Sundries removing and grass separating, cutting and smashing integrated mower

A lawn mower and weed dividing technology, which is applied to harvesters, graders, cutters, etc., can solve the problems of damaged blades, mowing blades encountering debris, and inconcentrated mowing shear force, etc., to prolong the service life, Simple separation and filtration, the effect of mowing and shearing force concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

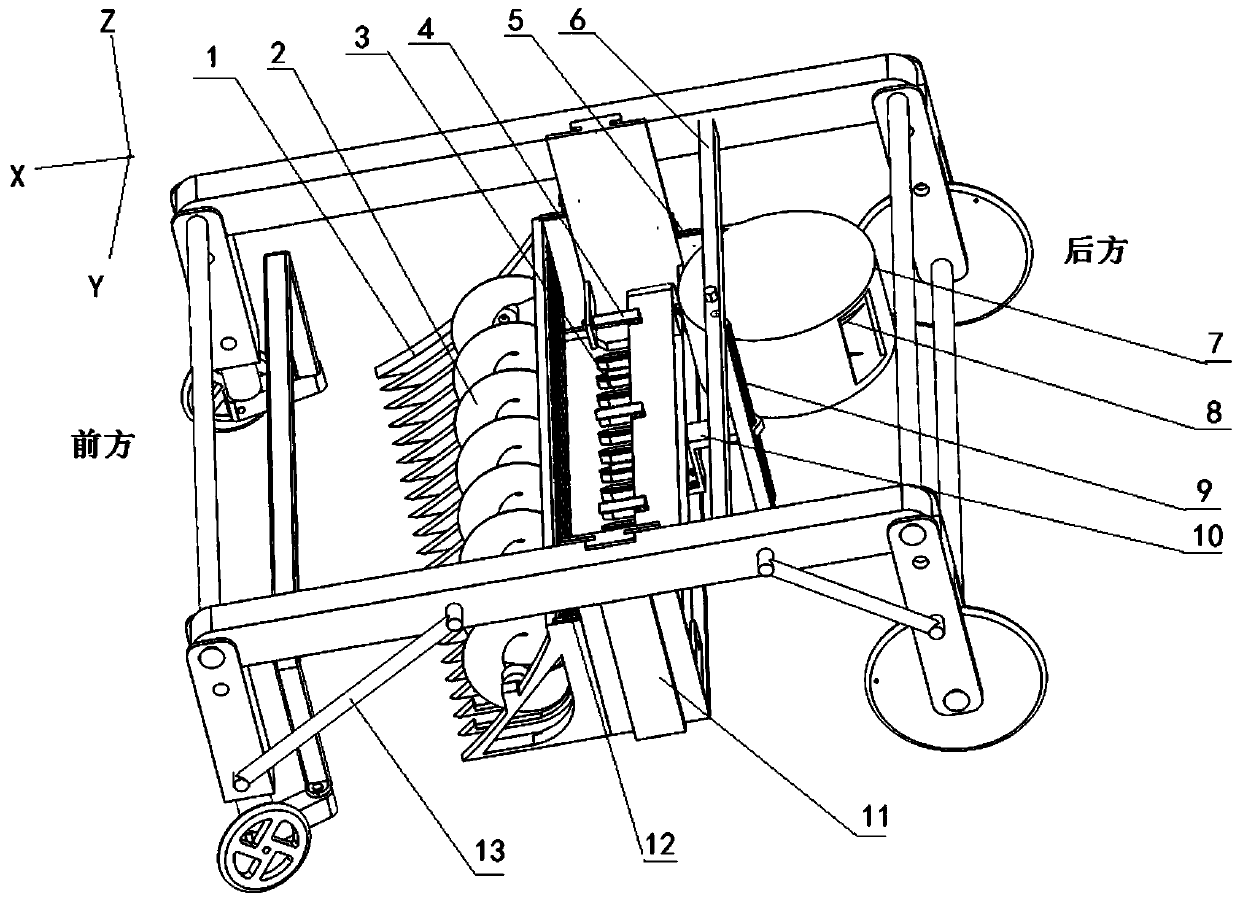

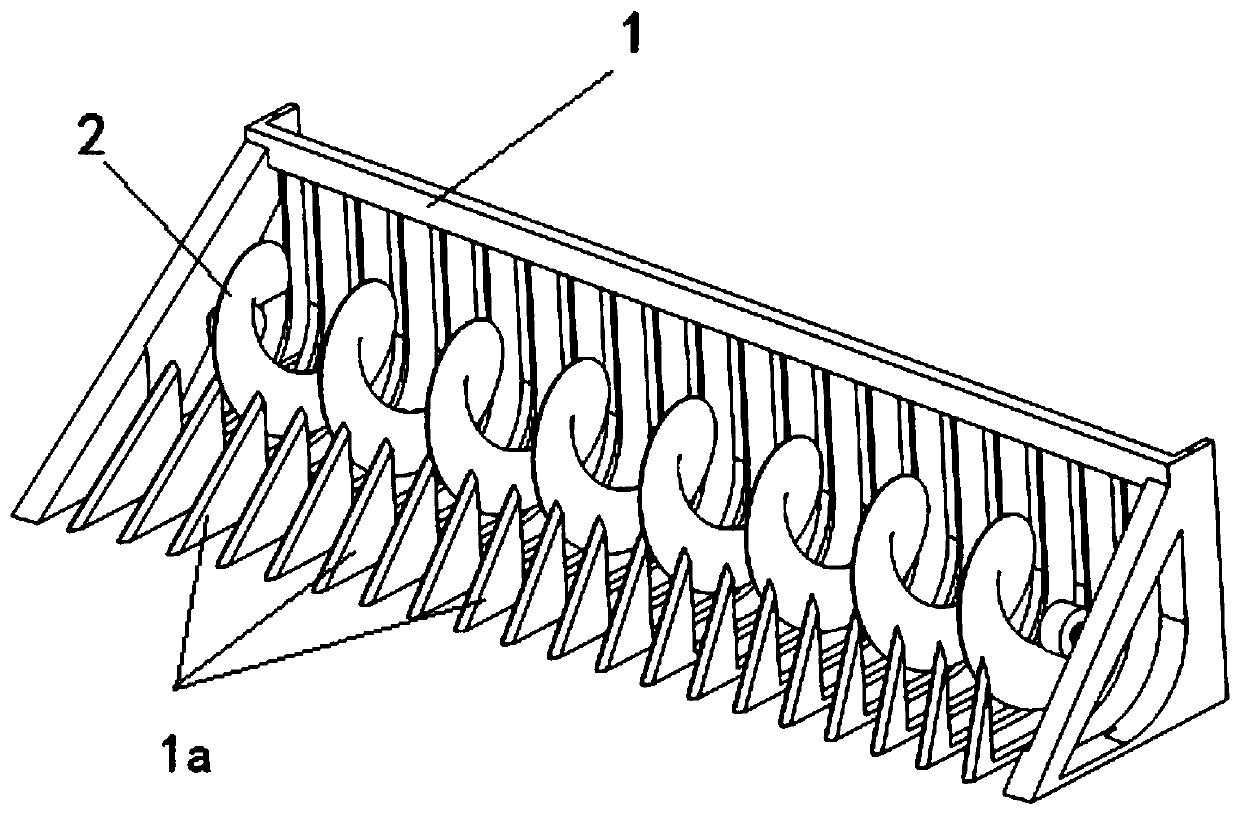

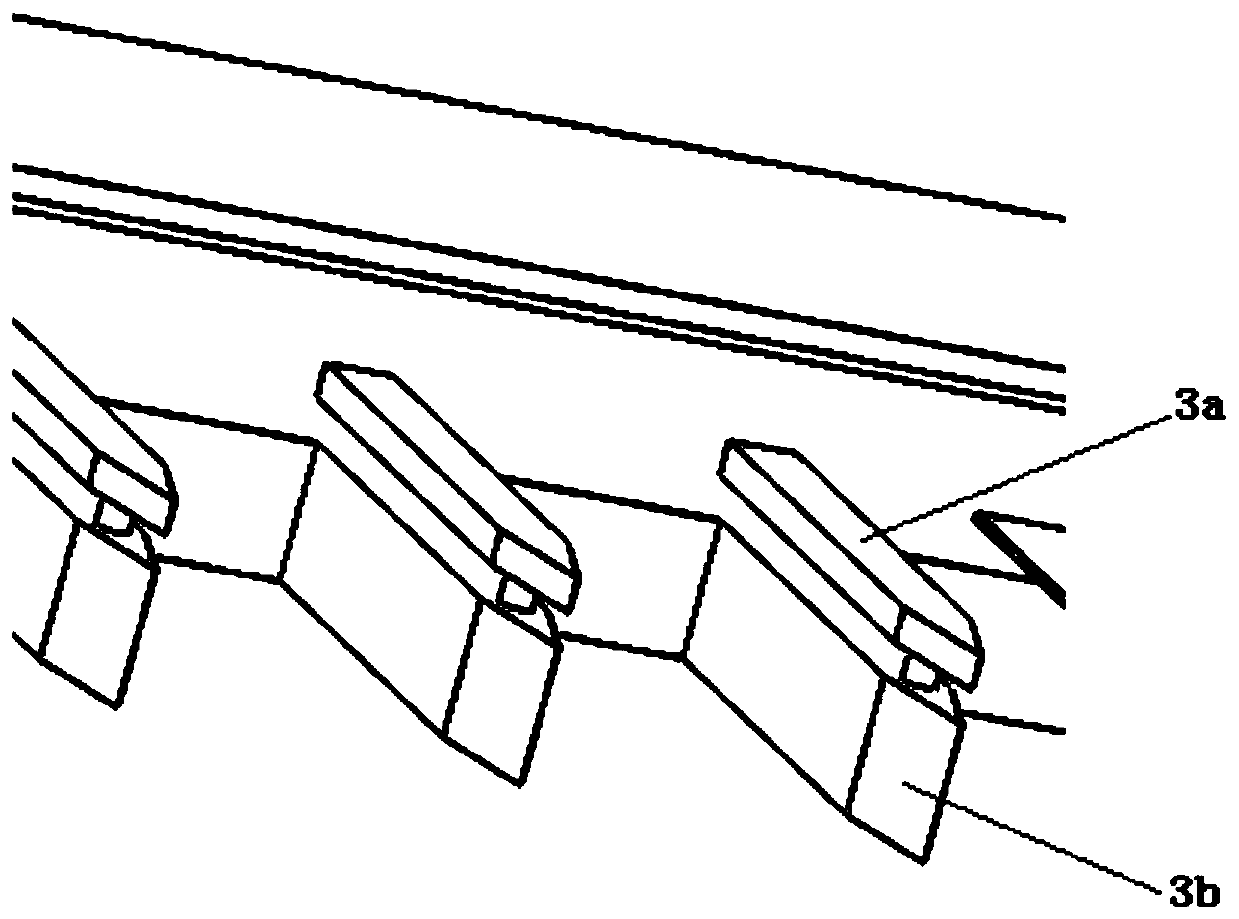

[0040] see figure 1 , an integrated lawn mower for removing weeds, dividing grass, cutting grass, and grass, the debris separation and removal device 1 is in the front of the X direction, and the spiral debris removal device 2 is arranged on the middle through hole of the debris separation and removal device 1 along the Y direction, Both ends of the screw removal device 2 are fixed with both ends of the debris separation and removal device 1, see figure 2 , the rear upper part on both sides of the debris separation and removal device 1 is connected to the lifting device through the lifting device and the "L"-shaped connecting piece 12 of the debris separation and removal device; see figure 1 and figure 2 , the grass dividing device 3 comprises two rows of upper and lower grass dividing parts composed of taper rods arranged at equal intervals ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com