Twin-web rotor disc provided with disc cavity flow-guide rib plates

A technology of turbine disk and double-spoke plate, which is applied in the direction of supporting elements of blades, engine elements, machines/engines, etc., can solve the problems of low heat exchange efficiency, low pressure at the outlet of the disk cavity, and increase the axial stiffness of the disk center, etc. Achieve the effects of strengthening heat transfer, increasing flow rate, and improving the ability to resist deformation in the axial direction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

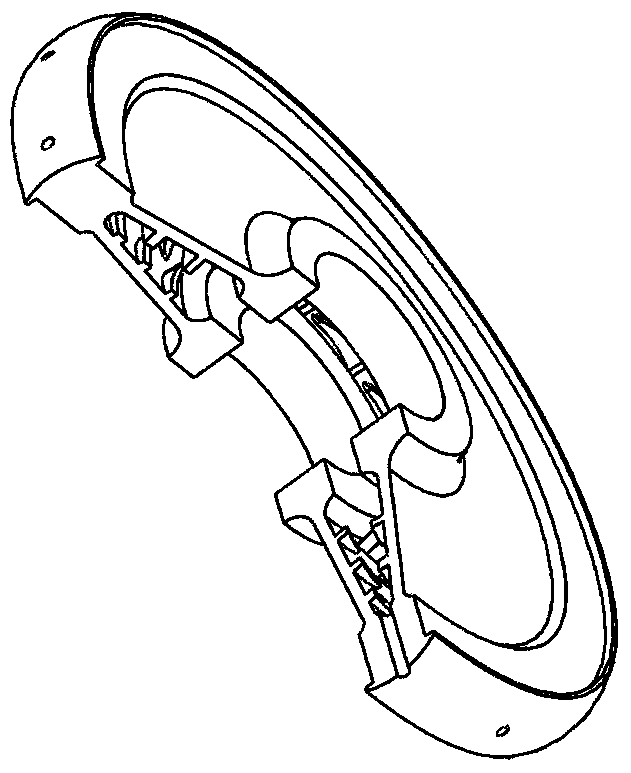

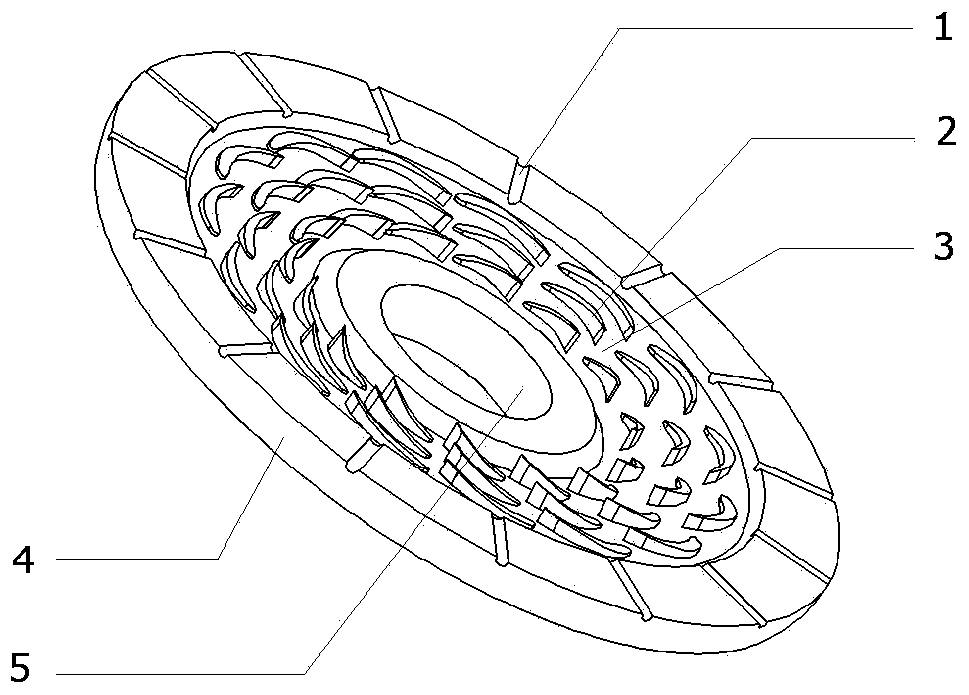

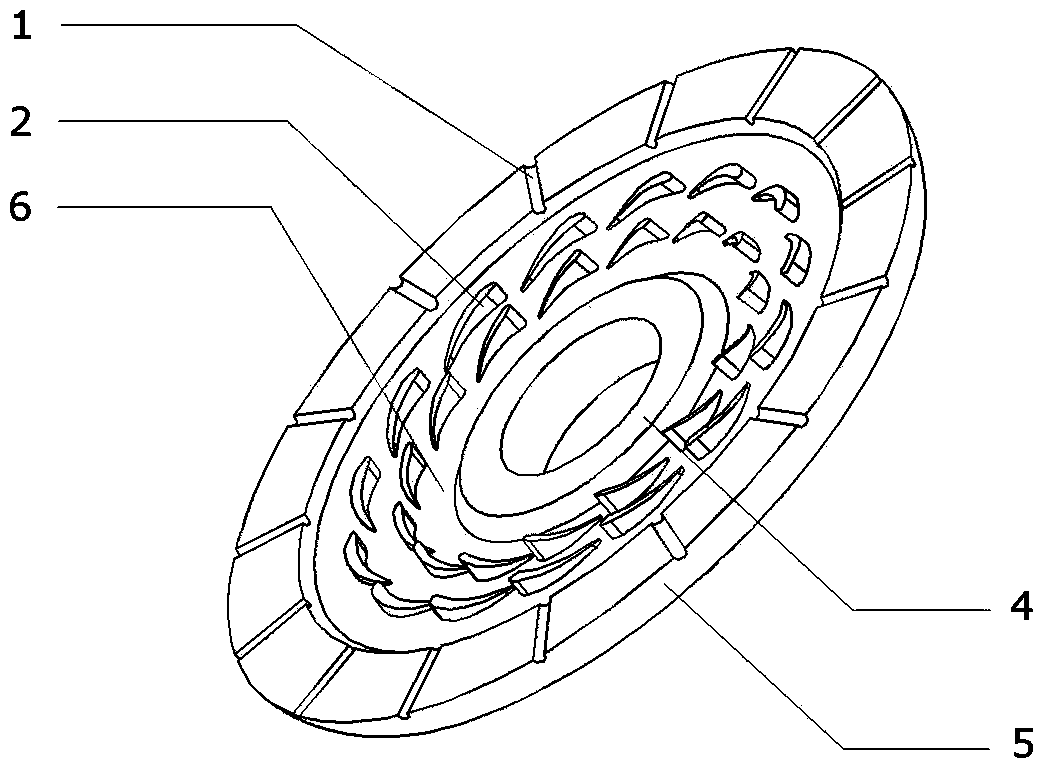

[0023] This embodiment is a double-spoke turbine disk with a disk cavity guide rib.

[0024] refer to Figure 1-Figure 5 , the double-spoke turbine disc in this embodiment includes a front spoke plate 3, a rear spoke plate 6, a guide rib 2, a tongue plate 10, a front hub 5, a rear hub 9, a cold air channel 1 and a turbine disc on the disc edge. The tenon and groove structure is omitted; the turbine disk edge 4 is evenly distributed with a plurality of disk edge cold air passages 1 along the radial direction of the circumference; 2 is a blade cross-sectional structure, and the bending direction of the guide rib plate 2 is the same as the rotation direction of the turbine disk. In this embodiment, the flow guide ribs 2 on the front web 3 extend radially toward the edge of the disk in three layers according to the center, and the flow guide ribs 2 on the rear web 6 extend radially toward the edge of the disk into two layers. , the inclination angle α between the front spoke pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com