Novel large-span repairable fabricated joint and fabricated method

An assembly method and a large-span technology, applied to building components, arch structures, dome structures, etc., can solve the problems of difficult to achieve standardized construction and mass production, poor bending resistance of bolt ball joints, complex installation and processing processes, etc. problems, to achieve the effect of improving the scope of application, improving the construction quality, and good ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

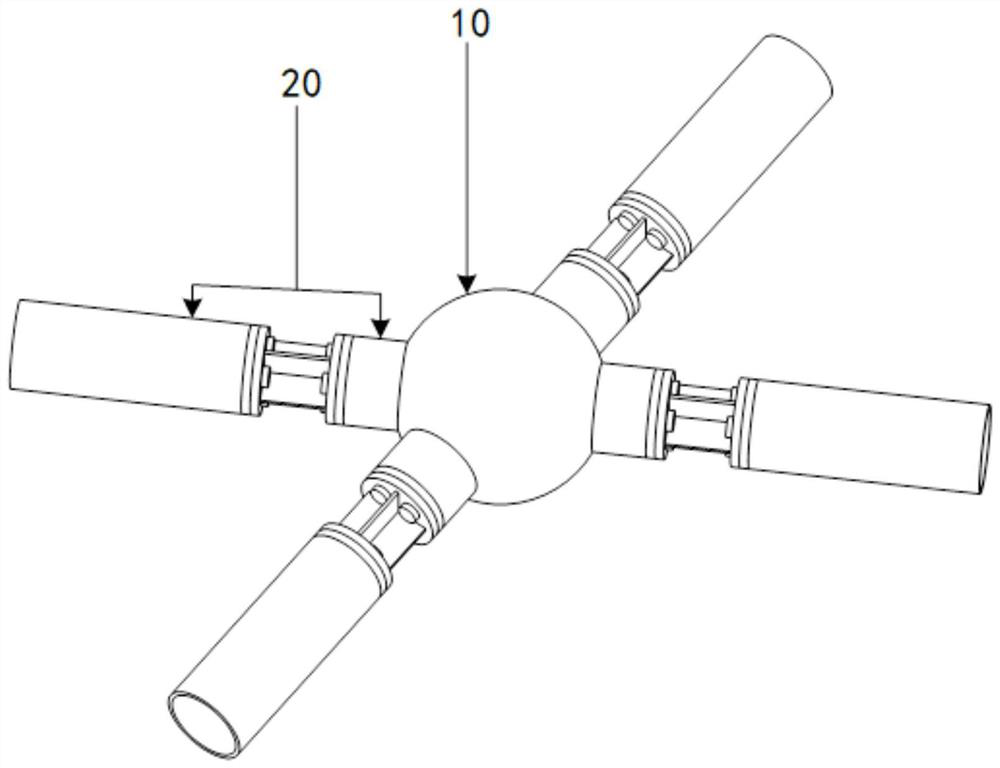

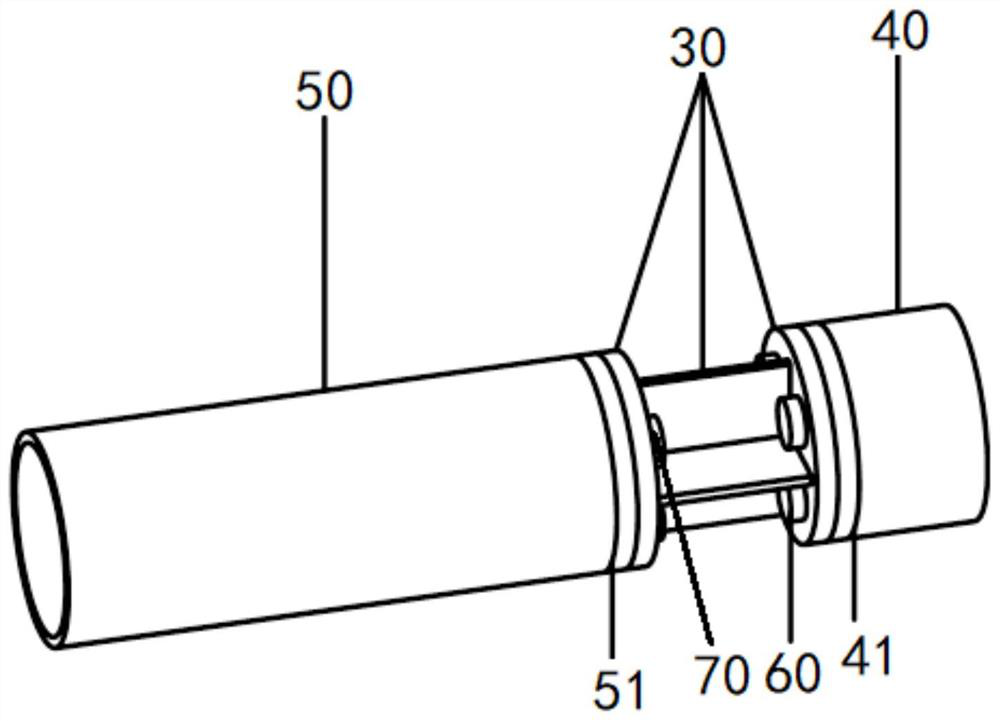

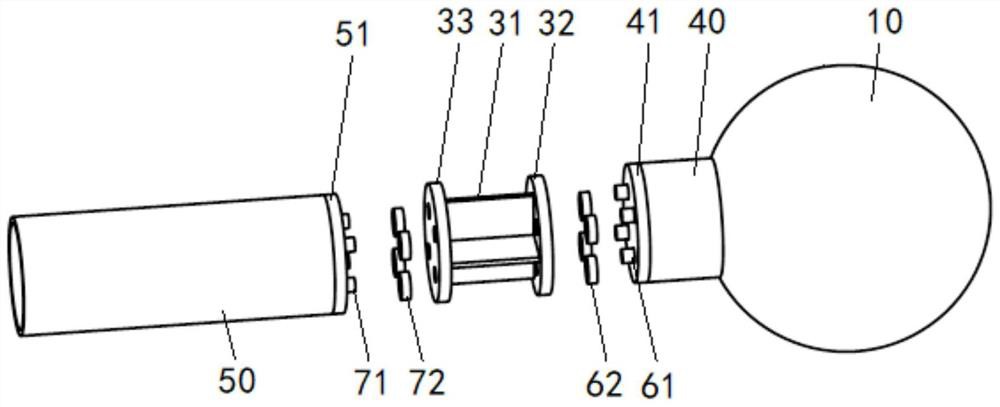

[0042] Such as Figure 1~5 As shown, the present invention provides a new type of large-span repairable assembled node, including: a hollow ball 10 and a plurality of round steel pipe connection assemblies 20 installed on the hollow ball;

[0043] The round steel pipe connection assembly 20 includes a repairable connector 30, a short cantilever round steel pipe section 40 and an ordinary round steel pipe section 50; one end of the short cantilever round steel pipe section 40 is installed on the hollow ball 10, and the other end is installed with a first round steel plate 41, One end of the repairable connector 30 is connected to the first round steel plate 41 through the first bolt group 60, and the other end is connected to the second round steel plate 51 installed at one end of the ordinary round steel pipe section 50 through the second bolt group 70; meanwhile, the present invention The yield strength of the repairable connector 30 is the lowest among the above-mentioned me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com