Thermal-destruction conductive sheet fuse clip, plug and socket

A conductive sheet and thermal destruction technology, applied in the direction of circuits, electrical components, parts of connecting devices, etc., can solve the problems of reduced heat conduction, incomplete destruction of connectors, poor heat conduction effect, etc., to ensure the safety of electricity use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0098] Based on the above technical features, the main functions of the heat-destructive conductive sheet safety clip of the present invention will be clearly presented in the following embodiments.

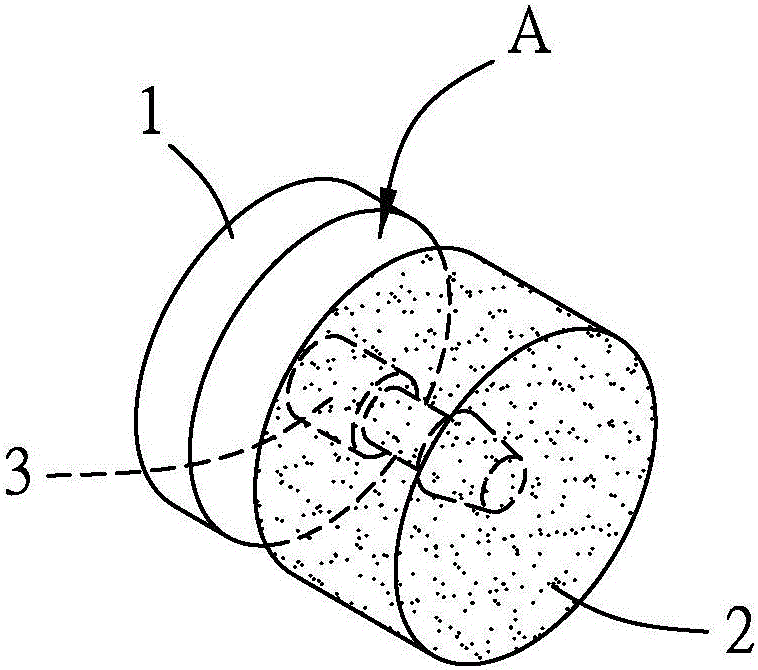

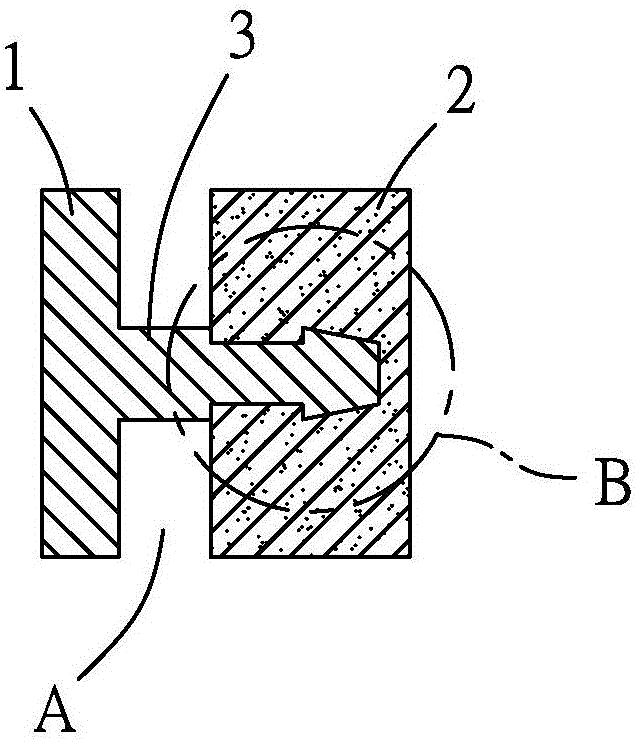

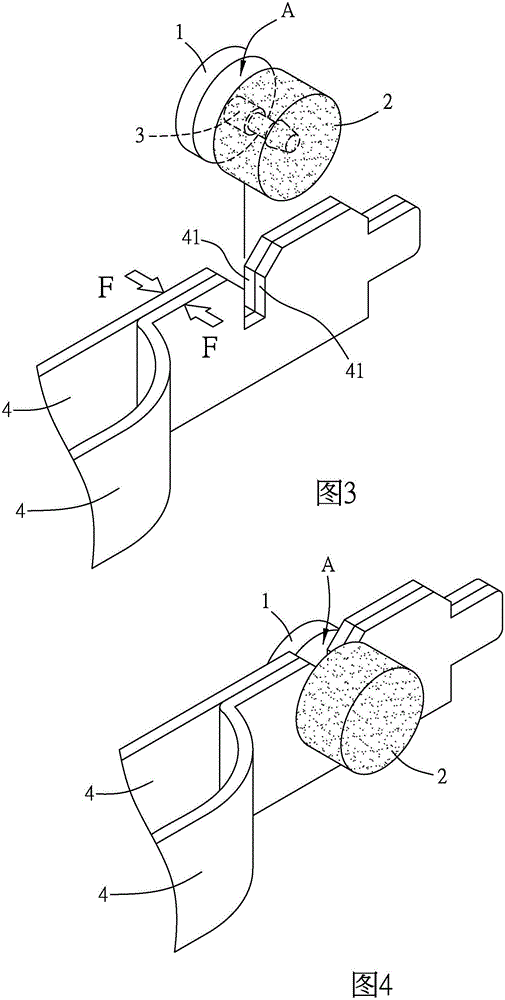

[0099] Please refer to the first embodiment of the present invention figure 1 and figure 2 As shown, the thermally destructive conductive sheet safety clip of this embodiment includes: a first restricting part 1, a second restricting part 2 and a connecting part 3, and the connecting part 3 connects the first restricting part 1 and the The second restricting part 2 makes the heat-destructive conductive sheet safety clip form an H-shaped structure, and defines an accommodating space between the first restricting part 1, the connecting part 3 and the second restricting part 2 a. Wherein, the first restricting part 1 and the connecting part 3 are made of metal, the second restricting part 2 is made of plastic, and a part B to be broken is formed at the junction of the plastic mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com