Well cementation flushing fluid evaluation device and method based on principle of identical shearing rate

A technology of shear rate and flushing fluid, which is applied in the direction of flushing wellbore, earthwork drilling, wellbore/well components, etc., can solve the problems of cumbersome measurement steps, etc., and achieve the effect of real evaluation and real flushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

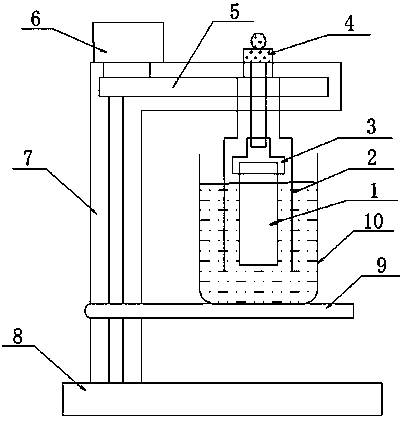

[0058] Example 1 Flushing Efficiency Testing Experiment of Flushing Fluid to Well Wall or Casing

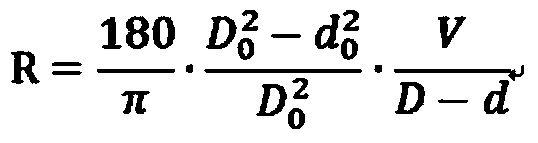

[0059] (1) A casing with an outer diameter of 139.70 mm is run in a wellbore with a diameter of 215.90 mm, and the drilling fluid is replaced at an average return velocity of the annular space of 0.5 m / s. When flushing with flushing fluid A for 8 minutes, evaluate the flushing of the well wall by flushing fluid A for 8 minutes washing efficiency.

[0060] In the first step, according to formula (1), the required rotational speed is 67.5r / min. In the second step, the artificial core is installed on the device of the present invention, and after the outer cylinder in the drilling fluid rotates at a speed of 67.5r / min for 30 minutes to form a mud cake, the core that forms the drilling fluid mud cake is removed and weighed to be 56.86g. The 3rd step, the rock core that forms mud cake is put back into the device of the present invention, replaces drilling fluid with flushing fluid A ...

Embodiment 2

[0063] Embodiment 2 flushing fluid system or formula optimal experiment

[0064] A casing with an outer diameter of 139.70 mm was run into a wellbore with a diameter of 215.90 mm, and the drilling fluid was replaced at an average annular velocity of 1.2 m / s. The flushing effects of the flushing fluids A, B and C were evaluated to select the flushing fluid.

[0065] When evaluating the advantages and disadvantages of various flushing fluids, one of the two, steel column or artificial core, can be used to simulate the flushing efficiency of casing or well wall. In this example steel columns are used for evaluation.

[0066] In the first step, according to formula (1), the required rotational speed is 162.0r / min. In the second step, the steel column is installed on the device of the present invention. After the outer cylinder in the drilling fluid rotates at a speed of 162.0r / min for 30 minutes to form a mud paste, remove the steel column adhering to the drilling fluid mud paste...

Embodiment 3

[0069] Implementation of 3 rinse solution dosage design

[0070] A casing with an outer diameter of 139.70 mm was run in a wellbore with a diameter of 215.90 mm, and the drilling fluid M was replaced by the average annulus return velocity of 0.8 m / s and 1.2 m / s respectively, and the reasonable dosage of flushing fluid S for these two return rates was designed.

[0071] In the first step, according to formula (1), the required speeds are 108.0r / min and 162.0r / min respectively when the return speed is 0.8m / s and 1.2m / s. In the second step, the artificial core is installed on the device of the present invention. After the outer cylinder in the drilling fluid rotates at a speed of 108.0r / min for 30 minutes to form a mud cake, the core that forms the drilling fluid mud cake is removed and weighed as 145.78g. The third step is to put the mud cake-forming rock core back into the device of the present invention, replace the drilling fluid with the flushing fluid S to be evaluated, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com