Measurement mechanism for lateral deformation of pressure chamber of true triaxial apparatus

A technology of true triaxial instrument and lateral deformation, applied in the direction of electric/magnetic solid deformation measurement, using stable tension/pressure test material strength, electromagnetic measuring device, etc., can solve the problems of main direction deformation measurement error, etc. Achieve the effect of strong contrast, reasonable design, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

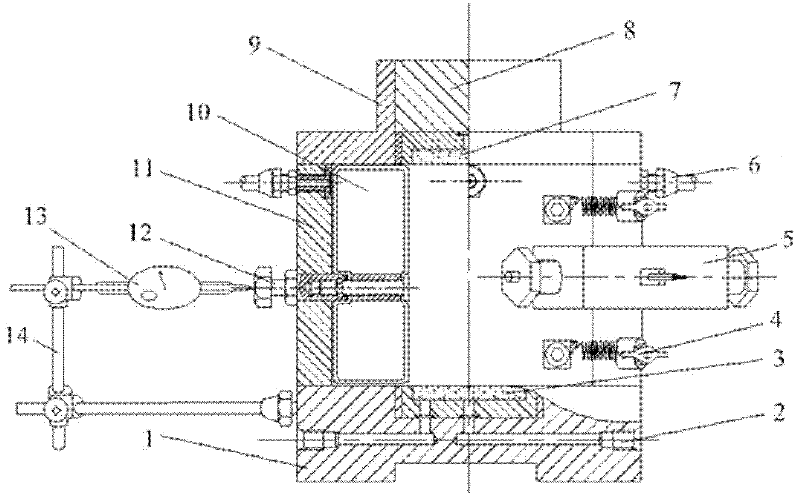

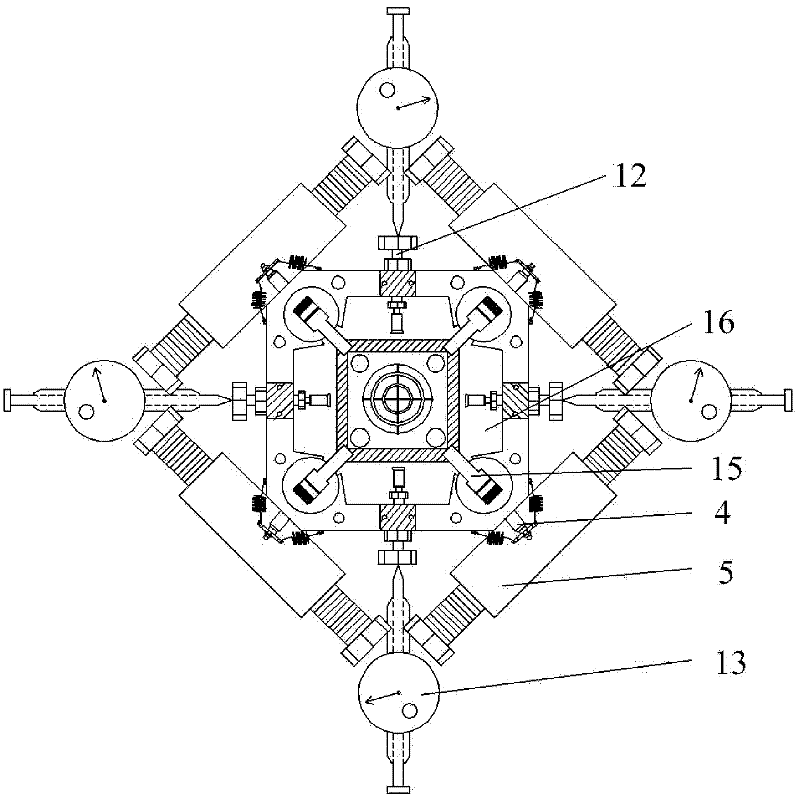

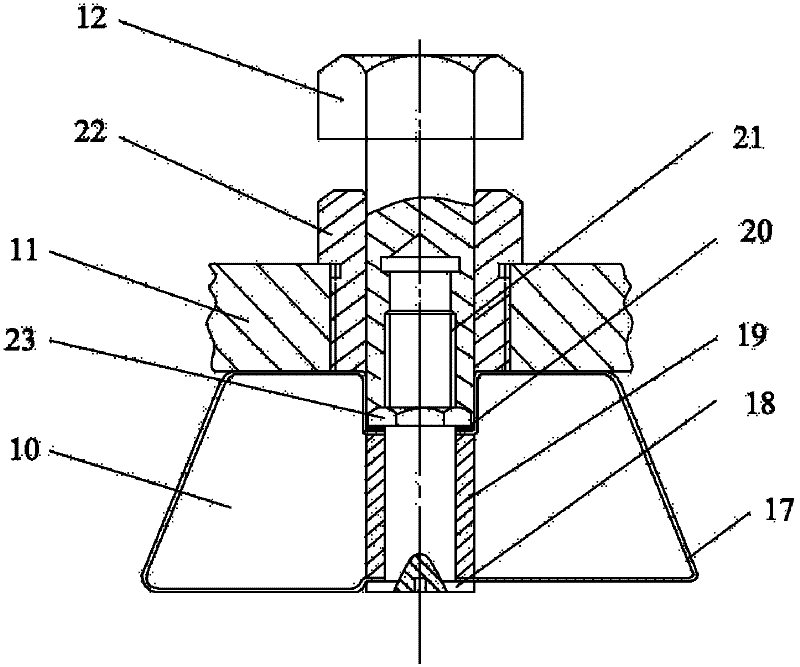

[0016] Such as figure 1 As shown, the present invention is a lateral deformation measurement mechanism of a true triaxial pressure chamber. The pressure chamber is composed of a pressure chamber base 1, a pressure chamber side wall 11 and a pressure chamber top cover 9 arranged in sequence from bottom to top. The center of the pressure chamber surrounded by the pressure chamber side wall 11 is the place where the sample is placed, and there are four pressure chambers 16 evenly distributed around the place where the sample is placed. Each of the four pressure chambers 16 is provided with a latex film 17. On the side of the pressure chamber Four hydraulic communication pipes 6 are installed on the wall 11, and the four latex membranes 17 are connected with the external pressure source through the corresponding hydraulic communication pipes 6, and form a T-shape for exerting lateral normal stress on the sample after being filled with liquid. Flexible hydraulic bladder 10. Betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com