A kind of gold/carbon composite microsphere and preparation method thereof

A carbon composite and microsphere technology, applied in the direction of microsphere preparation, microcapsule preparation, etc., can solve the problems such as solvent or surfactant is not easy to wash out, escaped gas and organic matter, and expensive raw materials, etc., to achieve easy direct application, The effect of uniform size distribution and solving the problem of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

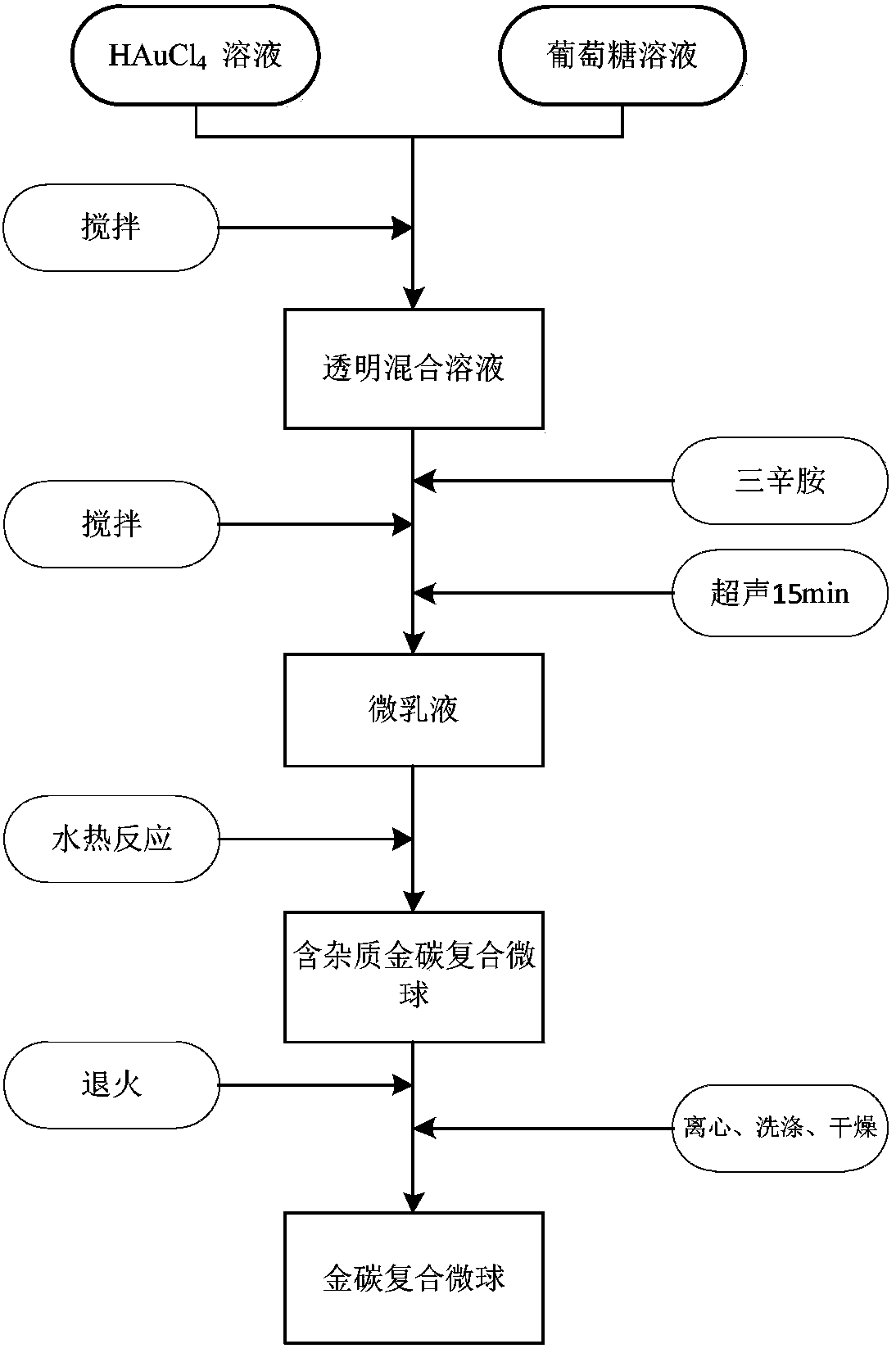

[0034] Step 1: Stir and mix 0.01M chloroauric acid solution and 0.25M glucose aqueous solution, and slowly add 1.0ml trioctylamine dropwise under stirring condition, and continue stirring for 10 minutes after the dropwise addition;

[0035] Step 2: Ultrasonic dispersion for 15 minutes to form a microemulsion;

[0036] Step 3: React the microemulsion at a constant temperature of 180°C for 12 hours;

[0037] Step 4: After naturally cooling to room temperature, the reaction liquid was alternately and repeatedly centrifuged with water and ethanol, and vacuum-dried at 60°C for 12 hours;

[0038] Step 5: The product is kept at 500° C. for 2 hours under the protection of an inert gas, and annealed to obtain gold / carbon composite microspheres.

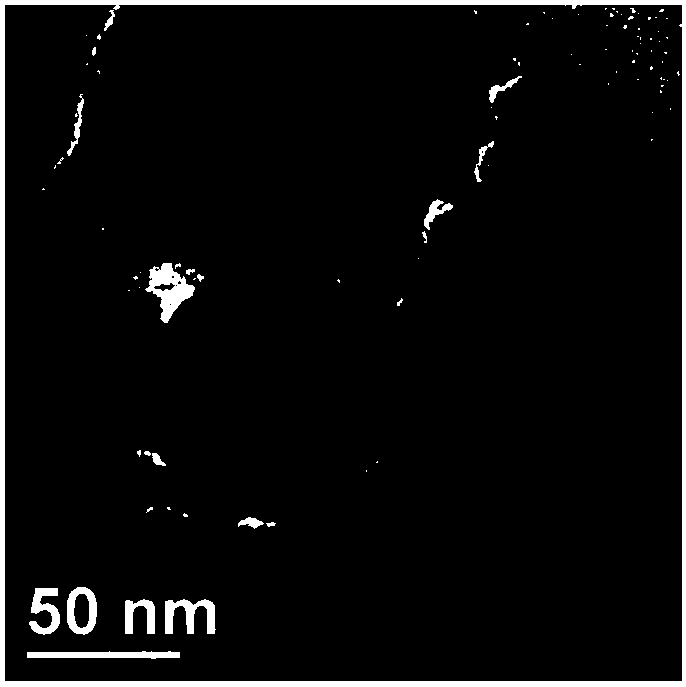

[0039] attached figure 2 It is the TEM photo of the morphology characterization diagram of the prepared gold / carbon composite microspheres. It can be seen from the picture that the gold particles are embedded in the carbon spheres, and the...

Embodiment 2

[0041] Step 1: Stir and mix 0.01M chloroauric acid solution and 0.25M glucose aqueous solution, and slowly add 0.75ml trioctylamine dropwise under stirring condition, and continue stirring for 10min after the dropwise addition;

[0042] Step 2: Ultrasonic dispersion for 15 minutes to form a microemulsion;

[0043] Step 3: React the microemulsion at a constant temperature of 160°C for 12 hours;

[0044] Step 4: After naturally cooling to room temperature, the reaction liquid was alternately and repeatedly centrifuged with water and ethanol, and vacuum-dried at 60°C for 12 hours;

[0045] Step 5: The product is kept at 500° C. for 2 hours under the protection of an inert gas, and annealed to obtain gold / carbon composite microspheres.

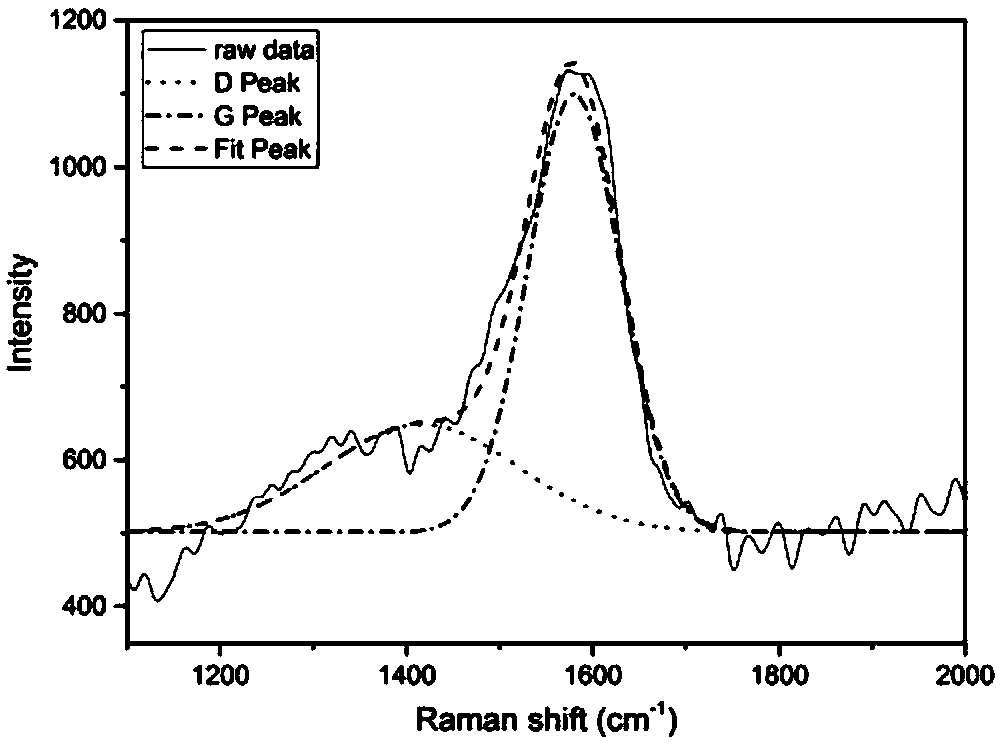

[0046] attached image 3 In order to characterize the structure of the obtained gold / carbon composite microspheres, the Raman spectrum can clearly see the Raman peak of carbon after fitting, which confirms the existence of carbon.

Embodiment 3

[0048]Step 1: Stir and mix 0.01M chloroauric acid solution and 0.25M glucose aqueous solution, and slowly add 0.5ml trioctylamine dropwise under stirring condition, and continue stirring for 10min after the dropwise addition;

[0049] Step 2: Ultrasonic dispersion for 15 minutes to form a microemulsion;

[0050] Step 3: React the microemulsion at a constant temperature of 180°C for 24 hours;

[0051] Step 4: After naturally cooling to room temperature, the reaction liquid was alternately and repeatedly centrifuged with water and ethanol, and vacuum-dried at 60°C for 12 hours;

[0052] Step 5: The product is kept at 400° C. for 2 hours under the protection of an inert gas, and annealed to obtain gold / carbon composite microspheres.

[0053] attached Figure 4 It is the SEM photo of the morphology characterization diagram of the prepared gold / carbon composite microspheres. It can be seen from the figure that the surface of the carbon spheres is uneven, and the particle size di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com