Brake cable type shape memory alloy driver

A technology of memory alloy and memory alloy wire, which is applied in the direction of machines/engines, mechanisms for generating mechanical power, mechanical equipment, etc., can solve problems such as complex structures, achieve good flexibility, improve actuation reliability, and simplify structures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

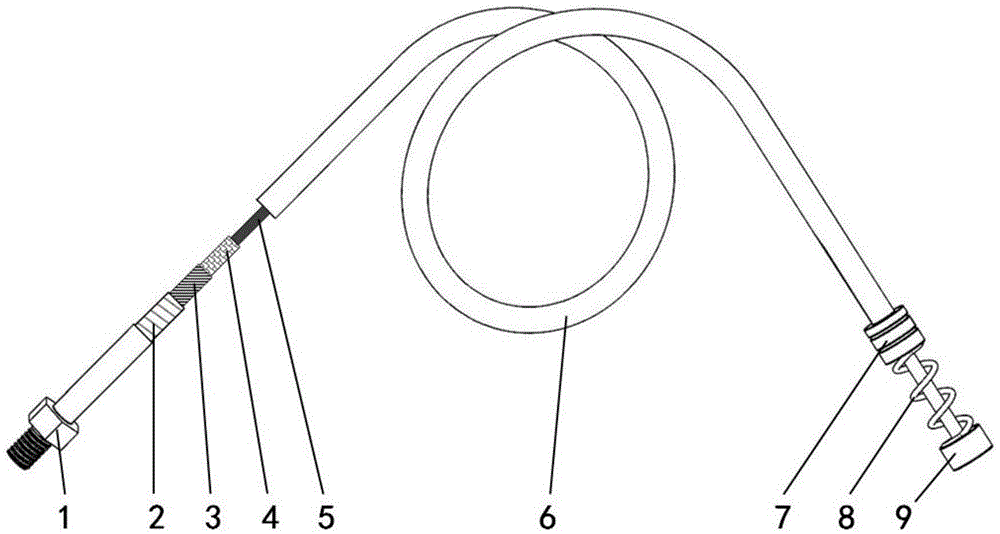

[0043] The specific structure of the present invention is as figure 1 shown.

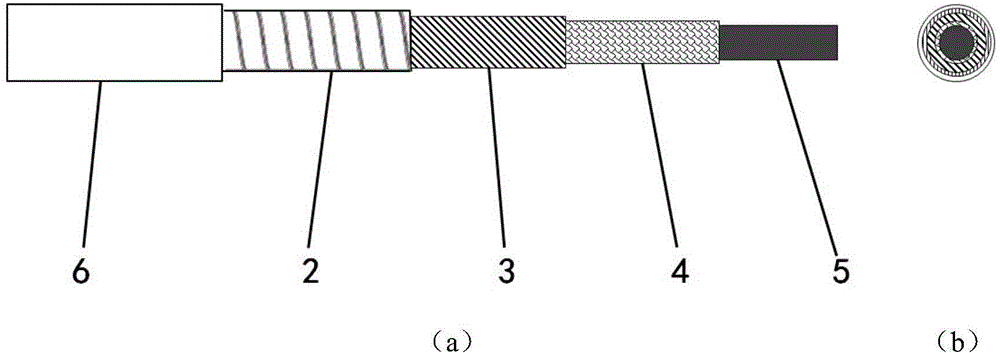

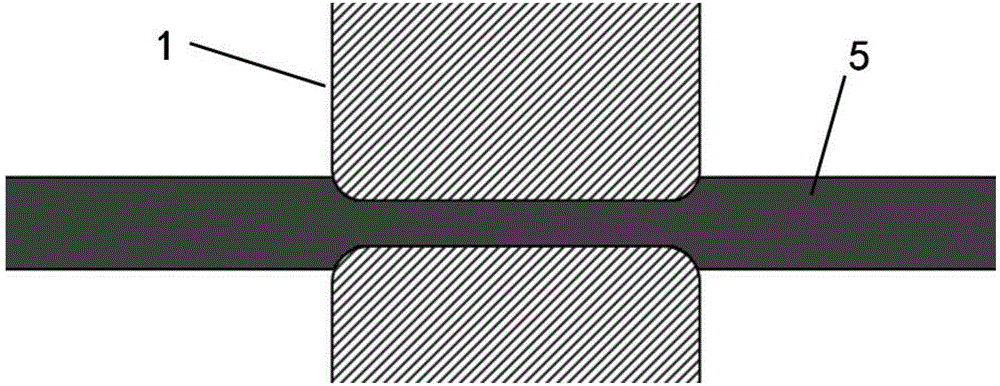

[0044] Such as figure 1 As shown, the main body of the present invention is a pipeline structure composed of shape memory alloy wire 5, molybdenum disulfide coating 4, polytetrafluoroethylene tube 3, metal spiral hose 2 and rubber tube 6, and one end of shape memory alloy wire 5 is fixed On the installation base 1 , the other end is connected with the actuating contact 9 ; the driver is fixed through the installation base 1 and the deck 7 , and a bias spring 8 is installed between the deck 7 and the operating contact 9 .

[0045] Such as figure 1 , figure 2 As shown, the surface of the shape memory alloy wire 5 of the present invention is coated with a molybdenum disulfide coating 4, and then wraps the polytetrafluoroethylene tube 3 and the metal spiral hose 2 in sequenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com