Edge sealing structure of water injection part of uniform temperature plate and its manufacturing method

A manufacturing method and vapor chamber technology, applied to lighting and heating equipment, indirect heat exchangers, etc., can solve the inconvenience of sealing the water injection pipe 31, break the working fluid and vacuum degree, and reduce the range or volume space of the vapor chamber 3 And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

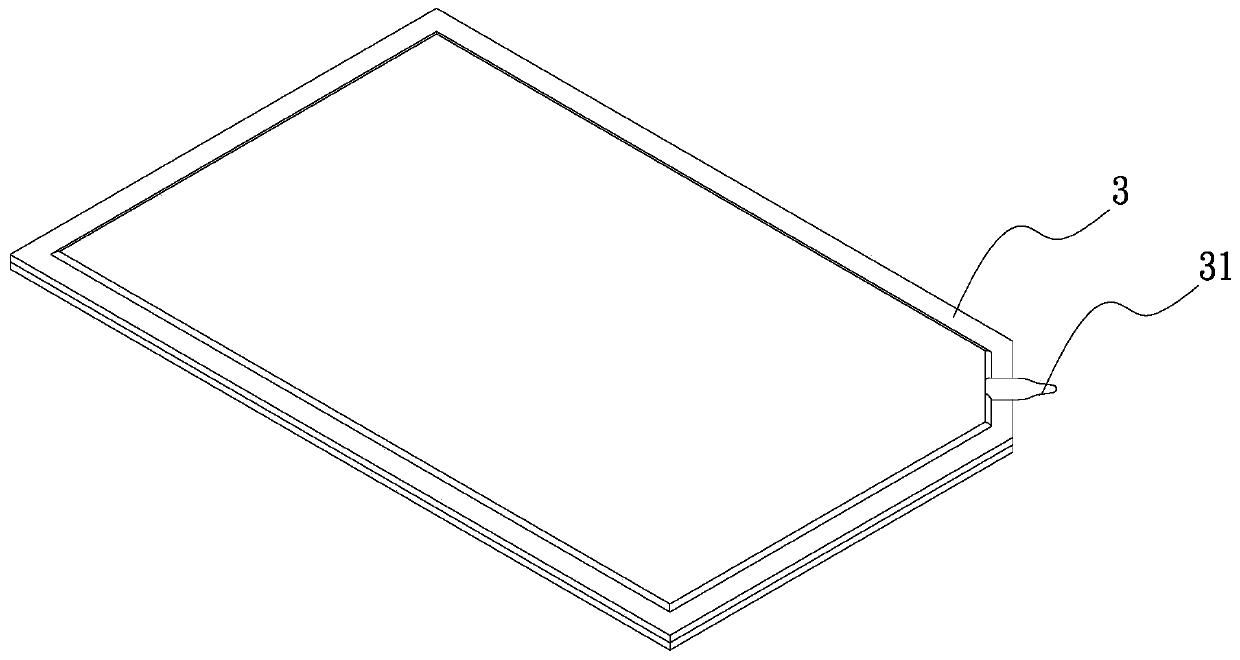

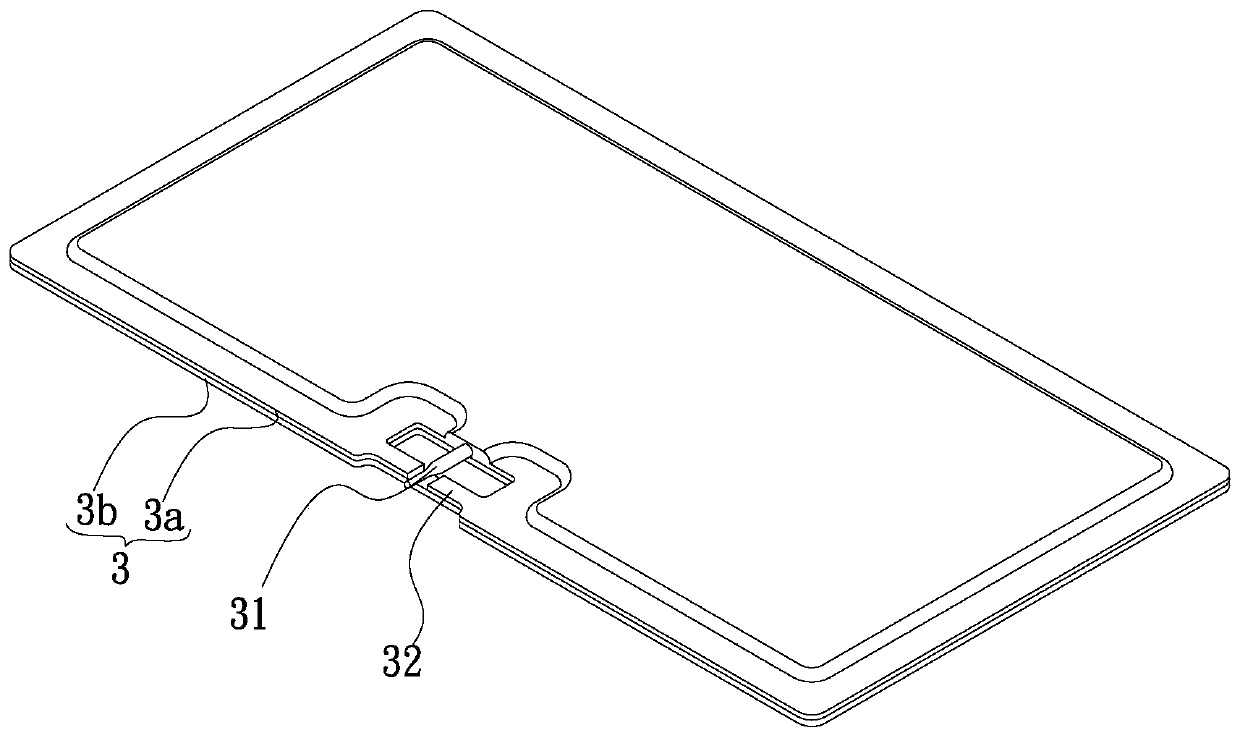

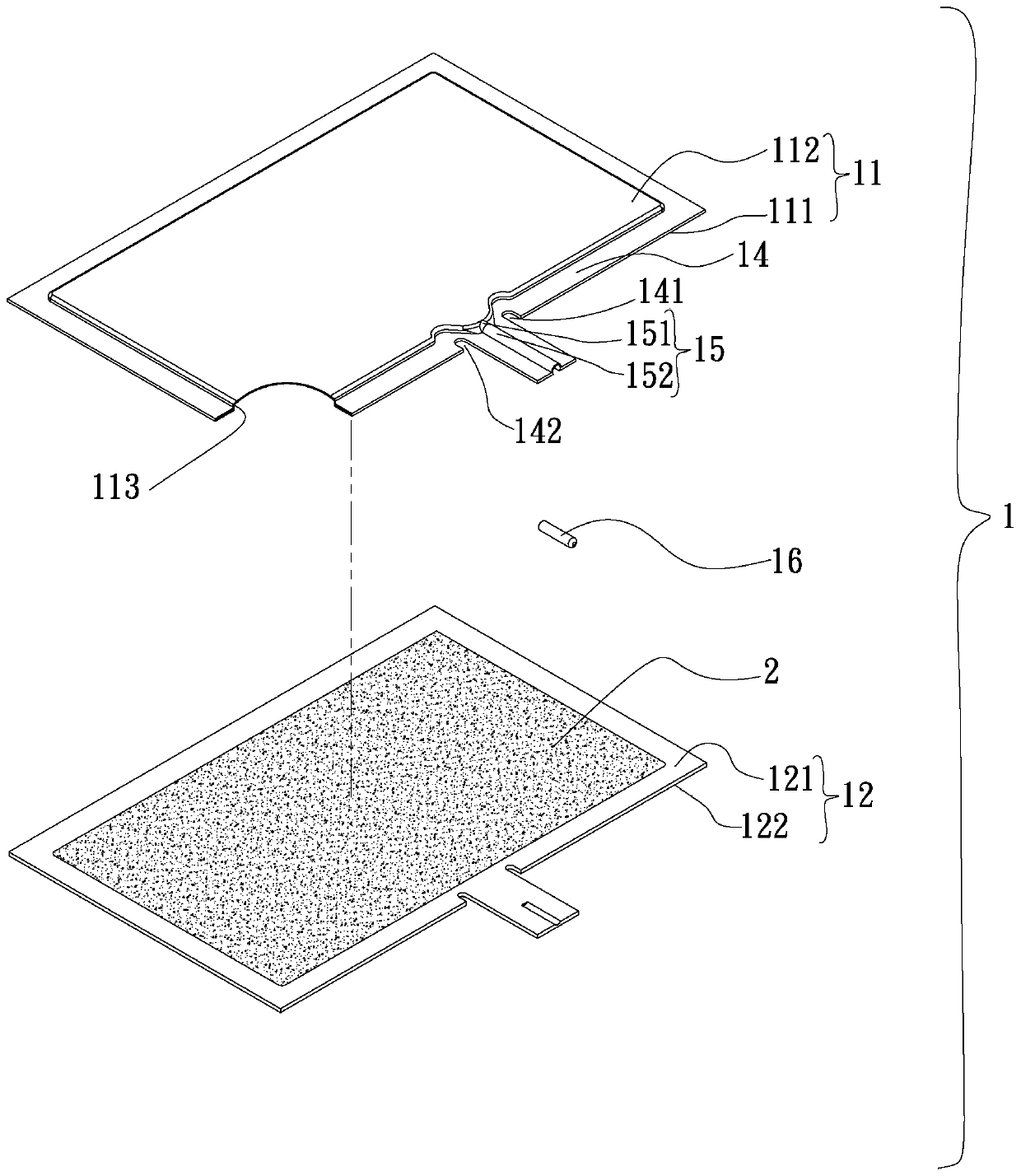

[0047] see image 3 , Figure 4 , is the three-dimensional disassembly and assembly diagram of the first embodiment of the edge sealing structure of the water injection part of the vapor chamber of the present invention. As shown in the figure, the edge sealing structure of the water injection part of the vapor chamber of the present invention includes: a body 1 and a capillary structure 2;

[0048] The body 1 has a first plate body 11 and a second plate body 12, and the first and second plate bodies 11, 12 are correspondingly covered to jointly define an airtight chamber 13, a water injection portion 15, and a lip 14 The ring is arranged on the outer edge of the main body 1 (that is, the outer edge ring of the first and second plates 11, 12 is provided with the lip 14), and the water injection part 15 has a water injection gap 151 and a water injection channel 152. One end of the water injection flow channel 152 is extended to connect with the lip 14, and the other end is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com