Forming method of liquid rubber composite joint with inner groove flow channel and joint

A liquid rubber, liquid technology, applied in the direction of shock absorber-spring combination, shock absorber, spring, etc., can solve problems such as difficulty in realization, and achieve the effect of ensuring product quality, optimizing product performance, and large axial stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

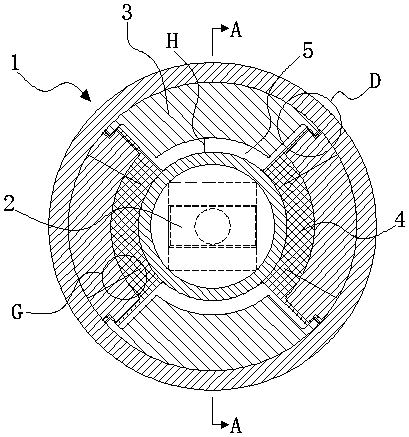

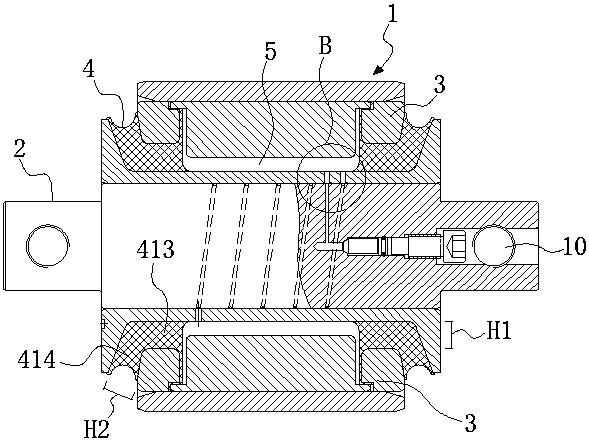

[0041] Embodiment 1: as figure 1 and figure 2 As shown, a method for forming a liquid rubber composite node with an inner groove flow path, which is to add an intermediate spacer 3 between the outer casing 1 and the mandrel 2, and bond the intermediate spacer 3 and the mandrel 2 through rubber 4 vulcanization. Connect together, and then assemble the integrated intermediate spacer and mandrel into the outer casing 1; set the inner groove flow channel in the mandrel 2, and hollow out multiple spaces on the middle spacer 3. After vulcanization, use The rubber 4 and the multiple spaces form a plurality of liquid cavities 5 that are independent of each other, and liquid (not shown in the figure) is arranged in the multiple liquid cavities 5, and the inner groove flow path is passed between the multiple liquid cavities 5 connected. The liquid rubber composite joint formed by the above method can provide smaller radial stiffness and greater axial stiffness, and achieve a larger dy...

Embodiment 2

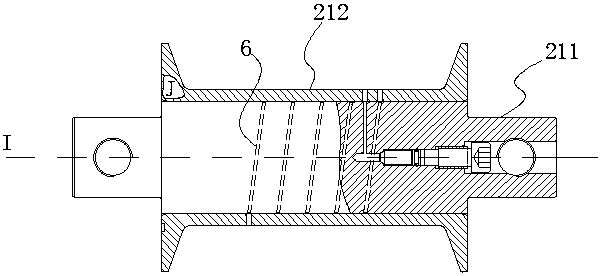

[0059] Embodiment 2: This embodiment mainly describes another end structure of the runner groove, such as Figure 12 As shown, compared with Embodiment 1, the difference lies in that the runner groove 6 of this embodiment adopts oblique end portions. The dynamic stiffness provided by the node with oblique end runner grooves is less than that provided by the node with right angle end runner grooves, and the inflection point of frequency increase is generally in the range of 2-4Hz.

Embodiment 3

[0060] Embodiment 3: This embodiment mainly describes another end structure of the runner groove, such as Figure 13 As shown, compared with Embodiment 1, the difference is that the runner groove of this embodiment adopts a closed end. One end of this type of runner groove includes a closing runner groove 1 613 , a closing runner groove 2 614 and a closing runner groove 3 615 connected in sequence, and the closing runner groove 1 613 is connected with a mandrel through hole 213 Pass, the third runner groove 615 of the closed mouth is connected with the middle runner groove of the spiral runner groove 6. The other end portion of this type of runner groove also includes a closed runner groove 1 613 , a closed runner groove 2 614 and a closed runner groove 3 615 connected in sequence, which will not be repeated here.

[0061] The groove width K3 of the closed runner groove 1 613 is greater than the groove width K4 of the closed runner groove 2 614, and the groove width K5 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com