Self-closing sheet for encapsulating and dumping a bulk of material

a self-closing sheet and bulk material technology, applied in special-purpose vessels, soil-shifting machines/dredgers, transportation and packaging, etc., can solve the problems of unusable practical use, adverse long-term effects, and inability to meet the requirements of use, and achieve low material strength, facilitate the degree of inner sheet extension, and reduce the effect of material strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

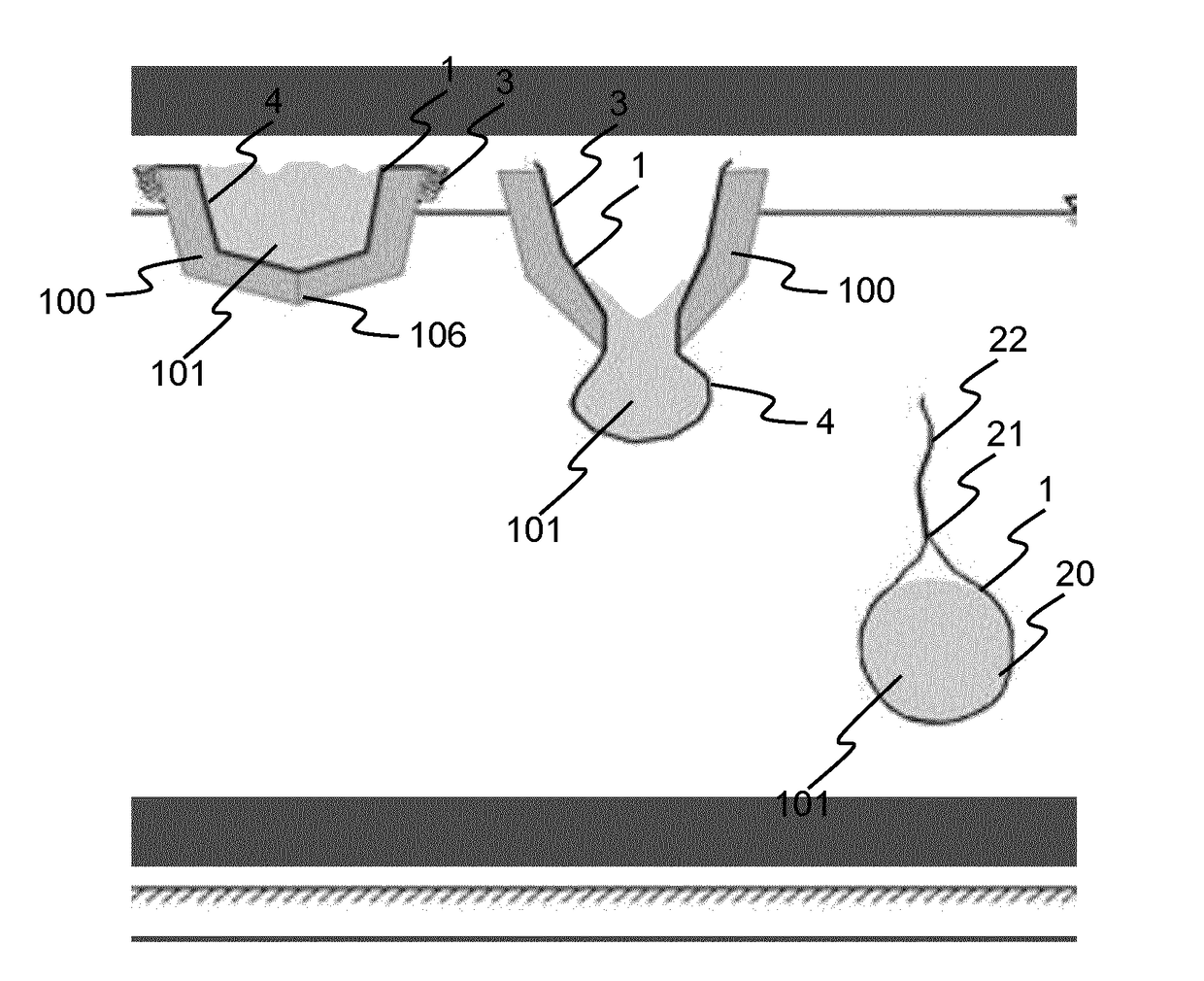

[0079]FIG. 1 schematically shows a sheet 1 according to the invention with a self-closing portion 22 and working by a self-closing concept, whereas the self-closing concept works as following:

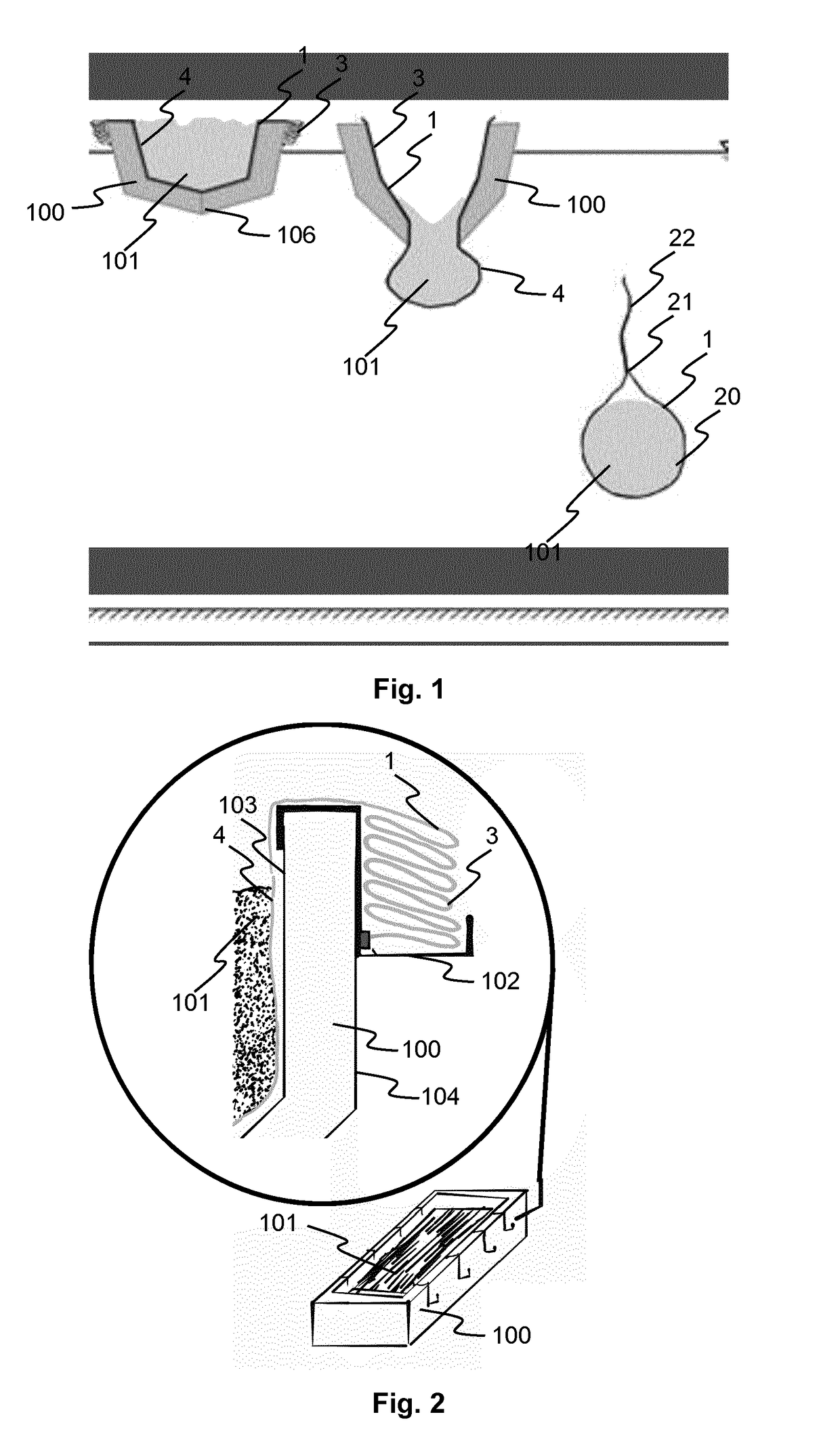

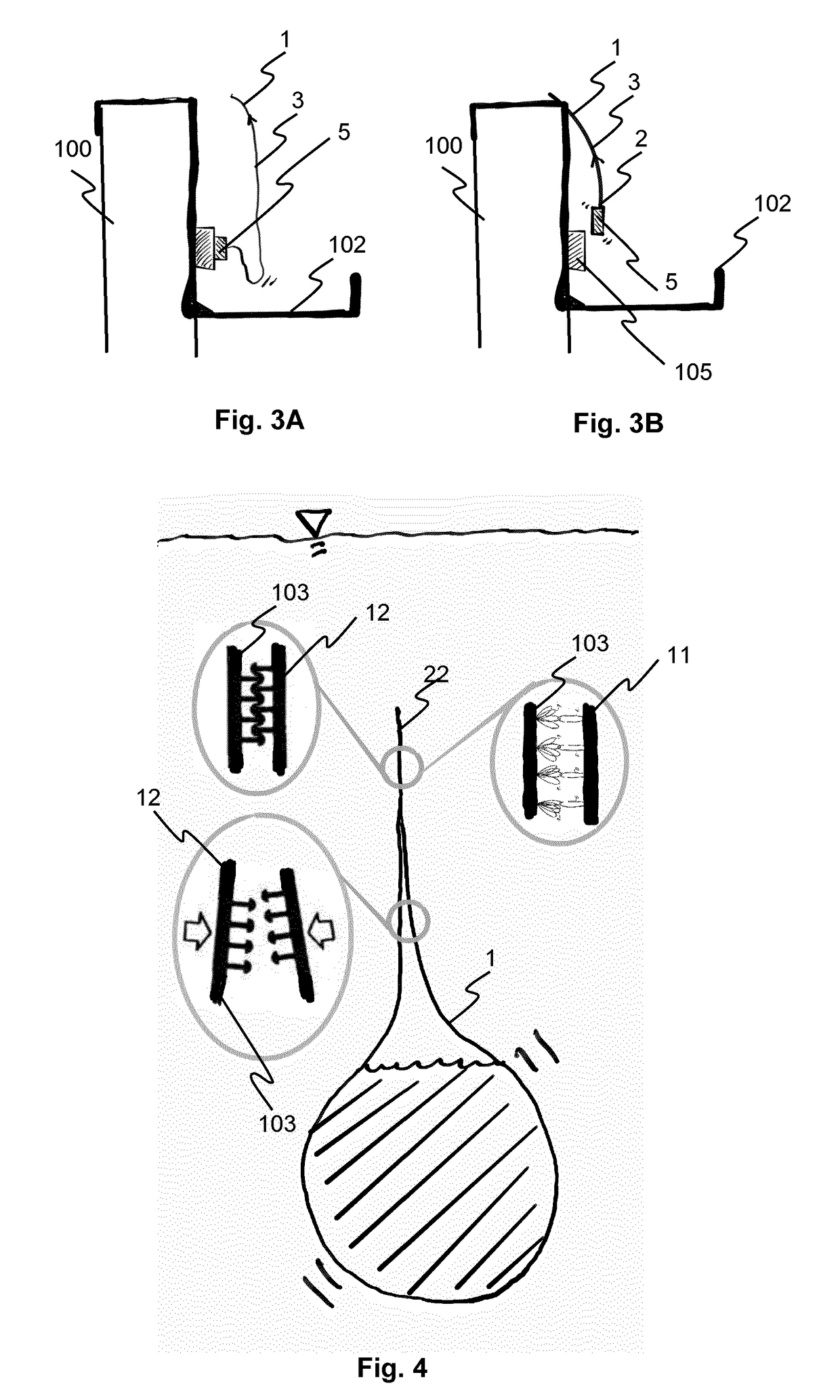

[0080]First the sheet 1 is arranged on or in a split barge 100 and a material containing portion 4 of sheet is filled with a bulk of material 101. A centreline of the sheet may approximately follow a centreline 106 of the split barge. A material free portion 3 of the sheet is hold along the edge of the split barge by a support element (not shown). In the presently illustrated embodiment and as shown in FIG. 2 the material containing portion of the sheet is arranged along an inside surface 103 of the split barge and the material free portion is hold by a support element 102 along an outside surface 104 of the split barge. Alternatively the sheet may be arranged along an outside surface of the split barge. The material free portion 3 may be zig-zag folded.

[0081]Then the split barge 100 is opened ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com