One-dimensional multi-layer nano-chain composite material, preparation method thereof and application in lithium ion battery

A nanocomposite material, lithium-ion battery technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of low capacity and poor cycle stability of negative electrode materials, and achieve stable cycle performance, large specific capacity, and batch controllable. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A one-dimensional multilayer Fe 2 P@SnP 0.94 @MoS 2 The preparation method of nano chain composite material, comprises the following steps:

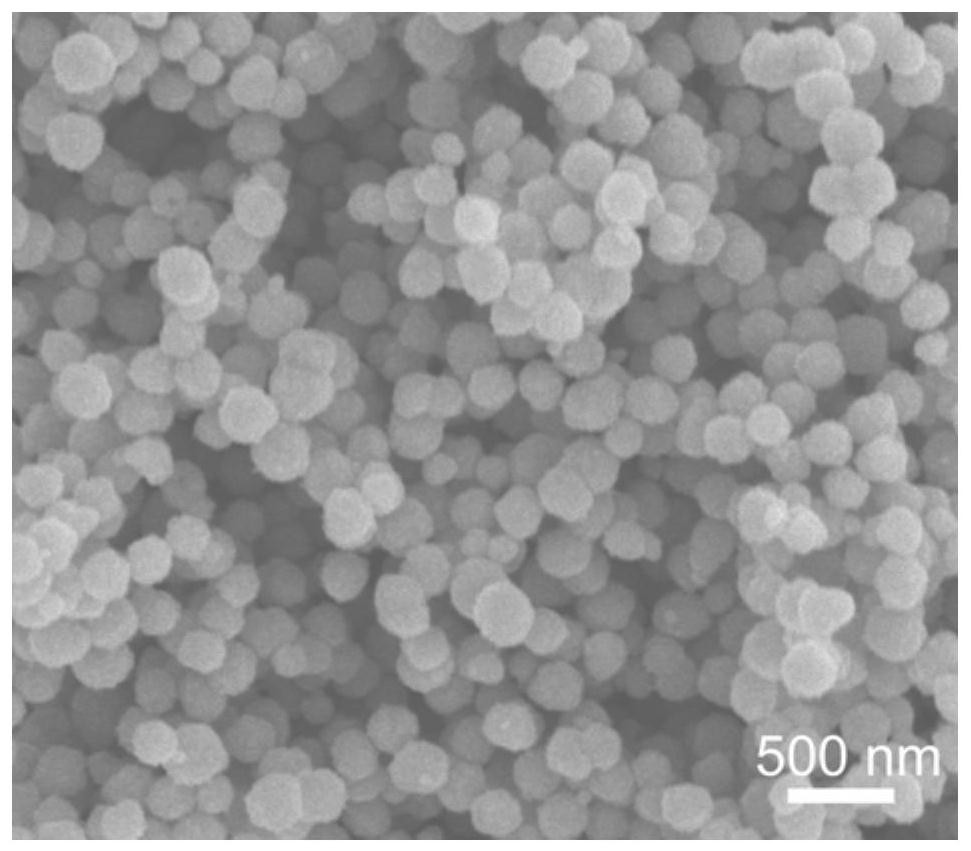

[0050] 1) Fe 3 o 4 Preparation of nanosphere material: Weigh 4.3g of FeCl 3 ·6H 2 0. The sodium acetate of 4.0g and the trisodium citrate of 1.0g are in the beaker, add 70mL ethylene glycol, make it dissolve completely under ultrasonic, the gained solution is poured in the liner of 100mL polytetrafluoroethylene reactor, in Under the condition of 200°C, react for 10h, cool down after the reaction, centrifuge at a speed of 8000 per minute / rev, wash with deionized water and ethanol three times, and dry in vacuum at 60°C for 12h to obtain Fe 3 o 4 Nanosphere material; its SEM image is shown in figure 1 As shown, it can be seen from the figure that it is a spherical structure with uniform size; its XRD pattern is as follows Figure 9 shown;

[0051] 2) Fe 3 o 4 @SiO 2 The preparation of nanochain composite material: take b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com