Motorized spindle device supported by high-speed hybrid bearings and lubricated by two phases of gas and liquid

A technology of dynamic and static pressure bearing and electric spindle, applied in metal processing equipment and other directions, can solve the problems of low rigidity, limited load capacity and difficult work of supporting spindle, and achieve the effect of improving life, increasing load capacity and reducing temperature rise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

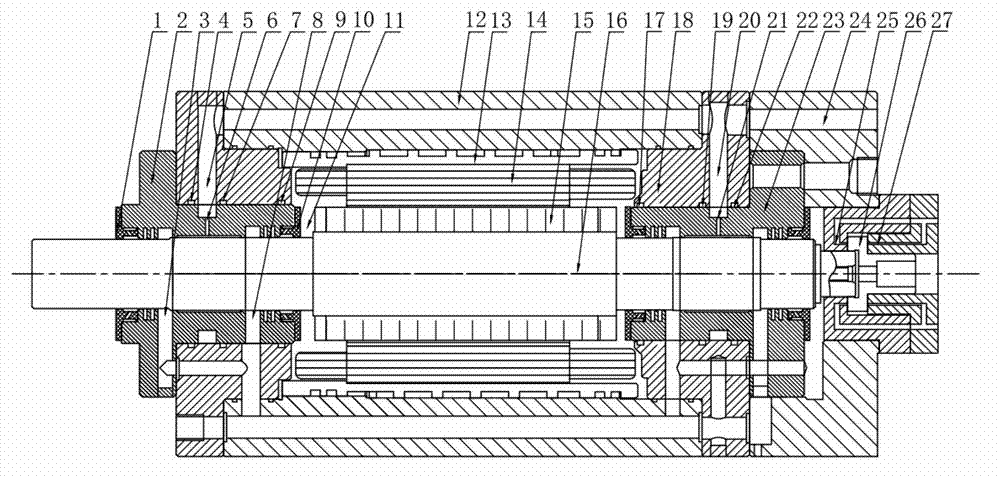

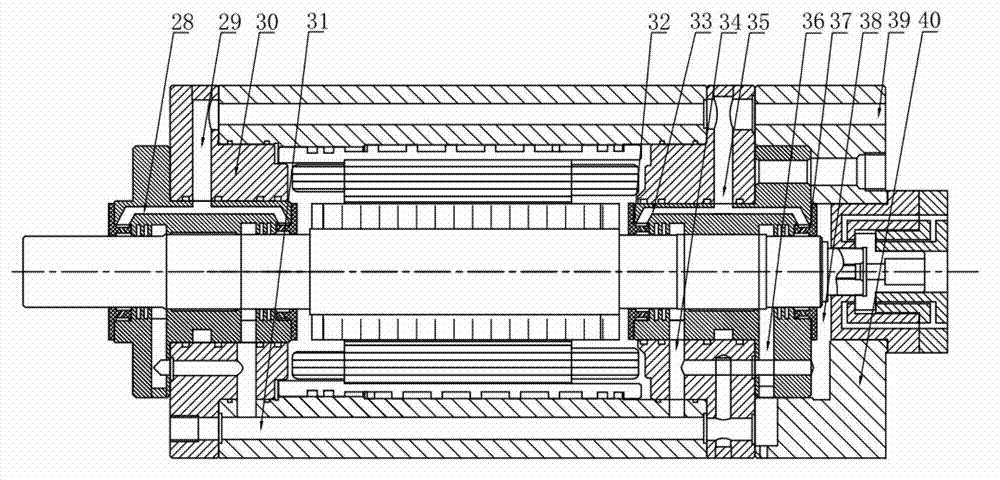

[0022] The technical solution adopted by the present invention to solve the technical problem: an electric spindle device supported by a high-speed dynamic and static pressure bearing using gas-liquid two-phase lubrication, including:

[0023] Housing 12, a cooling water jacket 13 and a motor stator 14 are fixed inside the housing 12, the cooling water jacket 13 is interference fitted on the housing 12, the motor stator 14 is installed on the cooling water jacket 13 with an interference fit, and the motor rotor 15 interference fit is installed on the main shaft, and corresponds to the motor stator 14.

[0024] The main shaft, the motor rotor 15 and the main shaft are integrated as the electric main shaft 16; the two ends of the electric main shaft 16 are equipped with front and rear bearings 2, 23, and the front and rear bearings are respectively a kind of dynamic and static pressure sliding bearings, The rigidity and stability of the high-speed electric spindle 16 can be impr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com