Mixed heating roller hearth type medium plate open-fire tempering furnace and application

A technology of open flame and heating rollers, applied in heat treatment furnaces, furnaces, furnace types, etc., can solve the problems of poor flue gas flow direction, unsatisfactory furnace temperature uniformity, and low heat transfer efficiency, etc. Or daily maintenance is convenient, and the effect of enhancing the convective heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

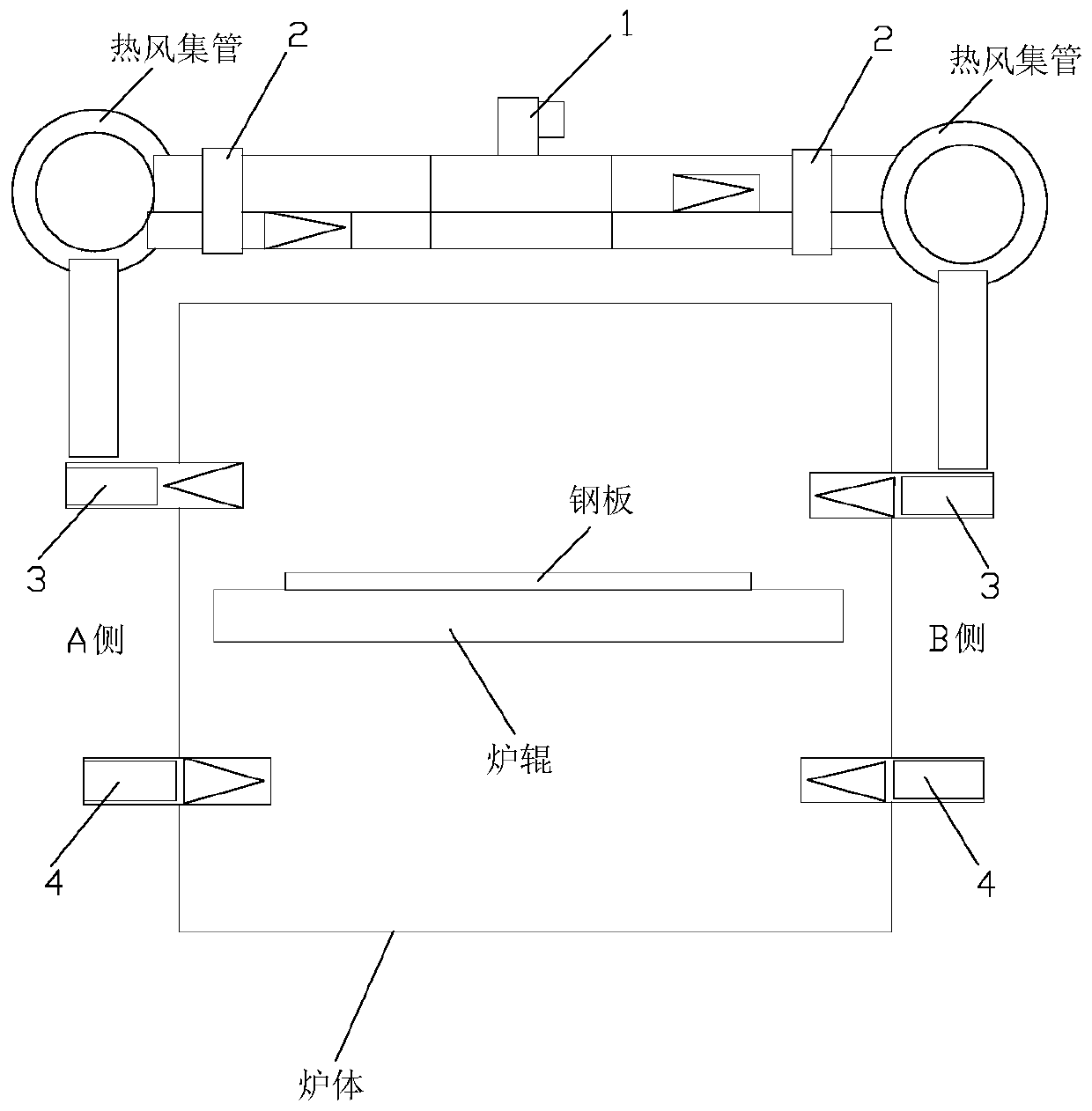

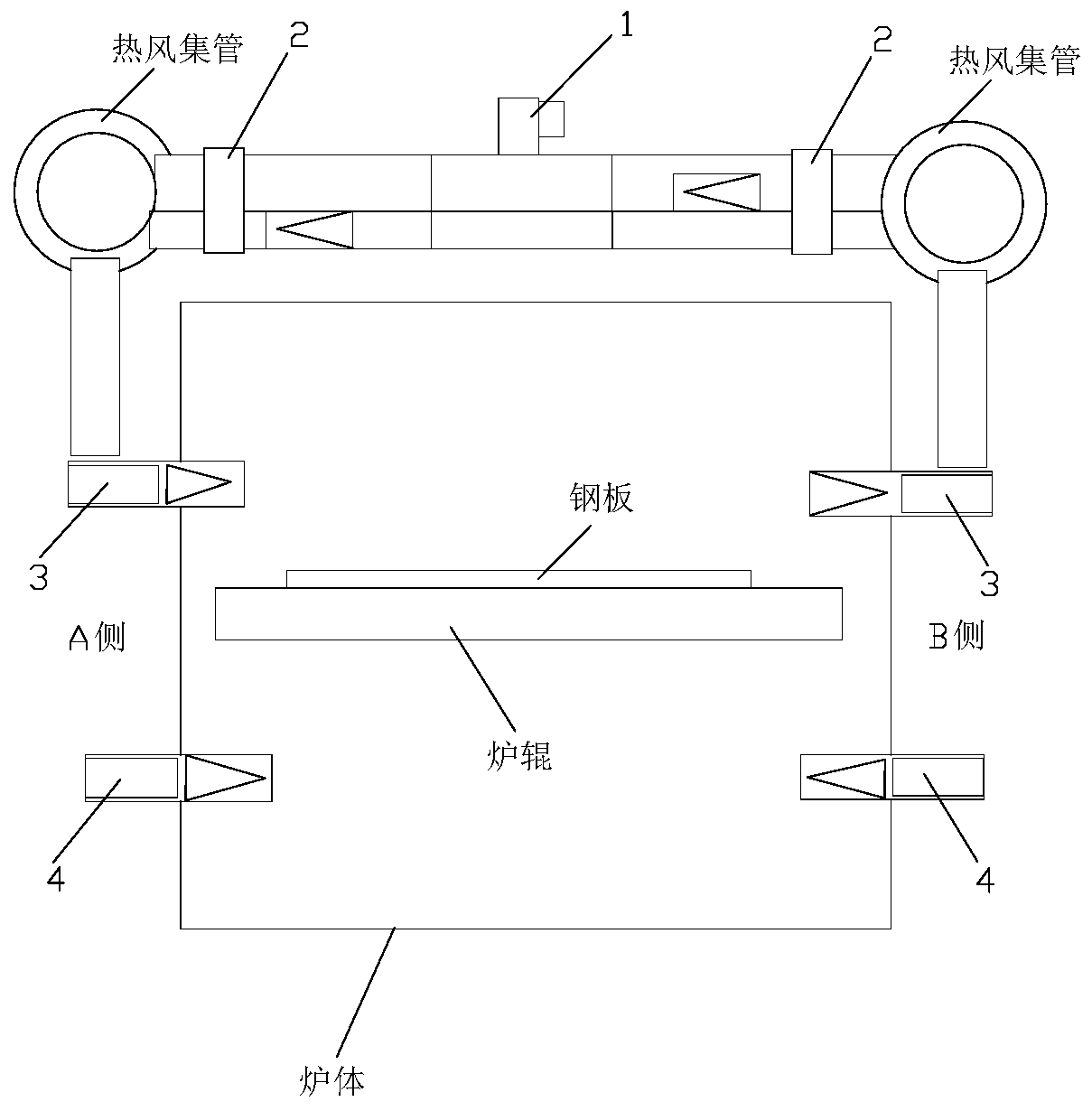

[0026] A mixed heating roller hearth type open flame tempering furnace for medium and thick plates provided in this embodiment includes an upper heating section and a lower heating section, the heating temperature range of the lower heating section is the same as that of the upper heating section, and the lower heating section uses gas The open flame burner 4, the upper heating section adopts several flue gas circulation heating systems distributed along the long direction of the tempering furnace, the flue gas circulation heating system and the gas open flame burner 4 are all arranged outside the tempering furnace body, the flue gas circulation heating system The circulating flue gas comes from the flue gas from the gas open flame burner 4.

[0027] Each flue gas circulation heating system includes a circulation fan 1 , a reversing valve 2 and a flue gas nozzle 3 . Circulation fan 1 is located directly above the furnace top of the tempering furnace. The operating temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com