Waste processing system

a technology of processing system and waste, applied in the direction of combined combustion mitigation, combustion process, lighting and heating apparatus, etc., can solve the problems of social inacceptability of the process and limited waste management solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

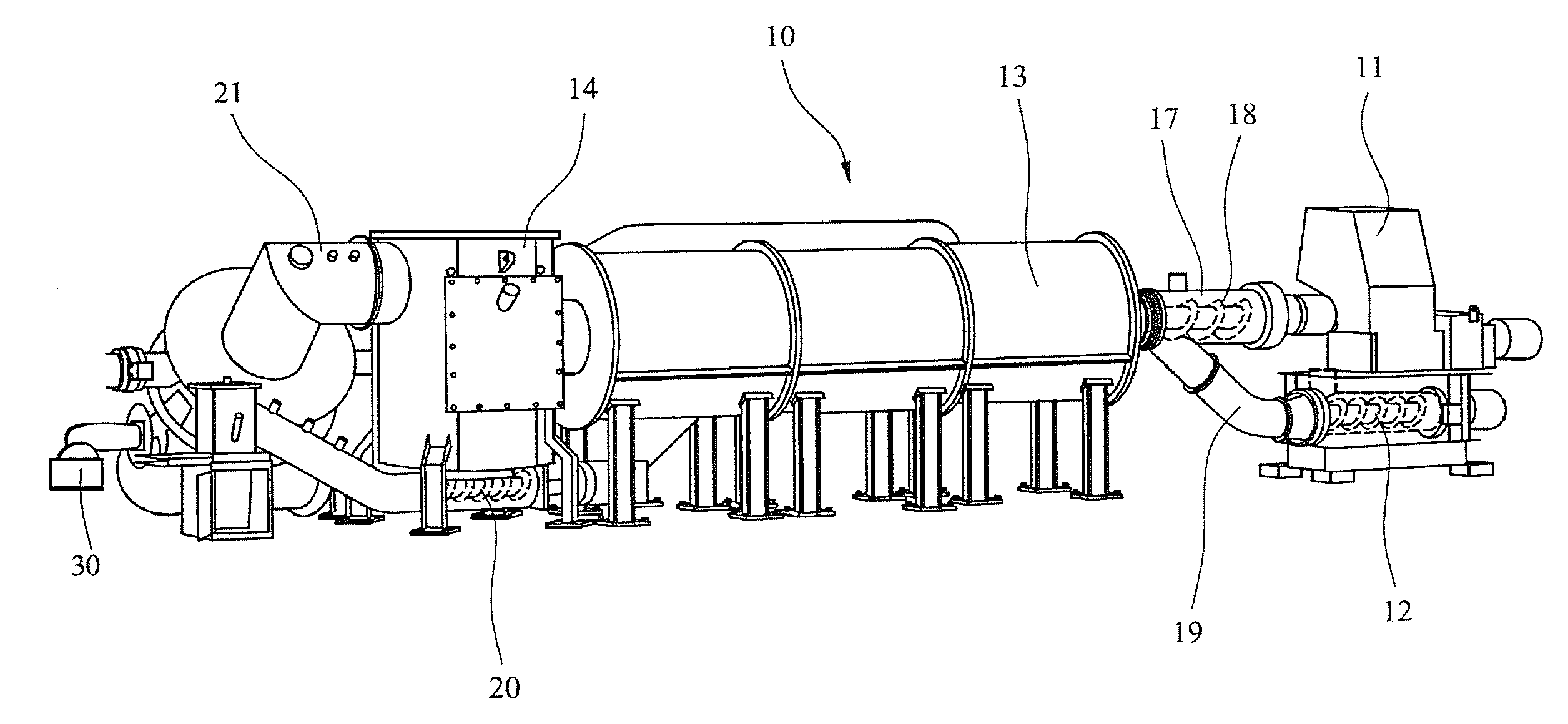

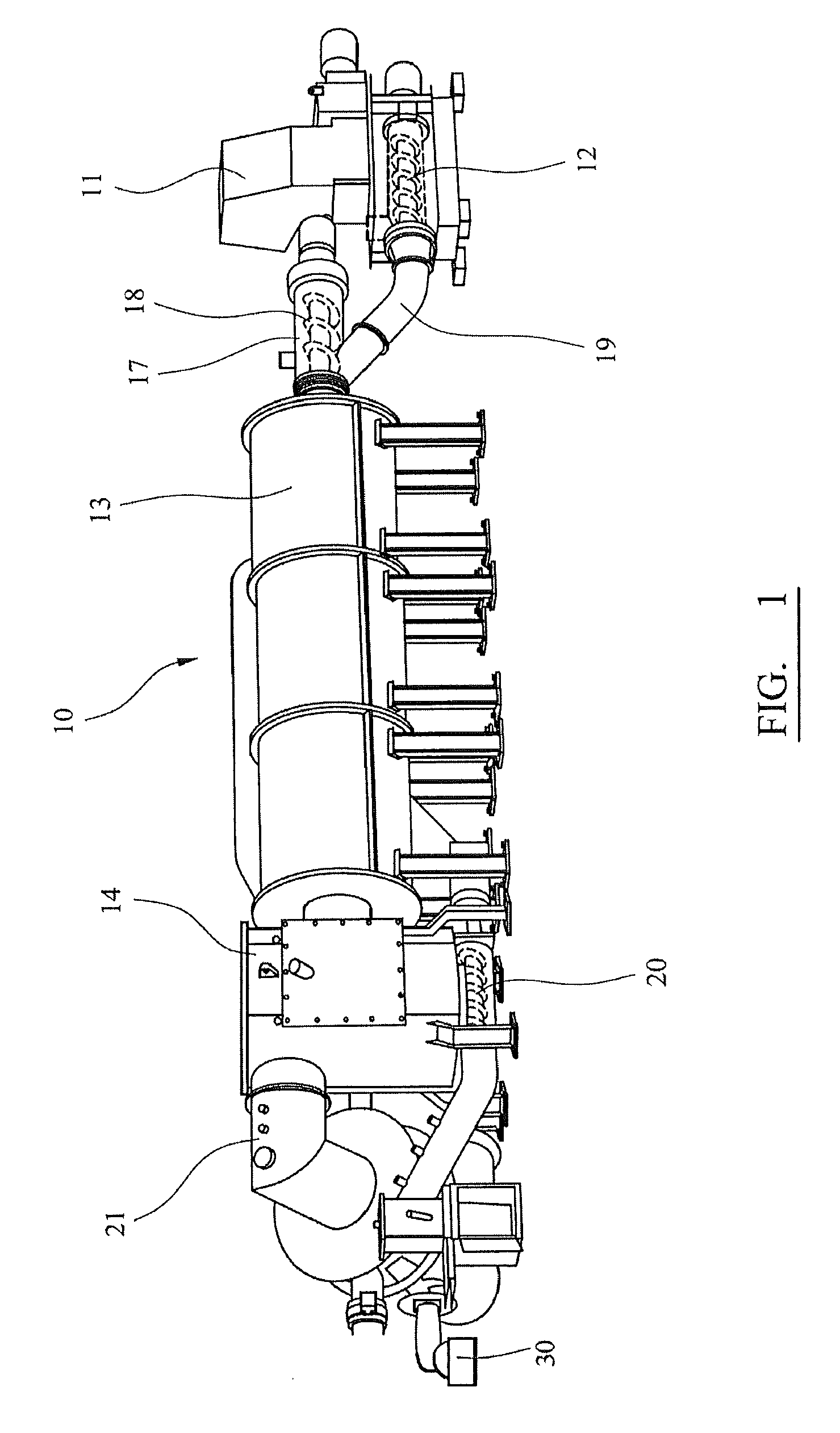

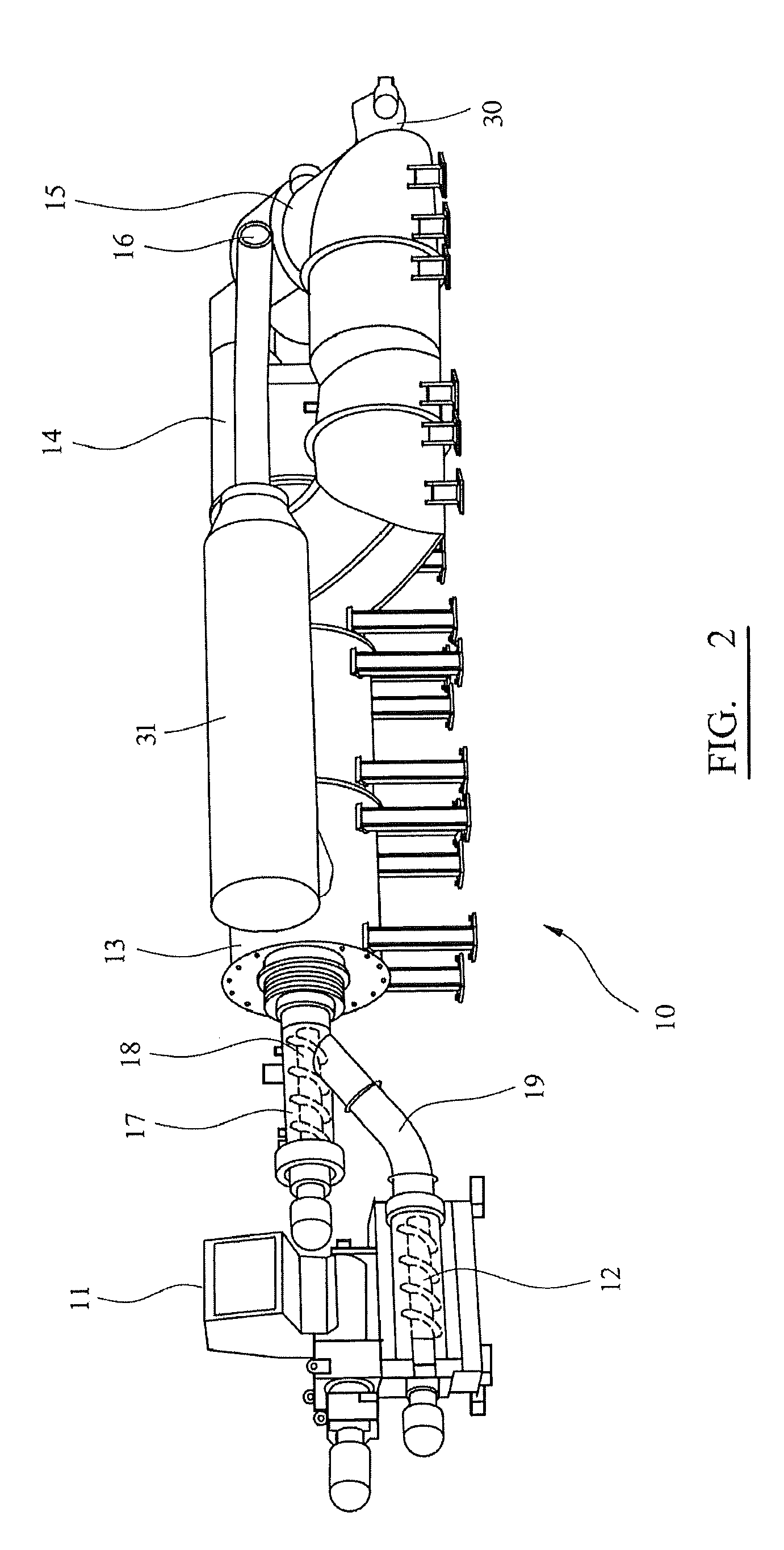

[0025]FIGS. 1 and 2 illustrate an external view of the components of a waste processing system according to the invention. The apparatus 10 includes a shredder 11, a compactor 12, a pyrolyser 13, a gasifier / ash vessel 14, an oxidiser 15, a heat reclaimer 31 and an outlet flue 16. Each stage of the system is discussed in detail below.

[0026]As a pre-feed treatment, the waste is processed through the shredder 11 to homogenize it and act as a separator for contaminants, mainly consisting of materials that may be injurious to mechanical handling.

[0027]The greater the homogeneity of the waste feed, the smoother the operation of the thermal plant, leading to increased processing capacity of the plant and increased life of the components. Preferably, before entering the shredder 11, large items and other damaging materials are removed. Separation may be performed by hand or automated depending on the application and available manual resources.

[0028]Size reduction of the waste has an added ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com