Comprehensive measuring method and circuit for electric motor rotating speed and rotor location

A technology of rotor position and motor speed, applied to devices using electric/magnetic methods, motor generator testing, electronic commutators, etc., can solve large measurement errors, encoder pulse sequences are no longer evenly spaced, and cannot be measured Problems such as motor rotors, to eliminate errors, reduce hardware configuration, and improve measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

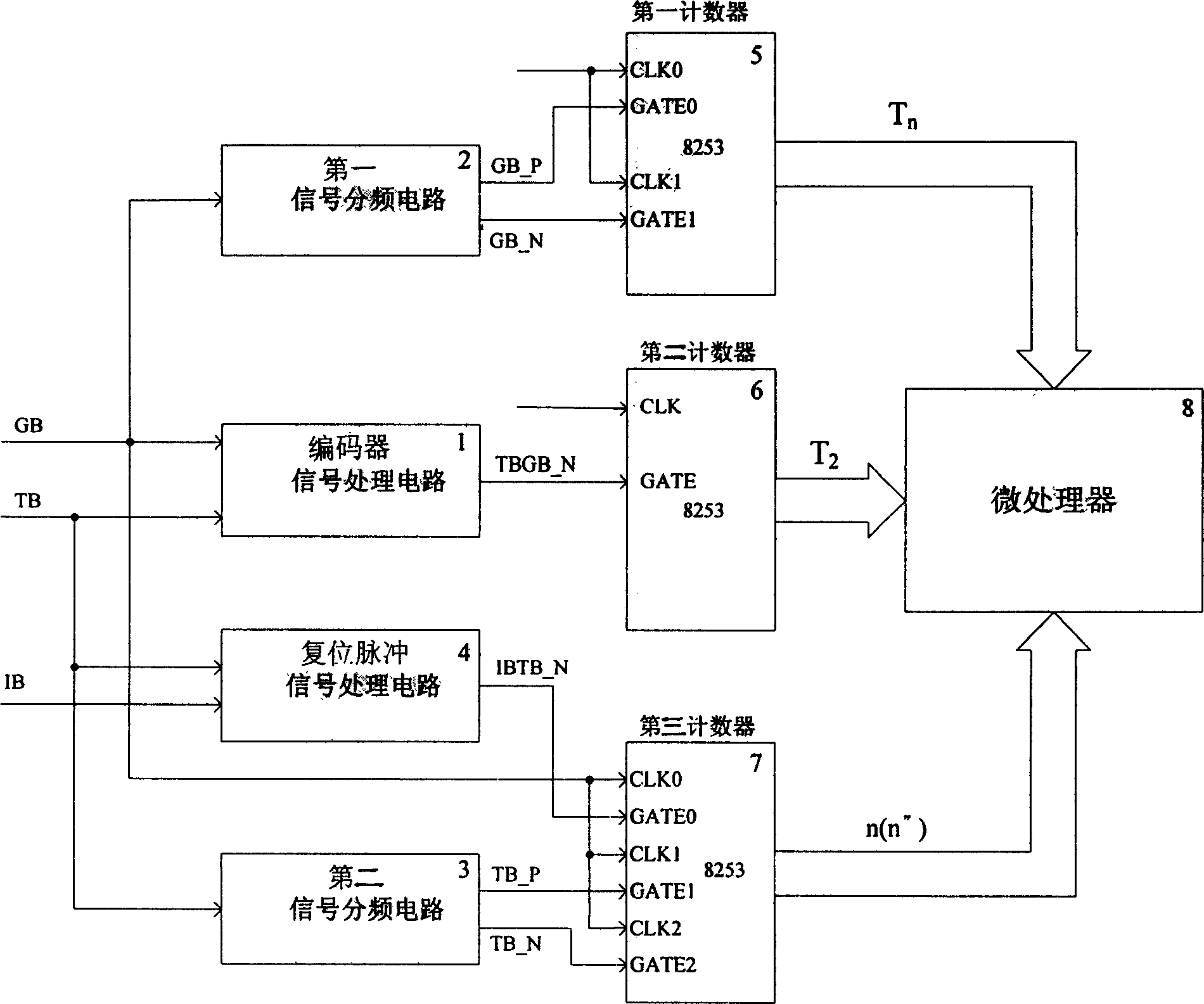

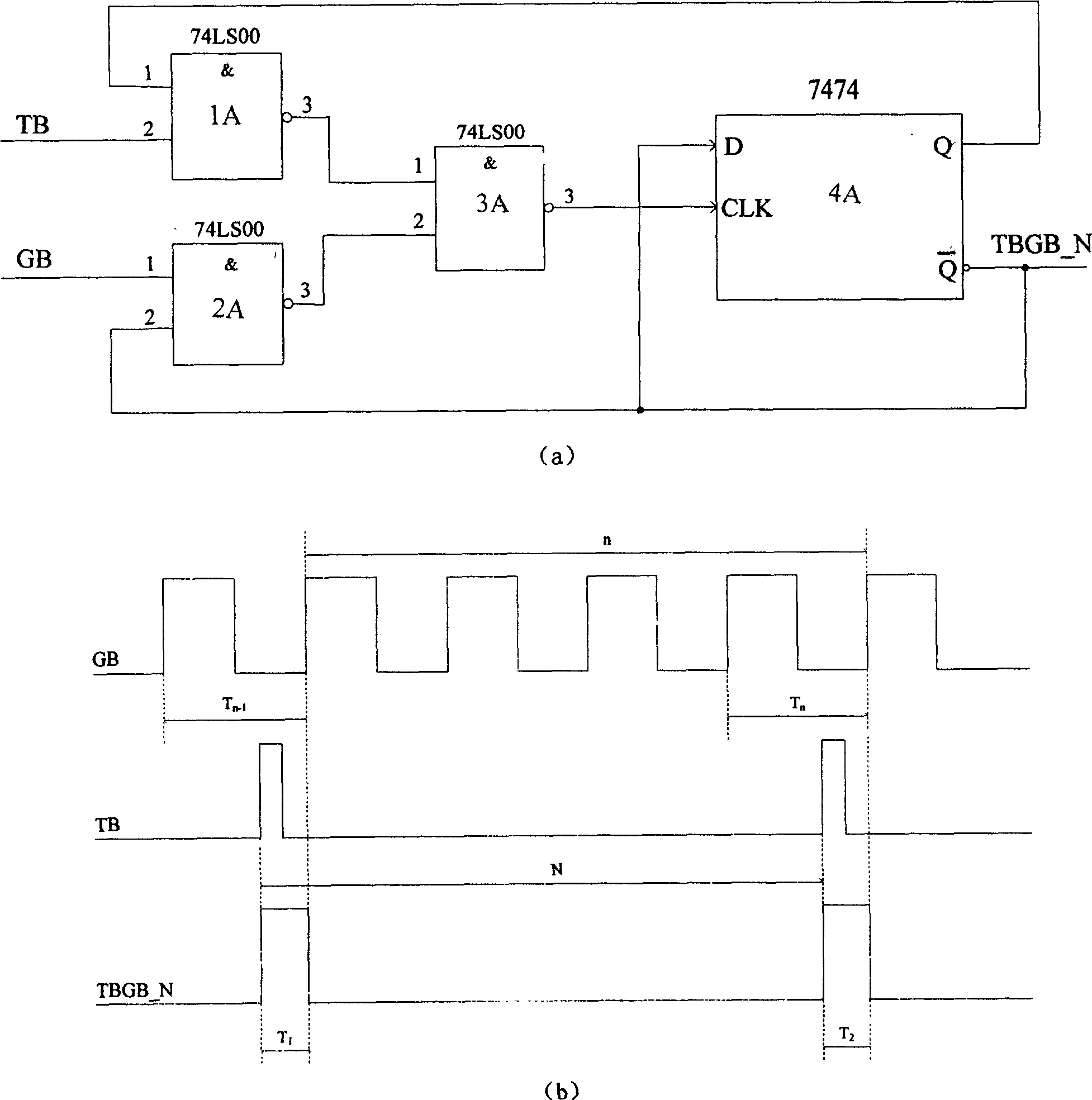

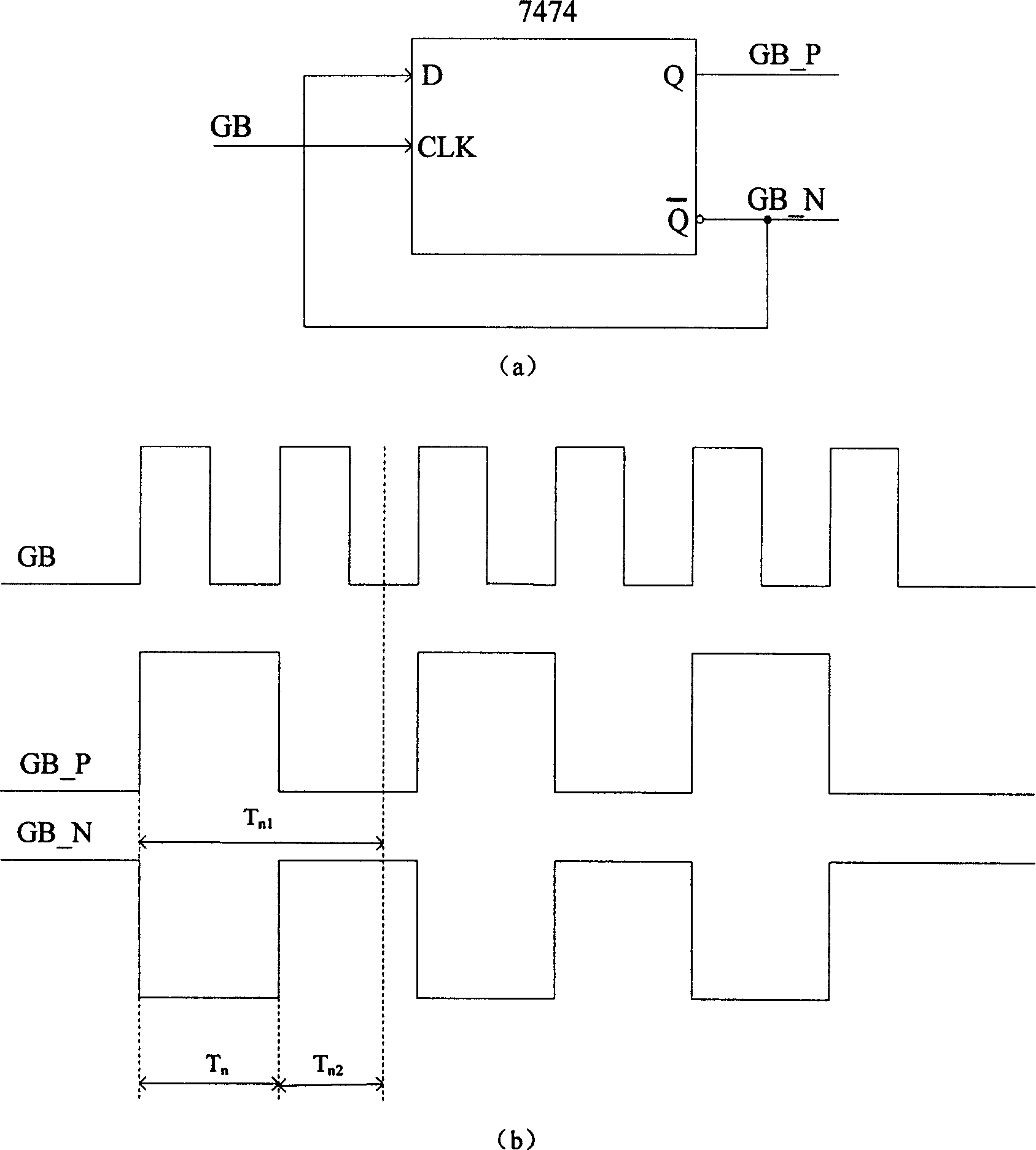

[0041] Reference figure 1 , The measurement circuit used in the integrated measurement method of motor speed and rotor position of the present invention includes an encoder signal processing circuit 1, a first signal frequency dividing circuit 2, a second signal frequency dividing circuit 3, a reset pulse signal processing circuit 4, The first counter 5, the second counter 6, the third counter 7 and the microprocessor 8, an input terminal of the encoder signal processing circuit 1 and the input terminal of the first signal frequency dividing circuit 2 and the clock terminal of the third counter 7, respectively Connect the pulse signal GB output by the encoder, the other input terminal of the encoder signal processing circuit 1 and the input terminal of the second signal frequency dividing circuit 3 and one input terminal of the reset pulse signal processing circuit 4 are respectively connected to the given measurement period pulse Signal TB, the other input terminal of the reset ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com