Indoor experimental device for antifriction resistance property of axial vibration of petroleum drilling pipe column

A technology of axial vibration and oil drilling, which is applied in the field of oil drilling pipe string mechanics research, can solve the problem of short length of simulated wellbore and drill string, without considering the impact of wellbore tortuosity, the influence of vibration drag reduction tool placement, insufficient Overcome problems such as end effect and achieve uniform loading effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

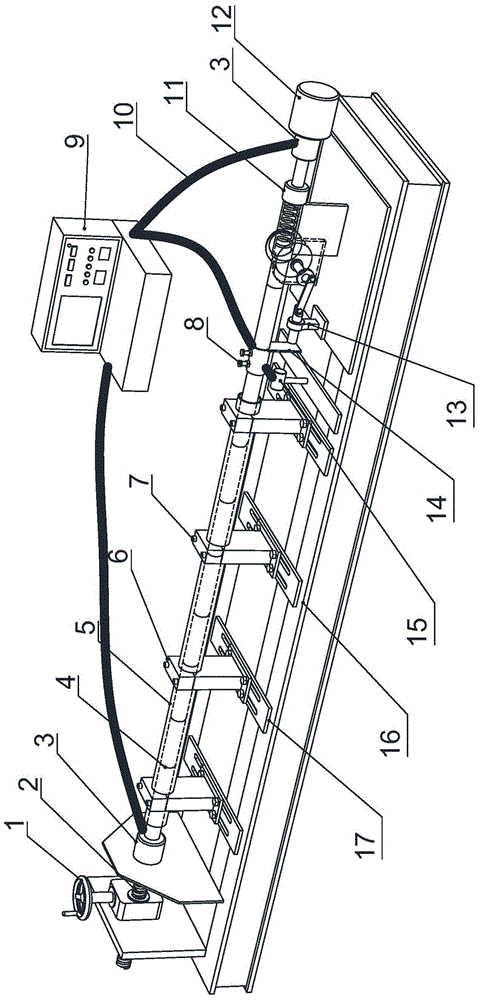

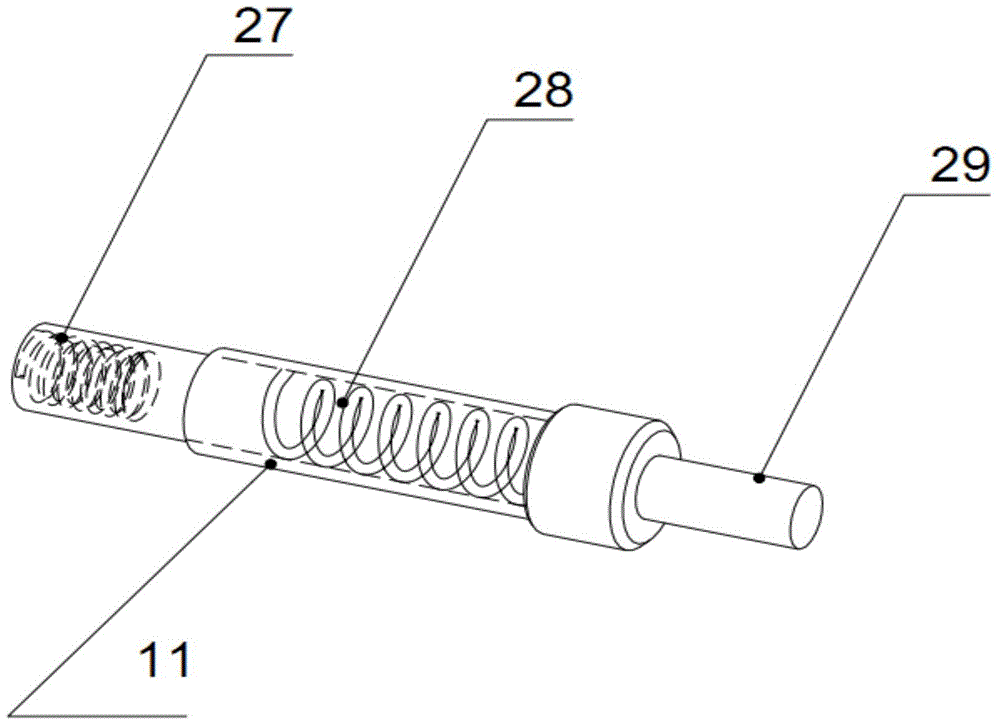

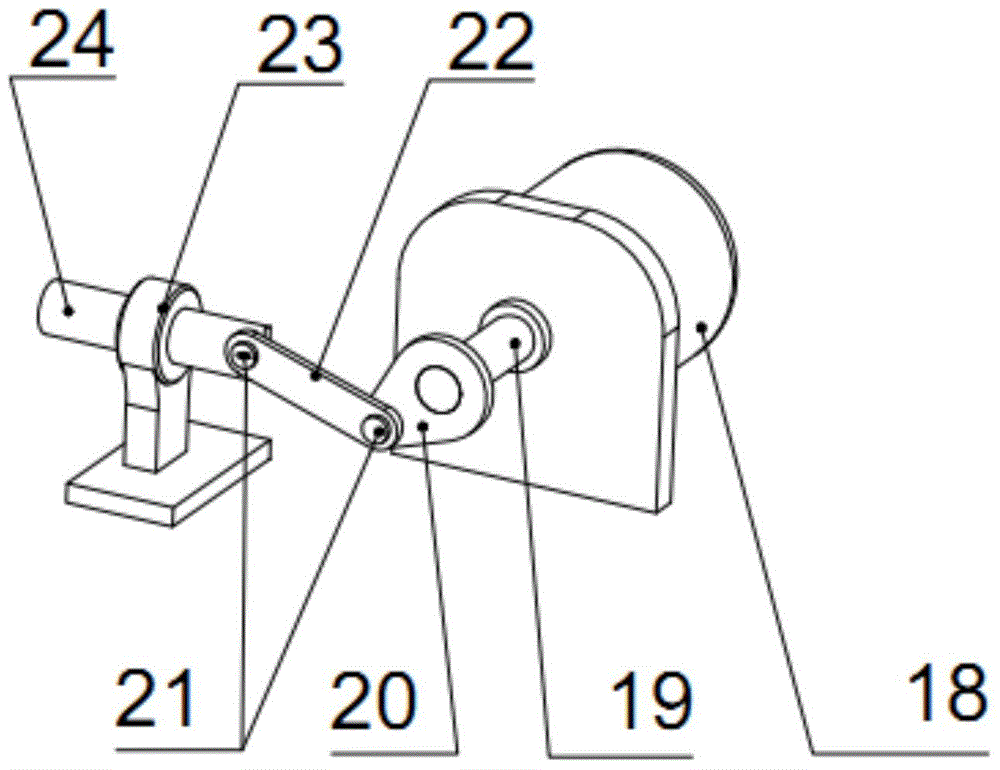

[0033] Such as figure 1 As shown in Fig. 1, an indoor experimental device for the axial vibration and anti-friction characteristics of an oil drilling string includes a simulated string combination system, a loading system, a vibration system, a measurement system and a fixing system. The simulated pipe string combination system includes a simulated pipe string 4 and a simulated wellbore 5 , and the simulated wellbore 5 is set on the outside of the simulated pipe string 4 . The loading system adopts a hand-operated screw-up loading device, which specifically includes a loading handwheel 1 and a loading screw 2. The loading screw 2 is connected to the left end of the simulated pipe string 4. The loading handwheel 1 is used to control the loading screw 2 to move along the simulated pipe. The axis of column 4 moves back and forth. The loading system can realize the uniform loading and unloading of simulated bit pressure. The vibration system includes a telescopic sleeve 11, a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com