Radial rigidity adjusting method and structure for liquid rubber composite joints

A technology of liquid rubber and radial stiffness, applied in the field of rail transit, can solve the problems of low stiffness performance, large wear of wheel rails and lines, and difficult to realize, and achieve the effect of improving critical speed and curve passing performance and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

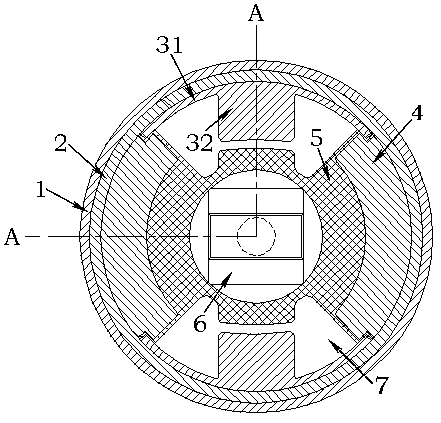

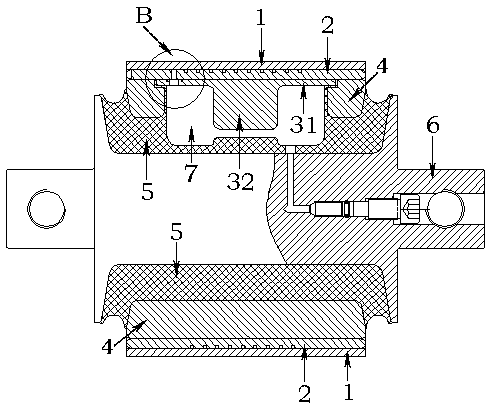

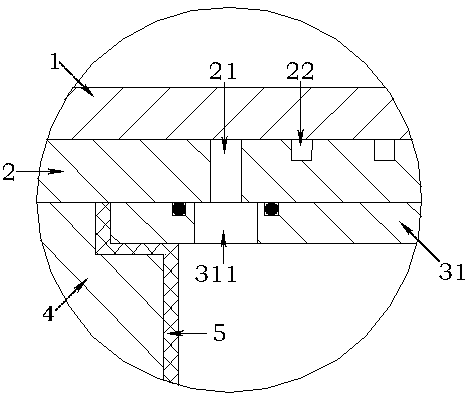

[0023] Such as figure 1 , figure 2 and image 3 As shown, the liquid rubber composite node includes an overall casing 1 , a runner casing 2 , a cover plate, an intermediate spacer 4 , a rubber body 5 and a mandrel 6 . The rubber body 5 is vulcanized between the middle spacer 4 and the mandrel 6, so that the middle spacer 4, the rubber body 5 and the mandrel 6 are connected as a whole. The cover plate includes an arc-shaped plate 31 and a protrusion 32 , and the protrusion 32 is arranged in the middle of the inner side of the arc-shaped plate 31 . The two ends on the outside of the middle spacer 4 are provided with a step mouth, and a rubber body 5 is vulcanized at the step mouth, and the two ends of the arc plate 31 are covered on the rubber body 5 at the step mouth, and the cover plate, the middle spacer 4, The rubber body 5 is assembled into the runner casing 2 together with the mandrel 6 . A liquid cavity 7 is provided between the cover plate and the rubber body 5 , an...

Embodiment 2

[0033] Such as Figure 4 As shown, the main difference between this embodiment and Embodiment 1 is that the stopper stiffness adjustment structure is different from Embodiment 1, and the mandrel 6 of this embodiment is set at a position corresponding to the arc-shaped plate 31 in the radial direction. A protrusion is formed, and when the liquid rubber composite node is deformed, the rubber body 5 at the protrusion contacts with the arc plate 31 to produce variable stiffness. Because the thickness of the protruding vulcanized rubber body 5 of the mandrel 6 in this embodiment is relatively small, when the rubber body 5 touches the curved plate 31, the effect of a sudden increase in rigidity is obvious, and a hard stop can be quickly provided. function, allowing the stiffness to increase dramatically in a short period of time.

Embodiment 3

[0035] Such as Figure 5 As shown, the main difference between this embodiment and Embodiment 1 is that the stopper stiffness adjustment structure is different from Embodiment 1, and the rubber body 5 of this embodiment is arranged at a position corresponding to the arc-shaped plate 31 in the radial direction. A bulge is formed, and when the liquid rubber composite node is deformed, the bulge of the rubber body 5 touches the curved plate 31 to produce a variable stiffness. Since the thickness of the rubber body 5 in this embodiment is very large, although the rubber body 5 abuts against the arc-shaped plate 31 can produce variable stiffness, the increase in stiffness is not obvious. Also because the thickness of the rubber body 5 is very large, after the protrusion of the rubber body 5 touches the curved plate 31, the change in the space stiffness of the liquid rubber composite joint is relatively gentle, and there is a good stability in the space direction of the liquid rubbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com