Method for increasing high temperature aging stability of polyacrylamide

A polyacrylamide, high temperature aging technology, applied in chemical instruments and methods, drilling compositions and other directions, can solve problems such as poor stability, and achieve the effects of improved stability, tight structure, and good technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

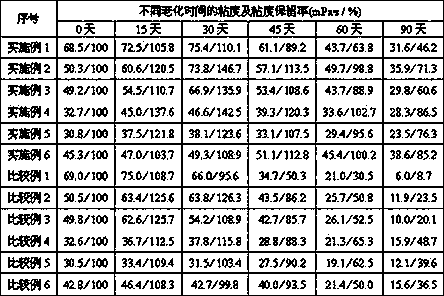

Embodiment 1

[0013] The self-made partially hydrolyzed polyacrylamide 1 (solid content is 90.5% according to the method of GB / T 12005.2-89; the intrinsic viscosity is tested according to the method of GB / T12005.10-92, and [η]=3.73×10 -4 mw 0.66 The calculated molecular weight is 32.5 million; the hydrolysis degree is 20.6% according to the GB / T12005.6-89 method), and the simulated water (the total salinity is 8730mg / L) is used to prepare a 1500mg / L solution, and 50mg / L of sulfur is added Urea, 100mg / L ethylene glycol, connect the clean ampoule bottle to the vacuum system, first evacuate the ampoule bottle at -0.1MPa for 2min, then twist the piston, put 30ml solution into the ampoule bottle, burn it with an alcohol blowtorch seal up. Put the fired-sealed ampoule into a constant temperature oven at 95±1°C for aging. Samples were regularly taken out at 15 days, 30 days, 45 days, and 60 days, and the viscosity value of the solution was measured with a Brookfield viscometer until 90 days, and...

Embodiment 2

[0015] The self-made partly hydrolyzed polyacrylamide 2 (the solid content is 89.8% according to the GB / T 12005.2-89 method; the intrinsic viscosity is tested according to the GB / T12005.10-92 method, and [η]=3.73×10 -4 mw 0.66 The calculated molecular weight is 28.35 million; the hydrolysis degree is 14.8% according to the GB / T12005.6-89 method), and a 1500mg / L solution is prepared with simulated water (the total salinity is 8730mg / L), and 200mg / L of sulfur is added Urea, 200mg / L ethylene glycol, 200mg / L glycerin, connect the clean ampoule bottle to the vacuum system, first evacuate the ampoule bottle at -0.1MPa for 2min, then twist the piston, put 30ml solution into In ampoules, seal with an alcohol blowtorch. Put the fired-sealed ampoule into a constant temperature oven at 95±1°C for aging. Samples were regularly taken out at 15 days, 30 days, 45 days, and 60 days, and the viscosity value of the solution was measured with a Brookfield viscometer until 90 days, and the visc...

Embodiment 3

[0017] The self-made partially hydrolyzed polyacrylamide 3 (solid content is 89.9% according to the method of GB / T 12005.2-89; the intrinsic viscosity is tested according to the method of GB / T12005.10-92, and [η]=3.73×10 -4 mw 0.66 The calculated molecular weight is 26.5 million; according to the method of GB / T12005.6-89, the degree of hydrolysis is 16.5%, and the simulated water (total salinity is 8730mg / L) is used to prepare a 1500mg / L solution, and 300mg / L of sulfur is added Urea, 400mg / L ethylene glycol, 300mg / L isopropanol, 300mg / L isobutanol, connect the clean ampoule to the vacuum system, first evacuate the ampoule at -0.1MPa for 2min, and then Twist the plunger, put 30ml of the solution into the ampoule, and seal it with an alcohol blowtorch. Put the fired-sealed ampoule into a constant temperature oven at 95±1°C for aging. Samples were regularly taken out at 15 days, 30 days, 45 days, and 60 days, and the viscosity value of the solution was measured with a Brookfiel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com