Test device capable of evenly applying axial compression load and shearing load

A technology of shear load and axial compression, which is applied in the direction of testing material strength by applying stable shear force and testing material strength by applying stable tension/pressure, which can solve the problems of non-coplanarity, inconvenient installation and use, and inconvenience Applicable to problems such as reinforced flat plates, to achieve the effect of uniform application and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing the present invention is described in further detail, please refer to Figure 1 to Figure 15 .

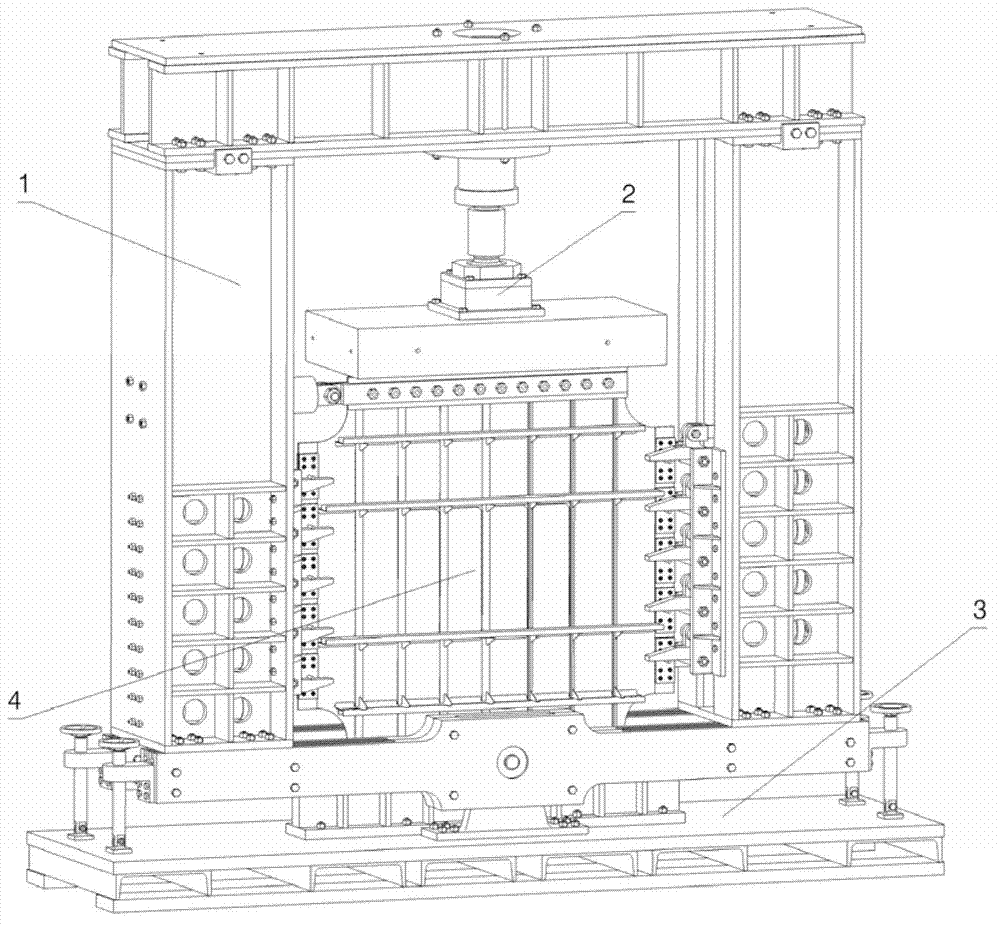

[0031] A test device capable of uniformly applying axial compressive loads and shear loads, such as figure 1 As shown, it includes a shear load application assembly 1 , an axial compression load application assembly 2 , a lower platform assembly 3 and a stiffened plate assembly 4 .

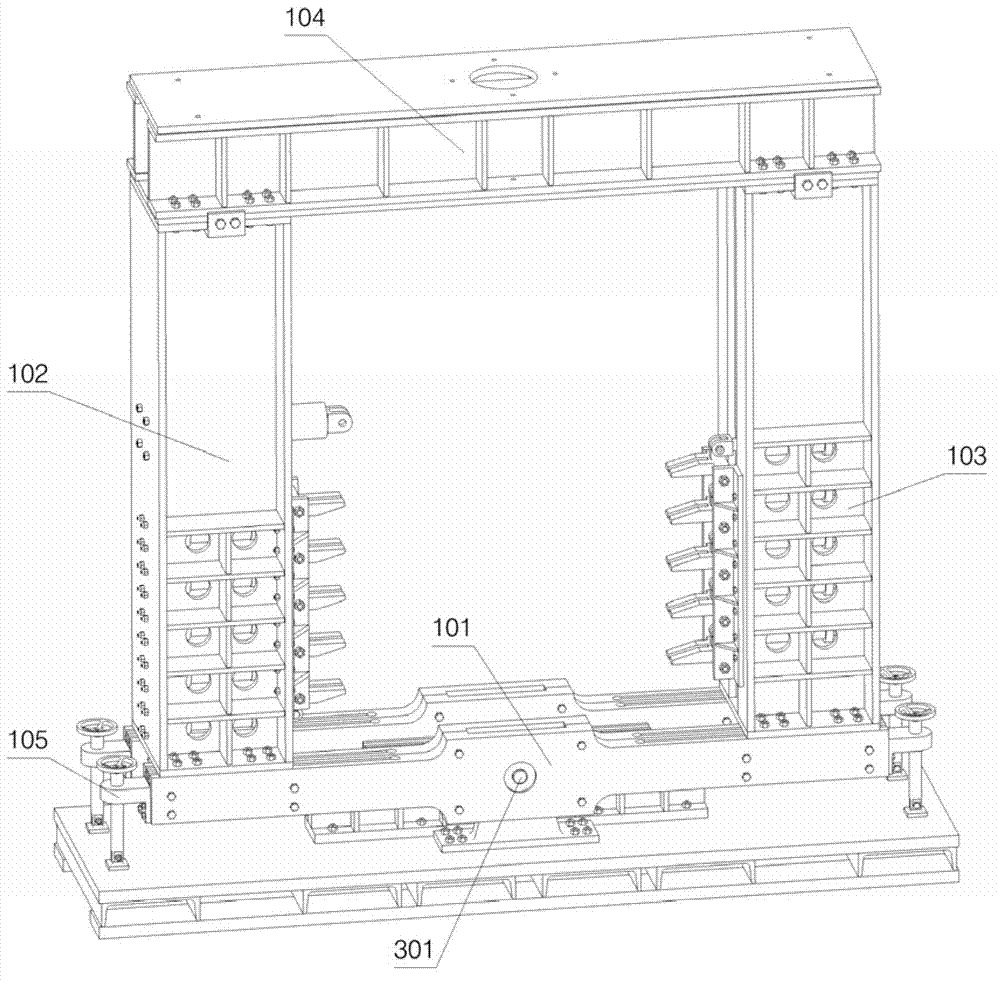

[0032] Such as figure 2 As shown, the shear load application assembly 1 includes a rotating platform 101, a left column assembly 102 and a right column assembly 103 fixed on the rotating platform 101, an upper beam 104, and a leveling device fixed on the rotating platform 101 105, the rotating platform 101 is connected with the lower platform assembly 3 through the large rotating shaft 301;

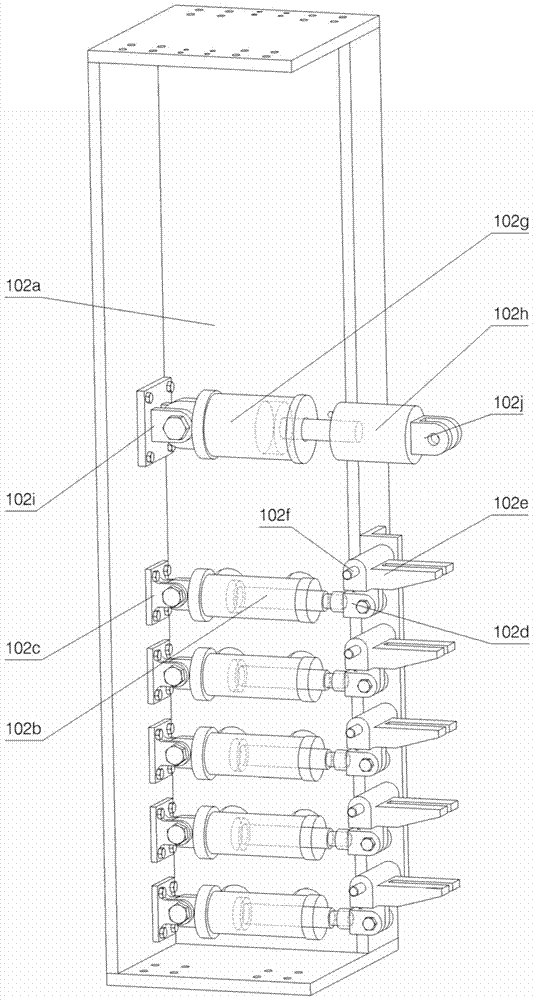

[0033] Such as image 3 , Figure 4 As shown, in order to make the layout of the internal structure clearly visible, part of the structure of the left co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com