Nozzle module and cleaning device with nozzle module

A nozzle and nozzle cavity technology, which is applied in the direction of using liquid cleaning methods, cleaning methods and utensils, injection devices, etc., can solve the problems of workpiece pollution, engine damage, affecting the technical function of the system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

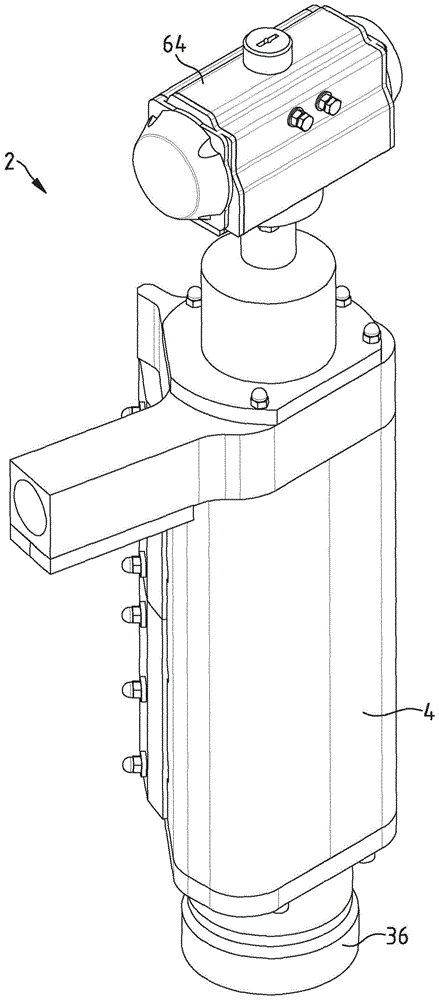

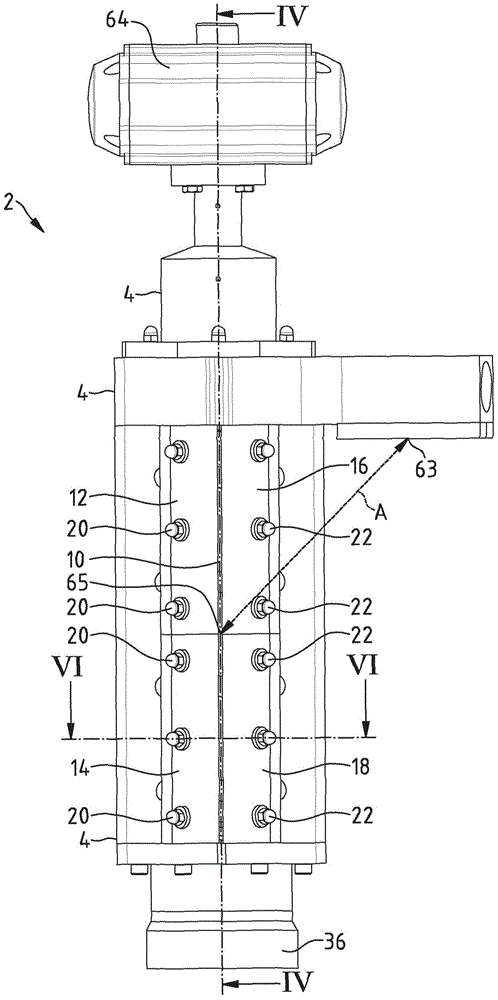

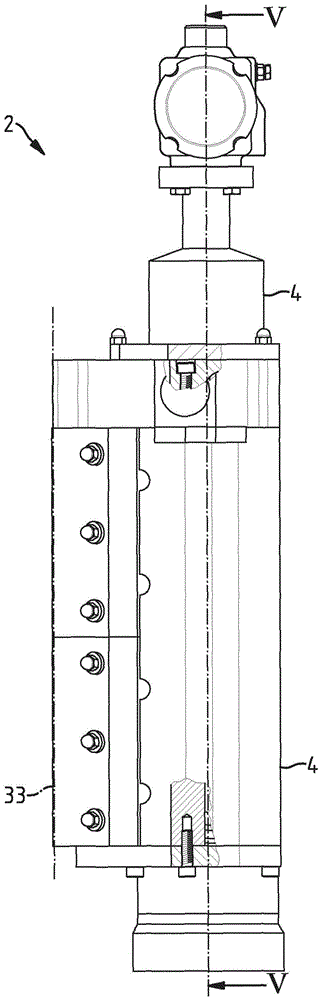

[0031] Figure 1 to Figure 8A nozzle module 2 for rinsing workpieces in a cleaning container is shown. The nozzle module 2 has a module body 4 . A first nozzle chamber 6 is formed in the module body 4 . The nozzle chamber 6 extends between the base section 3 and the cover section 5 in a longitudinal direction corresponding to the axis 8 . The nozzle chamber 6 is formed with a slit-shaped nozzle opening 9 which extends along a slit axis 33 . The nozzle chamber 6 has a slit-shaped nozzle opening 10 .

[0032] The opening gap of the nozzle opening 10 is in Figure 6 The width B shown in , is defined by means of adjusting elements in the form of nozzle orifice plates 12 , 14 , 16 and 18 , which are fastened to the module body 4 by means of fastening screws 20 , 22 . The fastening screws 20 , 22 have a thread 21 which engages in a thread 5 formed in the module body 4 . The nut 25 is guided on the thread 23 of the fastening screws 20 , 22 . The nozzle orifices 12 , 14 , 16 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com