Pneumatic valve for inhibiting back pressure of air-breathing pulse detonation engine

A pulse detonation and engine technology, applied in the direction of machine/engine, mechanical equipment, climate sustainability, etc., can solve the problems of large mass, forward flow resistance and one-way control ability cannot be solved at the same time, complex structure, etc. Reduce adverse effects, eliminate adverse effects, avoid the effect of periodic changes in flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

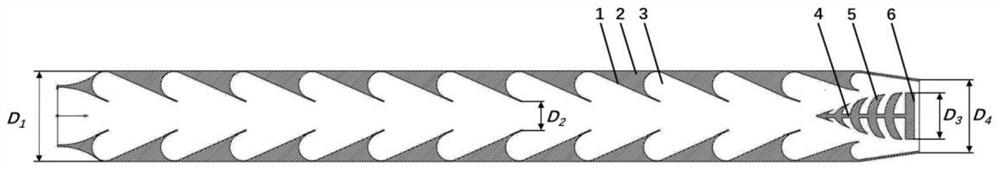

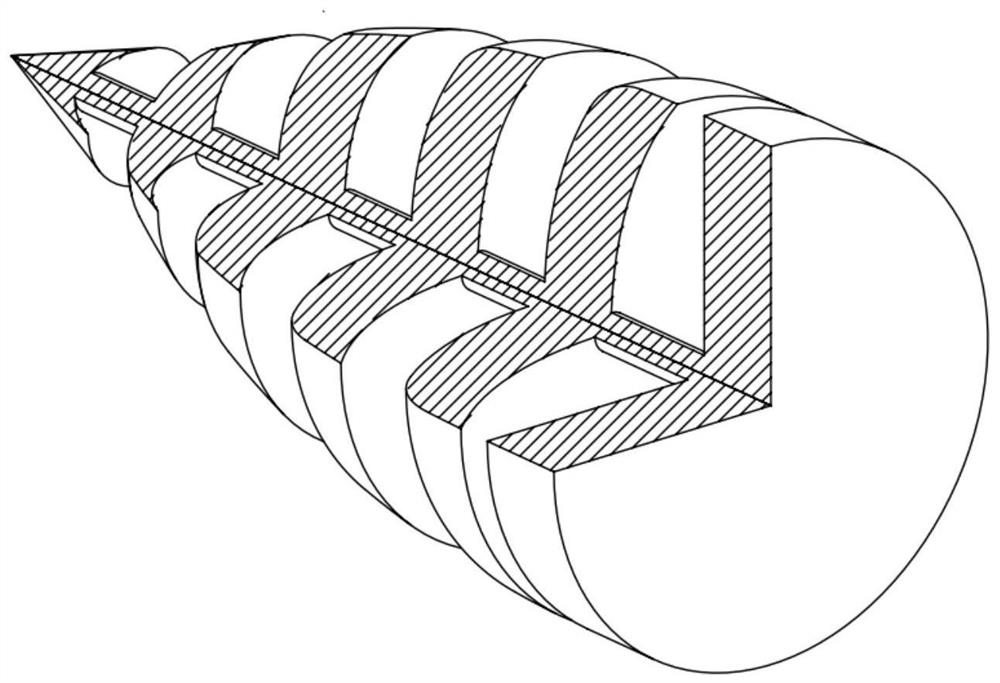

[0035] The pneumatic valve proposed in inhibiting the inhalation pulse explosion engine inhibition, the main structure includes: a back pressure suppression section cover, a central cone.

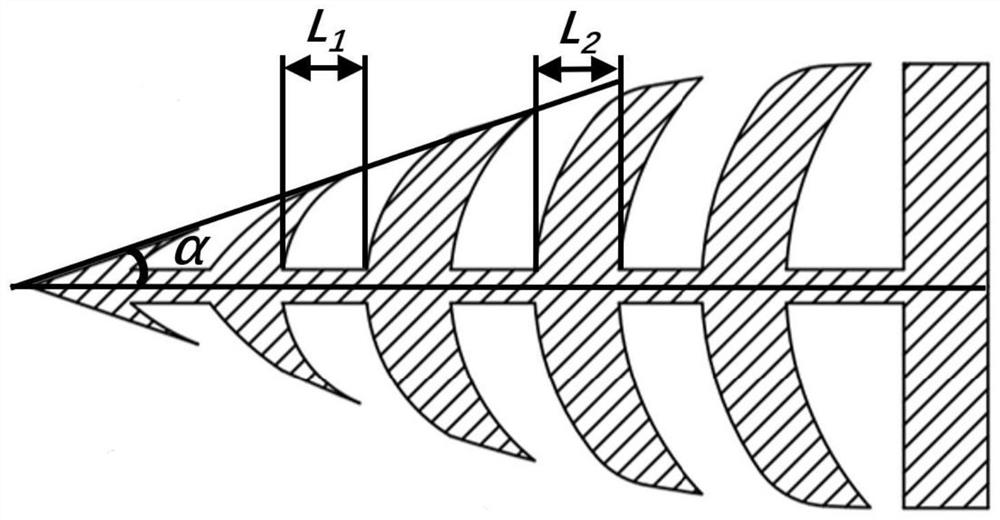

[0036] Such as figure 2 with image 3As shown, the central cone one end has a planar disc, which can be used to act as a thrust wall of the knock chamber; further a central axis and a plurality of curved discs mounted on the central axis, these arc circles The front and rear end faces of the disk are the curved surface; the center axis passes the center of these curved discs, and the edges of these curved discs are on conical surfaces of the cone 2 alpha, and the concave surface of the curved disc is oriented as a thrust wall. Plane disc. The preferred α angle is no more than 45 °, and further preferably takes 12.5 °.

[0037] In the present invention, the central thickness of these curved discs and the central axis connection position is L. 2 However, the central axis length between adjacent cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com