Multibarrel tube-confined concrete column and steel beam connection joint and manufacturing method thereof

A technology for concrete-filled steel tubular columns and connecting nodes, which is applied to buildings, building structures, etc., can solve the problems of failure to effectively exert the seismic performance of composite nodes, brittle failure, etc., and achieve the effect of enhancing deformation capacity, strength and deformation capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

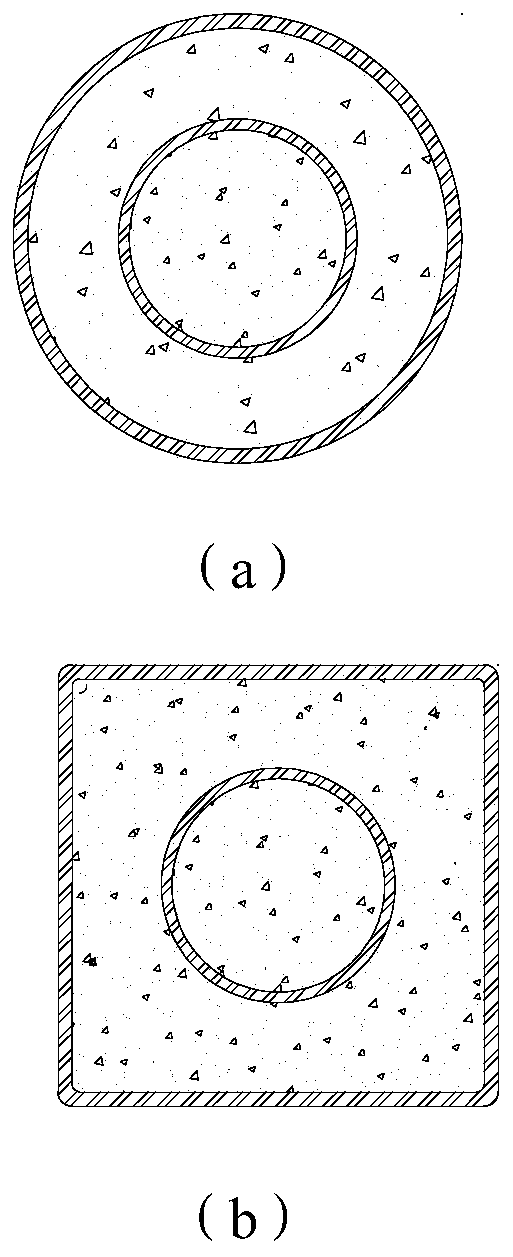

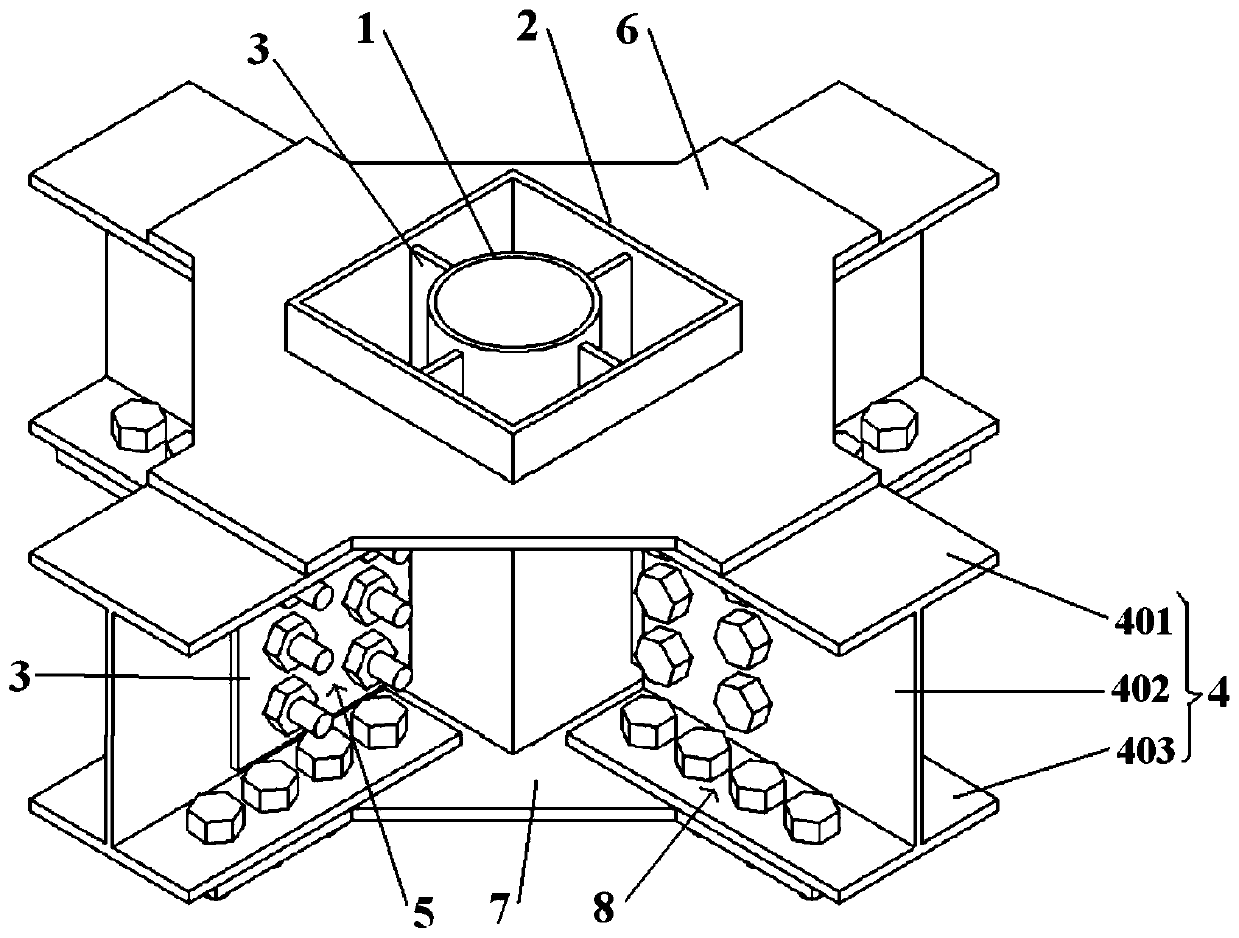

[0024] refer to figure 2 According to the embodiment of the content of the present invention, a composite steel pipe concrete column and steel beam 4 connection joints include: inner steel pipe 1, outer steel pipe 2, anchor plate 3, steel beam 4, upper outer ring plate 6 and lower Outer ring plate 7. Wherein, the inner steel pipe 1 is covered with an outer steel pipe 2, the inner steel pipe 1 is a circular steel pipe, the outer steel pipe 2 is a square steel pipe, and the inner steel pipe 1 and the outer steel pipe 2 form a composite steel pipe concrete column with an inner circle and an outer square.

[0025] Four anchor plates 3 are uniformly welded on the side wall of the inner steel pipe 1, and the outer steel pipe 2 is provided with a slot matching the anchor plate 3, and the four anchor plates 3 respectively pass through the slot and protrude outside the outer steel tube 2. Four steel beams 4 are respectively connected to the side walls of the outer steel pipe 2; a pai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com