Device for removing impurities from the lubricating oil of an internal combustion engine

A technology of internal combustion engine and lubricating oil, which is applied in the direction of engine lubrication, pressure lubricant, mechanical equipment, etc., can solve the problems of interference noise and efficiency reduction, and achieve the effect of small material thickness and simplified manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

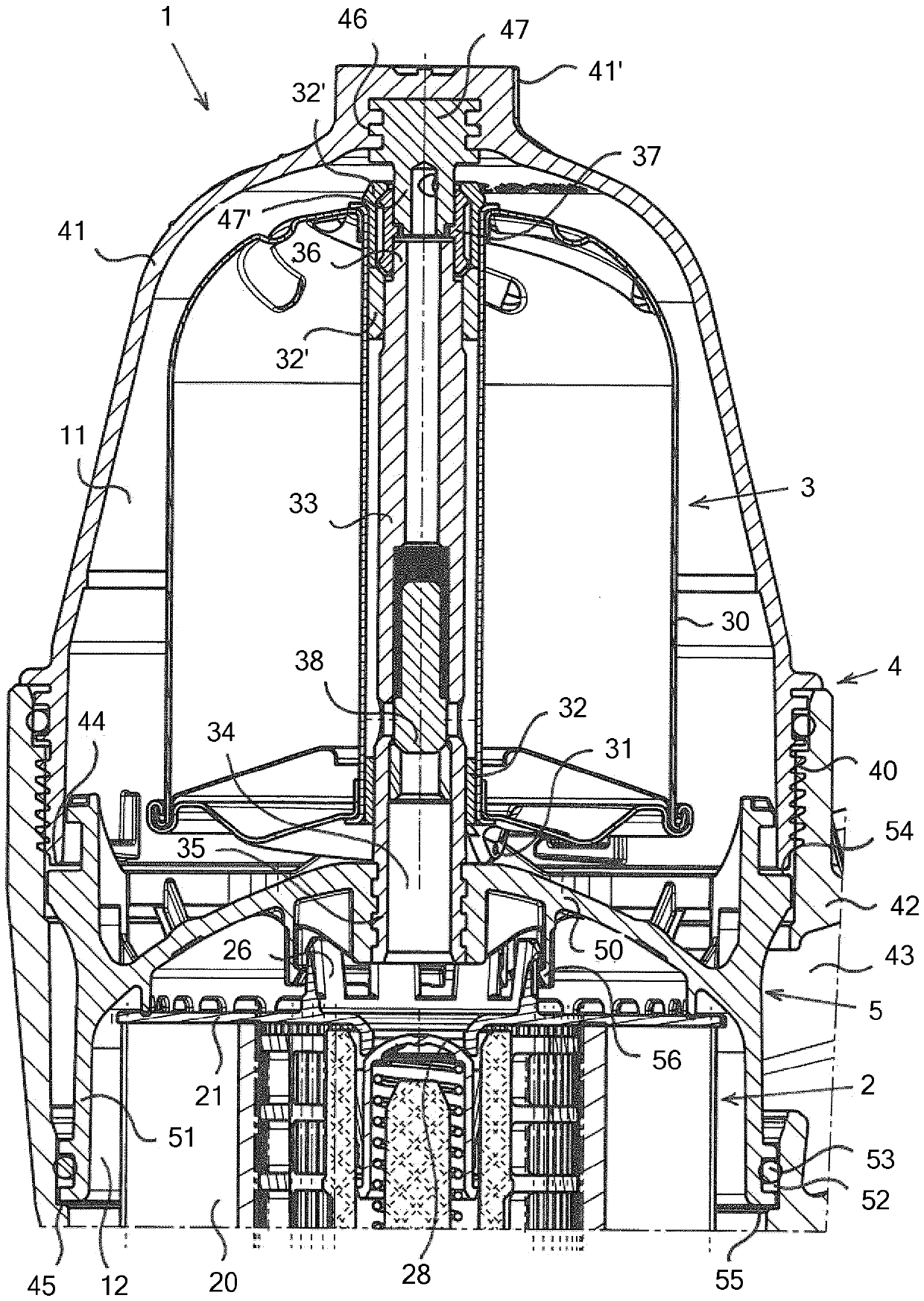

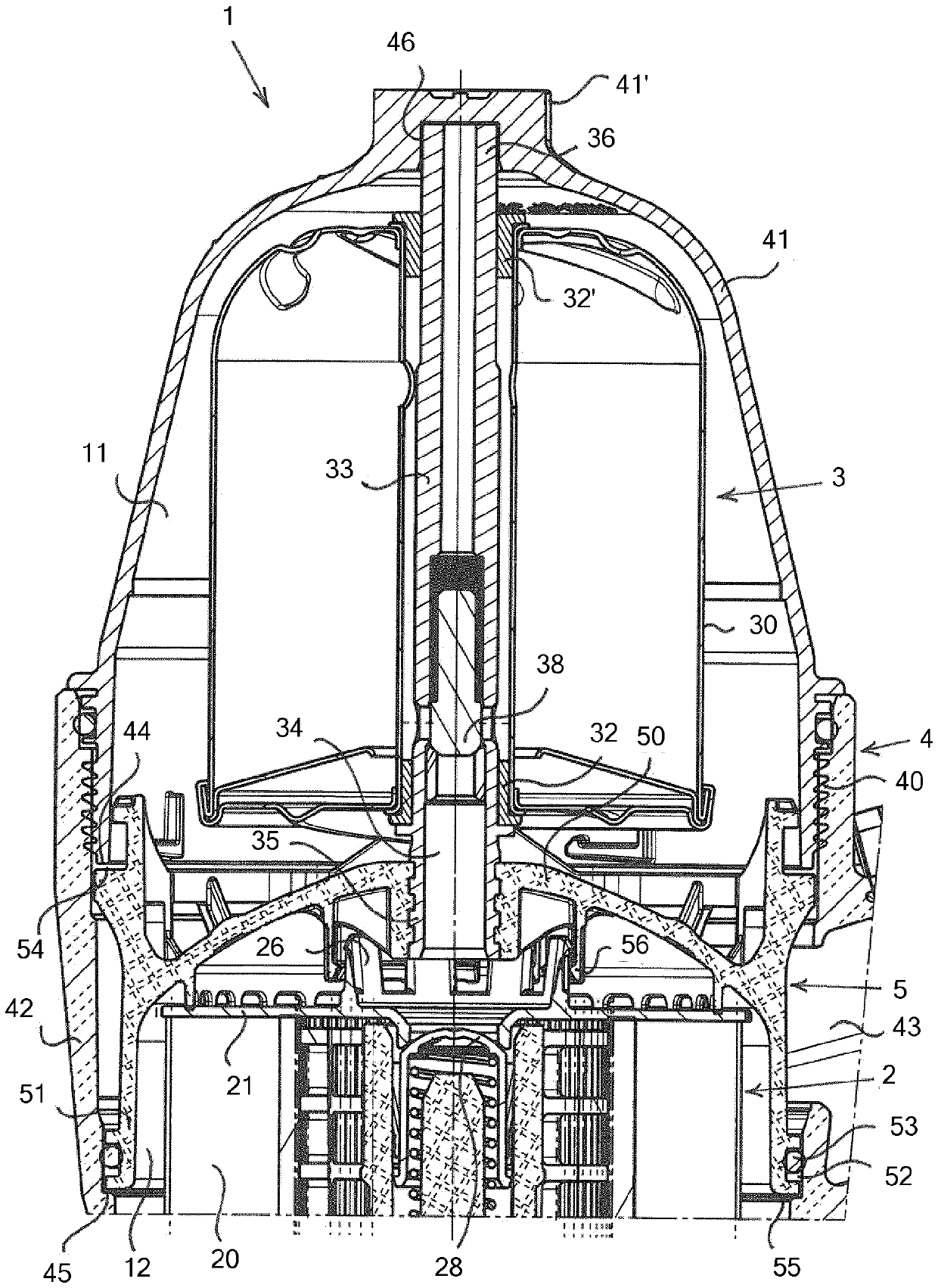

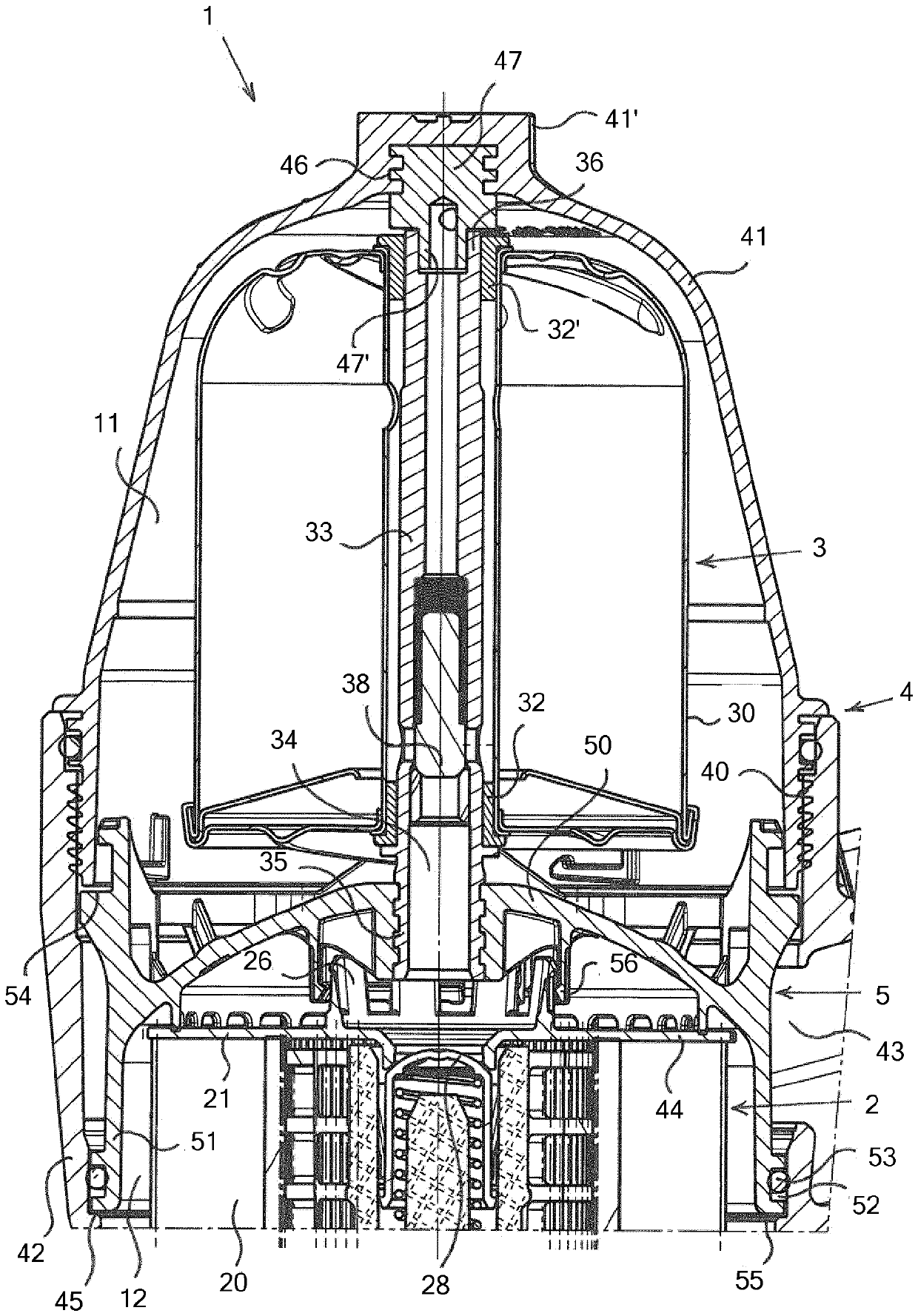

[0025] In the following description of the figures, identical parts are always provided with the same reference numerals, so that for each figure it is not necessary to explain all reference numerals which appear therein anew.

[0026] Attached figure 1 The device 1 for removing impurities from lubricating oil of an internal combustion engine in a first embodiment is shown in longitudinal section.

[0027] The device 1 has a housing 4 which is formed from a fixed lower housing part 42 , only partially shown here, and an upper, arranged cover 41 detachably connected thereto.

[0028] The cover 41 is designed here as a screw cap, which can be screwed and unscrewed by means of a screw thread 40 to a fixed lower housing part 42 . Externally, the cover 41 has at its central upper region a hexagon 41' which is used to place a tightening tool (for example a wrench) when the cover 41 is screwed or unscrewed.

[0029] In the housing 4 one above the other, the filter insert 2 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com