Composite activator used for vibration-cutting

A vibration-exciting device and vibration-cutting technology are applied in the direction of vibrating fluids, large-scale fixed members, metal processing machinery parts, etc., which can solve the problems of not being able to significantly reduce the axial force and exit burrs, not being easy to control parameters alone, limiting promotion and Application and other problems, to achieve the effect of eliminating adverse effects, convenient adjustment of vibration parameters, and accurate parameter adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

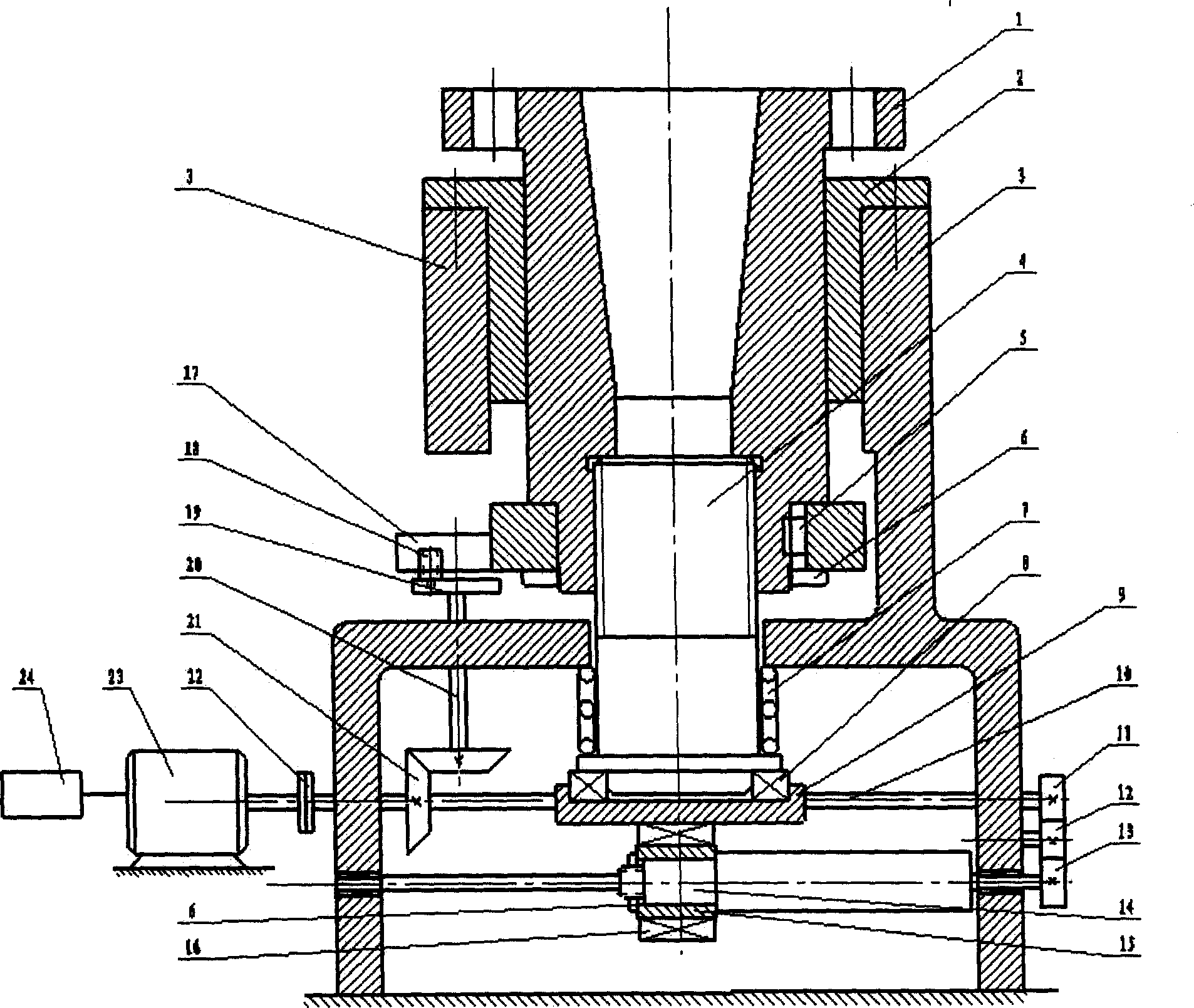

[0026] The present invention is a compound excitation device for vibratory cutting. On the premise of only one power source, through the crank slider mechanism and double eccentric mechanism, the present invention can convert the rotational motion output by the motor into one with a certain frequency and A torsional vibration and an axial vibration superimposed compound vibration of the amplitude, and the individual selection and control of axial vibration and torsional vibration can be realized. Its achievable axial vibration frequency is 10-50Hz (stepless adjustment), amplitude is 0-0.4mm (stepless adjustment), torsional vibration frequency is 1-100Hz (stepless adjustment), and angular amplitude is 3°-10 ° (with step adjustment).

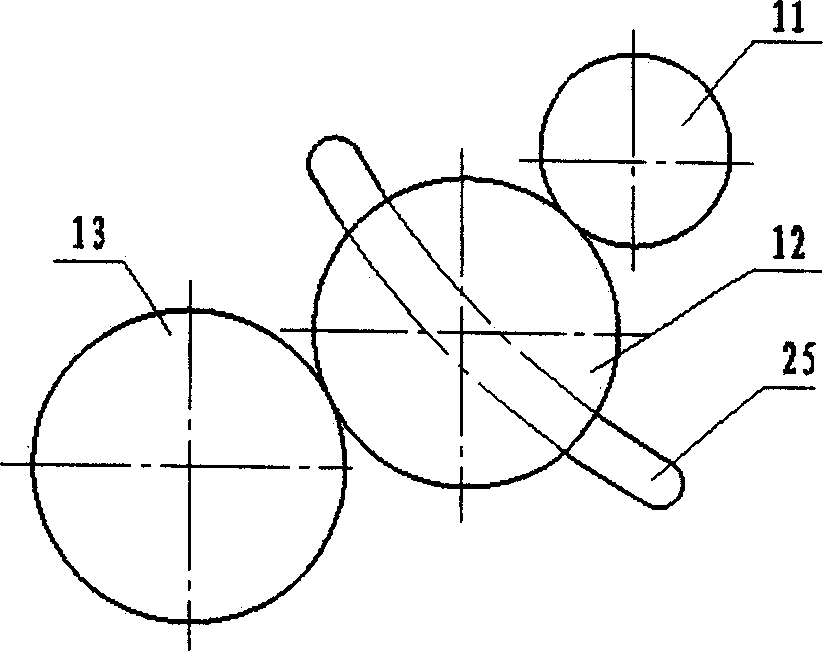

[0027] Such as figure 1 , the present invention is composed of housing (3), frequency converter (24), motor (23), shaft coupling (22), drive shaft (10), bevel gear pair (21), vertical shaft (20), crank slide Block mechanism, cylindrical gear tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com