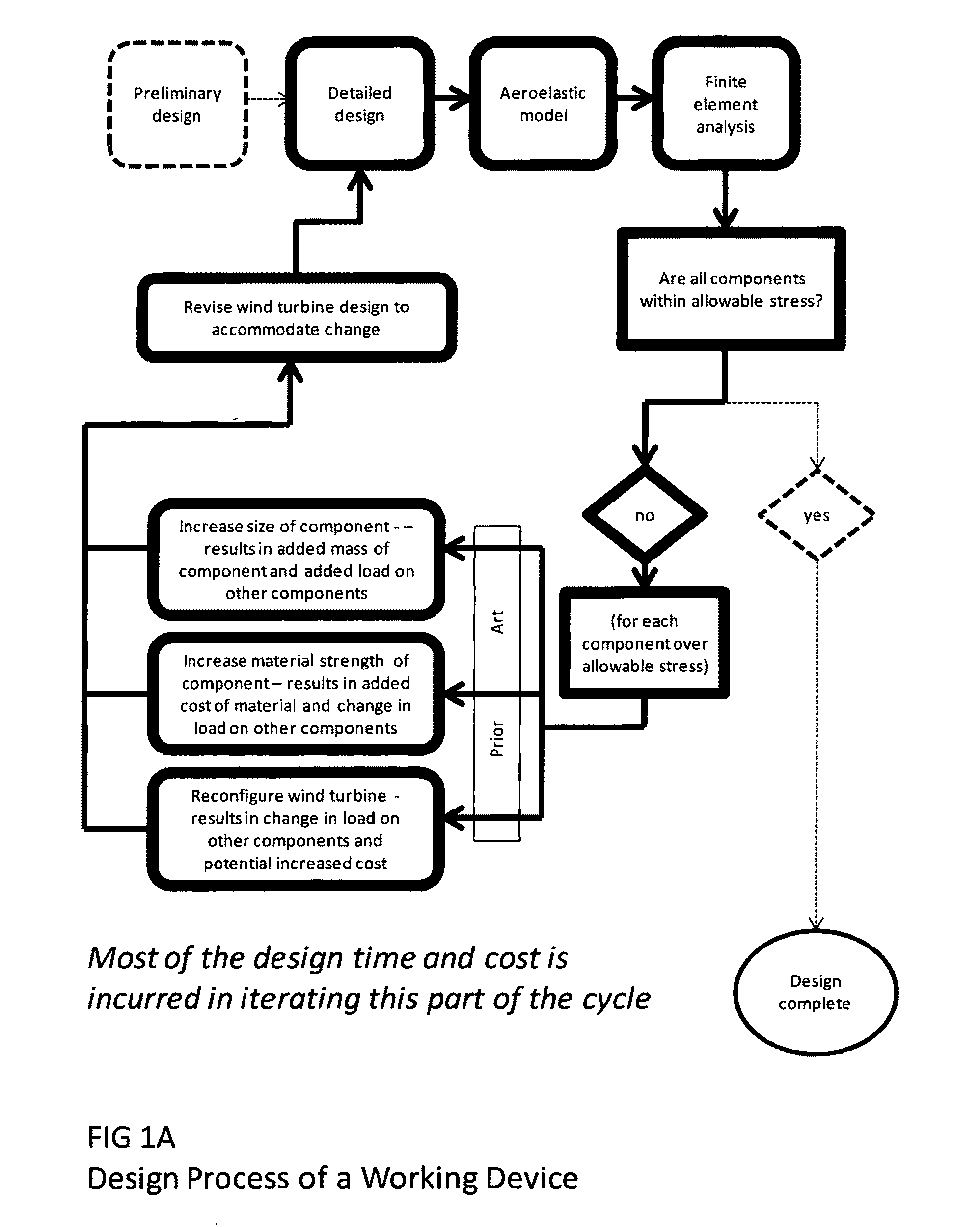

Use of devices for measuring fluid movement conditions at a distance to reduce the design and manufacturing cost of moving-fluid-driven working devices

ActiveUS20120010864A1Reduce the total massReduce material strengthDesign optimisation/simulationSpecial data processing applicationsEngineeringLidar

Owner:TABER JR WM STEVENS

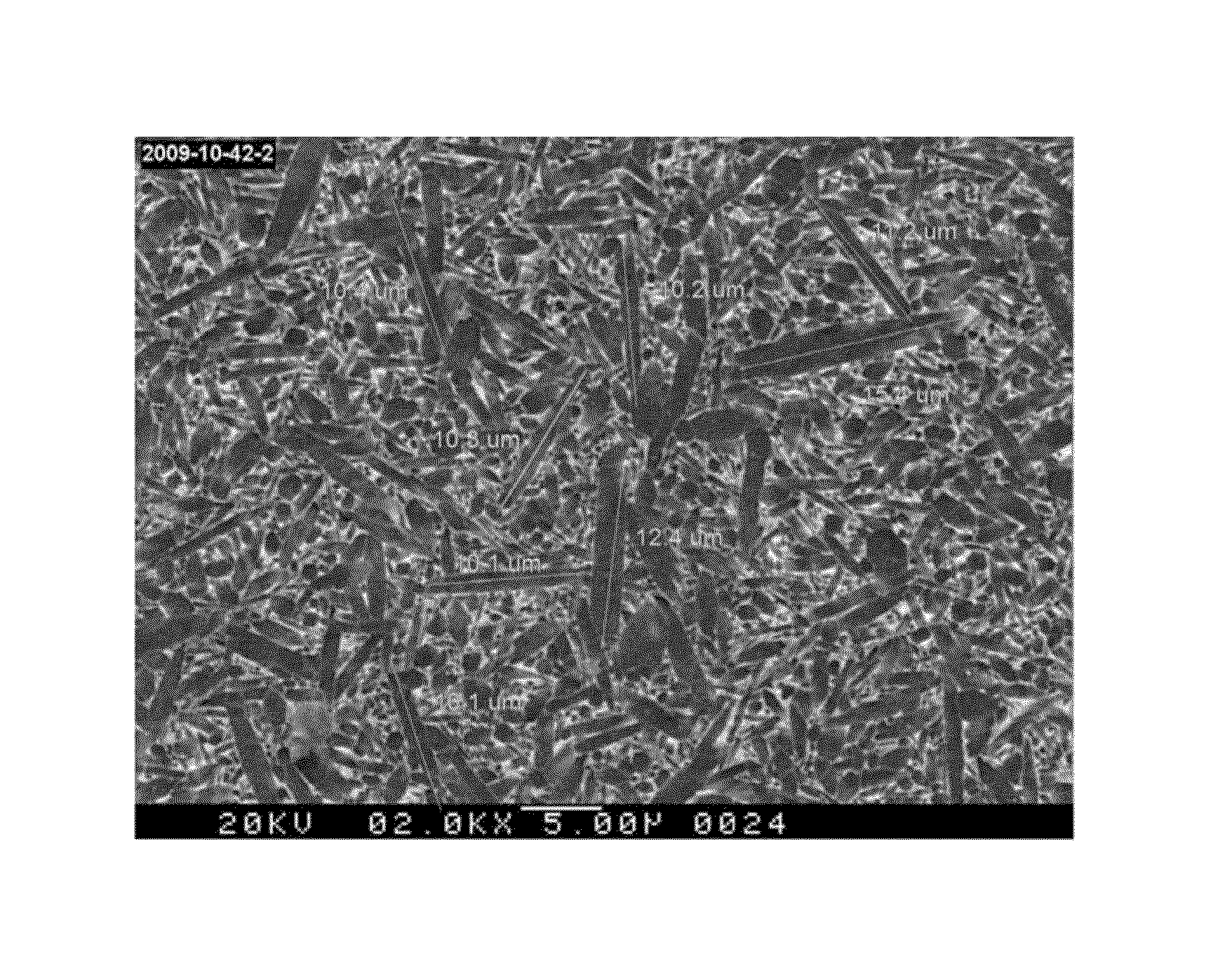

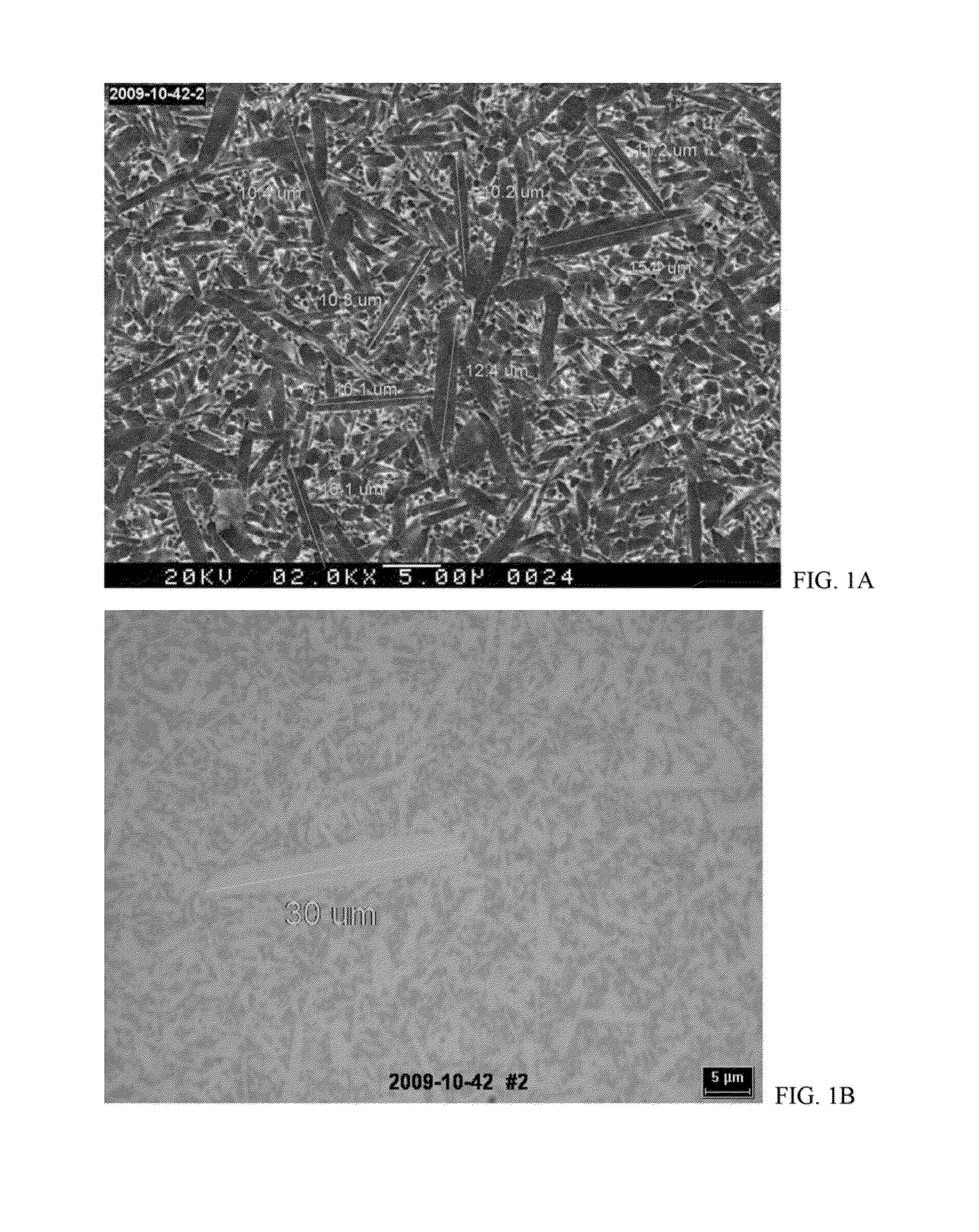

Dense silicon nitride body having high strength, high Weibull modulus and high fracture toughness

ActiveUS8652981B2Reduce material strengthEqually distributedNon-woven fabricsRaw material divisionHigh fractureGas pressure sintering

Owner:CERADYNE

Fixed connecting structure and method for conductor and insulator supporting conductor

ActiveCN108879170ALow costGuaranteed electrical reliabilityCoupling device detailsElectrical conductorEngineering

The invention provides a fixed connecting structure and a method for a conductor and an insulator supporting the conductor. First grooves are formed in the inner concave part of the outer wall of theconductor. The insulator is integrally formed outside a barrel body in a pouring manner, and the insulator sleeves the conductor. Second grooves and chutes connected to the second grooves are formed in the inner concave part of the inner wall of the barrel body. A first limiting key is embedded in the first groove and the second groove. A second limiting key is embedded in the chute, and the second limiting key is fixedly arranged between the first limiting key and the side wall of the chute. According to embodiments of the fixed connecting structure and method for the conductor and the insulator supporting the conductor, fixed connection between the conductor and the insulator supporting the conductor can be realized in an ultra-clean, normal temperature, light and low-cost manner.

Owner:XIAN XD SWITCHGEAR ELECTIC CO LTD +1

Vacuum pump

Disclosed is a low-cost composite-type vacuum pump having a strength capable of withstanding high loads and using a cylindrical rotor formed from a fiber-reinforced plastic material. Having a turbo-molecular pump section (14) and a thread groove pump section (15), the composite vacuum pump is formed by press-fitting a joint portion (20a) of a rotor (17) of the turbo-molecular pump section (14) into the upper end section of a cylindrical rotor (21) formed from the fiber-reinforced plastic material of the thread groove pump section (15). The joint portion (20a) of the rotor (17) is formed on the lower end side of the rotor (17) integrally with said rotor (17) and in the shape of a cylinder with an L shaped cross section, and is provided with: a contact portion (28) having an outer diameter enable press-fitting into the inner peripheral face of the cylindrical rotor (21); and a small-diameter section (29) positioned above said contact portion (28) and, having an outer diameter smaller than the inner diameter of the aforementioned cylindrical rotor (21), capable of being placed inside the cylindrical rotor (21) away from the inner peripheral face of the cylinder rotor (21).

Owner:EDWARDS JAPAN

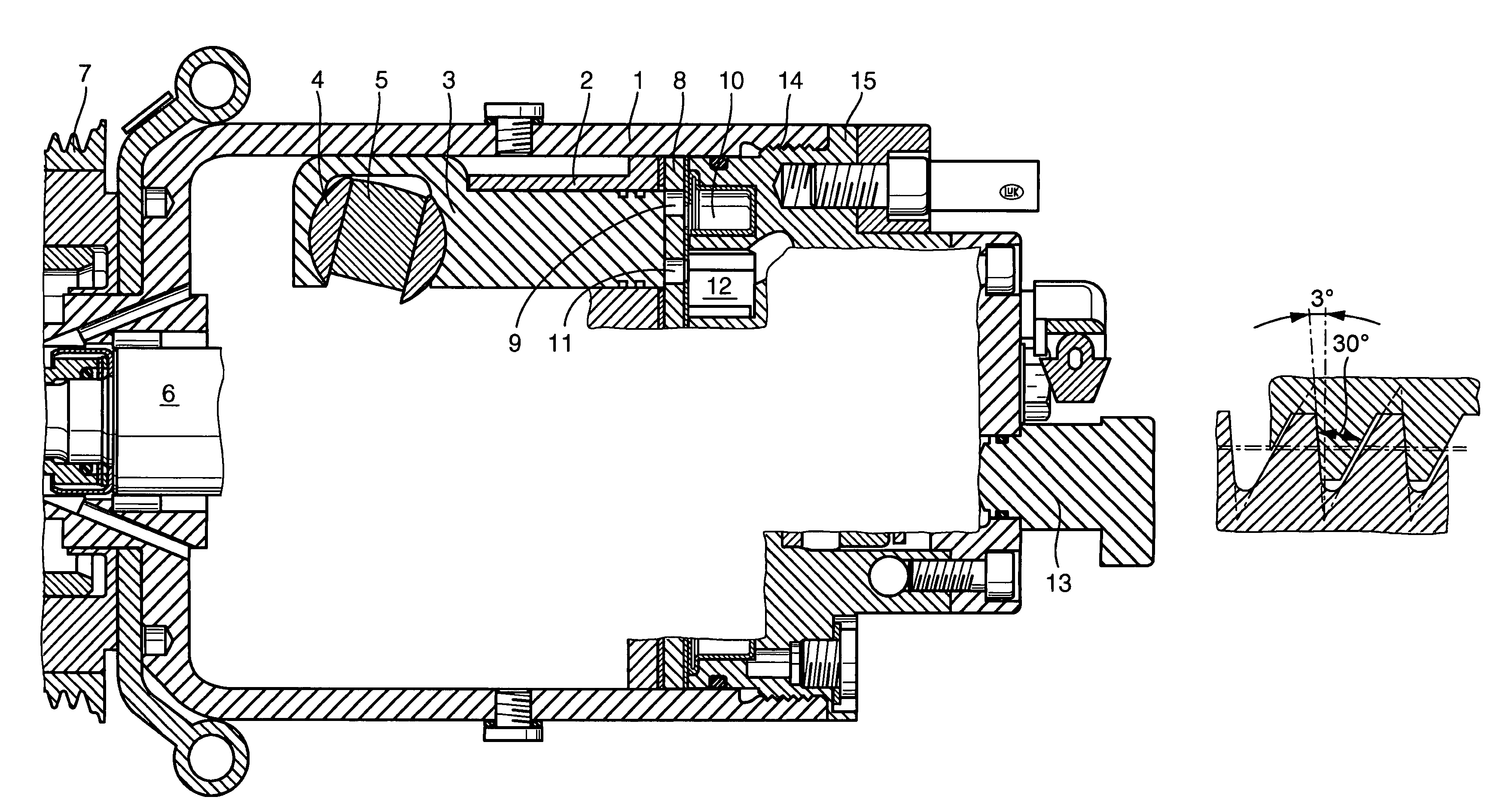

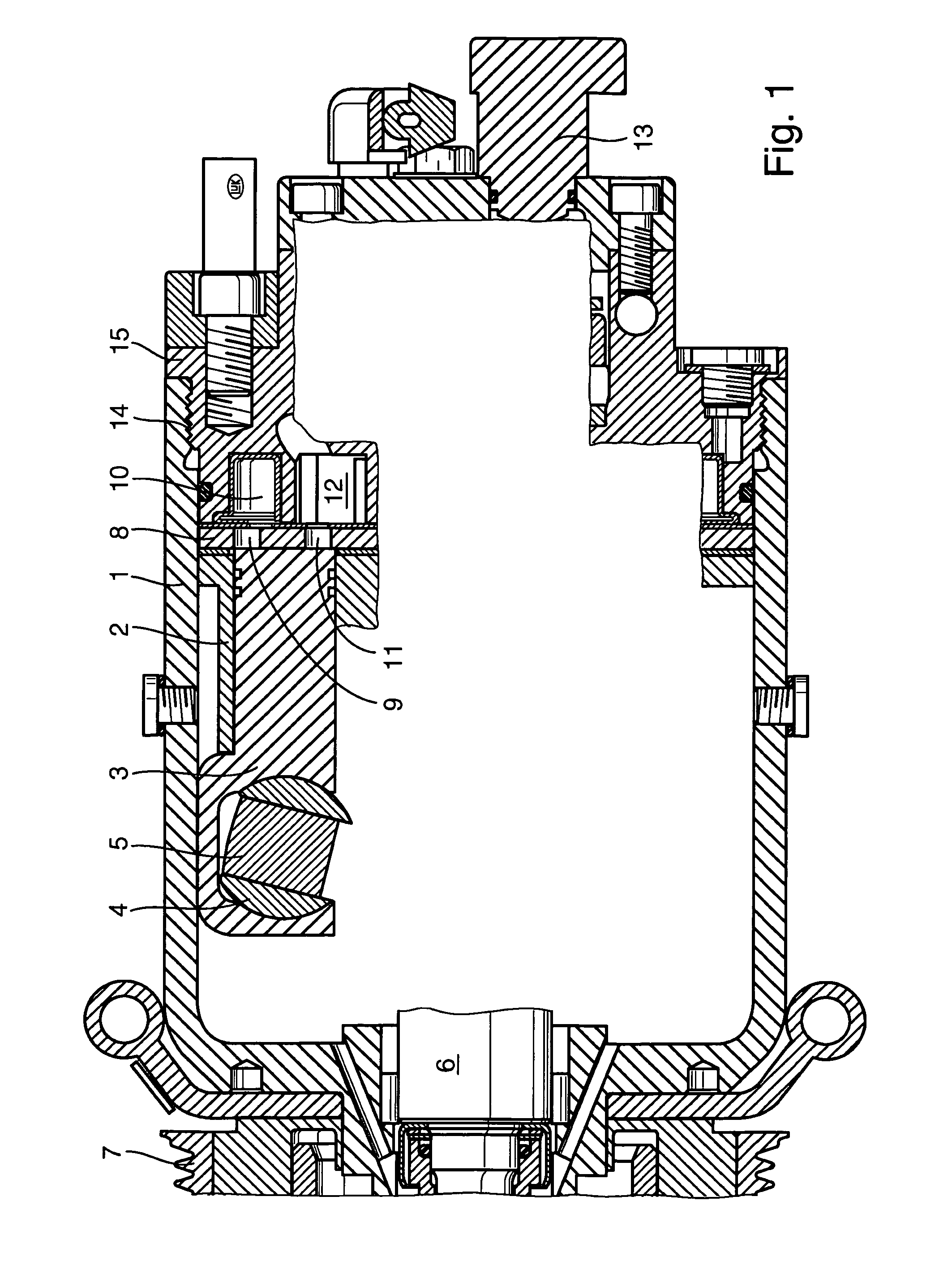

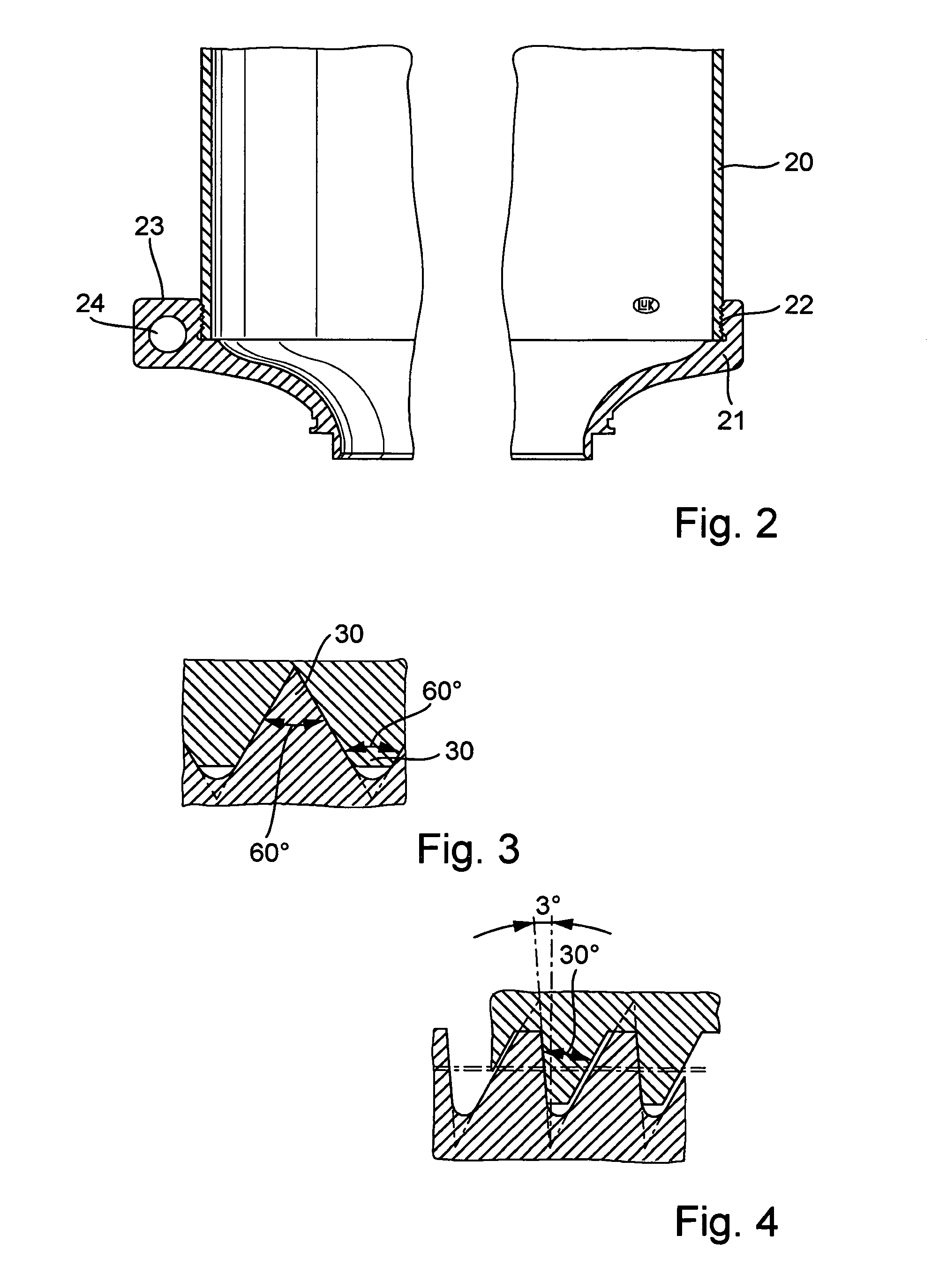

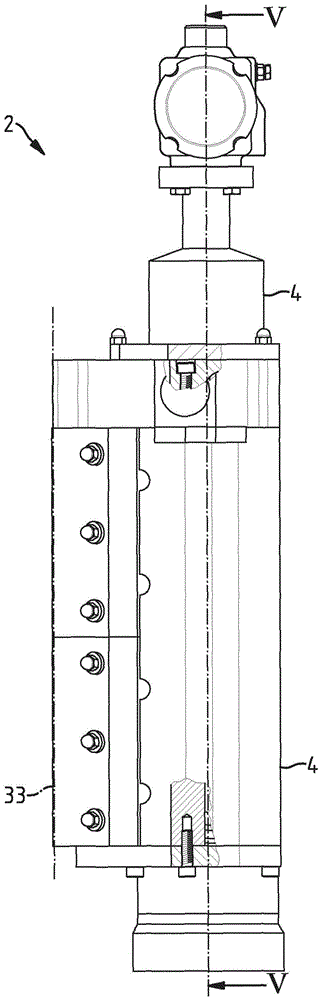

Reciprocating piston machine

InactiveUS7698989B2Reduce thermal stressSteeper pitchPositive displacement pump componentsCylindersWork unitEngineering

A reciprocating piston machine, in particular a compressor, such as for the air conditioning system of an automotive vehicle. The machine includes a casing and at least one casing cover. A working unit including pistons and is arranged or formed in the casing. The intake and exhaust zone or a front shaft bearing are arranged or formed in the casing cover (covers). The casing cover is screwed on the casing. The screw assembling is carried out with the aid of ring nuts or saw tooth screw threads between the casing and the casing cover, wherein the casing and cover are made of materials with different strengths and different thermal expansion coefficients.

Owner:LUK FAHRZEUG HYDRAULIK

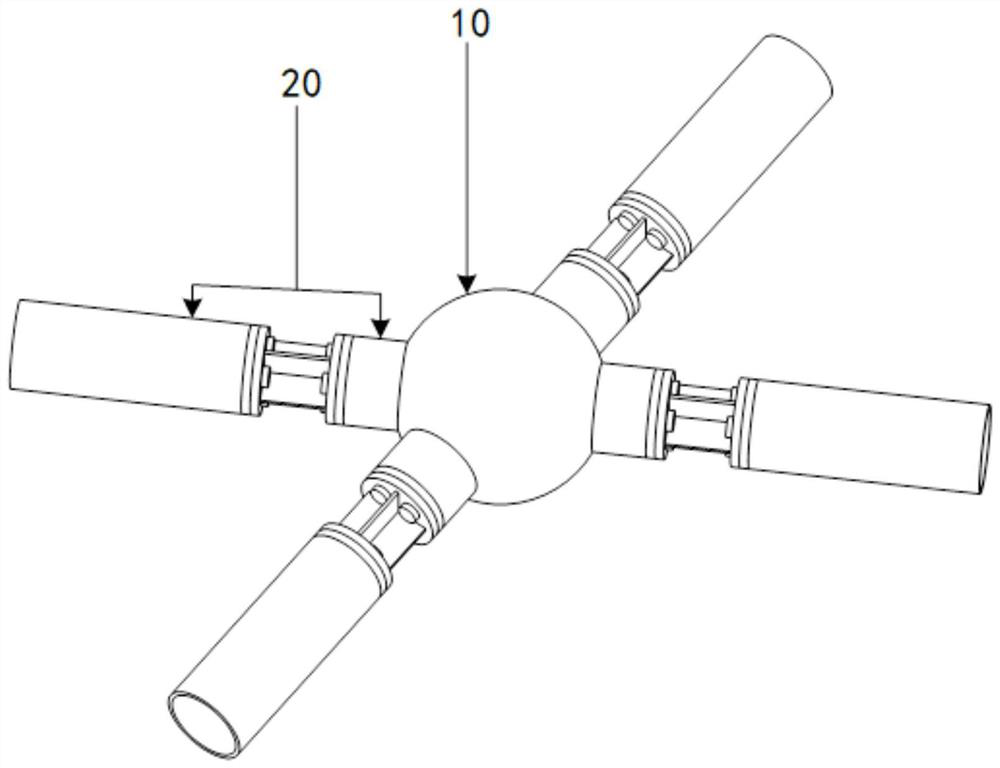

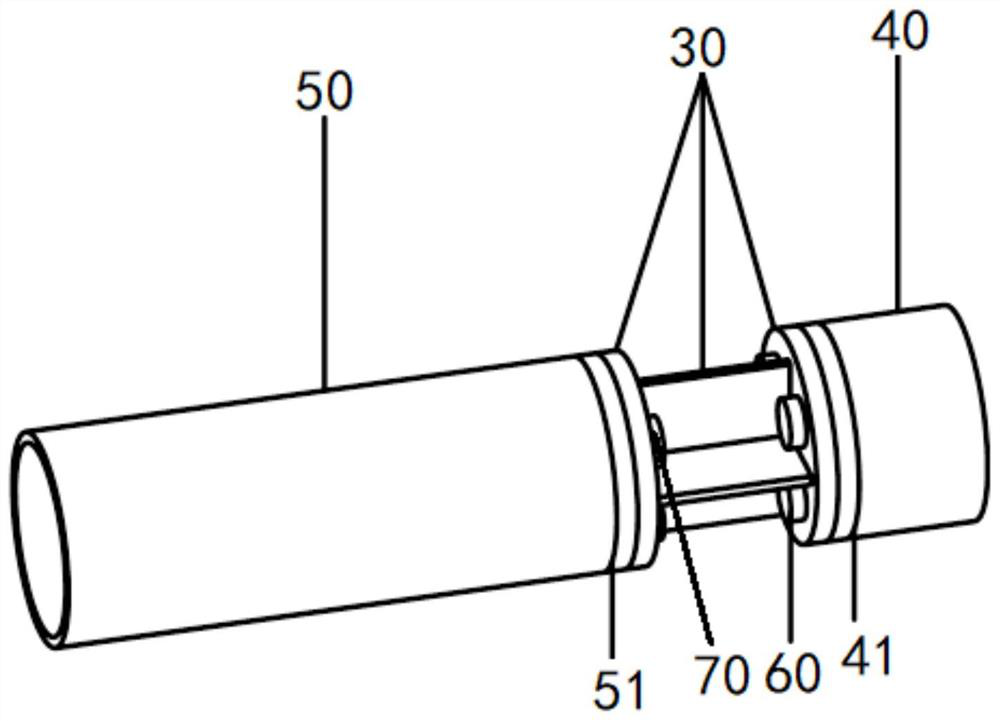

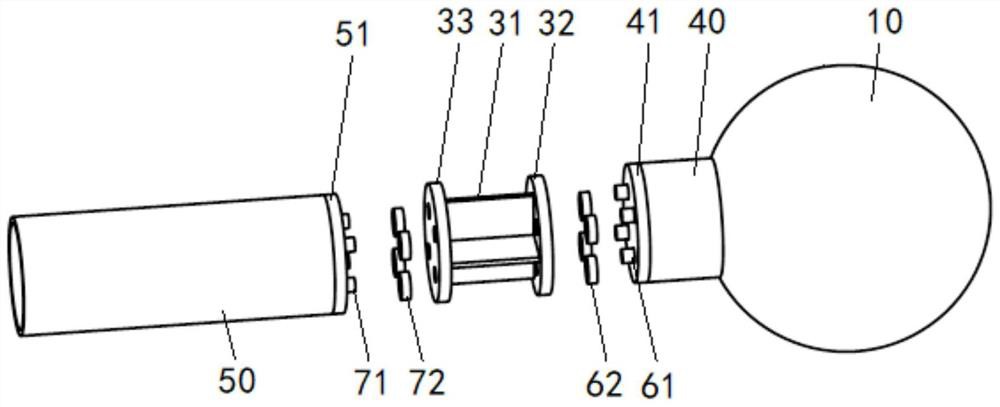

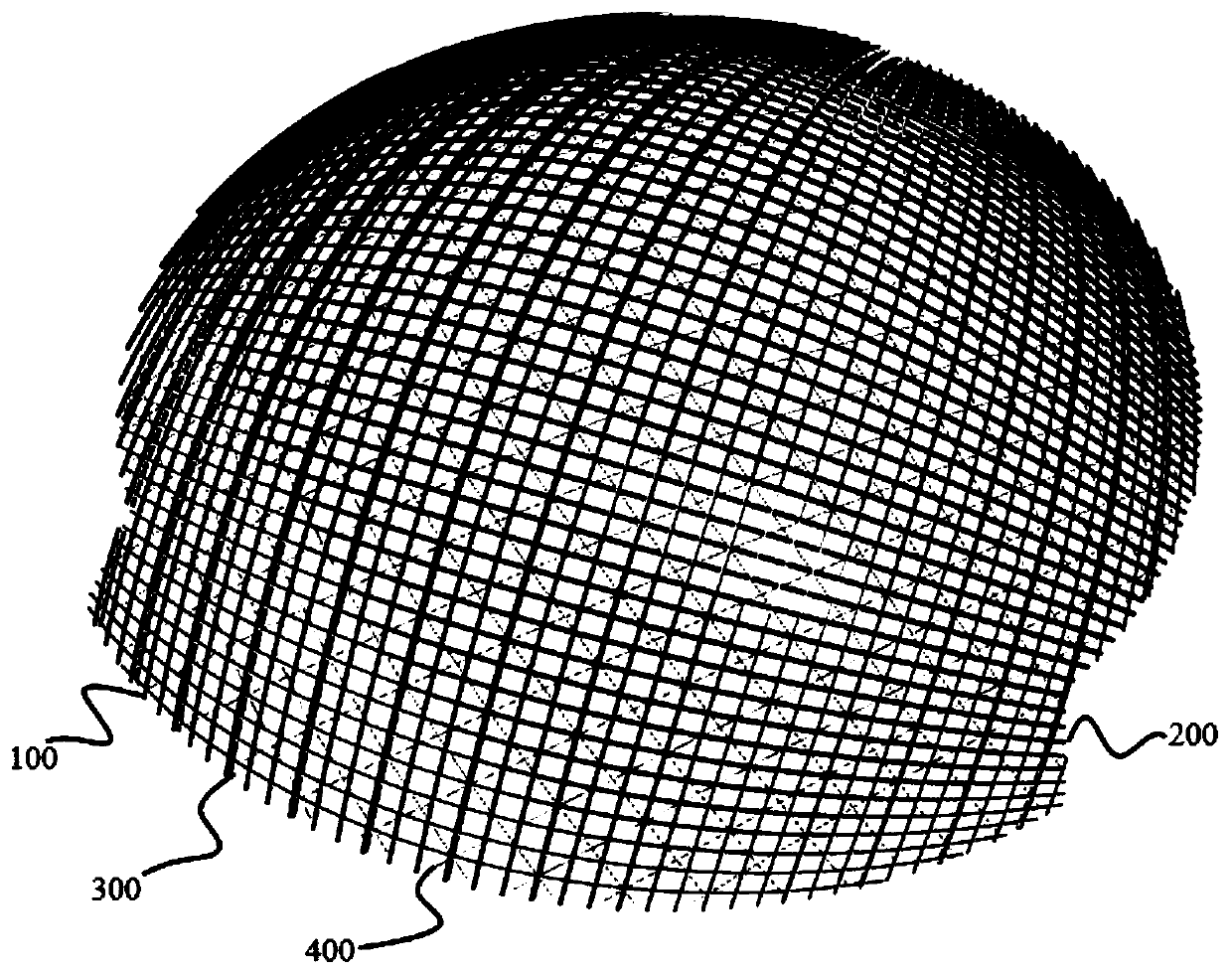

Novel large-span repairable fabricated joint and fabricated method

InactiveCN112323976AReduce material strengthReduce lossesArched structuresVaulted structuresLong spanPipe

The invention discloses a novel large-span repairable fabricated joint and a fabricated method, and belongs to the field of large-span space structure engineering. The novel large-span repairable fabricated joint can be applied to a large-span single-layer spherical reticulated shell. The novel large-span repairable fabricated joint comprises a hollow ball and a plurality of round steel pipe connecting assemblies installed on the hollow ball. The round steel pipe connecting assemblies comprise repairable connecting pieces, short cantilever round steel pipe sections and common round steel pipesections, and the yield strength of the repairable connecting pieces is the lowest; and one ends of the short cantilever round steel pipe sections are installed on the hollow ball, first round steel plates are installed at the other end of the short cantilever round steel pipe sections, one end of the repairable connecting pieces are connected with the first round steel plates through first bolt groups, and the other ends of the repairable connecting pieces are connected with second round steel plates installed at one ends of the common round steel pipe sections through second bolt groups. Thewelding connection parts can be machined in a factory and can be pre-installed in the factory, on-site high-altitude welding is avoided, and the construction efficiency is greatly improved.

Owner:BEIJING UNIV OF TECH

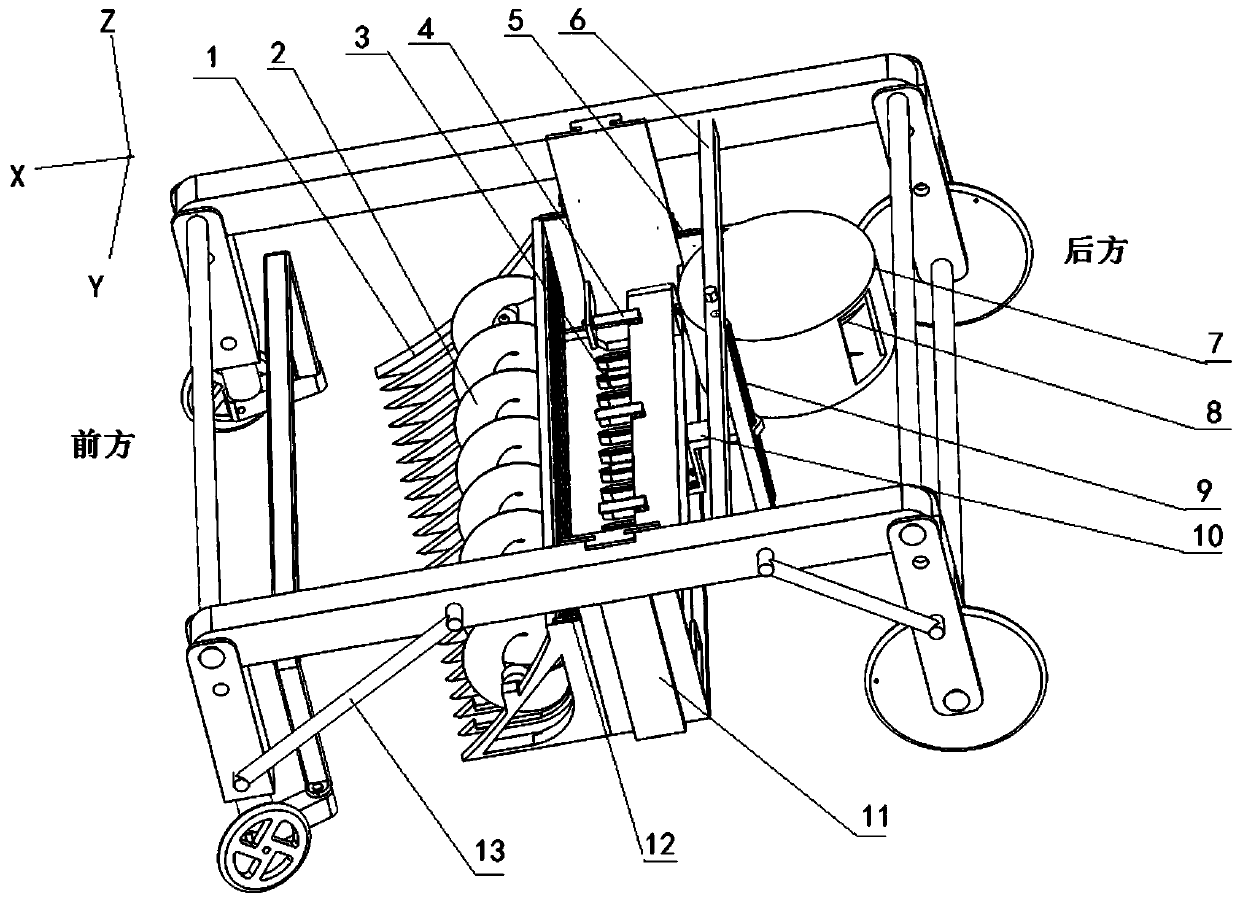

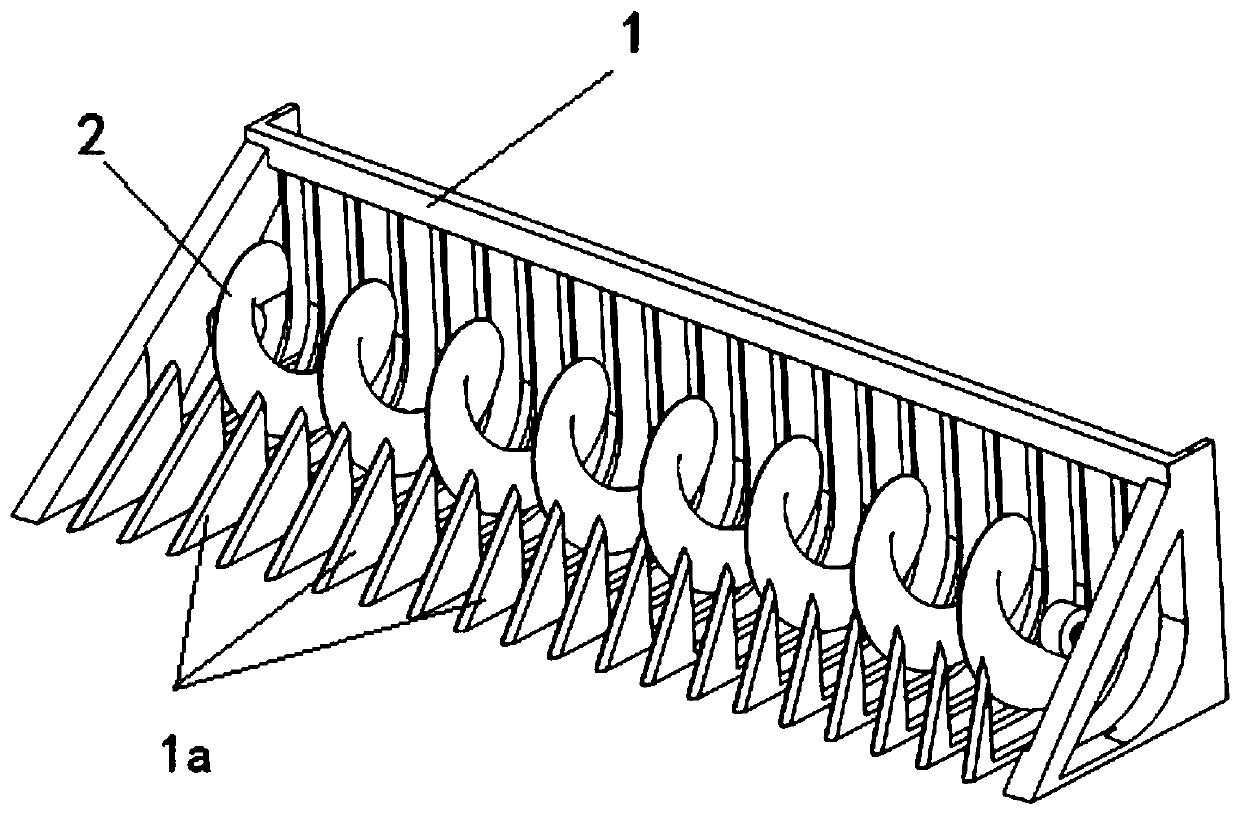

Sundries removing and grass separating, cutting and smashing integrated mower

ActiveCN109832008ADoes not affect backward movementStable separationMowersRenewable energy machinesResource savingEngineering

The invention relates to a sundries removing and grass separating, cutting and smashing integrated mower. A sundries separating and removing device is formed by transversely and uniformly arranging agroup of parallel separating sheets, a through hole is formed in the middle of each separating sheet, and the separating sheets are arranged in a transverse-spaced, equal-amplitude and gradual-shortening manner to form an oblique angle to push and discharge big sundries; after rotating, a spiral sundries removing device can laterally push medium sundries among spiral sheets to transversely penetrate the through holes to be discharged, and small sundries fall from space among the separating sheets; a mowing gap is formed between an upper conical rod and a lower conical rod of a grass separatingdevice; a cutter transversely moves along the mowing gap to cut off grass and sets aside the grass to one transverse side; an inlet is arranged in a tangential direction of moving directions of a grass smashing device and the cutter; the sundries separating and removing device, the spiral sundries removing device, the grass separating device, the cutter and the grass smashing device are fixed into a whole and fixedly connected with a screw connection frame which is assembled with a screw. The mower realizes integration of sundries removing and grass separating, cutting and smashing and is simple in process, convenient to operate and resource-saving.

Owner:SHANGHAI OCEAN UNIV

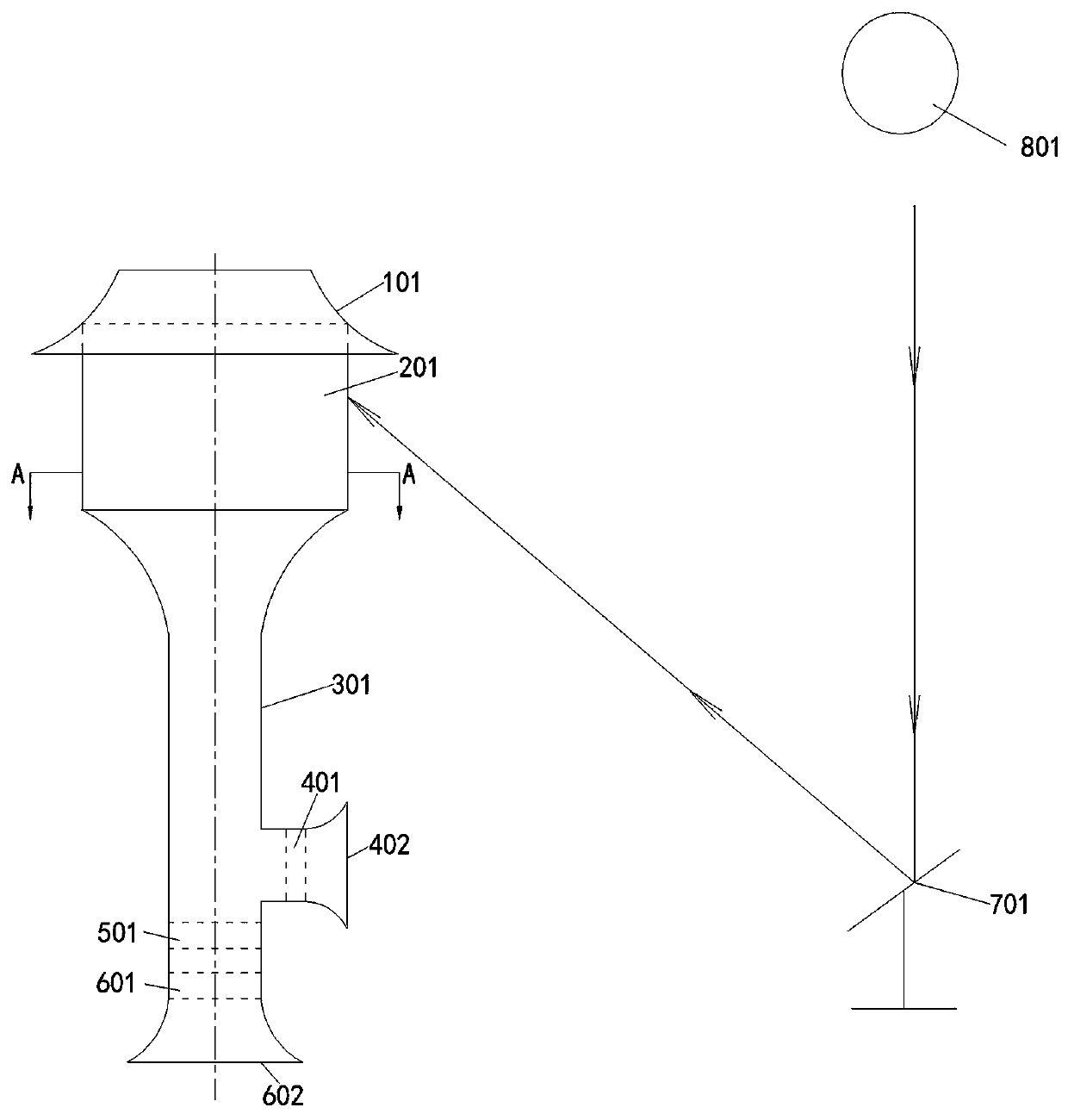

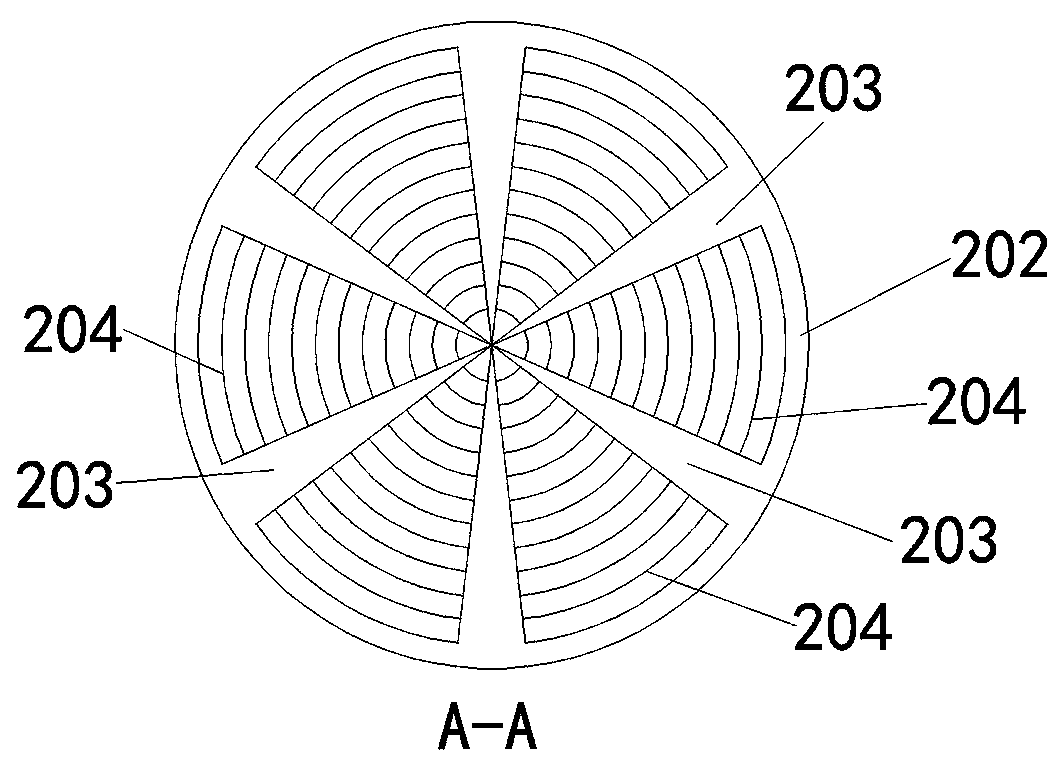

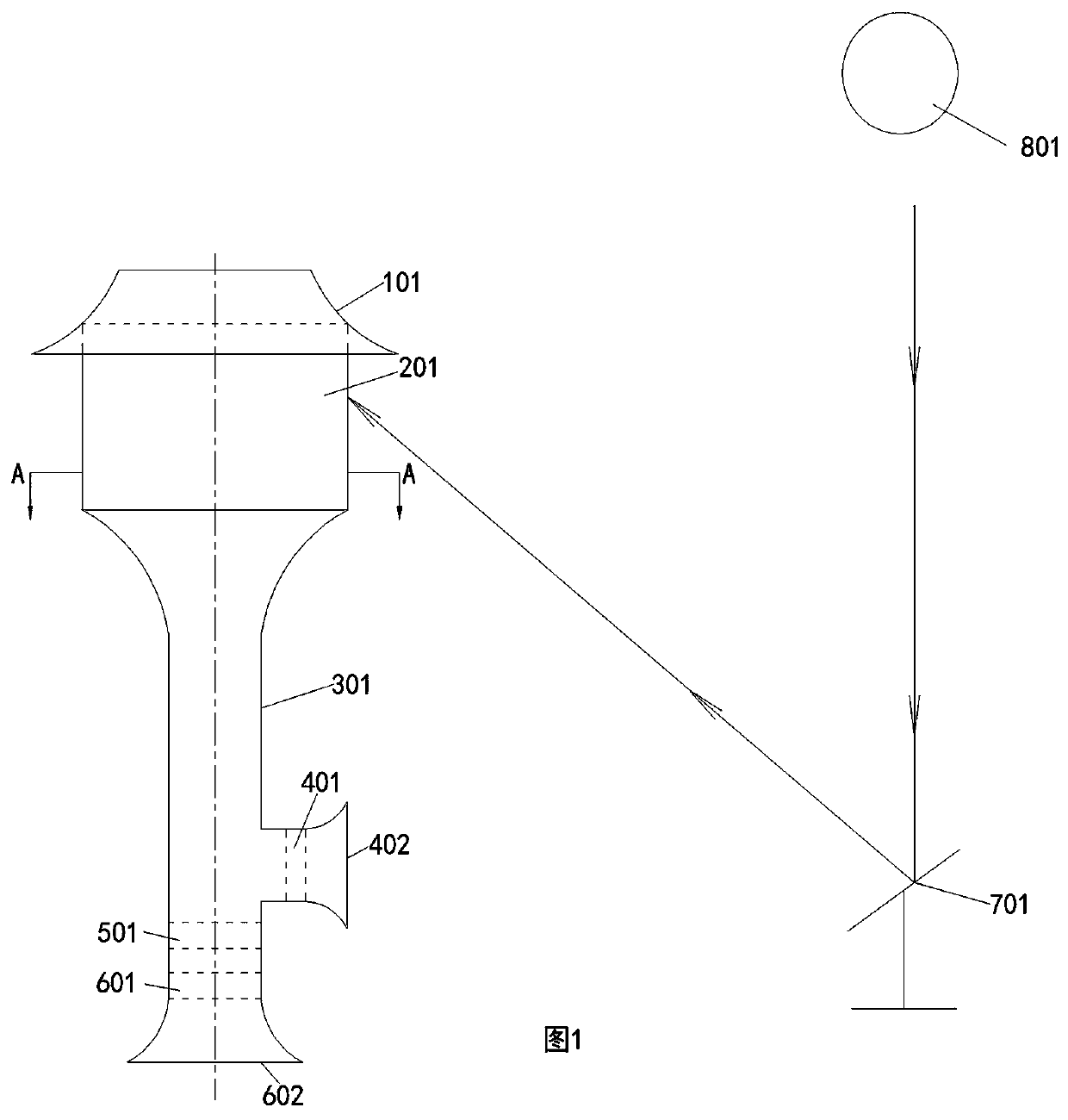

Solar heat collection power generation system

PendingCN111141037AImprove securityReduce material strengthSolar heating energyFrom solar energyHeat conductingLight reflection

The invention aims to provide a solar heat collection power generation system. Sunlight at different places is concentrated to a heat collection device through light reflecting mirrors, the heat collection device transfers heat to radiating fins through heat conducting columns, the radiating fins heat air, the air flows upwards after being heated, then a wind energy conversion device is installedon a track where the air flows to generate power, and an airflow flow adjusting device is installed on the track where the air flows to control the load of the solar heat collection power generation system.

Owner:GANSUWISDOMWINDENERGYCONSERVATIONLTD

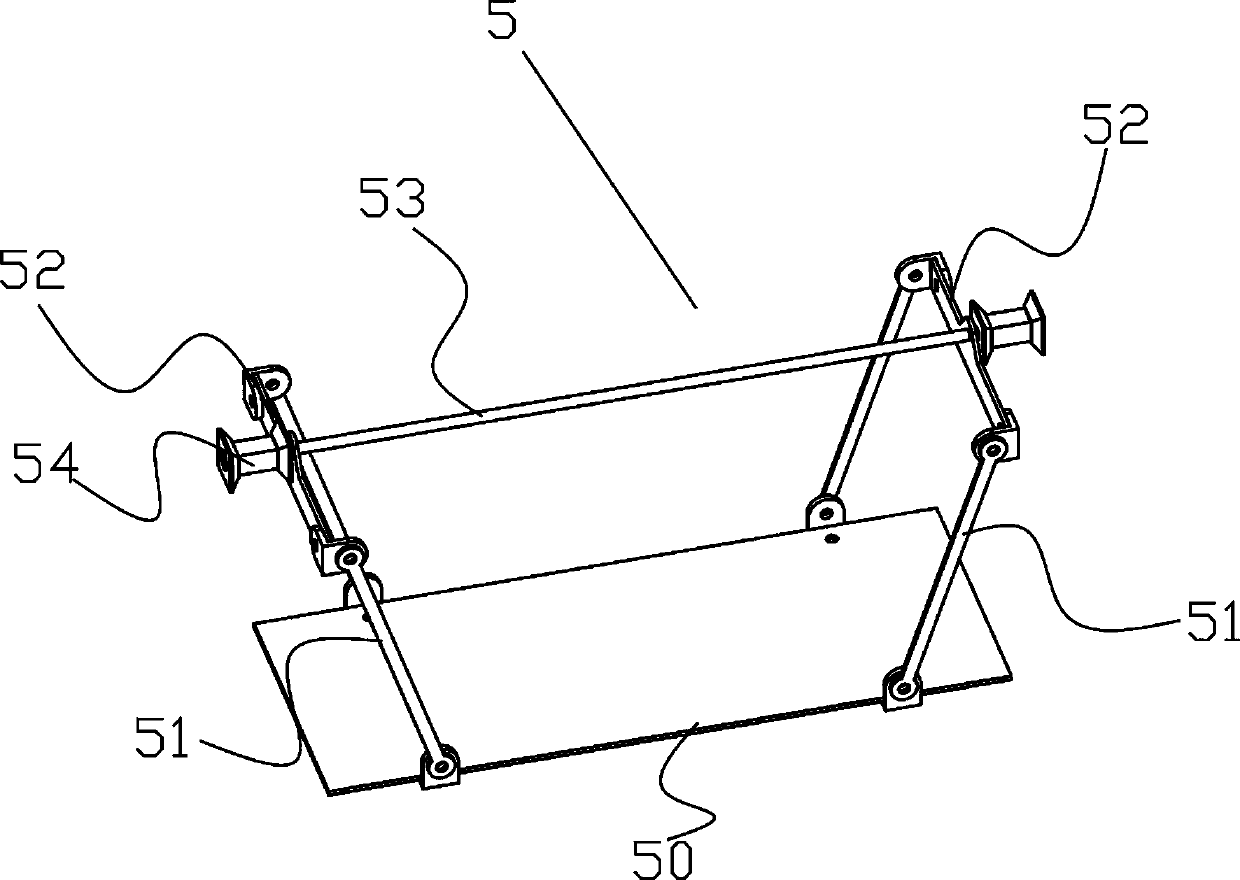

Three-dimensional parking device

The invention discloses a stereo parking device. The stereo parking device comprises a bracket, a plurality of sets of driving mechanisms arranged in the longitudinal direction of the bracket at intervals, rotating substrates driven by the driving mechanisms, handover clamping claws fixedly disposed at both ends of the rotating substrates and vehicle parking baskets fixed and transported by the handover clamping claws. The stereo parking device is small in size and realizes multi-layer parking of vehicles and layer-to-layer handover; and in addition, the clamping jaws of a handover structure of the stereo parking device do not require any control means, a purely mechanical structure is used for completion, the failure rate is reduced, vigorous popularization can be performed, and significant social benefits are achieved.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

Cutting blade that can be rotationally driven

InactiveUS9102072B2Increase stiffnessReduce weightMetal working apparatusKnife bladesBiomedical engineering

Owner:WEBER MASCHENBAU

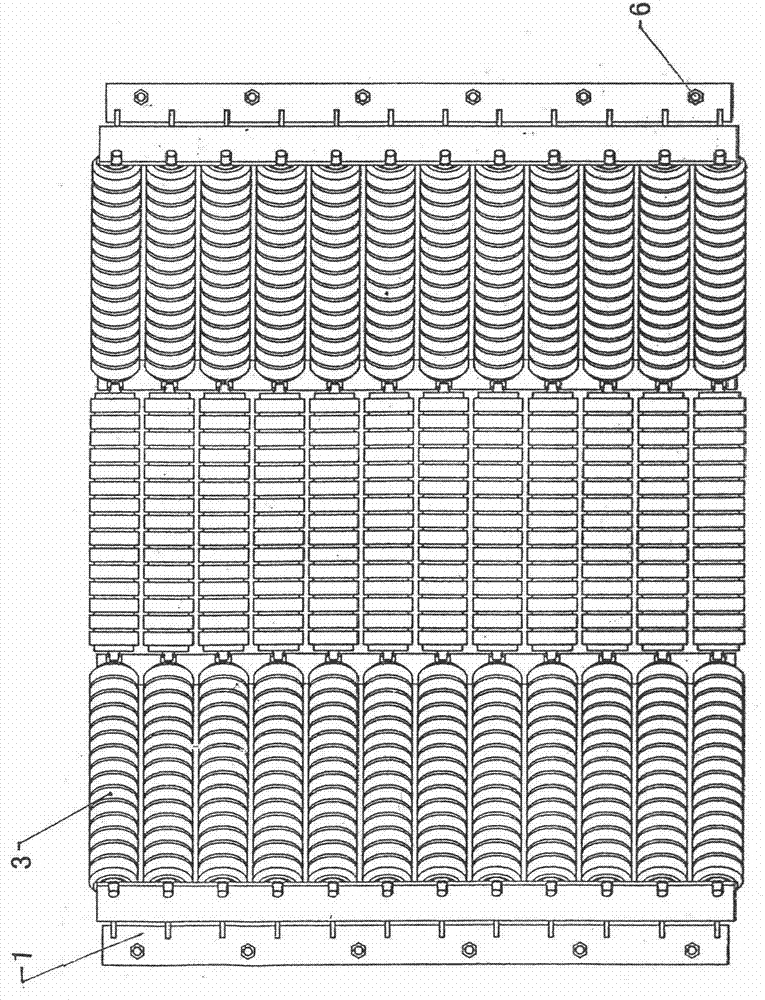

Nozzle module and cleaning device with nozzle module

ActiveCN103370146BSpeed up the flowReduce material strengthSpray nozzlesCleaning using liquidsNozzleEngineering

The invention relates to a nozzle module (2). The nozzle module (2) has a module body (4) with at least one nozzle chamber (6). The nozzle chamber (6) has at least one nozzle opening (10) for generating at least one fluid jet (56). The nozzle module contains means (39) for delivering pressurized fluid through a fluid channel (37) into at least one nozzle chamber (6). A device (39) for conveying pressurized fluid is connected to the module body (4). According to the invention, the device (39) for conveying fluid into at least one nozzle chamber (6) of the module body (4) has a hollow body (35). The hollow body (35) extends into the nozzle chamber (6). The hollow body (35) has at least one opening (41, 42) for fluid to flow into the nozzle chamber (6).

Owner:DUERR ECOCLEAN GMBH

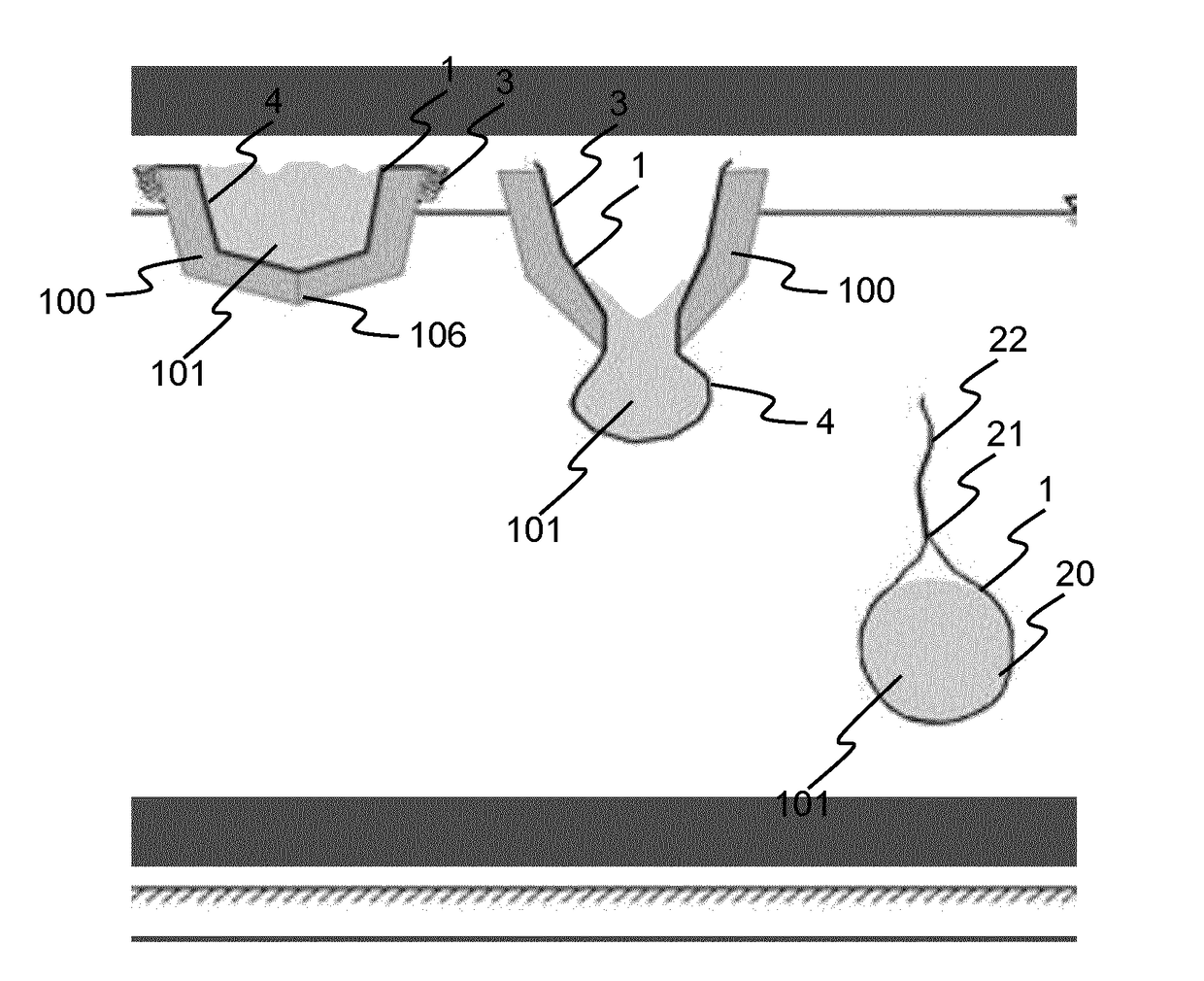

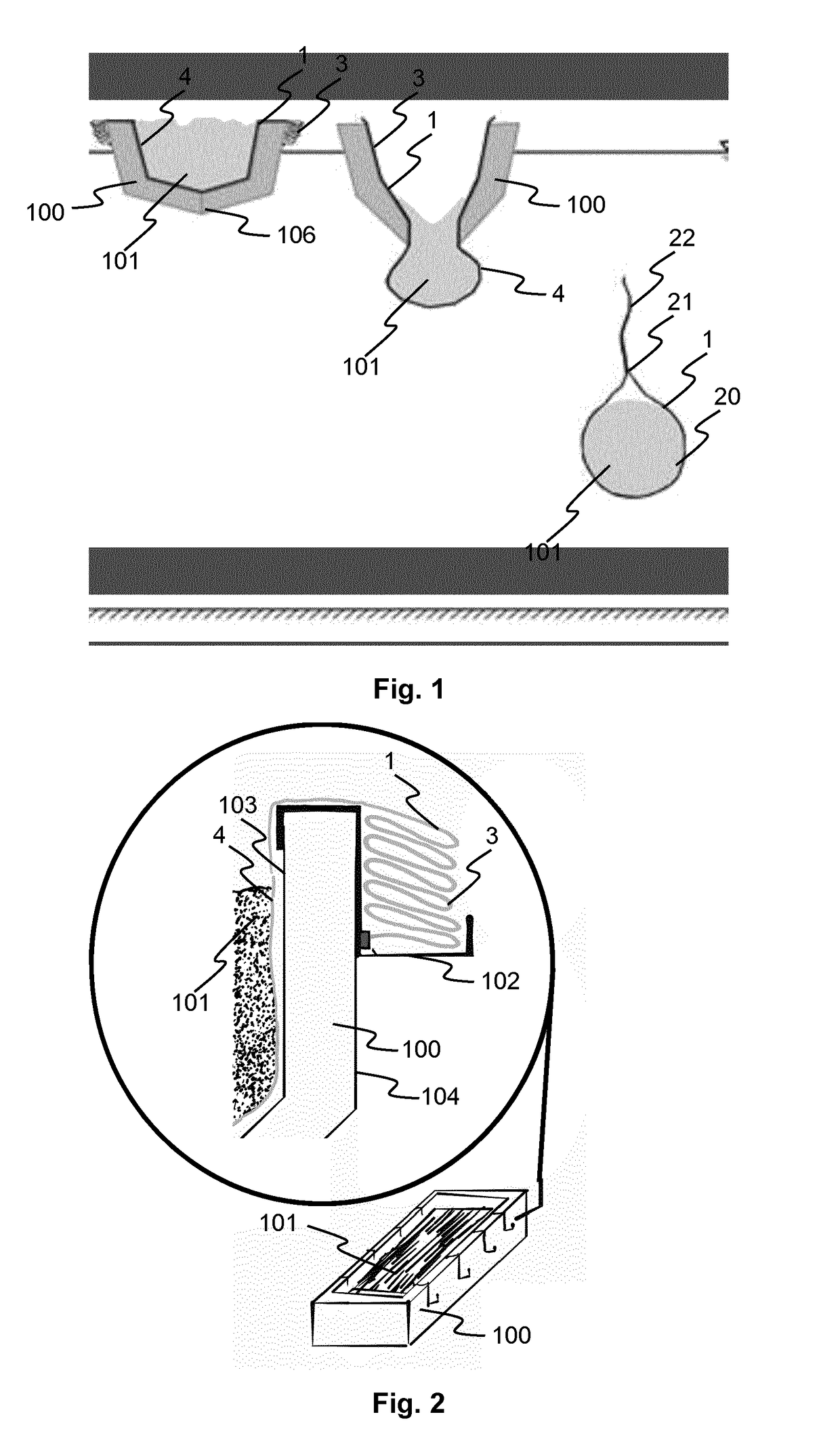

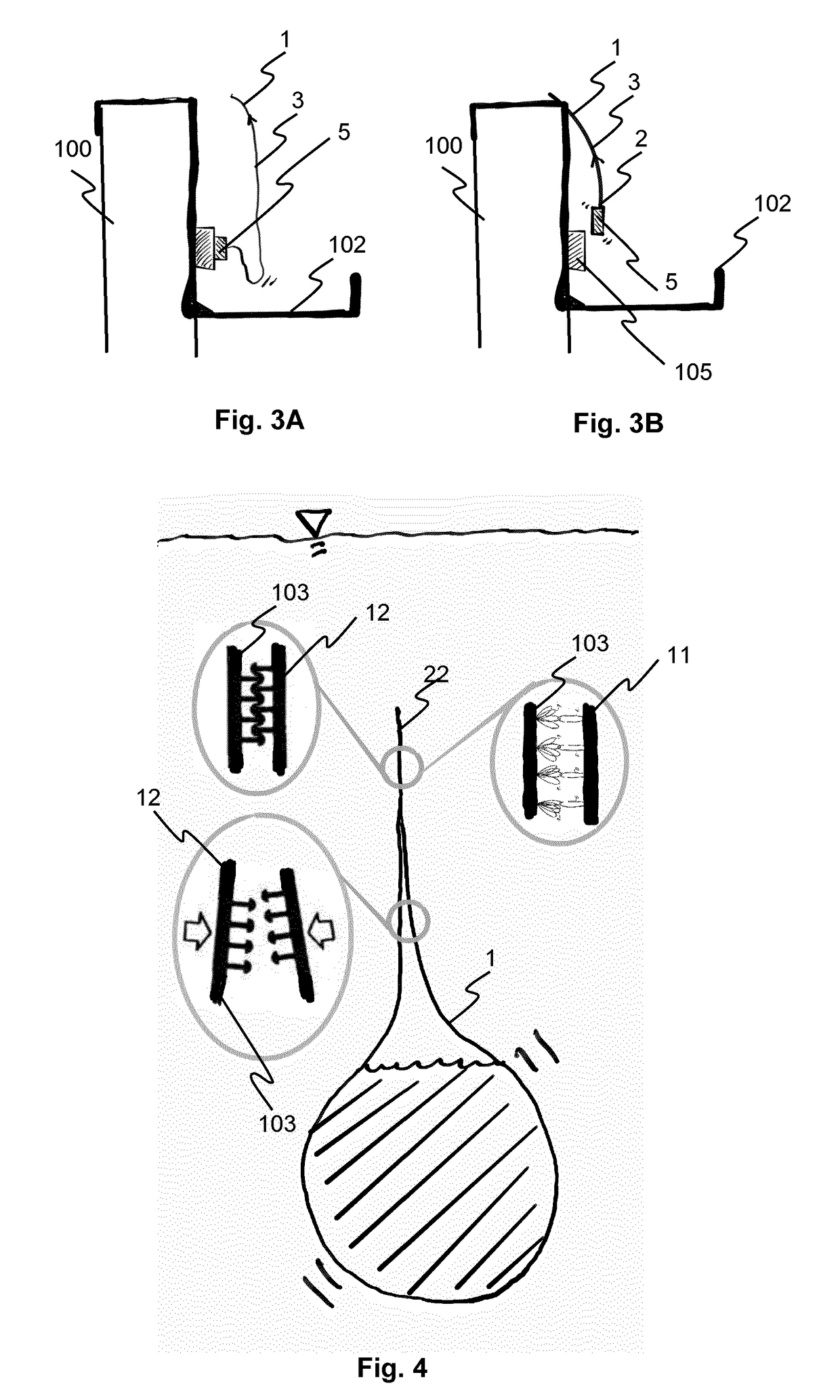

Self-closing sheet for encapsulating and dumping a bulk of material

InactiveUS20180208277A1Improve scalabilityReduce intensityWaterborne vesselsLarge containersEngineeringSheet material

The invention relates to a sheet (1) to be placed in relation to a split barge (100) for encapsulating a bulk of material (101) to be dumped when the bulk of material is released, the sheet comprising a material containing portion (4) and at least one material free portion (3) extending from at least two opposed sides of the material containing portion, wherein that the immersed sheet encapsulating the bulk of material comprises an encapsulated body (20) encapsulated by the material containing (4) portion and a self-closing portion (22) being at least a part of the material free portion (3) both extending from an assembly point (21), wherein a closing length of the self-closing portion (22) correspond to at least 5% of the circumventing length of the encapsulated body (20), the circumventing length extending from the assembly point (21) to the assembly point (21). The invention further relates to a method of encapsulating a bulk of material by means of a sheet.

Owner:DANMARKS TEKNISKE UNIV

Device for removing impurities from lubricating oil for internal combustion engines

ActiveCN106795784BReduce thicknessReduce weightMachines/enginesPressure lubricationEngineeringInternal combustion engine

The invention relates to a device (1) for removing impurities from the lubricating oil of an internal combustion engine, wherein the device (1) has a filter insert (2) at the bottom in the operating position of the device and a centrifuge (3) thereabove having a rotationally drivable rotor (30), wherein the filter insert (2) and the centrifuge (3) are arranged one above the other in a common two-part housing (4), which is closed during the operation of the device (1) and which has a removable upper closure cover (41) and a fixed lower housing part (42), wherein a removable intermediate cover (5) is arranged in the housing (4) between the filter insert (2) and the centrifuge (3), which intermediate cover is inserted in a sealing manner and separates a lower filter space (12), which is under the lubricating oil pressure during the operation of the device (1), from an unpressurized upper centrifuge space (11), wherein the intermediate cover (5) is supported radially outside on the closure cover (41) when the closure cover (41) is in the closed state, wherein a rotor shaft (33) rotatably supporting the rotor (30) is attached in or on the intermediate cover (5) by means of a lower end (35) of the rotor shaft and wherein the rotor (30), the intermediate cover (5) together with the rotor axis (33), and the filter insert (2) can be removed from the housing (4) when the closure cover (41) is in the open state. The device (1) according to the invention is characterized in that the closure cover (41) has a supporting surface at the center of the closure cover on the inside and that the rotor shaft (33) is supported axially on the closure cover (41) at the supporting surface by means of an upper end (36) of the rotor shaft when the closure cover (41) is in the closed state.

Owner:HENGST WALTER

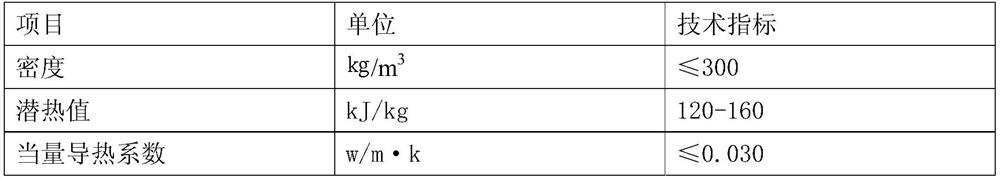

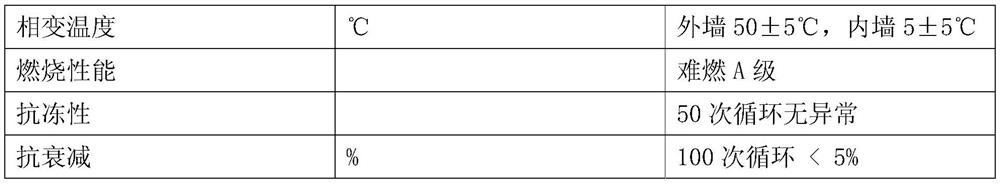

Heat-storage energy-saving sound-insulation building material

PendingCN112479739AReduce air pollutionGood controllabilityCeramicwareCitrate sodiumHydroxypropylmethyl cellulose

The invention relates to a heat-storage energy-saving sound-insulation building material, and the material is technically characterized by the following method which comprises the steps: mixing a certain amount of ceramsite, perlite, blast furnace slag, anhydrous gypsum, an antioxidant, anti-cracking fibers, a thixotropic agent, a solar energy storage material, sodium silicate, Wacker rubber powder, hydroxypropyl methyl cellulose, fly ash, sodium citrate, urotropine, redispersible latex powder, hydroxypropyl methyl cellulose, 206 organic silicon water repellent and polypropylene fiber, performing full and uniform mixing through cyclone separation, and after full and uniform mixing, performing packaging to obtain a finished product. When the heat-storage energy-saving sound-insulation building material is heated (a heat source such as sunlight), the building material reaches the saturation temperature and becomes a liquid phase, and heat energy is stored; when the external temperature is lower than the set temperature, the phase-change heat storage material starts to release heat, the phase-change material is changed into a solid phase from a liquid phase after heat release is completed, and circulation is conducted in cycles. The composite material can be made into profiles, plates, mortar and porous bricks, can absorb sound waves, has elasticity, generates tremble, rebound andreverse absorption under the impact of the sound waves, and is converted into different frequencies, so that the structural vibration is reduced, and the purpose of noise elimination is achieved.

Owner:刘丽荣

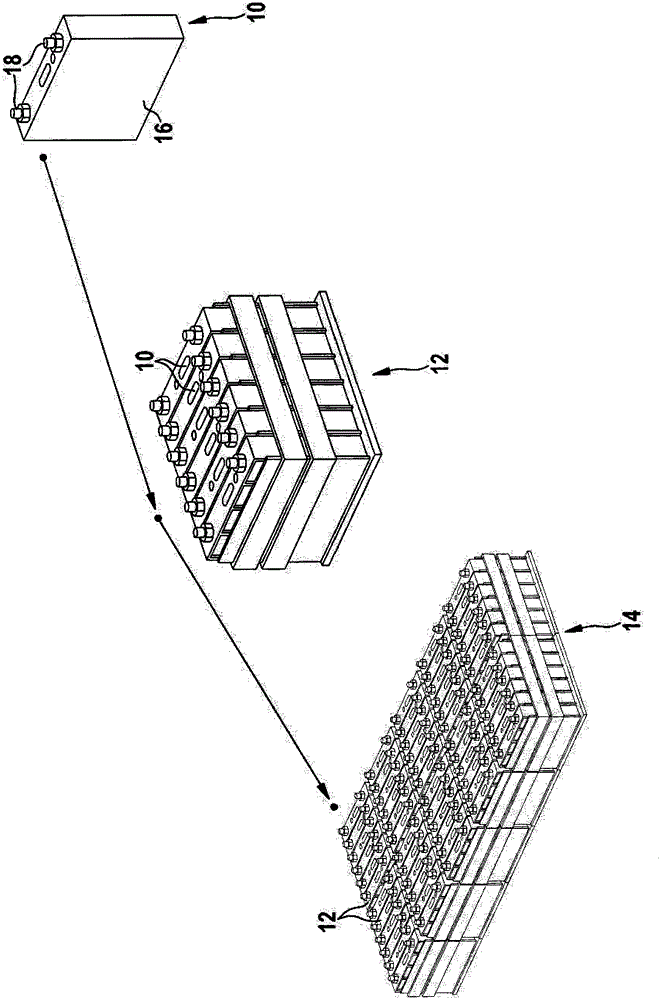

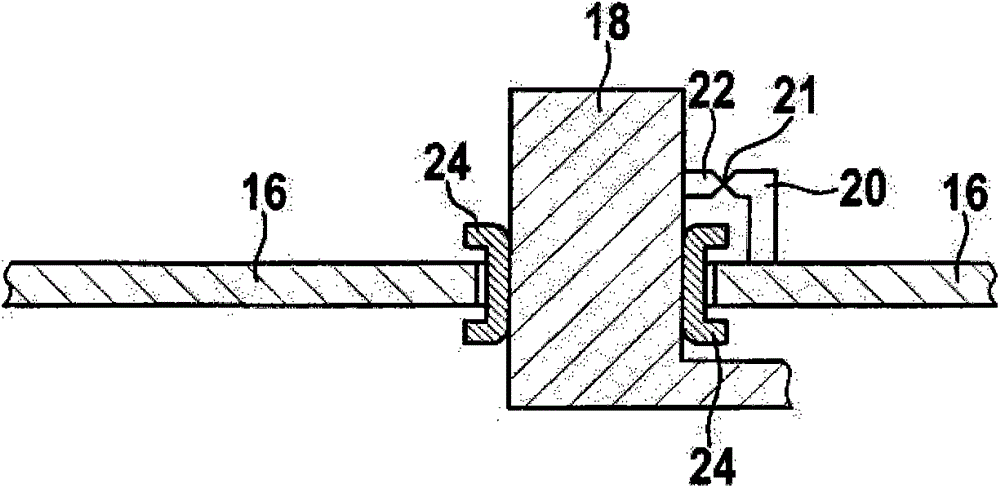

Battery cell, battery and motor vehicle

InactiveCN104115310AAvoid corrosionReduced risk of short circuitsElectric connector introductionBatteriesPre stressPre stressing

A battery cell (10) is provided which comprises two electrodes (18) and a battery cell housing (16). A characteristic feature consists in that one of the two electrodes (18) is electrically conductively connected to the battery cell housing (16) via a desired breaking point (21). The component part forming the desired breaking point (21) is pre-stressed such that, when the desired breaking point (21) is broken, a gap forms between the broken edges of the desired breaking point (21) as a result of the pre-stressed component part springing back elastically. In addition, a battery (14) with a plurality of battery cells (10) according to the invention and a motor vehicle with the battery (14) according to the invention are provided.

Owner:ROBERT BOSCH GMBH +1

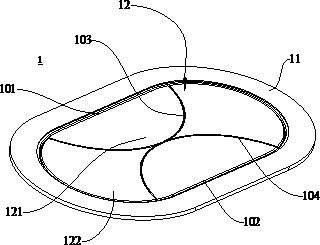

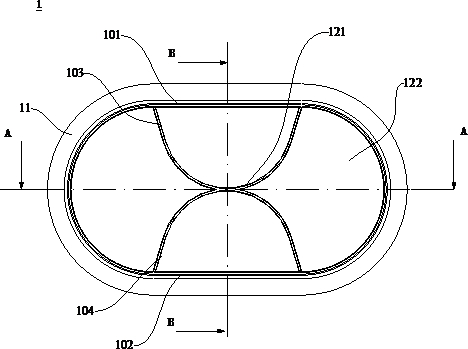

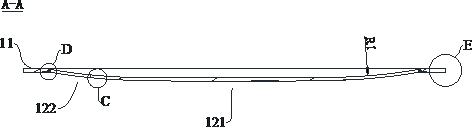

Explosion-proof valves for batteries, batteries and battery modules

ActiveCN112382826BLow costReduce thicknessCell component detailsStructural engineeringMechanical engineering

The application discloses an explosion-proof valve for electric cores, electric cores and battery modules. The explosion-proof valve includes: a base, the base is ring-shaped and suitable for being fixed on the cover plate of the electric core; The valve plate is fixedly connected to the inner periphery of the base and protrudes outward; wherein, the thickness of the base is greater than that of the valve plate. The explosion-proof valve according to the present invention has a valve plate and a base, the thickness of the valve plate is smaller than the thickness of the base, the valve plate has a first section line extending in the length direction, and the thickness direction of the valve plate is at the first section line. The upper section is an arc section, the radius of the arc section is R1, and the R1 satisfies: 50mm≤R1≤200mm, the valve plate can be broken in time after the pressure of the battery cell reaches the preset value, and the reaction speed is fast , good safety performance, the cross-section of the valve plate in the thickness direction is arc-shaped, which improves the pressure resistance of the valve plate and reduces the manufacturing cost of the valve plate.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

Transport and storage container for liquids

ActiveCN101508378BReduce material strengthReduce net weightLarge containersMaterials scienceMetal grating

The container (1) has an inner container (2) made of plastic, and an outer casing made of metal grating or sheet metal. A base frame (17) is made of plastic and formed with a runner pallet (18) or a frame pallet. The base(21) is made of plastic and formed as an injection molded part. The base has a longitudinal corrugation and a transverse corrugation that are provided for reinforcing the base(21) and as a support for the inner container(2).

Owner:PROTECHNA SA

Battery cells, batteries and motor vehicles

InactiveCN104115310BAvoid corrosionReduced risk of short circuitsCell component detailsBatteriesPre stressPre stressing

The invention relates to a battery cell (10) comprising two electrodes (18) and a battery cell housing (16). It is characterized in that one of the two electrodes (18) is electrically conductively connected to the battery cell housing (16) via a predetermined breaking point. The member forming the predetermined breaking point (21) is prestressed in such a way that when the predetermined breaking point (21) breaks, due to the elastic rebound of the prestressed member there will be A gap is formed between the broken edges. Furthermore, the invention proposes a battery (4) having a plurality of battery cells (10) according to the invention and a motor vehicle having a battery (14) according to the invention.

Owner:ROBERT BOSCH GMBH +1

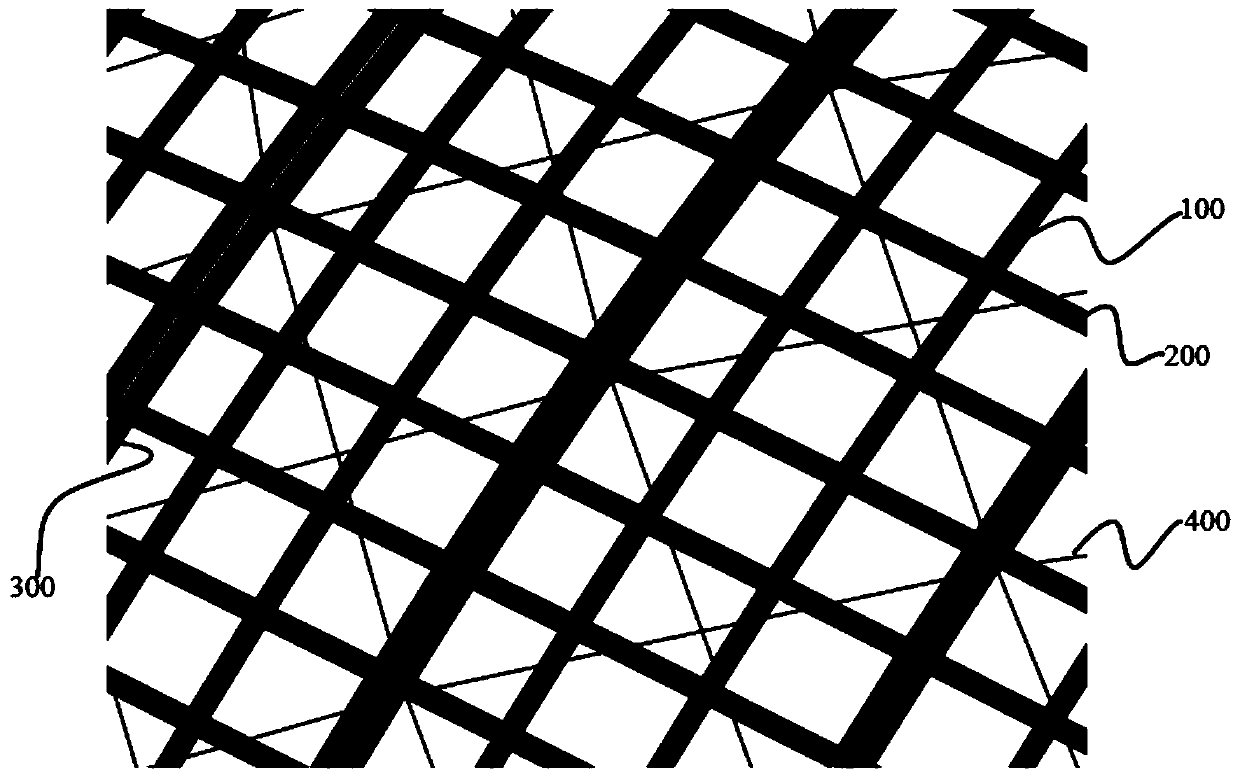

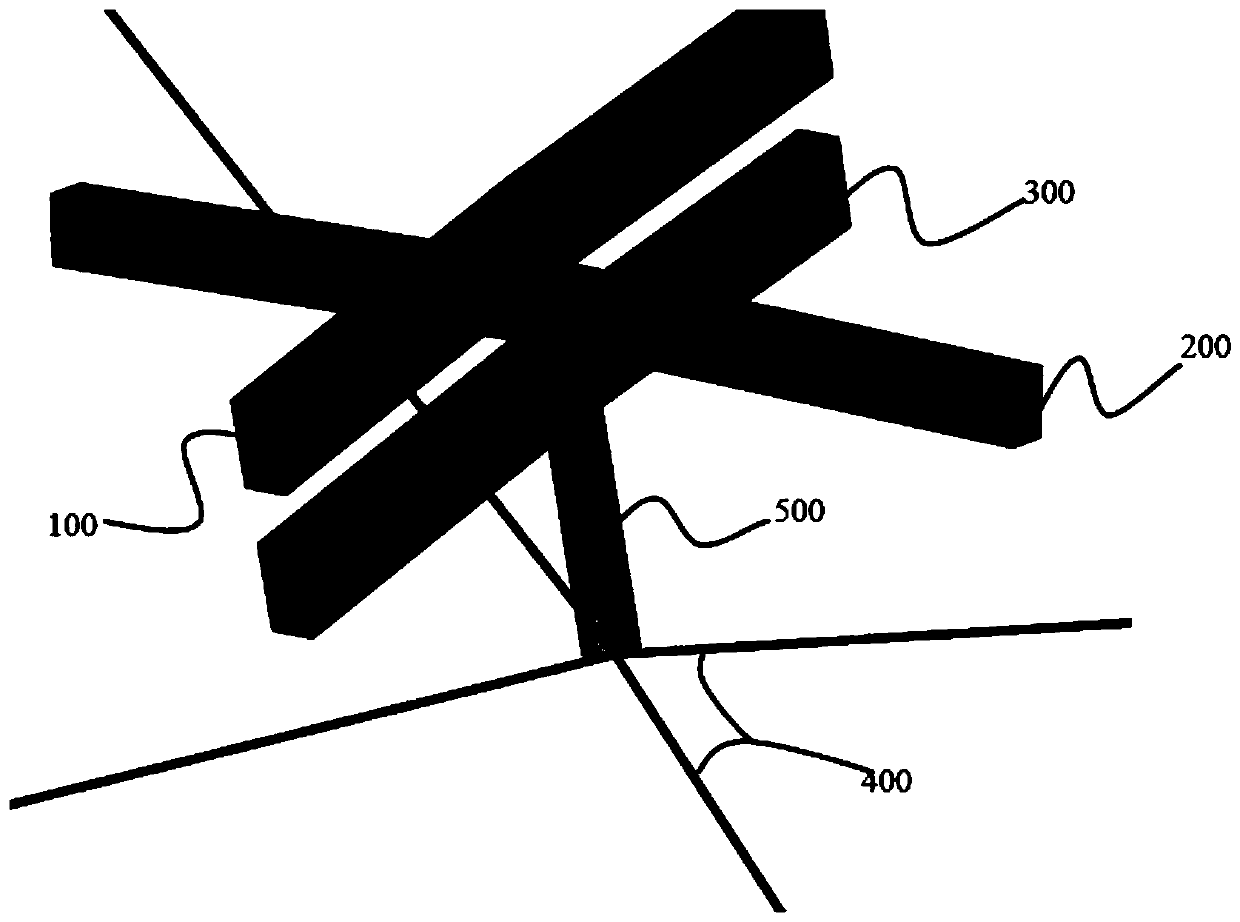

Laminated wood latticed shell structure

PendingCN111236431ALarge spanEasy to useArched structuresVaulted structuresStructural engineeringPulp and paper industry

The invention discloses a laminated wood latticed shell structure. A first overlap layer is formed by first laminated wood beams, a second overlap layer is formed by second laminated wood beams, thenthe first overlap layer is placed on the second overlap layer, and the first laminated wood beams and the second laminated wood beams are connected and fixed through high-strength screw set connectingparts arranged in order. In order to further improve the overall rigidity of the laminated wood latticed shell structure, reinforced laminated wood beams are arranged below the second laminated woodbeams in a manner of being aligned to the first laminated wood beams. Due to the fact that the wood beams are not on the same arc face, the wood beams are continuously connected in the connecting joint area, that is, each first laminated wood beam, each second laminated wood beam and each reinforced laminated wood beam are all intact in the extending direction and do not need to be broken in the connecting joint area. The problems that in the prior art, connecting of laminated wood beams is difficult in joint areas, rigidity is insufficient, steel plates are inserted internally to weaken the strength of the connecting joint area of the laminated wood beams, and the construction effect is poor after connecting parts are exposed by the joint area are solved.

Owner:SHANGHAI ARCHITECTURAL DESIGN & RES INST

Ventilation valve for a vehicle

InactiveCN110030416ANo impact noiseNo audible impact noiseAir-treating devicesVehicle heating/cooling devicesEngineeringMechanical engineering

Owner:ILLINOIS TOOL WORKS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com