Rolling type buffer bed

An impact bed, rolling technology, applied in the field of impact bed, can solve the problems of increased energy consumption, increased overall cost, belt conveyor resistance, etc., to achieve the effects of small resistance, reduced material strength, and reduced overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

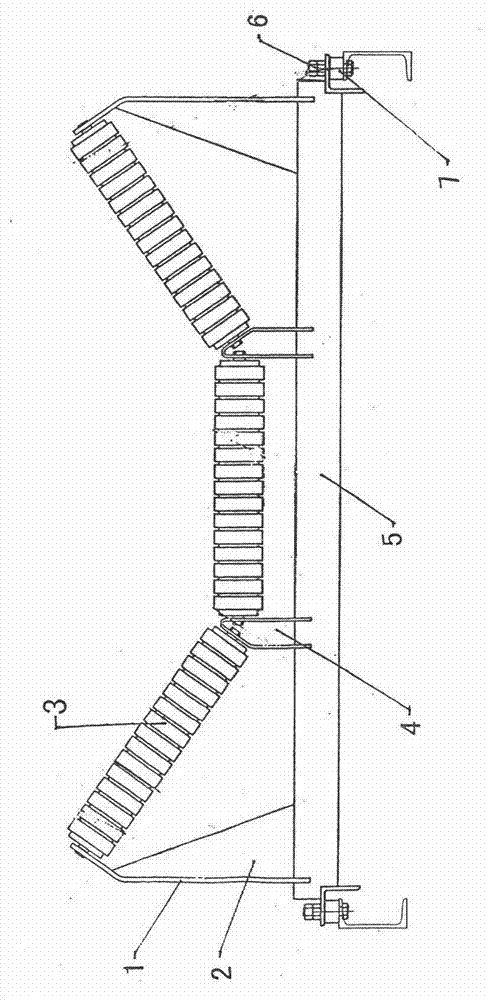

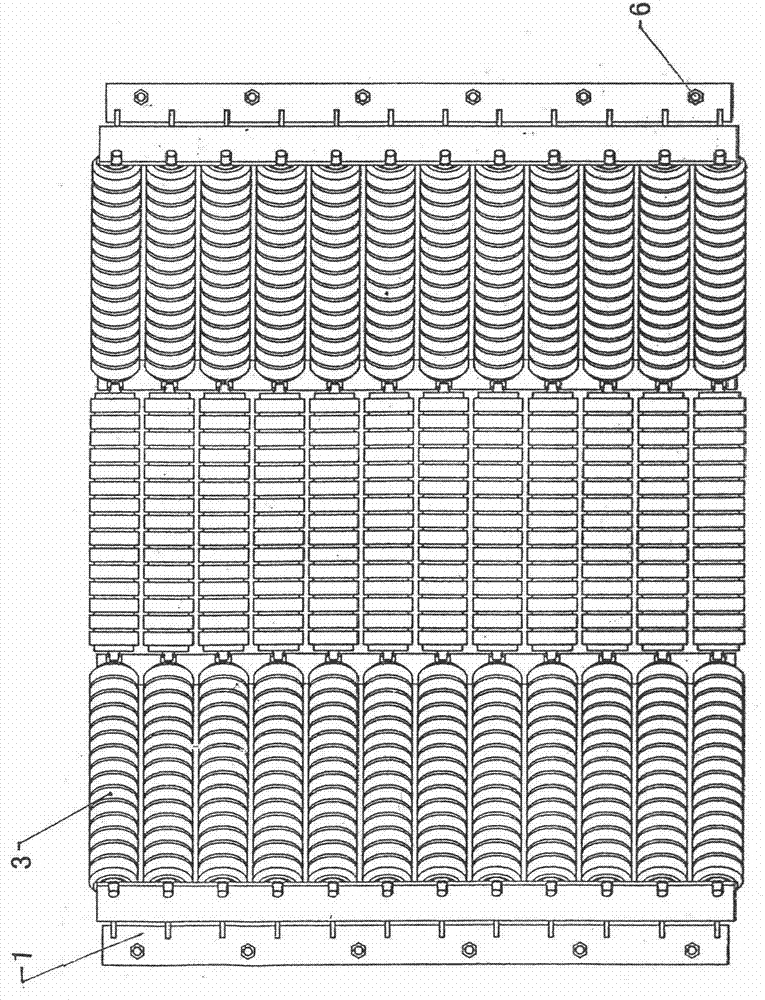

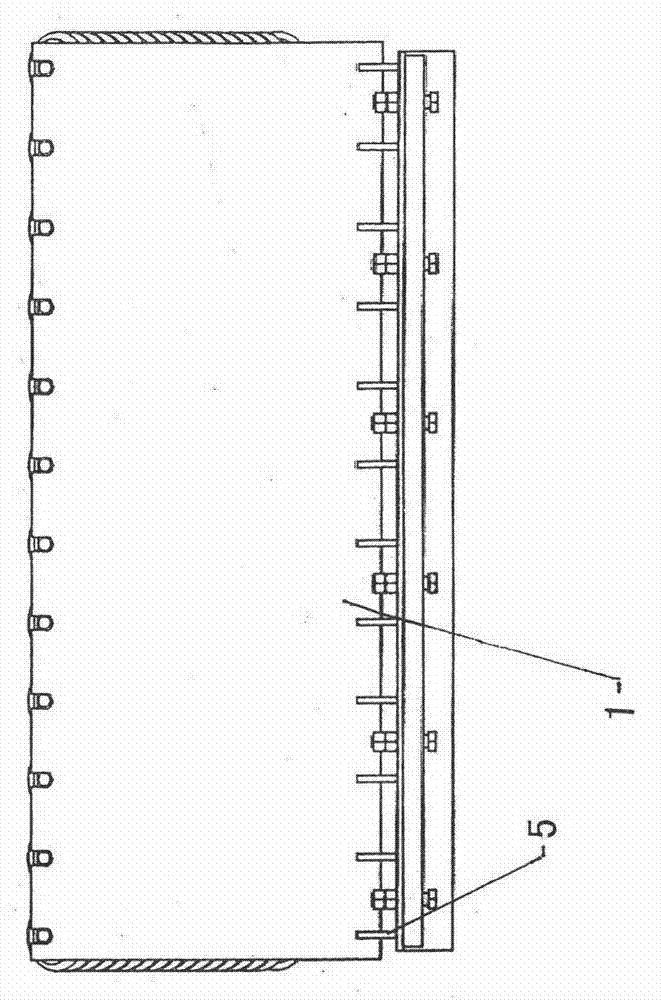

[0013] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0014] As shown in the accompanying drawings, the rolling impact bed includes a side support 1, a rib plate 2, a buffer roller 3, a middle support 4, a bed 5, a bolt group 6 and a buffer pad 7, and the bolt group 6 It is usually composed of bolts and gaskets (rings), known technology, and the bed 5 is an integral body made of neatly arranged steel plates with a quantity greater than 1 and angle steel welded at both ends of the steel plate, which ensures the stability of the rolling impact bed. The two ends of the bed 5 are connected with the legs through the bolt group 6 and the buffer pad 7, wherein the buffer pad 7 is made of rubber material and has an elastic function. The two ends of the upper surface of the bed 5 are symmetrically fixed with side brackets 1, the heights of each side bracket 1 are the same, and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com