Flexuose combined spherical hinge and producing/assembling method of the same

A zigzag, combined technology, applied to springs, springs/shock absorbers, mechanical equipment, etc. made of plastic materials, to achieve the effect of improving performance, increasing axial stiffness, and reducing the ratio of radial and axial stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The drawings show a specific embodiment of the present invention, and the present invention will be further described below through the drawings and embodiments.

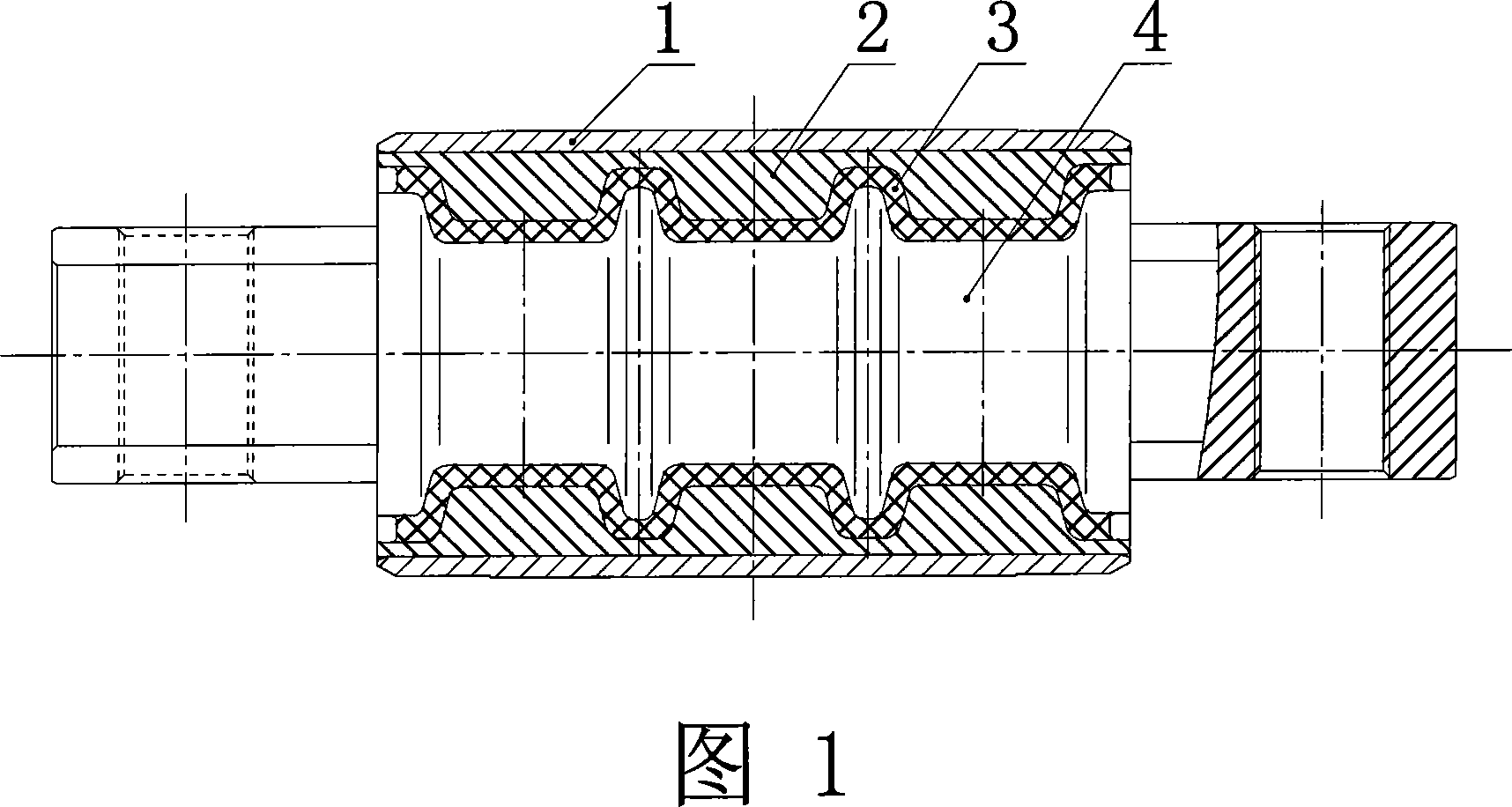

[0020] Figure 1 shows a specific embodiment of the present invention. It can be seen from the accompanying drawings that the present invention is a spherical hinge rubber elastic element, including a metal jacket 1, a mandrel 4 and an elastic rubber 3 body. Its characteristics are: There is a metal spacer 2 between the metal jacket 1 and the elastic rubber body 3. The metal spacer 2 has a two-petal structure, and the metal spacer 2 and the mandrel 4 are in a sawtooth shape. The saw teeth of the two are inlaid and interlocked with each other. Vulcanized together by elastic rubber 3. After being vulcanized, the metal spacer 2 and the elastic rubber body 3 are separated into a rubber metal vulcanized body with gaps in the radial direction compared with the original diameter.

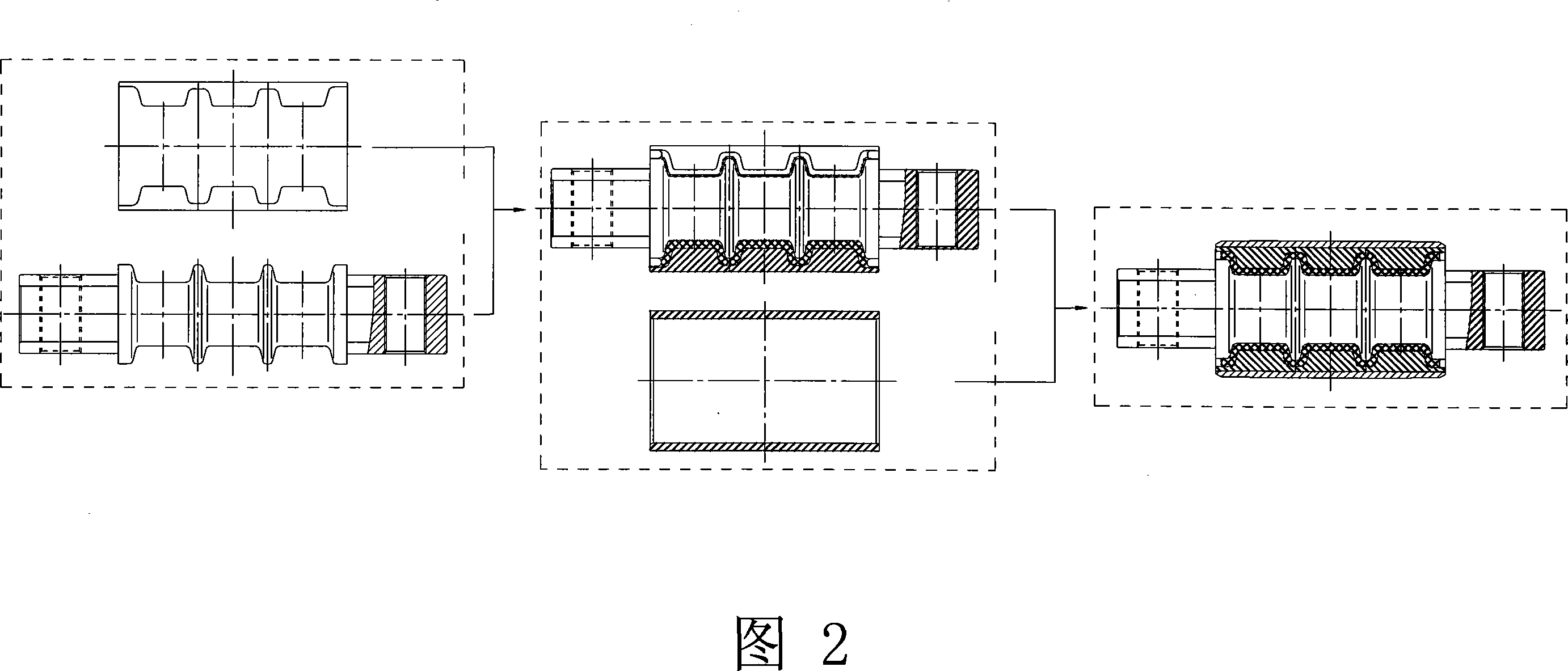

[0021] The production of spherical hing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com