Stirring structure for reinforcing olefin polymerization and method for reinforcing olefin polymerization

An olefin polymerization and agitator technology, which is applied in the field of strengthening olefin polymerization and strengthening the stirring structure of olefin polymerization, can solve the problems of uneven mass transfer and heat transfer, low conversion rate, low stirring efficiency, etc., so as to improve the convective heat transfer efficiency and promote the The effect of uniform mixing and improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

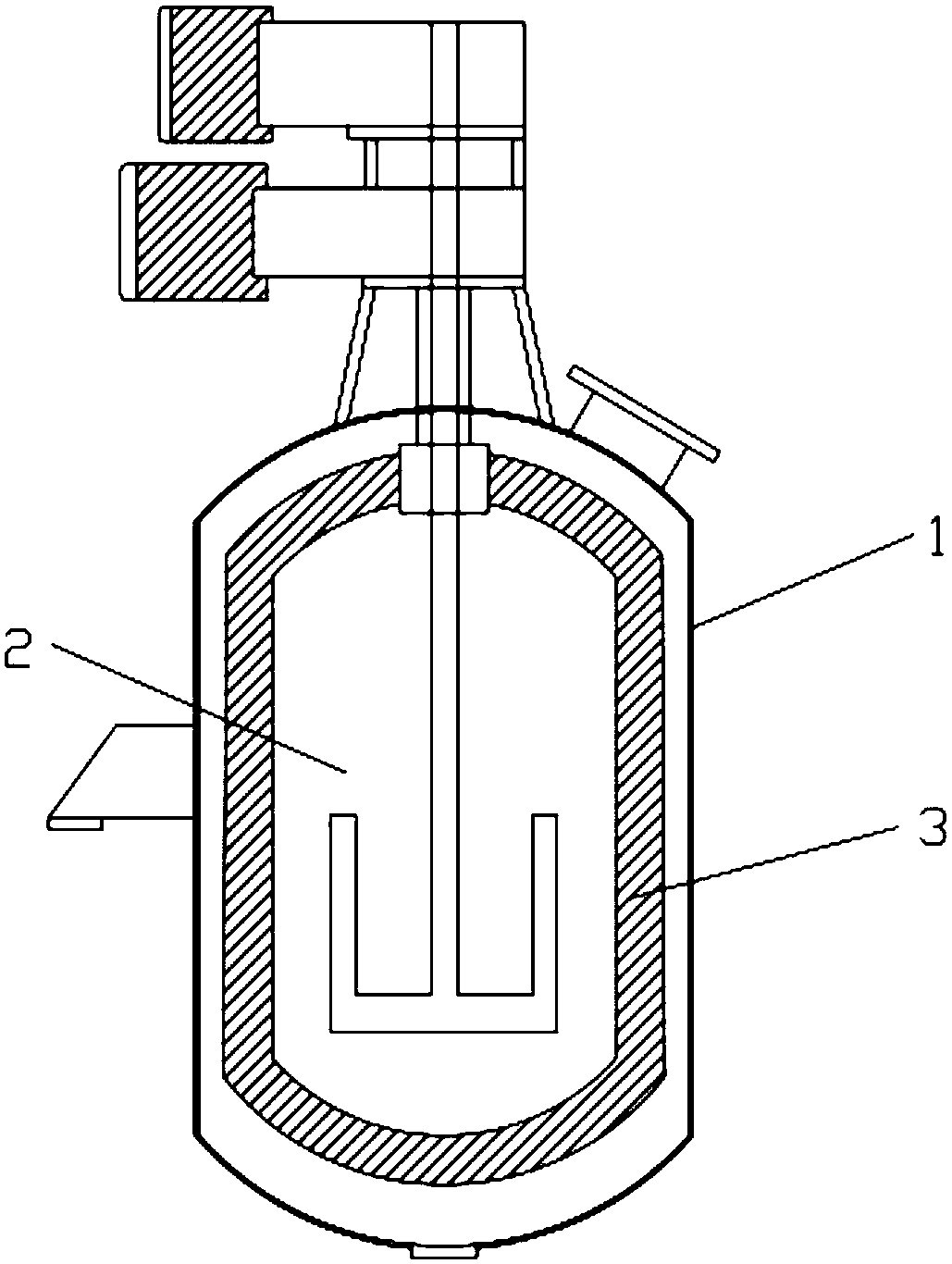

[0027] A method for strengthening batch type propylene slurry polymerization, such as figure 1 , including: the reaction kettle body 1 is a 5L vertical kettle body, the inner paddle 2 is an anchor paddle, and the outer layer paddle 3 is a frame paddle. The diameter of the kettle body is 144mm, the outer diameter of the inner paddle is 100mm, the layer spacing is 60mm, the inner diameter of the outer paddle is 110mm, and the outer diameter of the outer paddle is 135mm. The catalyst adopts a metallocene catalyst with a Zr content of 0.36%, the auxiliary agent is triisobutylaluminum, and Al / Zr=220 is controlled. First, open the outer paddle, adjust the rotation speed to 100r / min, and pass 2kg of liquid propylene, 200mg of hydrogen, 100mg of catalyst and a certain amount of triisobutylaluminum into the reaction device, and carry out prepolymerization at 40°C and 2MPa. 15min. After the pre-polymerization is completed, turn on the inner paddle, adjust the rotation speed to 100r / mi...

Embodiment 2

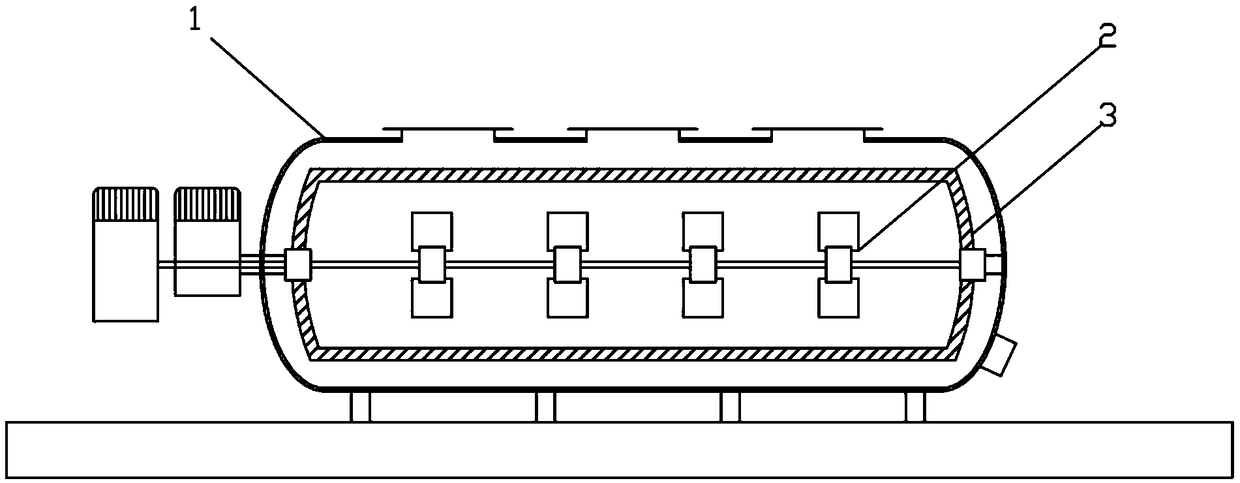

[0031]Change the reactor body in Example 1 into a 10L horizontal kettle body, the diameter of the kettle body is 200mm, the inner paddle is changed into four layers of folding blade paddles, the outer diameter of the inner layer paddle is 110mm, the interlayer distance is 60mm, and the outer layer paddle Inner diameter is 150mm, outer diameter of outer paddle is 180mm, 2kg liquid propylene, 200mg hydrogen, 100mg catalyst Zr content 0.36% change 4kg liquid propylene, 400mg hydrogen, 200mg catalyzer, others are identical with embodiment 1. The polypropylene obtained by the reaction is 3.82kg in total. The polypropylene particle size distribution obtained by the method is uniform, the particle size distribution D90-D10 / D50=1.88, and the fine powder produced is less, and the fine powder rate less than 200 mesh is 1.01%.

Embodiment 3

[0035] A method for strengthening batch-type propylene slurry polymerization, comprising: a reaction kettle body is a 5L vertical kettle body, an inner paddle is a three-layer propulsion type paddle, and an outer layer paddle is an anchor type paddle. The diameter of the kettle body is 144mm, the outer diameter of the inner paddle is 100mm, the layer spacing is 90mm, the inner diameter of the outer paddle is 110mm, and the outer diameter of the outer paddle is 135mm. The Ti content of Ziegler-Natta catalyst is 1.51%, the cocatalyst is triethylaluminum, and the external electron donor is dicyclopentyldimethoxysilane, and Al / Zr=220 is controlled. First turn on the inner and outer paddles, adjust the speed of the inner paddle to 100r / min, and the speed of the outer paddle to 150r / min, and the rotation direction of the two is opposite, and mix 2kg of liquid propylene, 200mg of hydrogen, 50mg of catalyst, 2ml of external electron donor and a certain A certain amount of triethylalum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com