Heat dissipating device for oil-immersed transformer

An oil-immersed transformer and cooling device technology, applied in the field of transformers, can solve problems such as weak heat dissipation performance, achieve the effects of improving work capacity, reducing costs, and improving convective heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

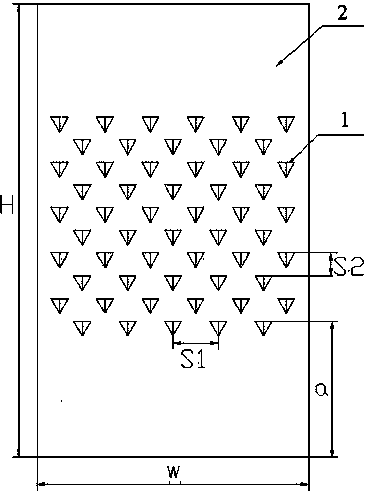

[0018] Examples such as figure 1 As shown, an oil-immersed transformer cooling device includes an oil-immersed transformer heat sink 1, the length H of the oil-immersed transformer heat sink 1 is 800mm, and the width W is 480mm; the oil-immersed transformer heat sink 1 is stamped There are several three-dimensional convex spoiler structures.

[0019] Several three-dimensional protruding spoiler structures are arranged in a staggered manner at a certain distance, the horizontal spacing S1 is 80 mm, and the longitudinal spacing S2 is 40 mm.

[0020] The distance a between the first row of three-dimensional protruding spoiler structures and the bottom of the heat sink of the oil-immersed transformer is 240mm.

[0021] The three-dimensional protruding spoiler structure is a triangular conical longitudinal vortex generator 2 .

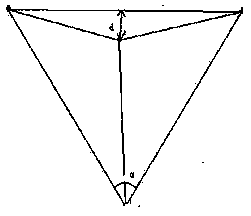

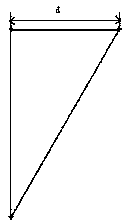

[0022] Such as figure 2 , image 3 As shown, the height d of the triangular conical longitudinal vortex generator 2 is 10 mm, and the angle of attack ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com