Battery cell, battery and motor vehicle

A battery and single cell technology, applied in batteries, battery pack components, battery boxes/jackets, etc., can solve safety risks and other issues, and achieve the effect of preventing corrosion and reducing the risk of short circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

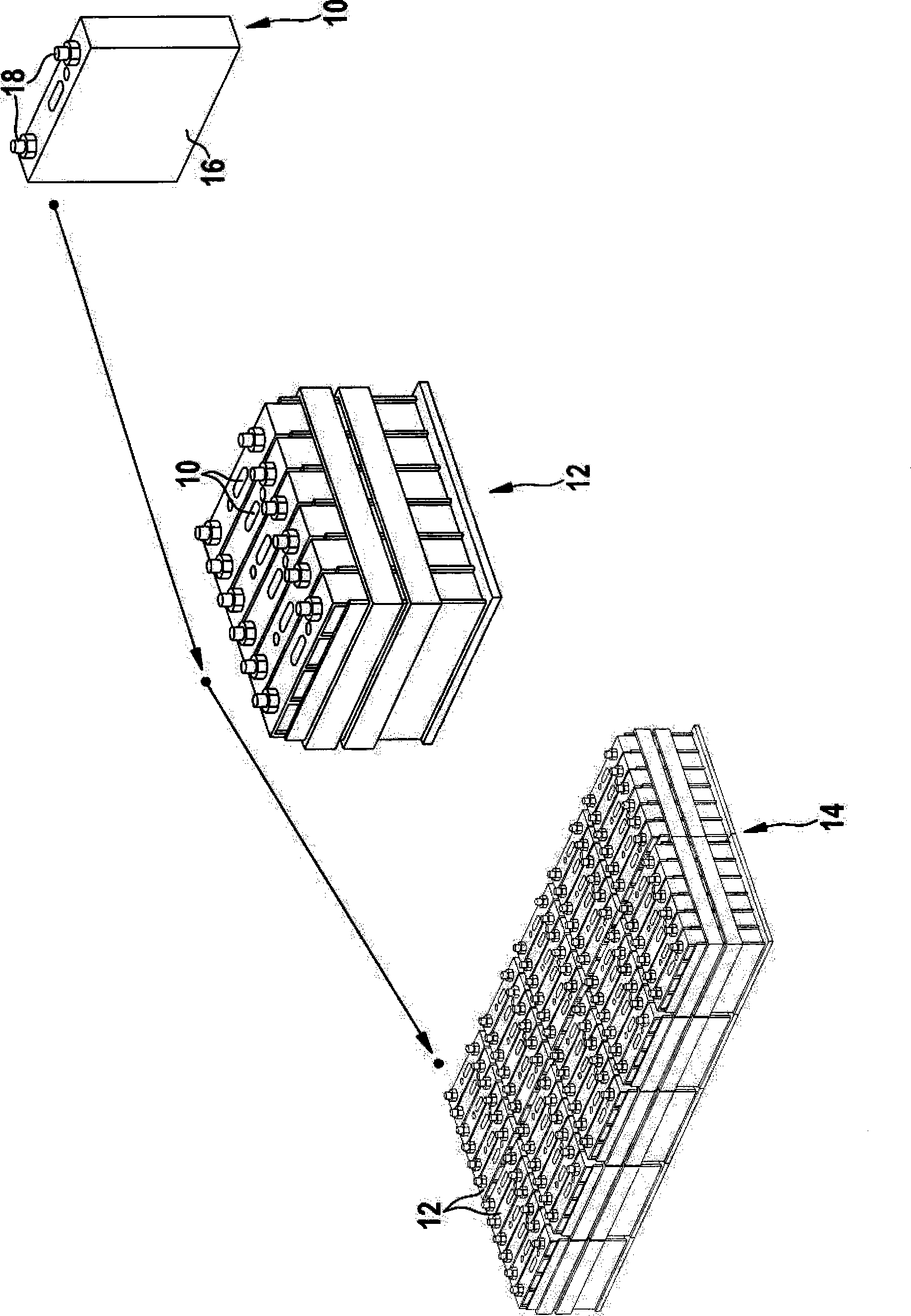

[0023] exist figure 1 The prior art has been described in .

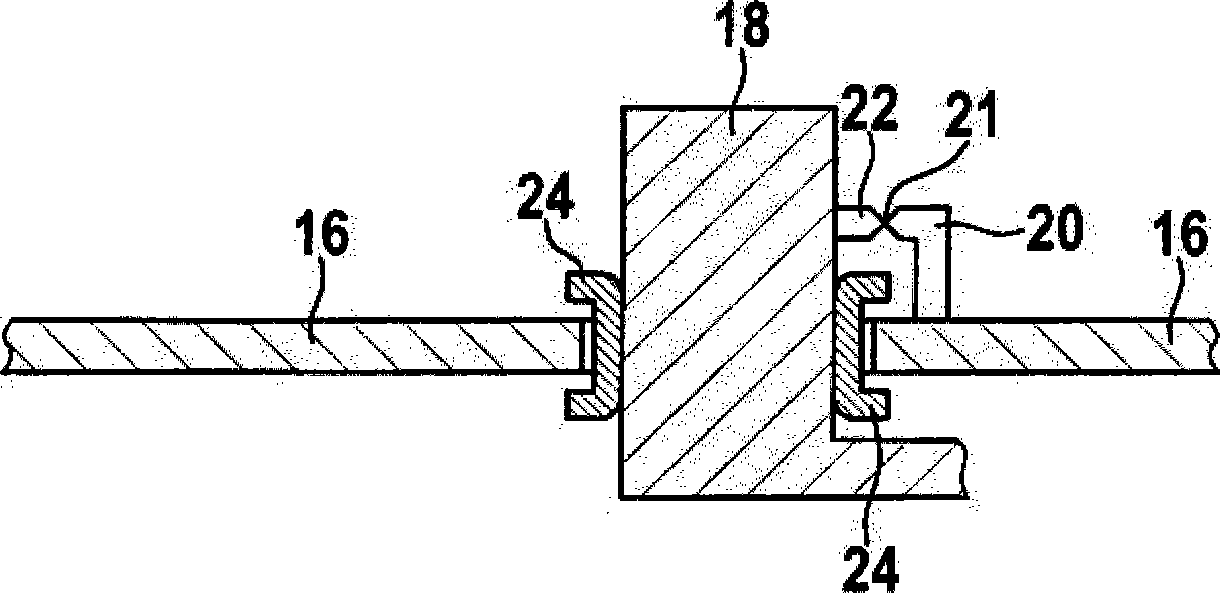

[0024] figure 2 A partial section through a battery cell 10 according to the invention is shown. An electrode 18 (battery pole), usually a negative electrode, is drawn from the interior of the battery cell 10 via the battery cell case 16 . In the lead-off region, the electrodes 18 are electrically isolated from the battery cell housing 16 by an electrical insulator 24 . An electrically conductive connection can be made on the outside of the battery cell housing 16 via the legs 20 and the pins 22 , the intended breaking point 21 being located in the transition region thereof. Such as figure 2 As shown, the predetermined breaking point 21 is not broken, so that current can flow between the electrode 18 and the battery cell housing 16 .

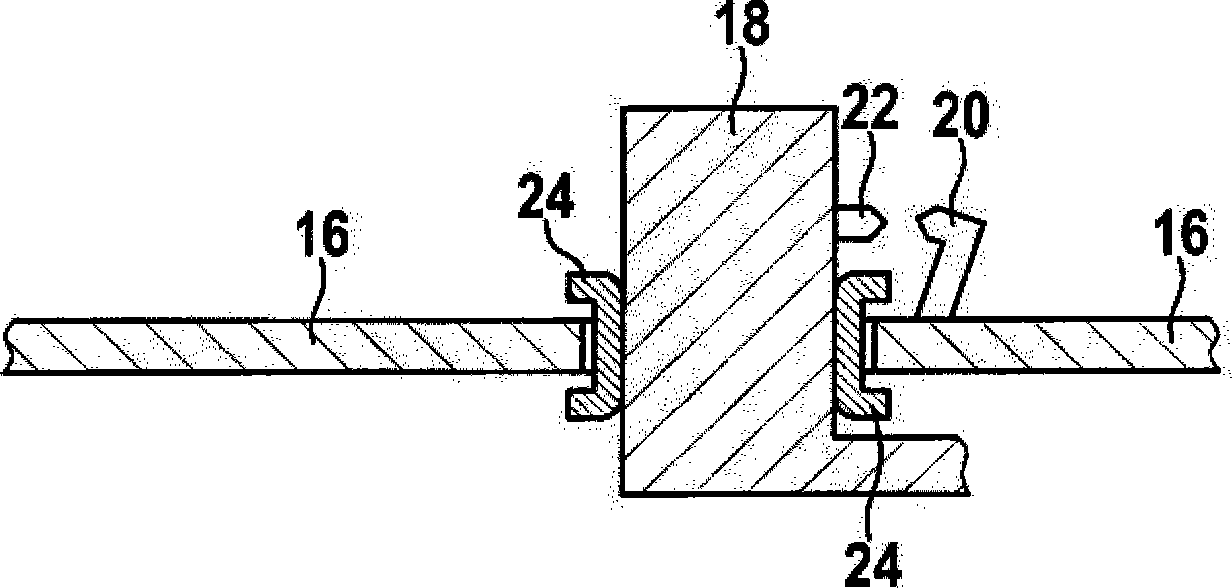

[0025] image 3 A cross-sectional view of the same part of the battery cell 10 according to the invention is shown, but with the intended breaking point 21 broken so as to sep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com